MAF Tuning Issue: AFR varies with Load at the Same Frequency

#1

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

I've been chasing my own tail for a while with this issue, and I'm hoping that someone else has some insight. My mods are in my signature.

I have been observing inconsistent AFR readings when running on the MAF. I was able to track it down to an apparent dependency on load, or MAP reading. For example, I cruise at highway speeds at around 5000 Hz, 65 kPa, and 2300 RPM. I can set the MAF curve so that I'm running 14.7 under those conditions. If I then climb a hill 5000 Hz, 90 kPa, and 1500 RPM (4th, TCC locked), I'll see an AFR of about 15.5. The issue is most apparent when DOD is enabled and turns on because the load on the 4 remaining cylinders doubles, pulse width approximately doubles (it crosses over the 4 ms threshold), and I'm running at 15.5 because my MAF is calibrated to typical V8-mode loads.

Shortly after I cammed the motor I upgraded the fuel injectors because I was well into the 90% duty cycle range and getting lean dips at WOT over 6000RPM. I pulled the tables from stock tunes, and cross checked several different years and models with the same injectors. My injector tables (short pulse adder, IFR, Inj. Offset, Min. Pulse) are straight out of an 08 Vette, and when I interpolate 10 Camaro and 10 Vette tables I get the same result (within the LSB of the table). I am confident that I have good factory data for my injectors.

I can mostly get rid of the AFR variation by tuning IFR. I'm still working on my post-processing, but with some more time it looks like I could dial it in so that I will get a consistent AFR reading regardless of load (I'm very close after 3 cuts). However, I'm not sure that is the best solution. Without a load-bearing dyno, the real world steady state conditions I can achieve (straight road V8, straight road DOD, long hill climb at a nearly constant grade V8) I invariably cross the 4ms short pulse adder boundary. I haven't exhausted the matter yet, but it is possible I could adjust the short pulse adder and achieve a similar result. I could also adjust the offset, but tuning IFR is the easiest and most intuitive. However, the change required is drastic enough that I am uncomfortable rebuilding my VE fit around the tweaked IFR without taking a step back.

Has anyone else experienced this issue? Is there potentially something mechanical that I'm missing that could cause this issue? Is there another part of the tune that I should look at or some other phenomenon at work here? I can provide additional details if needed.

By the way, going to SD won't work for me because there aren't enough break points between the 2D equation fits to get acceptable performance during both normal driving and WOT. I currently have my break points set to give me a good fit from idle to 3600 RPM to keep my transients under control, and then the last RPM range handles 3600-7000 RPM with enough accuracy that I won't burn up the engine if the MAF fails. Even when biased towards higher RPMs, the MAF is far better at estimating air mass than SD anyways.

I have been observing inconsistent AFR readings when running on the MAF. I was able to track it down to an apparent dependency on load, or MAP reading. For example, I cruise at highway speeds at around 5000 Hz, 65 kPa, and 2300 RPM. I can set the MAF curve so that I'm running 14.7 under those conditions. If I then climb a hill 5000 Hz, 90 kPa, and 1500 RPM (4th, TCC locked), I'll see an AFR of about 15.5. The issue is most apparent when DOD is enabled and turns on because the load on the 4 remaining cylinders doubles, pulse width approximately doubles (it crosses over the 4 ms threshold), and I'm running at 15.5 because my MAF is calibrated to typical V8-mode loads.

Shortly after I cammed the motor I upgraded the fuel injectors because I was well into the 90% duty cycle range and getting lean dips at WOT over 6000RPM. I pulled the tables from stock tunes, and cross checked several different years and models with the same injectors. My injector tables (short pulse adder, IFR, Inj. Offset, Min. Pulse) are straight out of an 08 Vette, and when I interpolate 10 Camaro and 10 Vette tables I get the same result (within the LSB of the table). I am confident that I have good factory data for my injectors.

I can mostly get rid of the AFR variation by tuning IFR. I'm still working on my post-processing, but with some more time it looks like I could dial it in so that I will get a consistent AFR reading regardless of load (I'm very close after 3 cuts). However, I'm not sure that is the best solution. Without a load-bearing dyno, the real world steady state conditions I can achieve (straight road V8, straight road DOD, long hill climb at a nearly constant grade V8) I invariably cross the 4ms short pulse adder boundary. I haven't exhausted the matter yet, but it is possible I could adjust the short pulse adder and achieve a similar result. I could also adjust the offset, but tuning IFR is the easiest and most intuitive. However, the change required is drastic enough that I am uncomfortable rebuilding my VE fit around the tweaked IFR without taking a step back.

Has anyone else experienced this issue? Is there potentially something mechanical that I'm missing that could cause this issue? Is there another part of the tune that I should look at or some other phenomenon at work here? I can provide additional details if needed.

By the way, going to SD won't work for me because there aren't enough break points between the 2D equation fits to get acceptable performance during both normal driving and WOT. I currently have my break points set to give me a good fit from idle to 3600 RPM to keep my transients under control, and then the last RPM range handles 3600-7000 RPM with enough accuracy that I won't burn up the engine if the MAF fails. Even when biased towards higher RPMs, the MAF is far better at estimating air mass than SD anyways.

#3

Banned

iTrader: (1)

This is a bad MAF xfer

the MAF xfer need to be a smooth xfer. Air flow doesn't go down or even stall when the HZ increases. If your MAF xfer is not smooth the you need to smooth it out and work on other tables.

When you tune the MAF you need to disable and set somethings fixed.

I turn off long term Fuel Trims. I would shut off DOD. I would set a fixed the fuel Pressure if you run a FPCM. I would disable PE, AE and anything else that will change the AFR. I would only tune the lower half with the Fuel Trims. The upper half I would set everything to a set AFR say 12.5 and then tune that part of the MAF.

Ignition timing can even effect the MAF xfer

the MAF xfer need to be a smooth xfer. Air flow doesn't go down or even stall when the HZ increases. If your MAF xfer is not smooth the you need to smooth it out and work on other tables.

When you tune the MAF you need to disable and set somethings fixed.

I turn off long term Fuel Trims. I would shut off DOD. I would set a fixed the fuel Pressure if you run a FPCM. I would disable PE, AE and anything else that will change the AFR. I would only tune the lower half with the Fuel Trims. The upper half I would set everything to a set AFR say 12.5 and then tune that part of the MAF.

Ignition timing can even effect the MAF xfer

#4

Moderator

iTrader: (11)

Join Date: Mar 2002

Location: East Central Florida

Posts: 12,605

Likes: 0

Received 6 Likes

on

6 Posts

At low RPM (like cruise) you are not all-MAF for airflow,

you're using Dynamic Airflow with a partial weighting.

Still a lot of speed-density weight, hence the MAP

dependence.

How does MAF Airflow g/sec compare to Dynamic

Airflow g/sec under these conditions?

The MAF may be pretty much right, if it's in factory

condition it's a factory-cal'd piece and probably

better than 5% accuracy. Of course that's an "if"

that wants considering.

Anyway you can't do a good job of fixing problems

on the S-D side, by MAF tweaking especially when

the MAF's not being listened to all that strongly.

you're using Dynamic Airflow with a partial weighting.

Still a lot of speed-density weight, hence the MAP

dependence.

How does MAF Airflow g/sec compare to Dynamic

Airflow g/sec under these conditions?

The MAF may be pretty much right, if it's in factory

condition it's a factory-cal'd piece and probably

better than 5% accuracy. Of course that's an "if"

that wants considering.

Anyway you can't do a good job of fixing problems

on the S-D side, by MAF tweaking especially when

the MAF's not being listened to all that strongly.

#5

Banned

iTrader: (1)

At low RPM (like cruise) you are not all-MAF for airflow,

you're using Dynamic Airflow with a partial weighting.

Still a lot of speed-density weight, hence the MAP

dependence.

How does MAF Airflow g/sec compare to Dynamic

Airflow g/sec under these conditions?

The MAF may be pretty much right, if it's in factory

condition it's a factory-cal'd piece and probably

better than 5% accuracy. Of course that's an "if"

that wants considering.

Anyway you can't do a good job of fixing problems

on the S-D side, by MAF tweaking especially when

the MAF's not being listened to all that strongly.

you're using Dynamic Airflow with a partial weighting.

Still a lot of speed-density weight, hence the MAP

dependence.

How does MAF Airflow g/sec compare to Dynamic

Airflow g/sec under these conditions?

The MAF may be pretty much right, if it's in factory

condition it's a factory-cal'd piece and probably

better than 5% accuracy. Of course that's an "if"

that wants considering.

Anyway you can't do a good job of fixing problems

on the S-D side, by MAF tweaking especially when

the MAF's not being listened to all that strongly.

******************************************

The MAF xfer is a rough starting point. You may need to change the xfer 30% at the max point, but it needs to be smooth. You spend 10 minutes doing the xfer and move on and fix the other tables.

Example: 3800 V6 cars & lets say all S/C cars. a 2000 Buick and a 2000 GTP will have different MAF xfers and have completely different air boxes and duct work

2000, 2001, 2002 & 2004 L36 3800 NA Impala's MAF xfers are all the same, but the 2003 L36 Impala runs a Impala L67 MAF xfer and it is a lot different. How can that work out? 2 sides to it Air mass and Fuel mass. Guess what the VE table is different between the 03 & 04

#6

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the feedback! Unfortunately, I wish the issue was as simple as my MAF curve being jagged or not running in the correct mode.

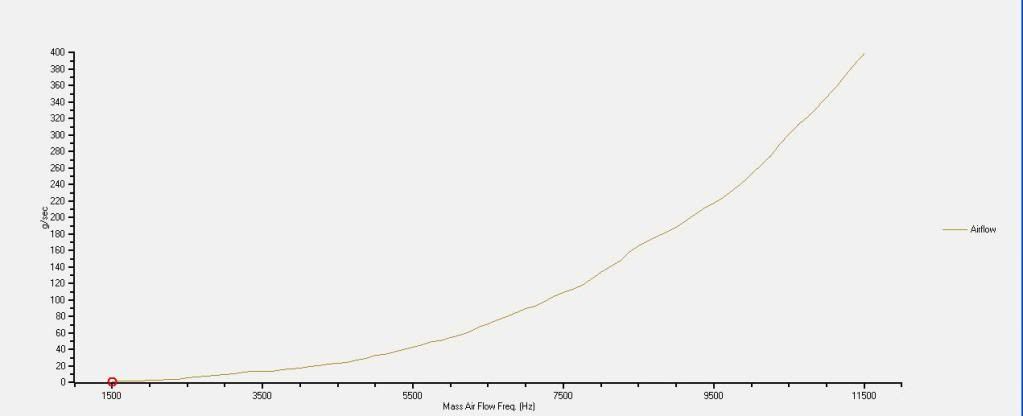

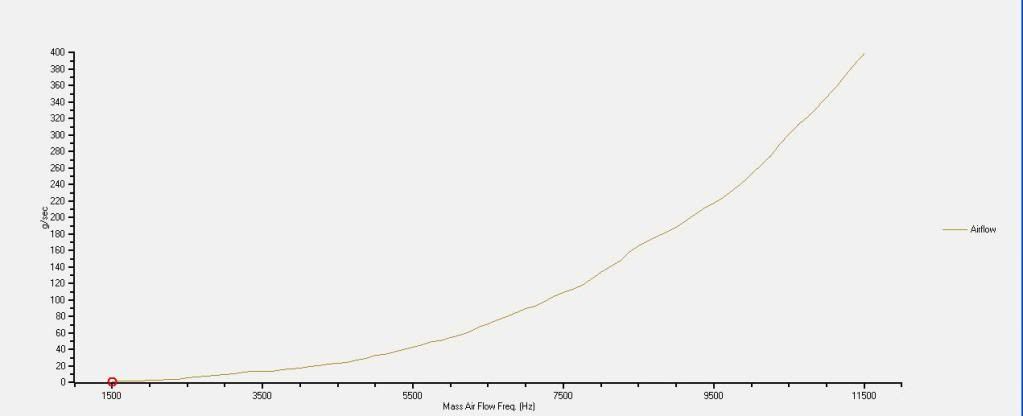

My MAF transfer is very smooth. It is currently characterized by the following equation:

[Air Mass] = 3.0990210544e-11 * [Hz]^3 + 1.0593384684e-07 * [Hz]^2 - 6.7912831711e-04 * [Hz] + 1.4513073172e+00

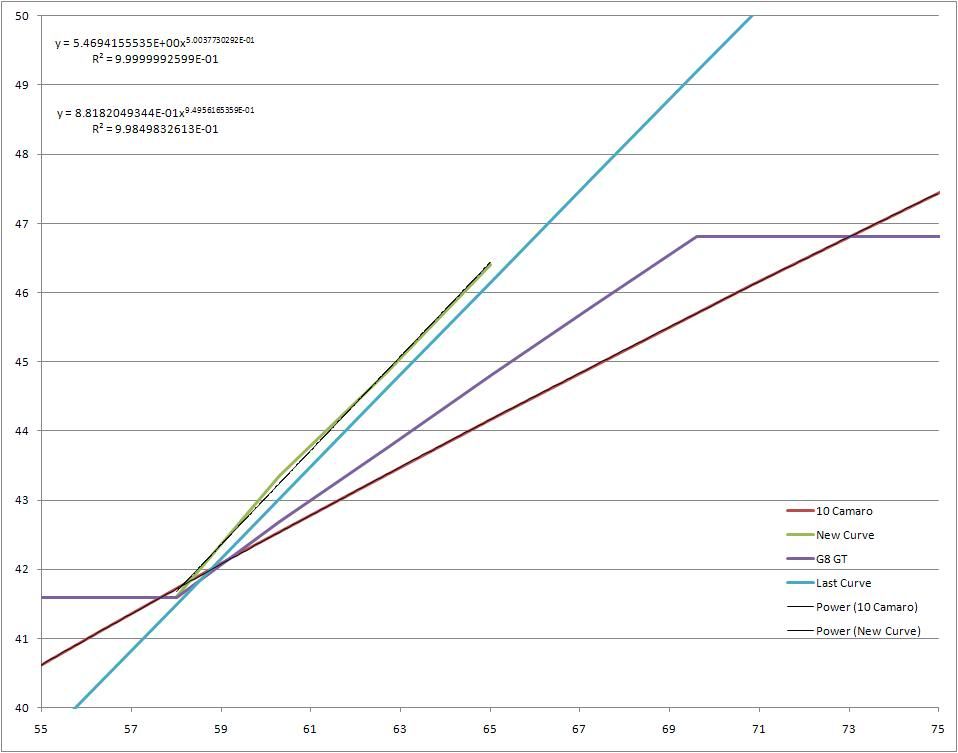

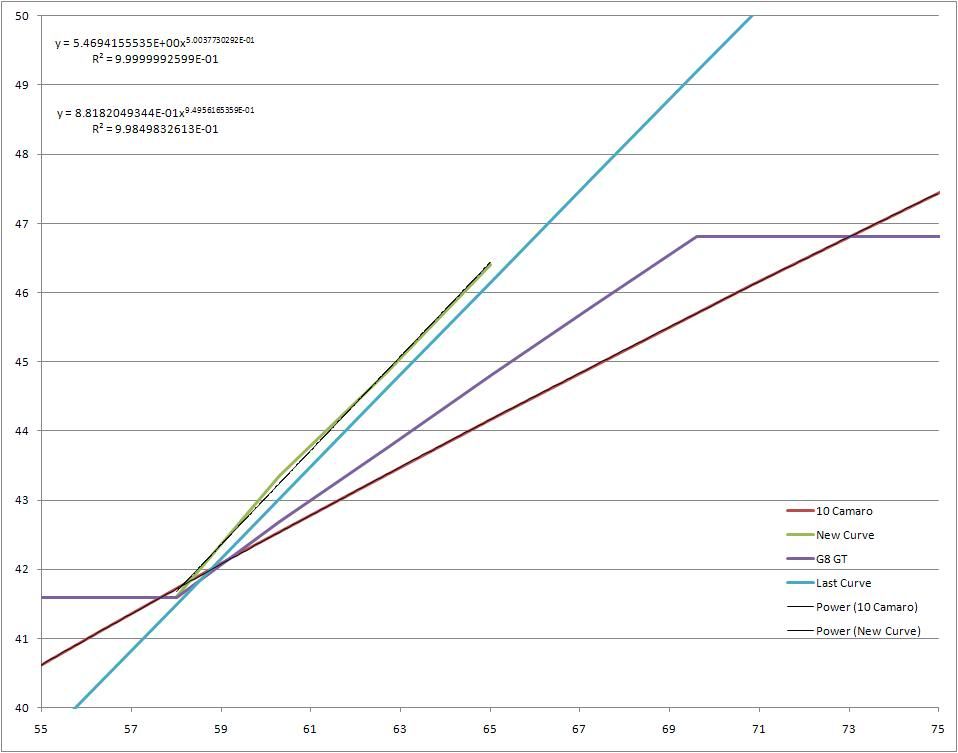

That fit leaves me with +/-1% error as long as I also use the following power fit for my IFR:

[IFR] = 0.93569730072*[Delta Pressure]^0.93388765981 + 0.28

(Note: The constant term is used match the curve at 4 bar to the factory spec. I'm only adjusting mid to low load fueling that way.)

I've done a pretty good job modifying my intake tract to give the MAF as close to laminar airflow as I can given my packaging constraints, so curve fitting works well because I don't have a lot of turbulence to move my MAF transfer very far from ideal performance.

Another point is that I've observed the phenomenon with two different MAFs, as I'm currently running an 85mm truck MAF (picked up a couple kPa at WOT doing so!).

Your point about timing is well taken; I've also seen a lot variation by altering injection timing. I tuned injection timing for the richest AFR reading a while ago.

I probably should have said this in my first post for clarity, but here we go. I'm running solely on the MAF (at the moment) for tuning purposes. This was done by changing the dynamic airflow enable/disable values to 0 and verified by monitoring the Air Calc Mode PID (shows Normal in the mode you are describing and High-Flow when running on just the MAF; the factory setting has the transition at about 4000 RPM because the MAF is better at metering air at high RPMs).

I am also running Open-Loop and logging AFR from my AEM Wideband. The AEM's output is being run through an instrumentation amplifier (to isolate the ground) and an analog filter. I can't remember the cutoff frequency, but it was set based on the sampling rate of my scanner so that I wouldn't alias the real signal.

I also gave up on HP Tuners histograms because you can't look at derivatives or run statistics. I filter all of my data for engine coolant temp, intake valve temp, pedal position (to remove off-throttle data), and the variance of a moving window of both measured AFR and throttle position (eliminates everything except steady state data).

As an aside, when in Normal Air Calc Mode the speed density mass air calc is only used during transients. It dominates the mass air calculation at the onset of a transient and then slowly passes control of fueling back to the MAF. The MAF handles the fueling by itself in steady state conditions.

This shows the adjustment to IFR that I have made:

Empirically, adjusting IFR like this means that for the same amount of metered air from the MAF I get the correct amount of fuel injected independent of the readings from the MAF (at least according to the wideband). I know that there is variation in fuel injectors (I've seen +/- 6% listed as the spec and at the maximum I'm around +6%), but I had thought that would take the form of a mean shift, not a change in the curve. Anyway, with the IFR adjustment I'm now reading commanded AFR independent of load (MAP reading).

Has anyone else seen this? If you run only speed density, you of course would not. Other than variation from factory specs in IFR and short pulse adder, the only other thing that I can think of is that my lumpy cam blows more raw fuel out the exhaust during part throttle than at WOT.

the MAF xfer need to be a smooth xfer. Air flow doesn't go down or even stall when the HZ increases. If your MAF xfer is not smooth the you need to smooth it out and work on other tables.

When you tune the MAF you need to disable and set somethings fixed.

I turn off long term Fuel Trims. I would shut off DOD. I would set a fixed the fuel Pressure if you run a FPCM. I would disable PE, AE and anything else that will change the AFR. I would only tune the lower half with the Fuel Trims. The upper half I would set everything to a set AFR say 12.5 and then tune that part of the MAF.

Ignition timing can even effect the MAF xfer

When you tune the MAF you need to disable and set somethings fixed.

I turn off long term Fuel Trims. I would shut off DOD. I would set a fixed the fuel Pressure if you run a FPCM. I would disable PE, AE and anything else that will change the AFR. I would only tune the lower half with the Fuel Trims. The upper half I would set everything to a set AFR say 12.5 and then tune that part of the MAF.

Ignition timing can even effect the MAF xfer

[Air Mass] = 3.0990210544e-11 * [Hz]^3 + 1.0593384684e-07 * [Hz]^2 - 6.7912831711e-04 * [Hz] + 1.4513073172e+00

That fit leaves me with +/-1% error as long as I also use the following power fit for my IFR:

[IFR] = 0.93569730072*[Delta Pressure]^0.93388765981 + 0.28

(Note: The constant term is used match the curve at 4 bar to the factory spec. I'm only adjusting mid to low load fueling that way.)

I've done a pretty good job modifying my intake tract to give the MAF as close to laminar airflow as I can given my packaging constraints, so curve fitting works well because I don't have a lot of turbulence to move my MAF transfer very far from ideal performance.

Another point is that I've observed the phenomenon with two different MAFs, as I'm currently running an 85mm truck MAF (picked up a couple kPa at WOT doing so!).

Your point about timing is well taken; I've also seen a lot variation by altering injection timing. I tuned injection timing for the richest AFR reading a while ago.

At low RPM (like cruise) you are not all-MAF for airflow,

you're using Dynamic Airflow with a partial weighting.

Still a lot of speed-density weight, hence the MAP

dependence.

How does MAF Airflow g/sec compare to Dynamic

Airflow g/sec under these conditions?

The MAF may be pretty much right, if it's in factory

condition it's a factory-cal'd piece and probably

better than 5% accuracy. Of course that's an "if"

that wants considering.

Anyway you can't do a good job of fixing problems

on the S-D side, by MAF tweaking especially when

the MAF's not being listened to all that strongly.

you're using Dynamic Airflow with a partial weighting.

Still a lot of speed-density weight, hence the MAP

dependence.

How does MAF Airflow g/sec compare to Dynamic

Airflow g/sec under these conditions?

The MAF may be pretty much right, if it's in factory

condition it's a factory-cal'd piece and probably

better than 5% accuracy. Of course that's an "if"

that wants considering.

Anyway you can't do a good job of fixing problems

on the S-D side, by MAF tweaking especially when

the MAF's not being listened to all that strongly.

I am also running Open-Loop and logging AFR from my AEM Wideband. The AEM's output is being run through an instrumentation amplifier (to isolate the ground) and an analog filter. I can't remember the cutoff frequency, but it was set based on the sampling rate of my scanner so that I wouldn't alias the real signal.

I also gave up on HP Tuners histograms because you can't look at derivatives or run statistics. I filter all of my data for engine coolant temp, intake valve temp, pedal position (to remove off-throttle data), and the variance of a moving window of both measured AFR and throttle position (eliminates everything except steady state data).

As an aside, when in Normal Air Calc Mode the speed density mass air calc is only used during transients. It dominates the mass air calculation at the onset of a transient and then slowly passes control of fueling back to the MAF. The MAF handles the fueling by itself in steady state conditions.

This shows the adjustment to IFR that I have made:

Empirically, adjusting IFR like this means that for the same amount of metered air from the MAF I get the correct amount of fuel injected independent of the readings from the MAF (at least according to the wideband). I know that there is variation in fuel injectors (I've seen +/- 6% listed as the spec and at the maximum I'm around +6%), but I had thought that would take the form of a mean shift, not a change in the curve. Anyway, with the IFR adjustment I'm now reading commanded AFR independent of load (MAP reading).

Has anyone else seen this? If you run only speed density, you of course would not. Other than variation from factory specs in IFR and short pulse adder, the only other thing that I can think of is that my lumpy cam blows more raw fuel out the exhaust during part throttle than at WOT.

Last edited by nmp0098; 11-09-2010 at 04:26 PM. Reason: finished the last sentence of the second to last paragraph based on the question below.

Trending Topics

#8

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

#9

Banned

iTrader: (1)

What is the Fuel Volatility read displaying?

What does the Fuel Alcohol Content display?

If your Fuel Alcohol Content displays any thing other than 0% you need to adjust to the correct stoich.

What does the Air Fuel Ratio display anyway. Does it reflex the Alcohol Content?

I have been doing this for 25 years now. A lot has changed in the last 25 years and we are still doing the same things. You just need to gather all of the data first.

I check the Alcohol Content on almost every car I see now a days. They either have a Alcohol Content sensor or like yours it has a Virtual Flex Fuel Sensor.

What does the Fuel Alcohol Content display?

If your Fuel Alcohol Content displays any thing other than 0% you need to adjust to the correct stoich.

What does the Air Fuel Ratio display anyway. Does it reflex the Alcohol Content?

I have been doing this for 25 years now. A lot has changed in the last 25 years and we are still doing the same things. You just need to gather all of the data first.

I check the Alcohol Content on almost every car I see now a days. They either have a Alcohol Content sensor or like yours it has a Virtual Flex Fuel Sensor.

Last edited by CalEditor; 11-09-2010 at 05:13 PM.

#10

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

If you are asking about PIDs, the only one available to me in HPT is Fuel Composition (in Hz?). It always reads zero, which I take to mean it is reading 100% gasoline because if I log Commanded EQ Ratio and AFR Commanded I can see that EQ Ratio = 1 corresponds to Commanded AFR = 14.68. Unfortunately, here in MI gas stations are not required by law to display the amount of Ethanol blended into their fuel. Do you know how the fuel composition is estimated? If it depends on sensors that have been affected by my mods or cal (like running open loop), then it's a crap shoot.

I should say that I am logging AFR Commanded and my actual AFR to generate my error.

I would think that Ethanol content would result in a linear % change in AFR because all of the injected fuel would have less energy in the same proportion. If I adjust stoich at 100% to correct value, I would think it would have the same effect as changing commanded EQ ratio. It is one more thing to investage though.

I should say that I am logging AFR Commanded and my actual AFR to generate my error.

I would think that Ethanol content would result in a linear % change in AFR because all of the injected fuel would have less energy in the same proportion. If I adjust stoich at 100% to correct value, I would think it would have the same effect as changing commanded EQ ratio. It is one more thing to investage though.

#11

Banned

iTrader: (1)

Just say the vehicle has a tank of fuel that is over 10%. Lets say 14%. The fuel trims will be way off,

so you adjust them. You get the tune all done and the guy fills up with E10%. Now it is rich.

so you adjust them. You get the tune all done and the guy fills up with E10%. Now it is rich.On a car with Virtual Flex Fuel Sensor software the PCM changes the AFR/Stoich when it sees a fule level change. I think it is +3 gallons and then it will retest the fuel for Alcohol Content.

Anyway a Tech II will display the Alcohol Content

#12

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

You have a Virtual Flex Fuel Sensor and it isn't the Hz type sensor. Ask HPT to add it to the PID's. In the mean time before going any further you need get that reading or you will be chasing your tail. The first thing I check is Alcohol Content. That is the very first and one of the most important checks. Say you are tuning a car that has E10% on a non flex fuel vehicle. You need to start with the correct Stoich settings to get the most power and to get your fuel trims correct

Just say the vehicle has a tank of fuel that is over 10%. Lets say 14%. The fuel trims will be way off, so you adjust them. You get the tune all done and the guy fills up with E10%. Now it is rich.

so you adjust them. You get the tune all done and the guy fills up with E10%. Now it is rich.

On a car with Virtual Flex Fuel Sensor software the PCM changes the AFR/Stoich when it sees a fule level change. I think it is +3 gallons and then it will retest the fuel for Alcohol Content.

Anyway a Tech II will display the Alcohol Content

Just say the vehicle has a tank of fuel that is over 10%. Lets say 14%. The fuel trims will be way off,

so you adjust them. You get the tune all done and the guy fills up with E10%. Now it is rich.

so you adjust them. You get the tune all done and the guy fills up with E10%. Now it is rich.On a car with Virtual Flex Fuel Sensor software the PCM changes the AFR/Stoich when it sees a fule level change. I think it is +3 gallons and then it will retest the fuel for Alcohol Content.

Anyway a Tech II will display the Alcohol Content

Just for grins, I changed the stoich AFR to 14.1 (I didn't bother with the exact number) at 100%. Like expected, the car felt peppier but nothing changed in my AFR error. My wideband just read around 14.1. Taking a step back, that makes perfect sense because I am altering the command side of the equation. As far as the command to the injectors is concerned, it doesn't matter whether I alter the AFR Commanded or the Commanded EQ Ratio (through PE or one of the open loop tables I had tuned to give me at least 14.68 while the intake valve warms up). The problem I'm seeing does not correlate to anything except MAP and maybe pulse width.

Like I said before, I'm running open loop so fuel trims aren't even in the picture. I may be running leaner than stoich at 14.68, but that's not any different than when I did my initial tuning at a Commanded EQ Ratio of 1.13 for safety. That's why I adjusted IFR; to always get the AFR that I am commanding.

I don't know if you picked this up from my first post, but I'm talking about inconsistancy during the same drive in open loop, DOD off, etc. On a level road with a dead steady throttle at 70 mph, I hit the exact same MAF frequency as when climbing a specific hill with a dead steady throttle at 50mph. If I compare steady state to steady state, exact same MAF reading, I get a different AFR unless I adjust the slope of my IFR curve. This is without turning the key off, getting gas, driving into a rainstorm, or any other source of variability. The result that I was getting was maddeningly consistent.

My car is running so consistently correct right now that I'm getting more and more convinced that I made the correct change.

Last edited by nmp0098; 11-10-2010 at 11:49 AM.

#14

10 Second Club

iTrader: (15)

Join Date: Nov 2001

Location: St. Michael, MN.

Posts: 4,519

Likes: 0

Received 0 Likes

on

0 Posts

I don't know if you picked this up from my first post, but I'm talking about inconsistancy during the same drive in open loop, DOD off, etc. On a level road with a dead steady throttle at 70 mph, I hit the exact same MAF frequency as when climbing a specific hill with a dead steady throttle at 50mph. If I compare steady state to steady state, exact same MAF reading, I get a different AFR unless I adjust the slope of my IFR curve. This is without turning the key off, getting gas, driving into a rainstorm, or any other source of variability. The result that I was getting was maddeningly consistent

I see the same occurence in both vehicles (and others I have tuned or logged) in my sig and have usually attributed the variable to the VE table because the MAP readings are different. However I also see a variance at different types of WOT (i.e. from a roll and from launch) but at the same rpm. The "from roll" values are almost always the richer of the two. It's more pronounced on M6 cars. In all cases the IFR is not adjusted for tuning AFR; just set based on fuel pressure and injectors then left alone. I created a spreadsheet to help minimize the AFR difference between the different loads (from roll vs from launch) in the same MAF cells. It's tedious but helps for a more consistent AFR. Sorry for the off tangent post.

#16

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

Ah. That makes sense because with dynamic airflow off I get lean spikes and **** off the knock sensor during throttle tip-in.

Not a tangent... it's good to know at least one other person has observed something similar. While I know and agree that adjusting IFR to tune the car is the wrong way, I disagree that everyone should just put in the stock tables and take them for Bible truth. Unless you spring for flow matched injectors, you can have considerable variation in Lambda from cylinder to cylinder. Most injectors flow close to spec, but in anything mass produced there will be variation (usually gaussian) from spec.

Very true, it is just a Lambda sensor. So I might be commanding 14.68 and getting anywhere between 14.1 and 14.3. I get 90% of my gas from a single station, so I'll just have to make that 100% when I tune and go out and get a graduated cylinder to see how much ethanol (if any) is in my fuel. According to the Michigan Department of Agriculture, almost half of all stations sell E6 or E10 (and are not required to label as such!). Still, that should be a linear % change on the whole MAF curve, not a load sensitive change.

Getting my car back to closed loop operation is not easy because my wideband is where the narrowband should go and I'd have to reset the gain and zero in my amplifier to get the wideband's narrowband simulation working.

I saw that and was going to post but noticed you're running MAF only. I assume you're referring to actual AFR from the WB and not the commanded. If so, I will throw in my .02.

I see the same occurence in both vehicles (and others I have tuned or logged) in my sig and have usually attributed the variable to the VE table because the MAP readings are different. However I also see a variance at different types of WOT (i.e. from a roll and from launch) but at the same rpm. The "from roll" values are almost always the richer of the two. It's more pronounced on M6 cars. In all cases the IFR is not adjusted for tuning AFR; just set based on fuel pressure and injectors then left alone. I created a spreadsheet to help minimize the AFR difference between the different loads (from roll vs from launch) in the same MAF cells. It's tedious but helps for a more consistent AFR. Sorry for the off tangent post.

I see the same occurence in both vehicles (and others I have tuned or logged) in my sig and have usually attributed the variable to the VE table because the MAP readings are different. However I also see a variance at different types of WOT (i.e. from a roll and from launch) but at the same rpm. The "from roll" values are almost always the richer of the two. It's more pronounced on M6 cars. In all cases the IFR is not adjusted for tuning AFR; just set based on fuel pressure and injectors then left alone. I created a spreadsheet to help minimize the AFR difference between the different loads (from roll vs from launch) in the same MAF cells. It's tedious but helps for a more consistent AFR. Sorry for the off tangent post.

Getting my car back to closed loop operation is not easy because my wideband is where the narrowband should go and I'd have to reset the gain and zero in my amplifier to get the wideband's narrowband simulation working.

#17

Banned

iTrader: (1)

Ah. That makes sense because with dynamic airflow off I get lean spikes and **** off the knock sensor during throttle tip-in.

Not a tangent... it's good to know at least one other person has observed something similar. While I know and agree that adjusting IFR to tune the car is the wrong way, I disagree that everyone should just put in the stock tables and take them for Bible truth. Unless you spring for flow matched injectors, you can have considerable variation in Lambda from cylinder to cylinder. Most injectors flow close to spec, but in anything mass produced there will be variation (usually gaussian) from spec.

Very true, it is just a Lambda sensor. So I might be commanding 14.68 and getting anywhere between 14.1 and 14.3. I get 90% of my gas from a single station, so I'll just have to make that 100% when I tune and go out and get a graduated cylinder to see how much ethanol (if any) is in my fuel. According to the Michigan Department of Agriculture, almost half of all stations sell E6 or E10 (and are not required to label as such!). Still, that should be a linear % change on the whole MAF curve, not a load sensitive change.

Getting my car back to closed loop operation is not easy because my wideband is where the narrowband should go and I'd have to reset the gain and zero in my amplifier to get the wideband's narrowband simulation working.

Not a tangent... it's good to know at least one other person has observed something similar. While I know and agree that adjusting IFR to tune the car is the wrong way, I disagree that everyone should just put in the stock tables and take them for Bible truth. Unless you spring for flow matched injectors, you can have considerable variation in Lambda from cylinder to cylinder. Most injectors flow close to spec, but in anything mass produced there will be variation (usually gaussian) from spec.

Very true, it is just a Lambda sensor. So I might be commanding 14.68 and getting anywhere between 14.1 and 14.3. I get 90% of my gas from a single station, so I'll just have to make that 100% when I tune and go out and get a graduated cylinder to see how much ethanol (if any) is in my fuel. According to the Michigan Department of Agriculture, almost half of all stations sell E6 or E10 (and are not required to label as such!). Still, that should be a linear % change on the whole MAF curve, not a load sensitive change.

Getting my car back to closed loop operation is not easy because my wideband is where the narrowband should go and I'd have to reset the gain and zero in my amplifier to get the wideband's narrowband simulation working.

I rattle my brain for some time trying to understand why the AFR reads 14.8 and the Lambda is 1.0. It is because the Lambda is 1.0 and the gauge is calibrated to read 14.68 at 1.0 lambda

I got it all figured out. Forget the AFR and only use the Lambda reading and the comanded AFR on the Tech II or the commanded Lambda on the Tech II

#19

TECH Regular

Thread Starter

Join Date: Nov 2009

Location: Farmington Hills, MI

Posts: 446

Likes: 0

Received 0 Likes

on

0 Posts

Every E10 I tune the Wide-Band Gauge reads an AFR of 14.6. The Tech II shows 14.1. The AFR open loop is 14.1 some times.

I rattle my brain for some time trying to understand why the AFR reads 14.8 and the Lambda is 1.0. It is because the Lambda is 1.0 and the gauge is calibrated to read 14.68 at 1.0 lambda

I got it all figured out. Forget the AFR and only use the Lambda reading and the comanded AFR on the Tech II or the commanded Lambda on the Tech II

I rattle my brain for some time trying to understand why the AFR reads 14.8 and the Lambda is 1.0. It is because the Lambda is 1.0 and the gauge is calibrated to read 14.68 at 1.0 lambda

I got it all figured out. Forget the AFR and only use the Lambda reading and the comanded AFR on the Tech II or the commanded Lambda on the Tech II

The manager of the gas station I usually go to says that I'm buying 100% gasoline. I'll test it myself this weekend to be sure.

That said, I'm going to change the PIDs I'm scanning and adjust my post-processing code to work with Lambda because it is clearly the more robust way to tune.