Pinion Angle Confusion

#1

New to me 2000 Camaro SS, manual trans, dynoed at 602/603 RWHP/TQ sprayed, QP fabricated bolt-in 9", adjustable UMI torque arm and LCA's. Will be primarily a drag car, currently on street radials. Never raced by me.

Several years ago I built a blown pro street '68 Nova back half 4-link car in my garage, FAB-9 rear, setting the trans angle down 3 deg, pinion up 3 deg, the thing never vibrated, no problems, ran on the strip several times. Why am I seeing so many different suggestions to set this Camaro up, from using the shaft angle/pinion angle to measuring all three angles and doing math, etc.?

At my age I'd rather not be crawling under this car a lot, would like to get it right the first time. The most reliable post I've read the OP set his drive shaft at zero deg, pinion up 2 deg with no issues. I'm at 2.5 deg trans down, 2 deg pinion up which puts the shaft at or near zero.

Any thoughts without going into an elaborate engineering discussion to make this easy out of the chute?

Thanks, Larry M.

Several years ago I built a blown pro street '68 Nova back half 4-link car in my garage, FAB-9 rear, setting the trans angle down 3 deg, pinion up 3 deg, the thing never vibrated, no problems, ran on the strip several times. Why am I seeing so many different suggestions to set this Camaro up, from using the shaft angle/pinion angle to measuring all three angles and doing math, etc.?

At my age I'd rather not be crawling under this car a lot, would like to get it right the first time. The most reliable post I've read the OP set his drive shaft at zero deg, pinion up 2 deg with no issues. I'm at 2.5 deg trans down, 2 deg pinion up which puts the shaft at or near zero.

Any thoughts without going into an elaborate engineering discussion to make this easy out of the chute?

Thanks, Larry M.

#2

LS1Tech Premium Sponsor

iTrader: (40)

New to me 2000 Camaro SS, manual trans, dynoed at 602/603 RWHP/TQ sprayed, QP fabricated bolt-in 9", adjustable UMI torque arm and LCA's. Will be primarily a drag car, currently on street radials. Never raced by me.

Several years ago I built a blown pro street '68 Nova back half 4-link car in my garage, FAB-9 rear, setting the trans angle down 3 deg, pinion up 3 deg, the thing never vibrated, no problems, ran on the strip several times. Why am I seeing so many different suggestions to set this Camaro up, from using the shaft angle/pinion angle to measuring all three angles and doing math, etc.?

At my age I'd rather not be crawling under this car a lot, would like to get it right the first time. The most reliable post I've read the OP set his drive shaft at zero deg, pinion up 2 deg with no issues. I'm at 2.5 deg trans down, 2 deg pinion up which puts the shaft at or near zero.

Any thoughts without going into an elaborate engineering discussion to make this easy out of the chute?

Thanks, Larry M.

Several years ago I built a blown pro street '68 Nova back half 4-link car in my garage, FAB-9 rear, setting the trans angle down 3 deg, pinion up 3 deg, the thing never vibrated, no problems, ran on the strip several times. Why am I seeing so many different suggestions to set this Camaro up, from using the shaft angle/pinion angle to measuring all three angles and doing math, etc.?

At my age I'd rather not be crawling under this car a lot, would like to get it right the first time. The most reliable post I've read the OP set his drive shaft at zero deg, pinion up 2 deg with no issues. I'm at 2.5 deg trans down, 2 deg pinion up which puts the shaft at or near zero.

Any thoughts without going into an elaborate engineering discussion to make this easy out of the chute?

Thanks, Larry M.

__________________

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

#3

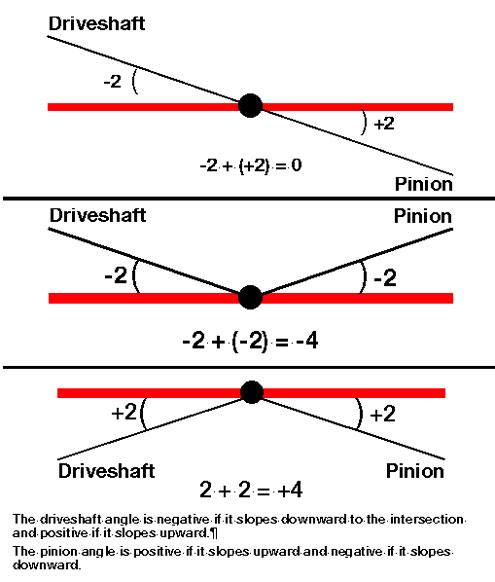

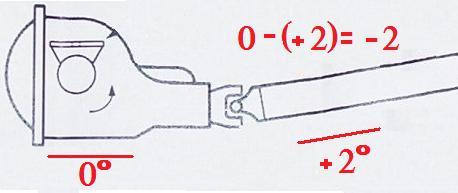

Thanks BMR, I've seen that video, so it would mean with my tail shaft at -2.5 (down) I subtract minus 2 from that and set my pinion angle at - .5 (down)? I apologize I can't wrap my head around that setting, seems the pinion should be adjusted up some degree past zero (offsetting the tail shaft down angle). Am I over thinking this? I think what I neede is for someone to tell me what to set the pinion at in degrees, positive or negative (up or down). I would really appreciate that.

The video says subtract 2 from the tail shaft angle, does he mean subtract -2?

I understand the setting will vary under hard acceleration perhaps, but can deal with that if there's an issue down the road.

The video says subtract 2 from the tail shaft angle, does he mean subtract -2?

I understand the setting will vary under hard acceleration perhaps, but can deal with that if there's an issue down the road.

#4

On The Tree

Hold your hands out flat in front of you with your fingertips touching each other. Now fold your hands like the roof of a house, fingertips up, wrists down. Imagine your left hand is the tailshaft, and your right is the pinion yoke. That's POSITIVE pinion angle. Bring your hands back parallel, that's 0 degrees, now keep raising your left wrist until you make a "V" with your fingertips down below the plane of your wrists. That's NEGATIVE pinion angle.

That's the only way my idiot brain could ever understand it, hope that helps.

One of the BMR videos shows the correct method but gives the math wrong IIRC. I think they fixed/updated it at some point though.

-2 is what works for most people, and what has always worked for me.

That's the only way my idiot brain could ever understand it, hope that helps.

One of the BMR videos shows the correct method but gives the math wrong IIRC. I think they fixed/updated it at some point though.

-2 is what works for most people, and what has always worked for me.

#6

Hold your hands out flat in front of you with your fingertips touching each other. Now fold your hands like the roof of a house, fingertips up, wrists down. Imagine your left hand is the tailshaft, and your right is the pinion yoke. That's POSITIVE pinion angle. Bring your hands back parallel, that's 0 degrees, now keep raising your left wrist until you make a "V" with your fingertips down below the plane of your wrists. That's NEGATIVE pinion angle.

That's the only way my idiot brain could ever understand it, hope that helps.

One of the BMR videos shows the correct method but gives the math wrong IIRC. I think they fixed/updated it at some point though.

-2 is what works for most people, and what has always worked for me.

That's the only way my idiot brain could ever understand it, hope that helps.

One of the BMR videos shows the correct method but gives the math wrong IIRC. I think they fixed/updated it at some point though.

-2 is what works for most people, and what has always worked for me.

For you -2 works, measured where? What are your numbers, negative tail shaft degrees and pinion degrees. I mean is your pinion down 2 degrees from level/0, 2 degrees less than your tail shaft, I'm upside down right now, and probably asking this wrong?

My tail shaft is down 2.5 degrees, where should my pinion be up or down (from level) and how many degrees? At 75 I may be losing my mind...ha ha

#7

On The Tree

I understand the positive and negative angles bu not the math I'm seeing online. I believe the pinion angle is to be opposite the tail shaft angle and assume it's suppose to be positive in relation to the tail shaft.

For you -2 works, measured where? What are your numbers, negative tail shaft degrees and pinion degrees. I mean is your pinion down 2 degrees from level/0, 2 degrees less than your tail shaft, I'm upside down right now, and probably asking this wrong?

My tail shaft is down 2.5 degrees, where should my pinion be up or down (from level) and how many degrees? At 75 I may be losing my mind...ha ha

For you -2 works, measured where? What are your numbers, negative tail shaft degrees and pinion degrees. I mean is your pinion down 2 degrees from level/0, 2 degrees less than your tail shaft, I'm upside down right now, and probably asking this wrong?

My tail shaft is down 2.5 degrees, where should my pinion be up or down (from level) and how many degrees? At 75 I may be losing my mind...ha ha

I measure the first way, so I reach -2 by adding my driveshaft and pinion yoke together. Adjusting the torque arm moves the rear end, so assuming my DS is a static +1 I would adjust my rear end angle to -3. (+1) + (-3) = -2

At 75 years old I’d say you’re kicking *** and taking names!

Last edited by War Prayer; 02-25-2021 at 09:14 PM.

Trending Topics

#8

I get it now War, thanks for your patience. For some reason I didn't think the pinion could be at a down angle, but it makes sense figuring the rear end rolling up under load.

About the 75 thing, I only feel it getting up off the cold shop floor when a creeper won't fit under the car, ha ha. Thanks again. Larry

About the 75 thing, I only feel it getting up off the cold shop floor when a creeper won't fit under the car, ha ha. Thanks again. Larry

#9

TECH Junkie

iTrader: (4)

For years most drivelines (motor/trans) were mounted 3* down from the factory so most people would angle the pinion at 3*up that way both U-joints angles basically cancel each other out, The only time a person needs to worry about the driveshaft working angle is when you're dealing with a lifted truck where the driveshaft is at such an extreme angle that puts the u-joints are under quite a bit more stress.

Here is a simple way to understand why you need to have opposing angles match.

"Unfortunately, as the front U-joint gets the power delivered to the driveshaft, it transforms smooth engine power into pulsating power. This happens because the U-joint travels an elliptical path caused by the angle through which it operates. You can visualize this by looking at a dinner plate straight on. If you tilt it the round plate appears to become an ellipse. In traveling this ellipse, the U-joint speeds up and slows down twice per shaft revolution. A second U-joint having an equal but opposite angle is used to convert this pulsating power back into smooth power feeding the pinion. The bigger the working angles are, the more violent these speed changes become."

Here is a simple way to understand why you need to have opposing angles match.

"Unfortunately, as the front U-joint gets the power delivered to the driveshaft, it transforms smooth engine power into pulsating power. This happens because the U-joint travels an elliptical path caused by the angle through which it operates. You can visualize this by looking at a dinner plate straight on. If you tilt it the round plate appears to become an ellipse. In traveling this ellipse, the U-joint speeds up and slows down twice per shaft revolution. A second U-joint having an equal but opposite angle is used to convert this pulsating power back into smooth power feeding the pinion. The bigger the working angles are, the more violent these speed changes become."

#10

On The Tree

I get it now War, thanks for your patience. For some reason I didn't think the pinion could be at a down angle, but it makes sense figuring the rear end rolling up under load.

About the 75 thing, I only feel it getting up off the cold shop floor when a creeper won't fit under the car, ha ha. Thanks again. Larry

About the 75 thing, I only feel it getting up off the cold shop floor when a creeper won't fit under the car, ha ha. Thanks again. Larry

I can only hope to still be crawling under cars in another 40 years.

#11

For years most drivelines (motor/trans) were mounted 3* down from the factory so most people would angle the pinion at 3*up that way both U-joints angles basically cancel each other out, The only time a person needs to worry about the driveshaft working angle is when you're dealing with a lifted truck where the driveshaft is at such an extreme angle that puts the u-joints are under quite a bit more stress.

Here is a simple way to understand why you need to have opposing angles match.

"Unfortunately, as the front U-joint gets the power delivered to the driveshaft, it transforms smooth engine power into pulsating power. This happens because the U-joint travels an elliptical path caused by the angle through which it operates. You can visualize this by looking at a dinner plate straight on. If you tilt it the round plate appears to become an ellipse. In traveling this ellipse, the U-joint speeds up and slows down twice per shaft revolution. A second U-joint having an equal but opposite angle is used to convert this pulsating power back into smooth power feeding the pinion. The bigger the working angles are, the more violent these speed changes become."

Here is a simple way to understand why you need to have opposing angles match.

"Unfortunately, as the front U-joint gets the power delivered to the driveshaft, it transforms smooth engine power into pulsating power. This happens because the U-joint travels an elliptical path caused by the angle through which it operates. You can visualize this by looking at a dinner plate straight on. If you tilt it the round plate appears to become an ellipse. In traveling this ellipse, the U-joint speeds up and slows down twice per shaft revolution. A second U-joint having an equal but opposite angle is used to convert this pulsating power back into smooth power feeding the pinion. The bigger the working angles are, the more violent these speed changes become."

in my solid 4-link car. What War describes that works for him has both angles negative but using the DS angle vs. tail shaft, assuming under moderate load angles would change to opposing or at least zero. Just my thought.

Thanks for the reply

#12

On The Tree

Correct, I have never measured from the crank pulley, trans, etc. always used the DS vs torque arm bracket. Not necessarily because thatís right but because itís so much easier, haha.

I have also had my car professionally aligned by Vengeance (big name shop in Atlanta area) and they told me my pinion angle didnít need any changing so I guess it did it right.

I have also had my car professionally aligned by Vengeance (big name shop in Atlanta area) and they told me my pinion angle didnít need any changing so I guess it did it right.

The following users liked this post:

lwmulno1 (02-24-2021)

#13

I'll do the same this afternoon, I'll zero/level the pinion, measure my DS and do the math to get -2 deg, maybe just put -2 on the pinion and see where the DS is at. I'm in Wasilla, Alaska, we had a bunch of snow last night with 7 or 8 days more forecast, fortunately, (for me, my son and the neighbors I like, ha ha) I have a plow on my truck.

I'm about to wrap up the winter upgrades, 9" install, cage, scatter shield, etc, this pinion thing is the last, our race season doesn't start until Mothers Day. Input from you guys is great, thanks to all. Larry

I'm about to wrap up the winter upgrades, 9" install, cage, scatter shield, etc, this pinion thing is the last, our race season doesn't start until Mothers Day. Input from you guys is great, thanks to all. Larry

The following users liked this post:

War Prayer (02-25-2021)