Take a Tour of Painless Performance

#1

Welcome to Painless Performance Products

This is the front view of our 43,000 square foot facility located in Fort Worth Texas, where we design, build and ship over 500 products for show cars, dragsters, rock crawlers and everything in between.

Raw Goods Inventory -Inventory Cage

At any one time we have up to 3 million individual parts in our raw inventory cage. Our top tier vendors provide us with Just-In-Time delivery to reduce overhead and production cost and to provide an uninterrupted flow of finsished goods.

Wire Inventory

We consume approximately 17 million feet of wire each year which is roughly 2500 – 3200 miles of wire. Only the highest quality multi-strand thermal cross-linked (TXL) wire is used in Painless products.

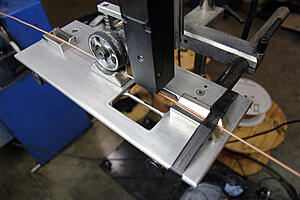

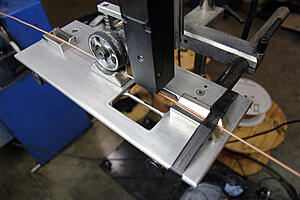

Wire Striping

This machine stripes the base colored wires in any color combination we need to better facilitate following OEM manufacturers color codes.

Print, Cut & Strip Wire Station

These machines pull the raw wire from the wire buckets or spools and then measure, cut, and strip each end of the wires.

Wire Printing

What makes Painless Wiring painless is that each wire is labeled every few inches with its terminal destination. To enhance readability we print with black ink on the light colored wires and white ink on the dark wires.

Wire Termination with AMP Presses

Each press is permanently set up for a particular gauge terminal. This eliminates costly set up and tear down of machines to accommodate various gauges sizes and reduces overall productions costs.

Fuse Block Loading

This is where the major busses and wires are inserted into the back of each fuse block, creating a building block that can be transformed into a variety of application and vehicle specific harnesses.

Chassis Harness Assembly

After the fuse block is populated we then place them onto an assembly board and the lay-in wires are added which will turn the harness into a specific application. To ease installation, we carefully bundle the wires in groups (engine compartment, dash, rear of vehicle, etc.) so the installer only has to route a single group of wires rather than 100+ individual wires.

Harness Assembly Boards

Each different engine and chassis application we support has its own assembly board. Each board has its specific lengths of wires and connectors to be applied.

Fuel Injection Test Board

After each fuel injection harness is built we then test ALL of them on the corresponding test board. Test boards check continuity, pin out and conductance (crimp quality). If you have purchased a Painless fuel injection harness, rest assured it has been thoroughly tested before it was sent out.

Parts Kits and Final Assembly Packaging

Once the harness, both fuel injection and chassis, has been finished and neatly wrapped up; we carefully place each of them into their designated boxes and add any small parts and instruction manuals.

Finished Goods Inventory Handling

All the time we are moving over finished goods from our production area.

Tech Department

Ensuring quality customer service both before and after the sale is important at Painless. Here one of our Tech Department employees walks a customer on the phone through the different menus available on our TORC Transmission controller.

Tech Samples to assist with calls

If you need some help trouble shooting an installation, Painless has a great team of experienced technicians on board to walk you through any issue. Every step of the way, our goal is to make it easy, simple and painless.

Reflash Program for GM's LS Engines

All customers who purchase a Painless EFI harness for LS engines are eligible for a free reflash of the ECM, saving potentially hundreds of dollars.

Test Install in R&D

We test each of our new vehicle specific harnesses by installing them into several of the vehicles in which the new harness is designed to fit. We even send out several of these new harnesses to individuals who have the vehicles we need to initiate valuable feedback on each new harness.

Thanks for check us out! Be sure to check out our website for more information painlessperformance.com

This is the front view of our 43,000 square foot facility located in Fort Worth Texas, where we design, build and ship over 500 products for show cars, dragsters, rock crawlers and everything in between.

Raw Goods Inventory -Inventory Cage

At any one time we have up to 3 million individual parts in our raw inventory cage. Our top tier vendors provide us with Just-In-Time delivery to reduce overhead and production cost and to provide an uninterrupted flow of finsished goods.

Wire Inventory

We consume approximately 17 million feet of wire each year which is roughly 2500 – 3200 miles of wire. Only the highest quality multi-strand thermal cross-linked (TXL) wire is used in Painless products.

Wire Striping

This machine stripes the base colored wires in any color combination we need to better facilitate following OEM manufacturers color codes.

Print, Cut & Strip Wire Station

These machines pull the raw wire from the wire buckets or spools and then measure, cut, and strip each end of the wires.

Wire Printing

What makes Painless Wiring painless is that each wire is labeled every few inches with its terminal destination. To enhance readability we print with black ink on the light colored wires and white ink on the dark wires.

Wire Termination with AMP Presses

Each press is permanently set up for a particular gauge terminal. This eliminates costly set up and tear down of machines to accommodate various gauges sizes and reduces overall productions costs.

Fuse Block Loading

This is where the major busses and wires are inserted into the back of each fuse block, creating a building block that can be transformed into a variety of application and vehicle specific harnesses.

Chassis Harness Assembly

After the fuse block is populated we then place them onto an assembly board and the lay-in wires are added which will turn the harness into a specific application. To ease installation, we carefully bundle the wires in groups (engine compartment, dash, rear of vehicle, etc.) so the installer only has to route a single group of wires rather than 100+ individual wires.

Harness Assembly Boards

Each different engine and chassis application we support has its own assembly board. Each board has its specific lengths of wires and connectors to be applied.

Fuel Injection Test Board

After each fuel injection harness is built we then test ALL of them on the corresponding test board. Test boards check continuity, pin out and conductance (crimp quality). If you have purchased a Painless fuel injection harness, rest assured it has been thoroughly tested before it was sent out.

Parts Kits and Final Assembly Packaging

Once the harness, both fuel injection and chassis, has been finished and neatly wrapped up; we carefully place each of them into their designated boxes and add any small parts and instruction manuals.

Finished Goods Inventory Handling

All the time we are moving over finished goods from our production area.

Tech Department

Ensuring quality customer service both before and after the sale is important at Painless. Here one of our Tech Department employees walks a customer on the phone through the different menus available on our TORC Transmission controller.

Tech Samples to assist with calls

If you need some help trouble shooting an installation, Painless has a great team of experienced technicians on board to walk you through any issue. Every step of the way, our goal is to make it easy, simple and painless.

Reflash Program for GM's LS Engines

All customers who purchase a Painless EFI harness for LS engines are eligible for a free reflash of the ECM, saving potentially hundreds of dollars.

Test Install in R&D

We test each of our new vehicle specific harnesses by installing them into several of the vehicles in which the new harness is designed to fit. We even send out several of these new harnesses to individuals who have the vehicles we need to initiate valuable feedback on each new harness.

Thanks for check us out! Be sure to check out our website for more information painlessperformance.com