code 341 help

#1

Hey guys. Im out of the states and dont have any wiring diagrams with me, my alldata id back home. I have a car with a code 341. Its a 98 fbody with a LS2 swap. I have cam high to low, and low to high counts, buts its setting this code instantly. Gearchatter doesnt have any diagrams for LS2s, just the LS1s. I tried swapping the outer 2 wires in the pigtail extender, but then I loose my switching, so apparently thats not it.

I have very limited info, no oscope, so not real easy diagnosing stuff right now. So, if anyone can gimme the pin layout, +/-/sensor return for an LS2 that would be awesome. Any input on the situation would be welcomed also.

thanks

I have very limited info, no oscope, so not real easy diagnosing stuff right now. So, if anyone can gimme the pin layout, +/-/sensor return for an LS2 that would be awesome. Any input on the situation would be welcomed also.

thanks

#3

10 Second Club

iTrader: (4)

Join Date: Oct 2006

Location: wisconsin

Posts: 855

Likes: 0

Received 0 Likes

on

0 Posts

I would verify that he is using the correct cam gear for the LS2

P0341

The ECM detects that the engine has started and is running, but receives less than 398 or more than 402 CMP pulses per 100 engine cycles in 800 of 1,000 engine cycles.

P0341

Ignition OFF, inspect the CMP sensor for correct installation.

⇒ If the CMP sensor is loose, inspect the sensor and the O-ring for damaged, replace as necessary.

Inspect the engine for the following conditions:

• Engine oil for debris

• Camshaft reluctor wheel for damage

• The timing chain, timing chain tensioner, and sprockets for wear or damage

⇒ If debris is found in the engine oil, inspect the internal engine components to determine the root cause. Repair or replace any worn or damaged components. Refer to Camshaft Timing Chain and Sprocket Cleaning and Inspection .

Camshaft Reluctor Wheel

The camshaft reluctor wheel is part of the camshaft gear. The reluctor wheel contains a pattern of 2 narrow teeth, and 2 wide teeth around the circumference of the wheel. The falling or trailing edges of the 4 teeth are evenly spaced at 90 degrees apart. The engine control module (ECM) recognizes the narrow and wide tooth patterns to identify camshaft position, or which cylinder is in compression, and which is in exhaust. The ECM also uses the reluctor wheel information to determine the camshaft relative position to the crankshaft position.

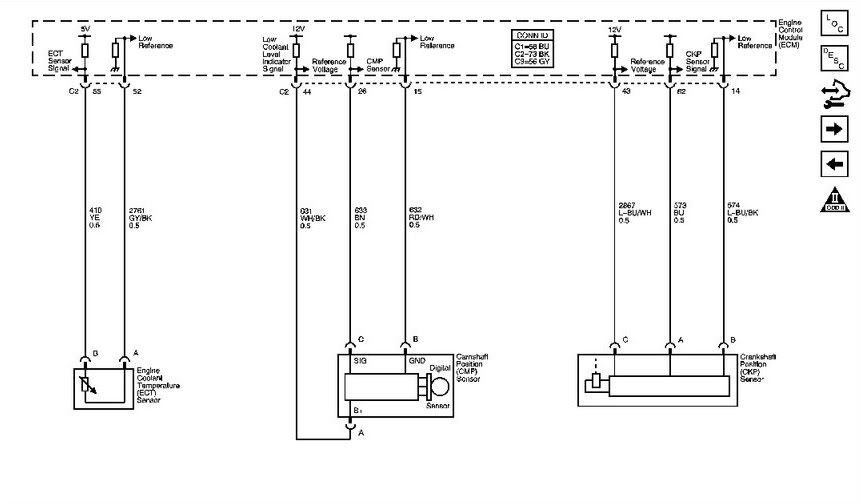

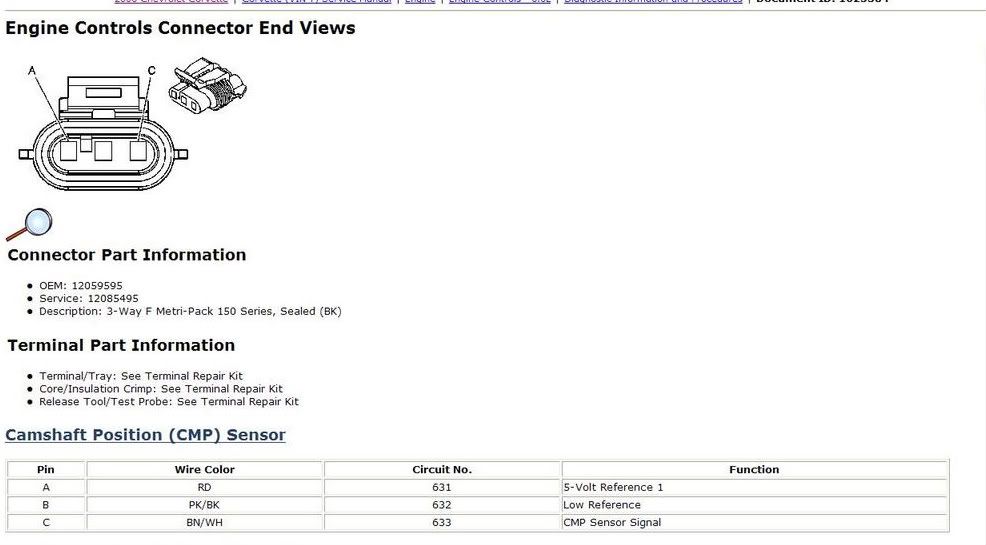

Camshaft Position (CMP) Sensor

The camshaft position (CMP) sensor is a 3-wire sensor that provides a digital output signal. The wire circuits consist of an engine control module (ECM) supplied 5-volt reference circuit, a low reference circuit between the CMP sensor and the ECM, and an output signal circuit from the CMP sensor to the ECM. The CMP sensor detects magnetic flux changes between the teeth and slots on the 4-tooth reluctor wheel. The CMP sensor provides a digital ON/OFF DC voltage of varying frequency, with 4 varying width output pulses, per each camshaft revolution. The frequency of the CMP sensor output signal depends on the speed of the camshaft. The ECM will recognize the narrow and wide tooth patterns to identify camshaft position, or which cylinder is in compression and which is in exhaust. The information is then used to determine the correct time and sequence for fuel injection and ignition spark events. The ECM also uses the CMP sensor output signal to determine the camshaft relative position to the crankshaft position.

P0341

The ECM detects that the engine has started and is running, but receives less than 398 or more than 402 CMP pulses per 100 engine cycles in 800 of 1,000 engine cycles.

P0341

Ignition OFF, inspect the CMP sensor for correct installation.

⇒ If the CMP sensor is loose, inspect the sensor and the O-ring for damaged, replace as necessary.

Inspect the engine for the following conditions:

• Engine oil for debris

• Camshaft reluctor wheel for damage

• The timing chain, timing chain tensioner, and sprockets for wear or damage

⇒ If debris is found in the engine oil, inspect the internal engine components to determine the root cause. Repair or replace any worn or damaged components. Refer to Camshaft Timing Chain and Sprocket Cleaning and Inspection .

Camshaft Reluctor Wheel

The camshaft reluctor wheel is part of the camshaft gear. The reluctor wheel contains a pattern of 2 narrow teeth, and 2 wide teeth around the circumference of the wheel. The falling or trailing edges of the 4 teeth are evenly spaced at 90 degrees apart. The engine control module (ECM) recognizes the narrow and wide tooth patterns to identify camshaft position, or which cylinder is in compression, and which is in exhaust. The ECM also uses the reluctor wheel information to determine the camshaft relative position to the crankshaft position.

Camshaft Position (CMP) Sensor

The camshaft position (CMP) sensor is a 3-wire sensor that provides a digital output signal. The wire circuits consist of an engine control module (ECM) supplied 5-volt reference circuit, a low reference circuit between the CMP sensor and the ECM, and an output signal circuit from the CMP sensor to the ECM. The CMP sensor detects magnetic flux changes between the teeth and slots on the 4-tooth reluctor wheel. The CMP sensor provides a digital ON/OFF DC voltage of varying frequency, with 4 varying width output pulses, per each camshaft revolution. The frequency of the CMP sensor output signal depends on the speed of the camshaft. The ECM will recognize the narrow and wide tooth patterns to identify camshaft position, or which cylinder is in compression and which is in exhaust. The information is then used to determine the correct time and sequence for fuel injection and ignition spark events. The ECM also uses the CMP sensor output signal to determine the camshaft relative position to the crankshaft position.

Last edited by jay_lt4; 03-30-2008 at 07:21 AM.

#7

TECH Fanatic

iTrader: (19)

Join Date: Jan 2005

Location: Phoenix AZ

Posts: 1,034

Likes: 0

Received 0 Likes

on

0 Posts

Bringing this one back from the dead... Which extention harness did you use with this swap? Katech, Caspers? Im about to switch the two outer wires on my caspers, it sucks that we have to deal with this