(UPDATE !!) P0336 Crankshaft position, Help I am at my end, I cant take this anymore

#1

Here is what is going on, I built a 383 stroker, once installed and running it had a miss above 3500 RPM, I checked everything I could, and ended up trailering it to my tuner who tried to do a crank learn. It didnt work, They put the car on the rack, and Long story short it ended up being a bent reluctor ring 24t (callies crank, Guess it happened during shipping).. I saw it when they showed it to me.. I pulled the crank, and sent it with a new correct 24T ring to LG motorsports in Wylie. 270 dollars later I picked it up, Put all new bearings in the car AGAIN, and put the engine back together. I put it in the car. I primed the oil system till I had it on the rockers and then put the coils and plugs in. Tried to start the car,,, Nothing just turns over a random light pop every now and then. It throws the PO336 crank pos code.

HERE IS WHAT I HAVE DONE,

1. I checked for spark by grounding all plugs, I have cyl 3 and 5 and cyl 2 and 8 have fire the others do not.

2. I used my tester and turned the car over checking one of my injectors, It is pulsing.

3. I checked my crank sensor connector this is how, I metered my green power wire, I have 12+ volts, I ohmed my ground wire on the connector to engine ground, Its good. I plugged my sensor in holding it in my hand, and with the ignition on tested the signal from the sensor (by waving a wrench in front of it, and hear the fuel pump kick In, let off and kick in as I wave the wrench). So I believe my sensor is working fine.

4.I called my tuner and asked him about the crank learn and if this could be the problem for the no start, and he said to do the crank learn the car has to be running first, ????

Someone please help, this crap has cost me more money than I care to mention, and to be honest is on the edge of making me just get rid of the whole car and never get another late model car.

HERE IS WHAT I HAVE DONE,

1. I checked for spark by grounding all plugs, I have cyl 3 and 5 and cyl 2 and 8 have fire the others do not.

2. I used my tester and turned the car over checking one of my injectors, It is pulsing.

3. I checked my crank sensor connector this is how, I metered my green power wire, I have 12+ volts, I ohmed my ground wire on the connector to engine ground, Its good. I plugged my sensor in holding it in my hand, and with the ignition on tested the signal from the sensor (by waving a wrench in front of it, and hear the fuel pump kick In, let off and kick in as I wave the wrench). So I believe my sensor is working fine.

4.I called my tuner and asked him about the crank learn and if this could be the problem for the no start, and he said to do the crank learn the car has to be running first, ????

Someone please help, this crap has cost me more money than I care to mention, and to be honest is on the edge of making me just get rid of the whole car and never get another late model car.

Last edited by RARON455; 09-16-2010 at 07:57 PM.

#2

I just put the sensor back in the car, Plugged it up, Turned the ignition on, and turned the motor by hand, I hear the fuel pump Kicking on then off then on and off as I rotate the crank using the balancer bolt and a ratchet. So I would think there is no problem with the crank sensor or wiring.. I dont have a clue whats going on. Any help would be greatly appreciated.

#3

TECH Regular

iTrader: (3)

Join Date: Jan 2005

Location: Magnolia, Texas

Posts: 464

Likes: 0

Received 0 Likes

on

0 Posts

I'm looking into this, it's what I do for a living. No chance of bringing it to Houston is there? There's no easy answer on this one. First thing I would do is replace the Crank Sensor. Bent reluctor would mean contact damage to the sensor in most cases. The wrench test while productive isn't conclusive. Check for witness marks on the sensor, if there's any at all that's a indication of contact damage. If you could scope the signals you could move more quickly but I understand that's usually not an option at home. See if you can find a simple reason why four cylinders aren't getting spark, like loose connection plug or bad fuse.

I'll check back and give further advise if you do this.

Vernon

I'll check back and give further advise if you do this.

Vernon

#5

Thats the one thing I highly doubt, after searching around I decided on LG motorsports for their reputation, They are LS specialists, mainly corvettes. High dollar shop. I called them up and asked them about it, after talking with him I dont believe that could be the problem. And that would be the absolute worst situation,. I am going to check my coils and all fuses, and then get a new crank sensor. See what happens.

#6

never say never... your car was running... the mecanical part was pulled down and had the reluctor changed and put together... now doesnt run.. seems very coincidental...

everyone makes mistakes...

you got 12volts to both sets of coil plugs... you tried starting it with no cam sensor plugged in

everyone makes mistakes...

you got 12volts to both sets of coil plugs... you tried starting it with no cam sensor plugged in

#7

Yes I have 12 volts going to the coil plug harnesses on the pink wire. I did not try to start it without a cam sensor, Would that do anything?

I just checked every fuse in the car, none are blown. connector on the crank sensor is fine, Crank sensor itself looks good no marks or anything on the face.

I just checked every fuse in the car, none are blown. connector on the crank sensor is fine, Crank sensor itself looks good no marks or anything on the face.

Trending Topics

#8

well car either feels the crank sensor isnt working or is in the wrong spot.. and its other point of reference is the cam sensor.. so with out that it will just have to resort to crank only.. worth a shot seeing you dont believe anything is wrong with the only part changed since it ran. (other thing it may be is timing is not right with chain when refitted)..

#9

On The Tree

Join Date: Mar 2008

Location: Acworth, GA

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

Strange that you get fire on every other cylinder. The only thing that comes to mind is crank reluctor installed backwards (if thats even possible, i dont know). Do you have access to a graphing multimeter or scanner? If you do you can backprobe crank signal wire and compare with what its suppose to look like and see if your reluctor is backwards without tearing it down. I understand your frustration - I really do. I can probably get a sample of how the signal is suppose to look tomorrow if you can take a sample off of your sensor.

#10

there are posts like this all the time.. its almost always a reluctor off

even pros mess up. i checked mine about 10 times because of these posts befor i installed it

another one ive seen a few times is the mains being alighn honed and the crank moves up in the block and then the gap for the crank sensor is too little and the runout of the reluctor hits it

even pros mess up. i checked mine about 10 times because of these posts befor i installed it

another one ive seen a few times is the mains being alighn honed and the crank moves up in the block and then the gap for the crank sensor is too little and the runout of the reluctor hits it

#11

Ohmed all my crank sensor wires back to the pcm all good. I also put a washer behind the mounting tab of the crank sensor to shim it some, Got a good pop and then nothing. Now I am reading and really getting scared that they may have messed the ring up. I guess the only thing else I can do is throw a new sensor in and see if that may be the issue. If not Then I guess I am screwed. I dont have a scanner, I have my meter but its not a graphing meter.

How can you tell if the reluctor is on backwards or correctly?

I am sure about the timing set, I have a rollmaster double roller setup on the engine and have it lined up.

How can you tell if the reluctor is on backwards or correctly?

I am sure about the timing set, I have a rollmaster double roller setup on the engine and have it lined up.

Last edited by RARON455; 09-02-2010 at 08:47 PM.

#12

TECH Regular

iTrader: (3)

Join Date: Jan 2005

Location: Magnolia, Texas

Posts: 464

Likes: 0

Received 0 Likes

on

0 Posts

Well if the reluctor is right and is on correctly that leaves these possibilitys:

1. The sensor isn't switching correctly. Until it's changed this is my first guess.

2. The wiring connectors in this circut are loose or corroded on either end (inc. PCM pins). Sounds like the wires themselves are ok. These are the three wires you've been checking.

3. The circut wiring is routed to close to a source of electromagnetic interference. (solenoid, motor, spark cable, relay). Any aftermarket or OEM stuff like this near the harness and working with the key on or cranking?

4. Excessive crankshaft end play.

5. PCM defective or a big mistake in the base tune like a key punch error on number of cylinders etc.

Observe the crank pulley while cranking, is it turning smoothly and steady in the correct direction. If the crank ever jumps backwards this code will set. If there were some sort of timing problem that caused the crank to jump back or stall it could set this code but the problem would be elsewhere.

To check if the circut is working correctly you would need to scope the signal pattern while cranking and compare that to a known good pattern.

Have you done a compression check on multiple cylinders to verify the cam timing is correct? This would go with the occaisional pop that may be sending the crank backwards or stalling it for a split second. Another thing you could do is just remove all the plugs and clear the code then crank for 15 seconds and recheck if the code returned. Without compression the crank should spin constantly at the will of the starter and if there is no electrical problem on the CKS circut you'll have no code.

Vernon

1. The sensor isn't switching correctly. Until it's changed this is my first guess.

2. The wiring connectors in this circut are loose or corroded on either end (inc. PCM pins). Sounds like the wires themselves are ok. These are the three wires you've been checking.

3. The circut wiring is routed to close to a source of electromagnetic interference. (solenoid, motor, spark cable, relay). Any aftermarket or OEM stuff like this near the harness and working with the key on or cranking?

4. Excessive crankshaft end play.

5. PCM defective or a big mistake in the base tune like a key punch error on number of cylinders etc.

Observe the crank pulley while cranking, is it turning smoothly and steady in the correct direction. If the crank ever jumps backwards this code will set. If there were some sort of timing problem that caused the crank to jump back or stall it could set this code but the problem would be elsewhere.

To check if the circut is working correctly you would need to scope the signal pattern while cranking and compare that to a known good pattern.

Have you done a compression check on multiple cylinders to verify the cam timing is correct? This would go with the occaisional pop that may be sending the crank backwards or stalling it for a split second. Another thing you could do is just remove all the plugs and clear the code then crank for 15 seconds and recheck if the code returned. Without compression the crank should spin constantly at the will of the starter and if there is no electrical problem on the CKS circut you'll have no code.

Vernon

#13

RARON455

I have experienced this exact issue before. The car came in with coil signals on 4 cylinders only. 24X LS. Engine was fresh installed by a dealership and they couldn't figure it out and were at their wits end.

We found during balancing the machine shop had welded a slug of mallory metal or tungsten in the rear counterweight and this had apparently magnetized the crank and the reluctor wheel in this area. We never got a clear understanding of why it caused the PCM to affect 4 cylinders and not just the ones in the welded area, but that was the case. We sent the rotating assembly off with a new crank and had it rebalanced and notified the machine shop of our concern with welding and it fired right up. We then tuned it on the dyno and it runs fine today. I still have that crank with the reluctor wheel still on it so I'll never forget.

I have experienced this exact issue before. The car came in with coil signals on 4 cylinders only. 24X LS. Engine was fresh installed by a dealership and they couldn't figure it out and were at their wits end.

We found during balancing the machine shop had welded a slug of mallory metal or tungsten in the rear counterweight and this had apparently magnetized the crank and the reluctor wheel in this area. We never got a clear understanding of why it caused the PCM to affect 4 cylinders and not just the ones in the welded area, but that was the case. We sent the rotating assembly off with a new crank and had it rebalanced and notified the machine shop of our concern with welding and it fired right up. We then tuned it on the dyno and it runs fine today. I still have that crank with the reluctor wheel still on it so I'll never forget.

#14

Well, more bad news,, Bought new crank sensor but same old problem..

I hate this bitch.

My next step is to double check my cam/crank timing by running a compression check.. If this passes then I guess I will be pulling the engine out again and then tearing it down again..

God I miss my old pontiac 462

I hate this bitch.

My next step is to double check my cam/crank timing by running a compression check.. If this passes then I guess I will be pulling the engine out again and then tearing it down again..

God I miss my old pontiac 462

Last edited by RARON455; 09-03-2010 at 07:33 PM.

#15

last chance saloon, I just ran a compression check on cyl. #1 and then 2-4-6-8 the easiest ones to get to. the results all were 150-170 psi. So that would tell me that the crank/cam timing is good.

I was trying to figure out why only 2 coil packs on each side would fire, and the answer to me is that the PCM is firing the ones it decides to. I dont think there is any way the PCM lost is programming So NOW I am down to my last card, the crank.

And I do know that when I had the assembly balanced that the shop added metal. And when I had this new ring put on they had to cut the old one off,, IT had a couple 1/2 inch welds and they did the same on install.

I was trying to figure out why only 2 coil packs on each side would fire, and the answer to me is that the PCM is firing the ones it decides to. I dont think there is any way the PCM lost is programming So NOW I am down to my last card, the crank.

And I do know that when I had the assembly balanced that the shop added metal. And when I had this new ring put on they had to cut the old one off,, IT had a couple 1/2 inch welds and they did the same on install.

#16

I had similar problems in 02 camaro...turns out one wire was stretched. It checked out ok until you wiggled it. soldered in new section and problem solved. Not saying it is yours but... Good luck.

#17

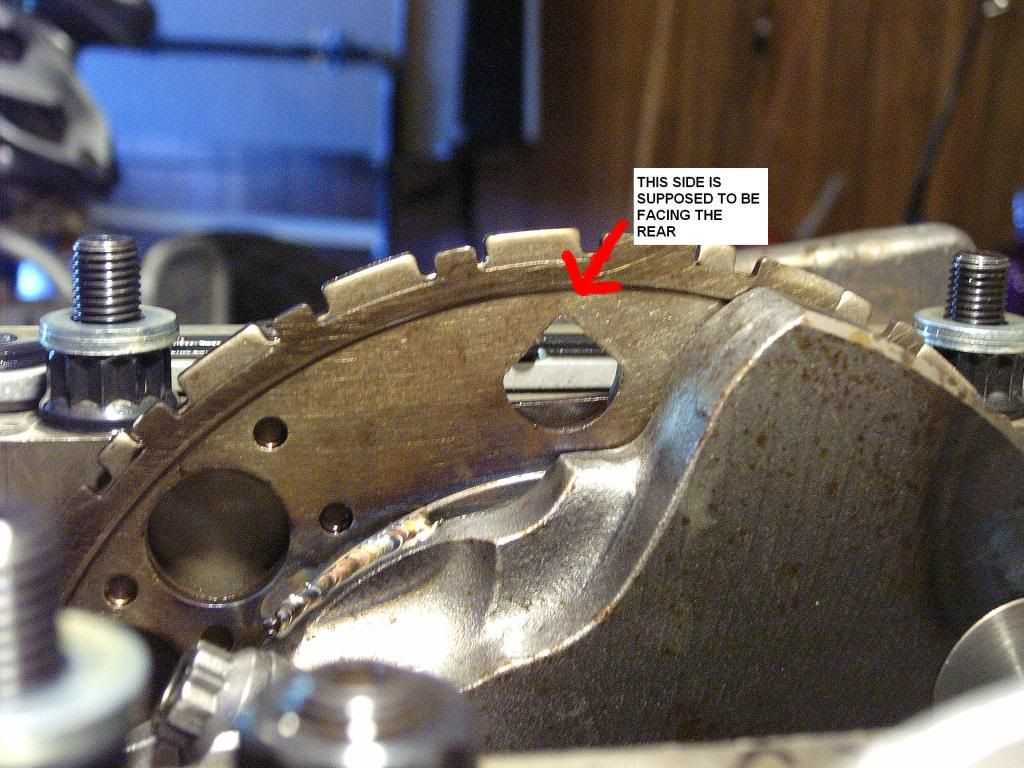

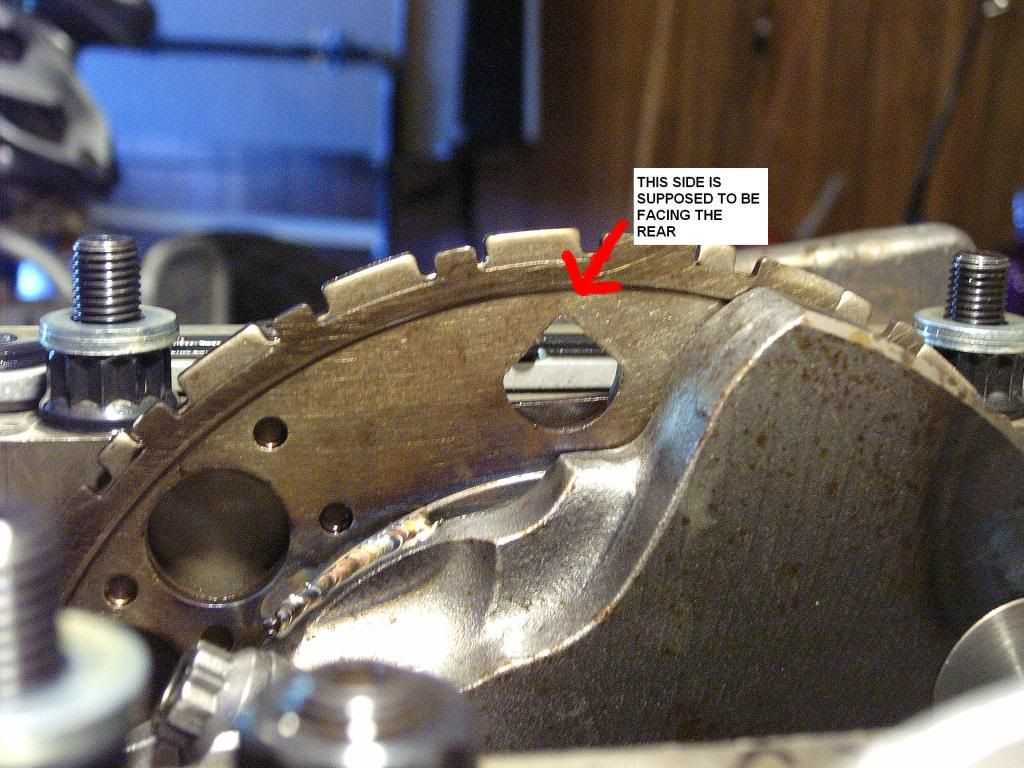

Well, after chasing every thing that I believed to be possible I ended Up pulling the engine Yesterday and putting it on the stand.. Today I pull the oil pan off and here we go, THE RELUCTOR WHEEL WAS INSTALLED BACKWARDS So to all of you who said that is what was wrong,, You were right, I never wanted to believe that could be the case but these pictures dont lie.. NOW I have sent the pictures to the shop that did it, Hopefully they will make everything Right..They have a great reputation so I will see. Much more cost involved than a new ring and puttin it on, Got gaskets, bearings, seals, bolts,$$$

#18

WOW!!! they welded it ON!!!! only needs to be heated and place on then i cools and stays... wonder if will make it harder to remove and fit....

oh well glad you have found the problem... as i mentioned before eveyrone makes mistakes but it is how they fix their mistakes and with what sort of attitude towards you is what makes a "business' a "great business"

as i mentioned before eveyrone makes mistakes but it is how they fix their mistakes and with what sort of attitude towards you is what makes a "business' a "great business"

oh well glad you have found the problem...

as i mentioned before eveyrone makes mistakes but it is how they fix their mistakes and with what sort of attitude towards you is what makes a "business' a "great business"

as i mentioned before eveyrone makes mistakes but it is how they fix their mistakes and with what sort of attitude towards you is what makes a "business' a "great business"

#20

On The Tree

Join Date: Mar 2008

Location: Acworth, GA

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

Glad you finally got it figured out! I knew it was the last thing you wanted to see happen but at least it wont happen again.... Good luck with the rest of your build..