Gforce Engineering Fabricated 9" bolt in IRS for the G8

#1

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Sep 2009

Location: Wichita, KS

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

I'd like to show you guys what we have been building for the G8's. We've been selling the 9" kits to guys in Australia that have the Australian version of the G8.

We got busy and never did get on here to show them off, so here it is.

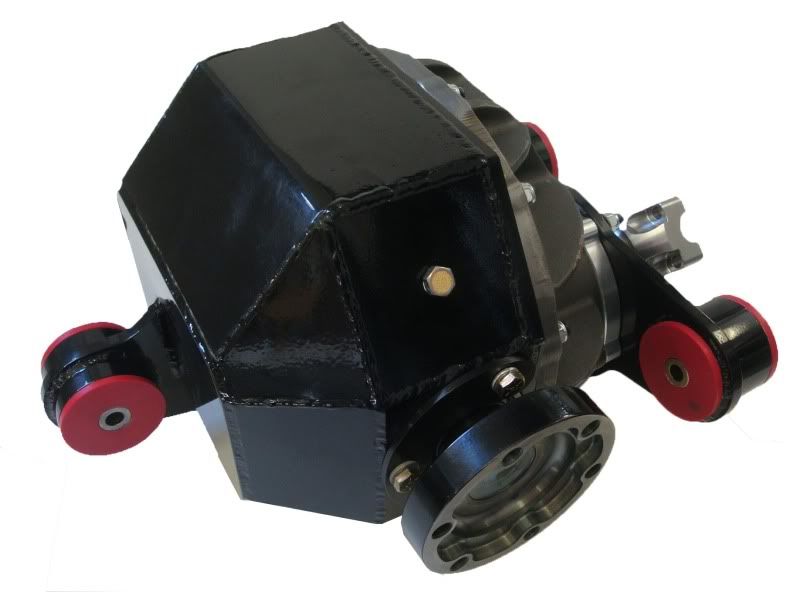

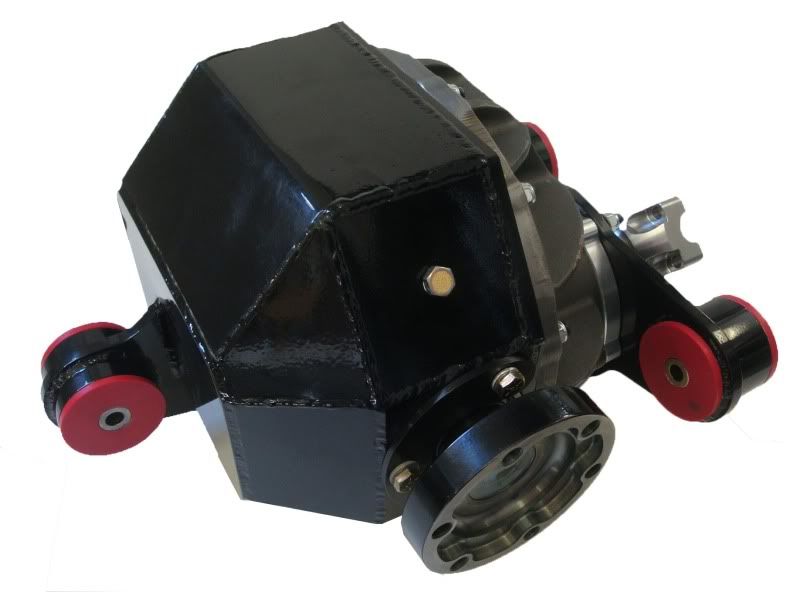

We fabricate the entire housing in house on our cnc equipment, everything is tig welded and jig located.

It is the strongest IRS housing you can buy. The face plates are 3/8" thick and the cover and sides are all 3/16" thick. The side bearing blocks are a full 1.25" thick.

All the brackets are laser cut from 3/8" thick steel and it comes with heavy duty BMR bushings.

This housing would be right at home in a ProMod car.

We supply our 9" rears complete with a pre-built Strange Engineering or Moser pumpkin as we are dealers for both and both companies offer excellent products. We can also supply the rear without a pumpkin.

The base kit comes with the 31 spline Eaton Truetrac posi and our billet 300m inner stubs.

We don’t throw fancy names and sales gimmicks on the materials we use, we only use aircraft certified 300m that is heat treated to our specs in our specialized heat treat processes.

There is NO stronger material then 300m to make axles from..

We can also supply your rear with the heavy duty 35 spline Wavetrac posi that comes with a lifetime warranty.

When paired with our huge 35 spline 300m stubs, the 35 spline wavetrac is the strongest set up on the market hands down.

We supply our proven 300m 1000+hp axles that have our anti wheel hop axle technology designed into them, you get a regular size axle for the drivers side and a large diameter axle for the passenger side (unless your in Australia and then it's the drivers side )

We have a great track record with our 300m axles, there has never been a set broken to date in any car we make them for and that is one hell of a track record. That is why we offer a 2 year warranty, twice as long as anyone else.

For the ultimate 9" for the guys making really big power, we can supply the 9" with our huge 33 spline "Outlaw" axles.

These are biggest and strongest axles on the market. The axle bars are 33 spline and made from 300m and are a full 1.5" diameter.

Some modification is required to the upper control arm to clear these monsters.

There are several choices on the driveshaft, it can be either a 2 piece 3" chromoly/3.5" Aluminum, 3.5" one piece aluminum or our 3.75" Carbon Fiber shaft at an additional cost.

Heavy duty drivetrain parts and fabrication is what we specialize in. Its what we do day in and day out. We've been in this business for 20 years and love designing and making killer setup like the 9" IRS, we are really proud of this bad boy.

It's pretty rare that a company does everything in house now days, most places farm it out and just slap stickers on it.

We do all our design work in house and we also do all our cnc machine work in house. We dont farm much of anything out, that way we can control quality and we can design on the fly.

We have one of our 9" kits going into a 2010 Camaro that Nelson Racing Engines is building in California, this car will be putting down around 1800hp to the tires. This build is using the 35 spline Wavetac and our 33 spline "Outlaw" axles.

We have another 9" rear going into a 1500hp Camaro that is being built at Cinci Speed as well as several others.

The big power boys call Gforce for the ultimate 9" IRS rears

Give a call if you would like to talk about our 9" Fabricated rears.

The base 9" kit is $5500. and comes complete with pumpkin, your choice of gears, driveshaft, axles and axlle stubs for a complete turn key kit.

Thanks

Chris @ Gforce

Shown with optional 35 Spline “Outlaw” one piece stubs.

Shown with optional Carbon Fiber driveshaft

We can powder coat the entire rear and axles in just about any color to match your car.

Here are our patent pending billet 300m bolt together inner stubs.

The bolt together stubs make it easy to up-grade to our larger 33 or 35 spline stubs later without spending a fortune and complete stubs.

Our 300m stubs have proven to be un breakable as we have never had a set broken to date.

Here is our huge 35 spline inner stubs compared to the smaller 31 spline stubs that come with the 31 spline truetrac.

We got busy and never did get on here to show them off, so here it is.

We fabricate the entire housing in house on our cnc equipment, everything is tig welded and jig located.

It is the strongest IRS housing you can buy. The face plates are 3/8" thick and the cover and sides are all 3/16" thick. The side bearing blocks are a full 1.25" thick.

All the brackets are laser cut from 3/8" thick steel and it comes with heavy duty BMR bushings.

This housing would be right at home in a ProMod car.

We supply our 9" rears complete with a pre-built Strange Engineering or Moser pumpkin as we are dealers for both and both companies offer excellent products. We can also supply the rear without a pumpkin.

The base kit comes with the 31 spline Eaton Truetrac posi and our billet 300m inner stubs.

We don’t throw fancy names and sales gimmicks on the materials we use, we only use aircraft certified 300m that is heat treated to our specs in our specialized heat treat processes.

There is NO stronger material then 300m to make axles from..

We can also supply your rear with the heavy duty 35 spline Wavetrac posi that comes with a lifetime warranty.

When paired with our huge 35 spline 300m stubs, the 35 spline wavetrac is the strongest set up on the market hands down.

We supply our proven 300m 1000+hp axles that have our anti wheel hop axle technology designed into them, you get a regular size axle for the drivers side and a large diameter axle for the passenger side (unless your in Australia and then it's the drivers side )

We have a great track record with our 300m axles, there has never been a set broken to date in any car we make them for and that is one hell of a track record. That is why we offer a 2 year warranty, twice as long as anyone else.

For the ultimate 9" for the guys making really big power, we can supply the 9" with our huge 33 spline "Outlaw" axles.

These are biggest and strongest axles on the market. The axle bars are 33 spline and made from 300m and are a full 1.5" diameter.

Some modification is required to the upper control arm to clear these monsters.

There are several choices on the driveshaft, it can be either a 2 piece 3" chromoly/3.5" Aluminum, 3.5" one piece aluminum or our 3.75" Carbon Fiber shaft at an additional cost.

Heavy duty drivetrain parts and fabrication is what we specialize in. Its what we do day in and day out. We've been in this business for 20 years and love designing and making killer setup like the 9" IRS, we are really proud of this bad boy.

It's pretty rare that a company does everything in house now days, most places farm it out and just slap stickers on it.

We do all our design work in house and we also do all our cnc machine work in house. We dont farm much of anything out, that way we can control quality and we can design on the fly.

We have one of our 9" kits going into a 2010 Camaro that Nelson Racing Engines is building in California, this car will be putting down around 1800hp to the tires. This build is using the 35 spline Wavetac and our 33 spline "Outlaw" axles.

We have another 9" rear going into a 1500hp Camaro that is being built at Cinci Speed as well as several others.

The big power boys call Gforce for the ultimate 9" IRS rears

Give a call if you would like to talk about our 9" Fabricated rears.

The base 9" kit is $5500. and comes complete with pumpkin, your choice of gears, driveshaft, axles and axlle stubs for a complete turn key kit.

Thanks

Chris @ Gforce

Shown with optional 35 Spline “Outlaw” one piece stubs.

Shown with optional Carbon Fiber driveshaft

We can powder coat the entire rear and axles in just about any color to match your car.

Here are our patent pending billet 300m bolt together inner stubs.

The bolt together stubs make it easy to up-grade to our larger 33 or 35 spline stubs later without spending a fortune and complete stubs.

Our 300m stubs have proven to be un breakable as we have never had a set broken to date.

Here is our huge 35 spline inner stubs compared to the smaller 31 spline stubs that come with the 31 spline truetrac.

#3

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Sep 2009

Location: Wichita, KS

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Our Fabricated 9" has really taken off in a big way since introduction.

We will have these on the shelf eventually but right now we sell them about as fast as we can make them.

Yes, a spool would be lighter and cheaper, about 10 lbs and $200. cheaper.

Were sending a couple 9" rears to Australia with our big 35 spline stubs and 35 spline spool.

We can make you a 3.5" one piece shaft, give me a call at the shop Monday if you want.

Thanks

Chris @ Gforce

#6

Wouldn't the one piece DS have vibration at higher speed compared to the 2 piece aluminum DS you make?

Thanks,

MH