2 point vs 3 point sfc

#1

12 Second Club

Thread Starter

iTrader: (10)

Join Date: Sep 2005

Location: From Ohio now in that state up north

Posts: 948

Received 0 Likes

on

0 Posts

I was surprised not to find this in a search but are 3 point sfc worth the extra money? What advantages do they provide over 2 point? At what point would you need to upgrade if you need to upgrade?

#2

I went with the 3 point sfc because I figured I might as well do the job once haha. I would talk to some of the SFC sellers like UMI or BMR and see if they have any details.

#3

FormerVendor

iTrader: (77)

This is always a tough debate, how do you really show if one is overkill or not?

In most cases the 3-points are overkill, but again can it hurt to have too much bracing?

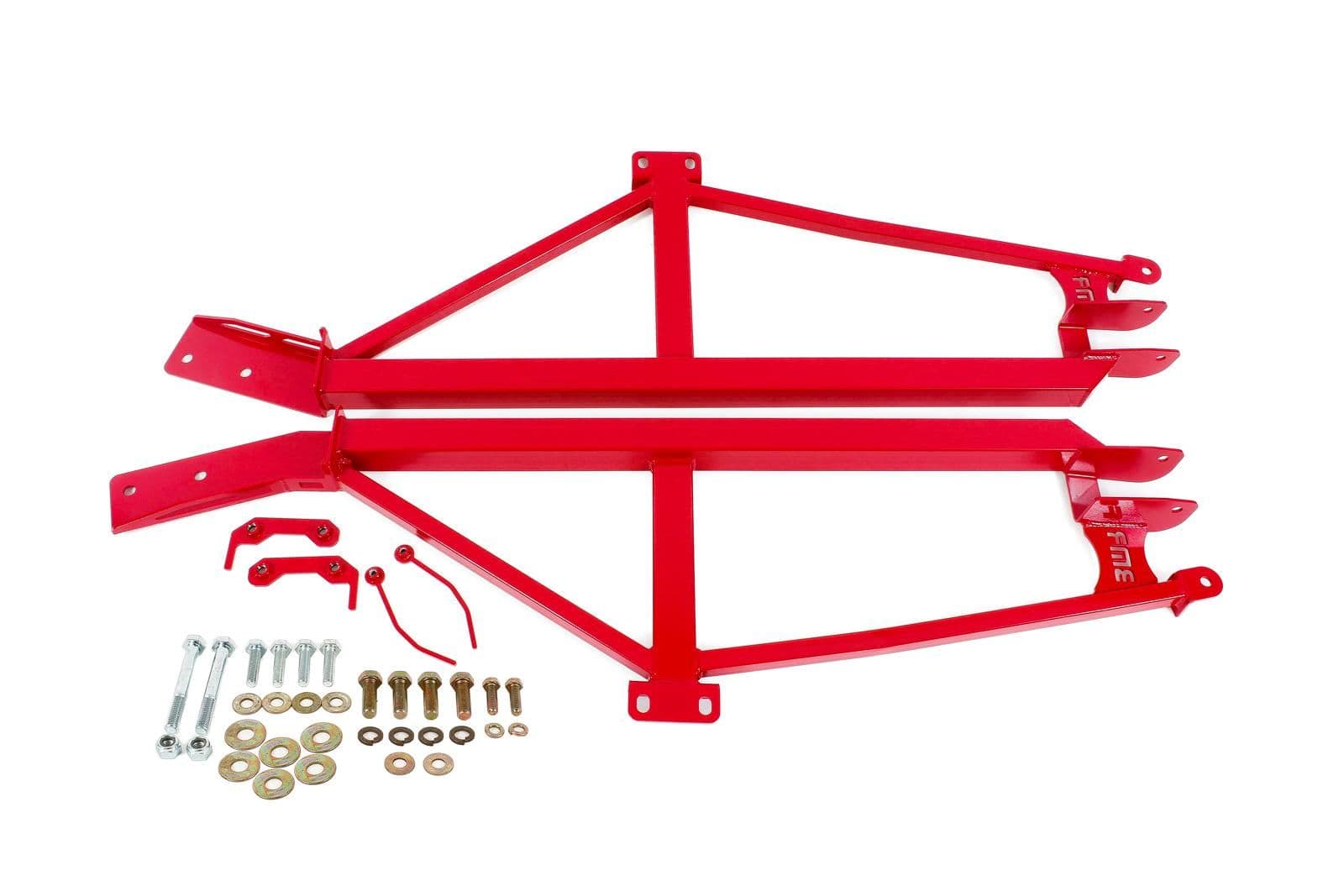

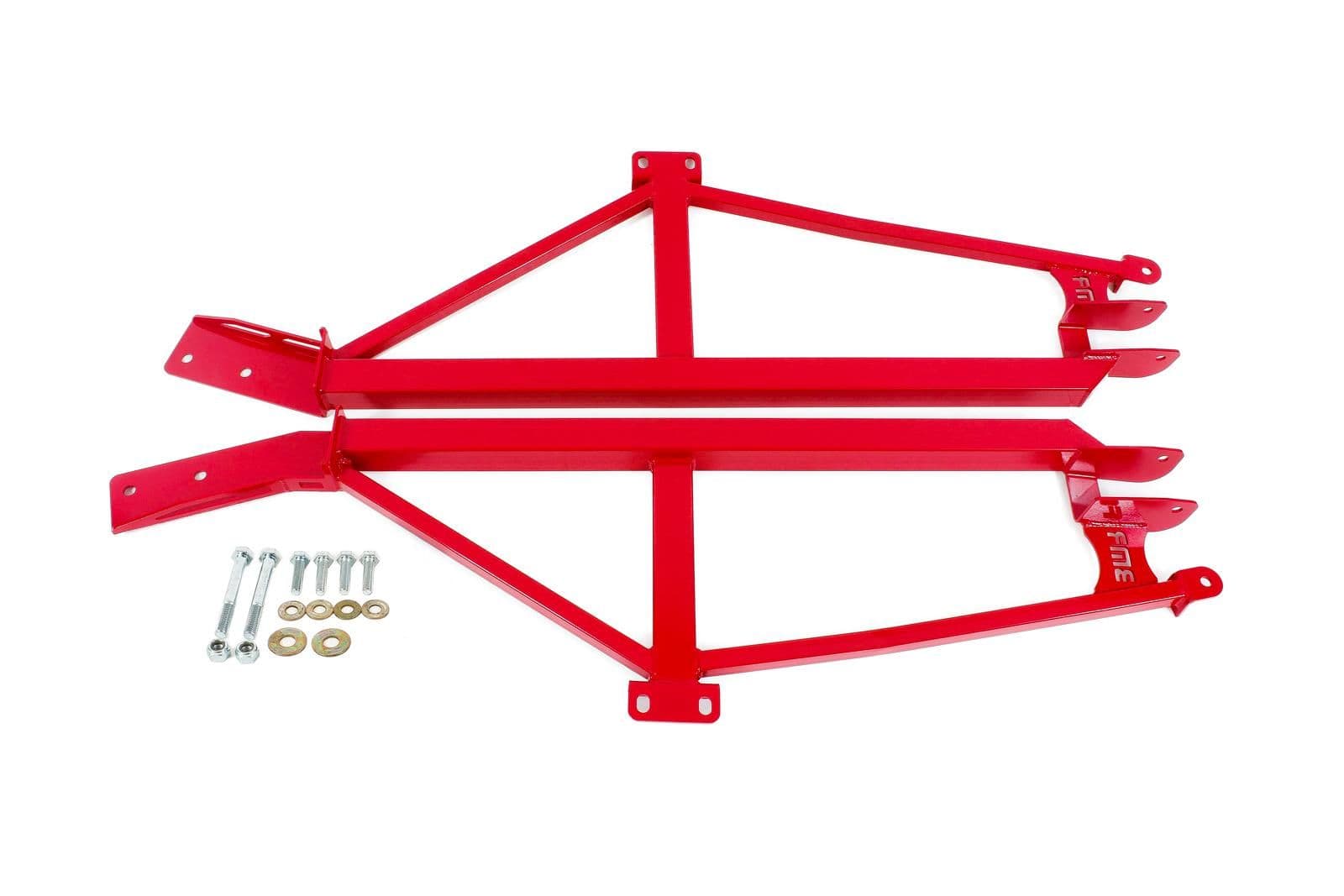

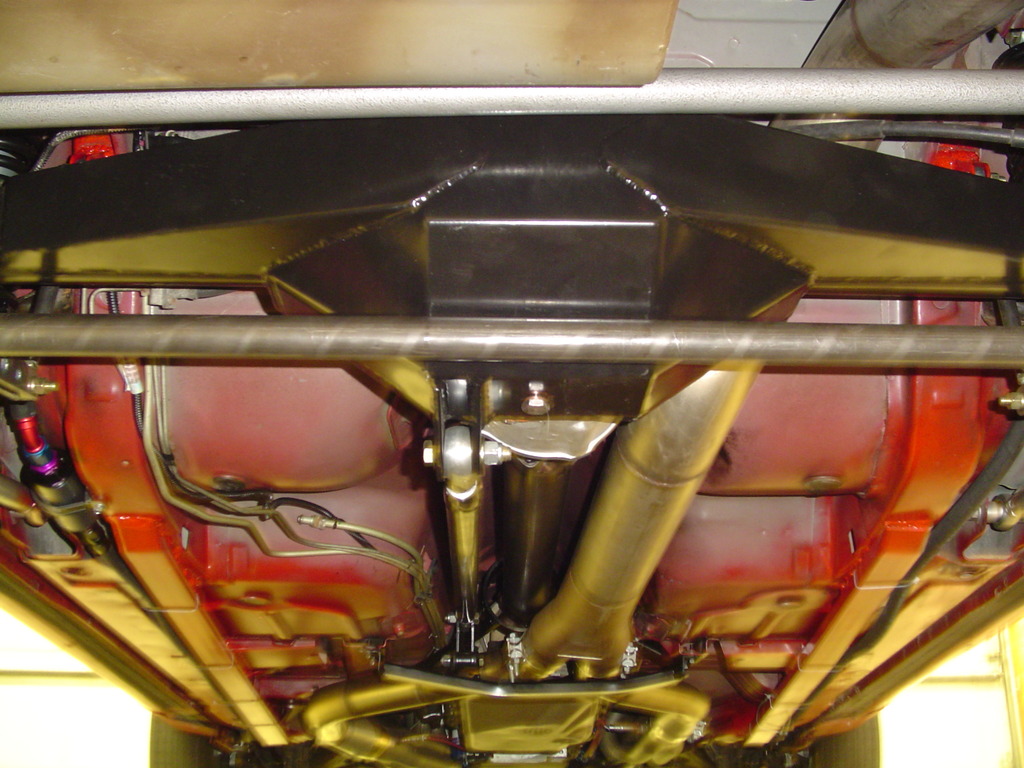

I recommend the 3-point SFC's when and if you run one of the shorter tunnel mounted torque arms. The torque arms bolt to the tunnel under the SFC's and this allows the stress of the torque arm to be applied into the SFC's rather than the body mounts. Picture below is a great example. I hope this helps.

In most cases the 3-points are overkill, but again can it hurt to have too much bracing?

I recommend the 3-point SFC's when and if you run one of the shorter tunnel mounted torque arms. The torque arms bolt to the tunnel under the SFC's and this allows the stress of the torque arm to be applied into the SFC's rather than the body mounts. Picture below is a great example. I hope this helps.

#4

LS1Tech Premium Sponsor

iTrader: (40)

We have a couple bolt-in and weld-in options that would take care of you so if there is anything we can help you out with just let us know.

BMR Boxed weld-in 2 point subframe connectors (SFC001)

BMR Tubular weld-in 2 point subframe connectors (SFC004)

BMR Boxed bolt-in 4 point subframe connectors (SFC019)

BMR Boxed weld-in 4 point subframe connectors (SFC020)

BMR Boxed bolt-in 2 point subframe connectors (SFC023)

__________________

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

#5

LS1Tech Premium Sponsor

iTrader: (26)

The SFC issue has always been a debate. The biggest concern is installing a component that does the job it is intended to... connect the real subframes of the unibody.

The LCA mount is NOT the rear subframe. The floor cross brace is NOT the front subframe. Concerning bolt-in stiffening items: ANY bolt-on item will flex or move at the connection joint before the purpose of the item will do it's job. When it comes to chassis flex, we're only talking thousandths of an inch of movement, therefore a bolt-in item for the purpose of stiffening is for the most part worthless...IMHO.

#6

LS1Tech Premium Sponsor

iTrader: (26)

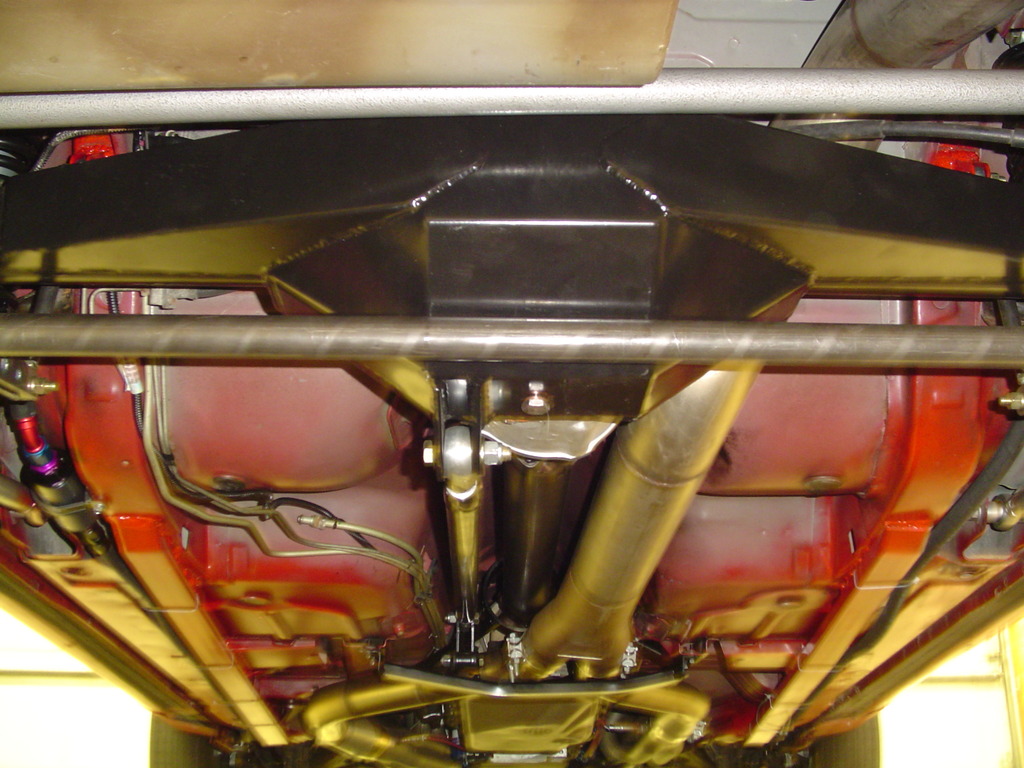

Here's pics to help understand the principal of connecting the true subframes of the car:

This is the right rear. As you can see the LCA box is nowhere near the rear subframe. Additionally the outermost structure you see is the pinch weld of the rocker panel. The rocker is already the strongest point of a uni-body car, and no sense in going so far outboard of the direct line of the subframes.

This is the passenger side front subframe from the front. The structure directly behind the subframe is the floor crossbrace and if a connector is only tied to this part there is no additional support to the subframe. As you can see in this pic there was what was originally called a SFC, was connected to the floor crossbrace and not the subframe. It is not in a direct line between the front and rear subframes, inherently weaker design vs. unbent and inline. This car had this design removed as it was doing nothing but adding weight and not actually connecting the subframes.

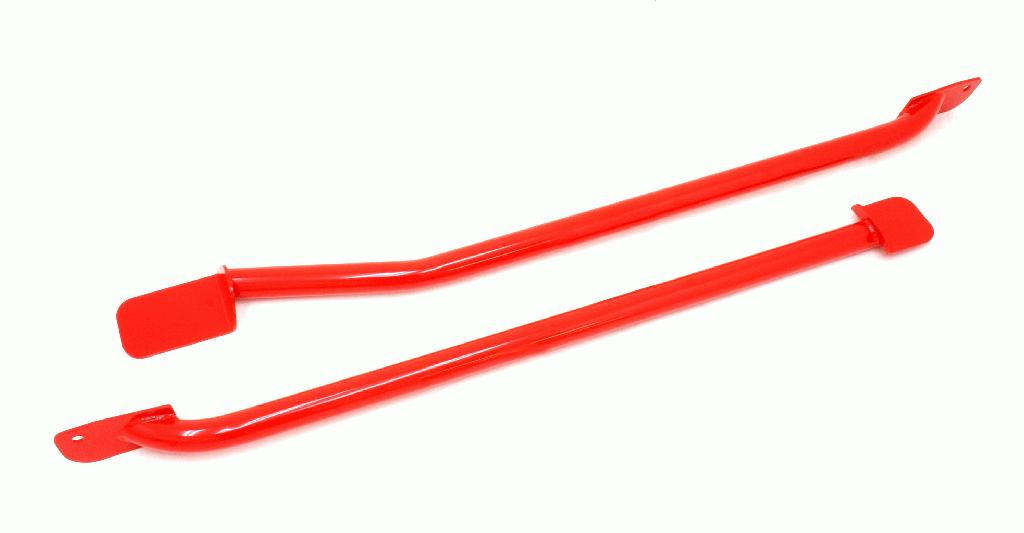

Last is a real set of welded in, true frame connectors. Simple, light weight, easy to install, do the job intended.

This is the right rear. As you can see the LCA box is nowhere near the rear subframe. Additionally the outermost structure you see is the pinch weld of the rocker panel. The rocker is already the strongest point of a uni-body car, and no sense in going so far outboard of the direct line of the subframes.

This is the passenger side front subframe from the front. The structure directly behind the subframe is the floor crossbrace and if a connector is only tied to this part there is no additional support to the subframe. As you can see in this pic there was what was originally called a SFC, was connected to the floor crossbrace and not the subframe. It is not in a direct line between the front and rear subframes, inherently weaker design vs. unbent and inline. This car had this design removed as it was doing nothing but adding weight and not actually connecting the subframes.

Last is a real set of welded in, true frame connectors. Simple, light weight, easy to install, do the job intended.

#7

12 Second Club

Thread Starter

iTrader: (10)

Join Date: Sep 2005

Location: From Ohio now in that state up north

Posts: 948

Received 0 Likes

on

0 Posts

A lot of good info here and we touched on one of my bigger questions will having a 3 point help with the torque arm being relocated will that do anything to improve traction?

A torque arm is in my future as well and if it will help them that's a consideration.

The car is mostly street driving and drag strip and I plan on going for 11s of this impacts the decision.

A torque arm is in my future as well and if it will help them that's a consideration.

The car is mostly street driving and drag strip and I plan on going for 11s of this impacts the decision.

Trending Topics

#8

^ while this is all fine and dandy, the actual load it being applied to the lower control arm mounts NOT the "actual sub-frame". Bracing the subframe and leaving the control arm mount unsupported will actually create a shear point between the lca mount and subframe that will now be doing the lifting. And being that it is only sheetmetal between those points, that's a lot of stress to be applying on not a lot of metal. The idea of tying the lca's directly to the front is so that the lifting and forward pushing force your lca's create is applied directly to the front of the car, and not absorbed into the chassis. It would be the same idea as having a full frame car and mounting the suspension components to the body instead. Can you do it? Yeah. Is it a good idea? No.

#10

A lot of good info here and we touched on one of my bigger questions will having a 3 point help with the torque arm being relocated will that do anything to improve traction?

A torque arm is in my future as well and if it will help them that's a consideration.

The car is mostly street driving and drag strip and I plan on going for 11s of this impacts the decision.

A torque arm is in my future as well and if it will help them that's a consideration.

The car is mostly street driving and drag strip and I plan on going for 11s of this impacts the decision.

Here's the basic break down of what will help you decide which is right for you. How will you be using the car? will you be primarily using it as a street/strip car? Will you be doing any handling oriented stuff, auto-x etc? For a street/strip application, all of your force will be applied in a straight forward motion. Therefore a standard 2 point sfc will be fine. A multi-point SFC helps with lateral support on the chassis to reduce torsional flex under hard cornering

#12

you options are:

A) not the subframe

B) not the subframe

or C) not the subframe

I'm glad you are willing to put your faith and customer's lives on a car that caliber in a piece of sheetmetal. I guess we are all doing it wrong building 25.2 chassis and stuff. We can just use the stock floorpans

#13

LS1Tech Premium Sponsor

iTrader: (26)

A lot of good info here and we touched on one of my bigger questions will having a 3 point help with the torque arm being relocated will that do anything to improve traction?

A torque arm is in my future as well and if it will help them that's a consideration.

The car is mostly street driving and drag strip and I plan on going for 11s of this impacts the decision.

A torque arm is in my future as well and if it will help them that's a consideration.

The car is mostly street driving and drag strip and I plan on going for 11s of this impacts the decision.