Specialty LSx tools, DIY!

#21

In my pic you can see the angle-meter app opened up. For comparison of angles, is extremely accurate, down to one tenth of degree. I calibrate it on our Birmingham knee mill table and it repeats itself 100% of the time to within .1 degree! Excellent for setting/comparing trans output to diff input angles during engine conversions.  (I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).

(I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).

http://www.plaincode.com/products/clinometer/

(I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).

(I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).http://www.plaincode.com/products/clinometer/

#22

11 Second Club

iTrader: (19)

In my pic you can see the angle-meter app opened up. For comparison of angles, is extremely accurate, down to one tenth of degree. I calibrate it on our Birmingham knee mill table and it repeats itself 100% of the time to within .1 degree! Excellent for setting/comparing trans output to diff input angles during engine conversions.  (I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).

(I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).

http://www.plaincode.com/products/clinometer/

(I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).

(I use the iPhone more for its apps than for its losey phone, but thats a topic for another thread).http://www.plaincode.com/products/clinometer/

#23

LSx engine oil primer.

I realize that just cranking the engine over on the starter with the coils/injectors disabled is the norm and most have done so with no ill affects with that method, I just prefer to go that little extra pressurizing the oil system prior to spinning the crank on the starter.

Feeds 4 qts of fresh oil under pressure into the engine oil galley just above the oil filter, (also back feeds to the pump), with a piston using compressed air. Built in piston stop at the bottom protects the pistons seals, manual flow valve etc. Worked perfectly today.

Engine was LM7 short block that had been sitting for over 3 years, fresh top end. Removed valve covers to verify oil made it up and out the pushrods. Rest of the sump capacity poured in over the top of the rockers. Engine fired right up on first crank, no oiling issues.

End cap and pistons bits prior to assembly;

Engine Oil Primer with piston, manual flow valve, high pressure clear hose connected to LSx galley cover;

Disclaimer. If anyone attempts to duplicate, be sure to use a shut off valve and a clear tube capable of the pressure being applied. Air can and will still get past the piston due to the ABS/PVC not so smooth inner walls and if left unnoticed will push all the oil out of the galleys, bearings, etc leaving you worse off than before you started! Also, the piston is not necessary, but I built it that way as means to reduce the possibility of rapidly introducing air into the system once empty.

I realize that just cranking the engine over on the starter with the coils/injectors disabled is the norm and most have done so with no ill affects with that method, I just prefer to go that little extra pressurizing the oil system prior to spinning the crank on the starter.

Feeds 4 qts of fresh oil under pressure into the engine oil galley just above the oil filter, (also back feeds to the pump), with a piston using compressed air. Built in piston stop at the bottom protects the pistons seals, manual flow valve etc. Worked perfectly today.

Engine was LM7 short block that had been sitting for over 3 years, fresh top end. Removed valve covers to verify oil made it up and out the pushrods. Rest of the sump capacity poured in over the top of the rockers. Engine fired right up on first crank, no oiling issues.

End cap and pistons bits prior to assembly;

Engine Oil Primer with piston, manual flow valve, high pressure clear hose connected to LSx galley cover;

Disclaimer. If anyone attempts to duplicate, be sure to use a shut off valve and a clear tube capable of the pressure being applied. Air can and will still get past the piston due to the ABS/PVC not so smooth inner walls and if left unnoticed will push all the oil out of the galleys, bearings, etc leaving you worse off than before you started! Also, the piston is not necessary, but I built it that way as means to reduce the possibility of rapidly introducing air into the system once empty.

#24

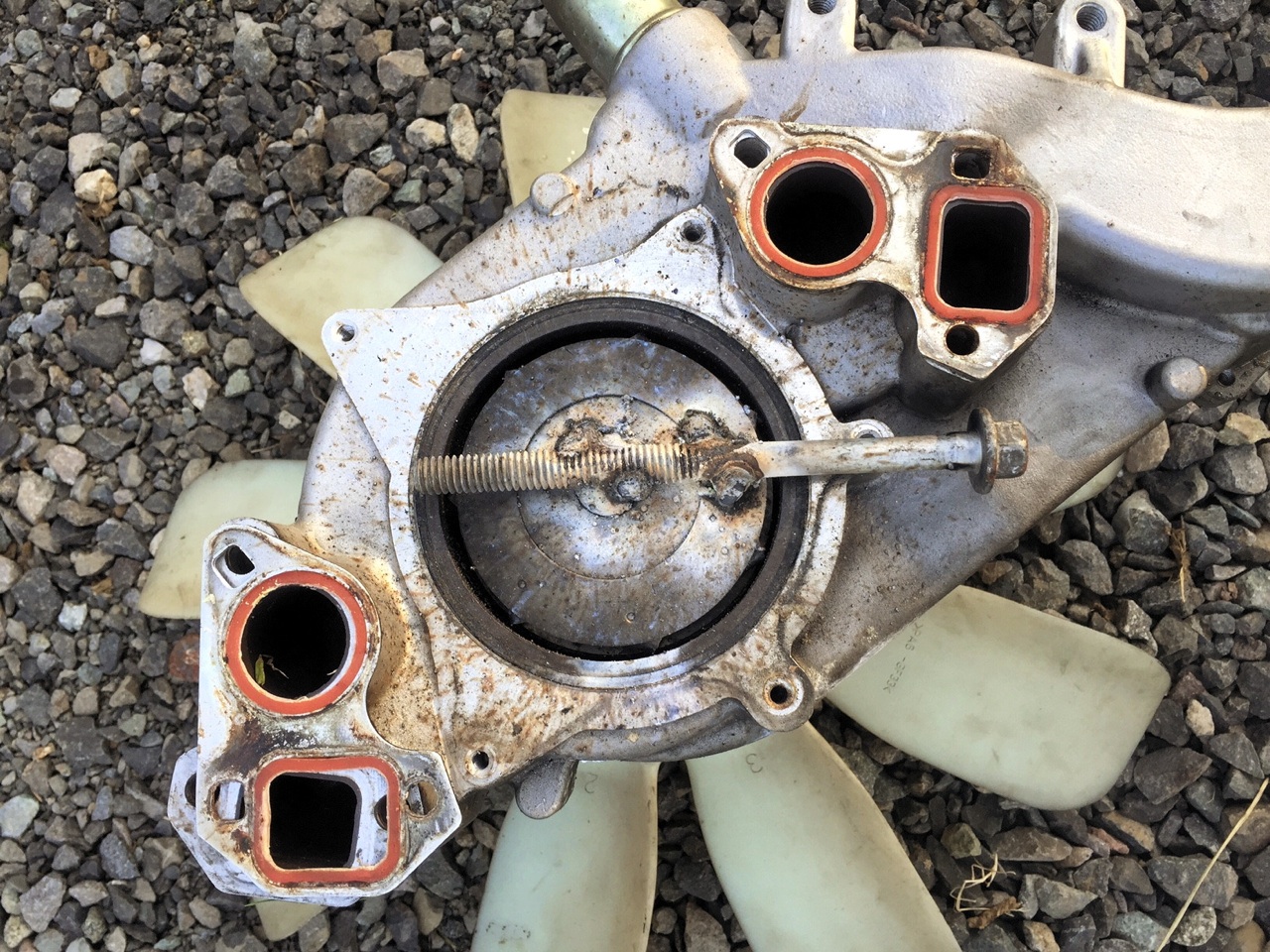

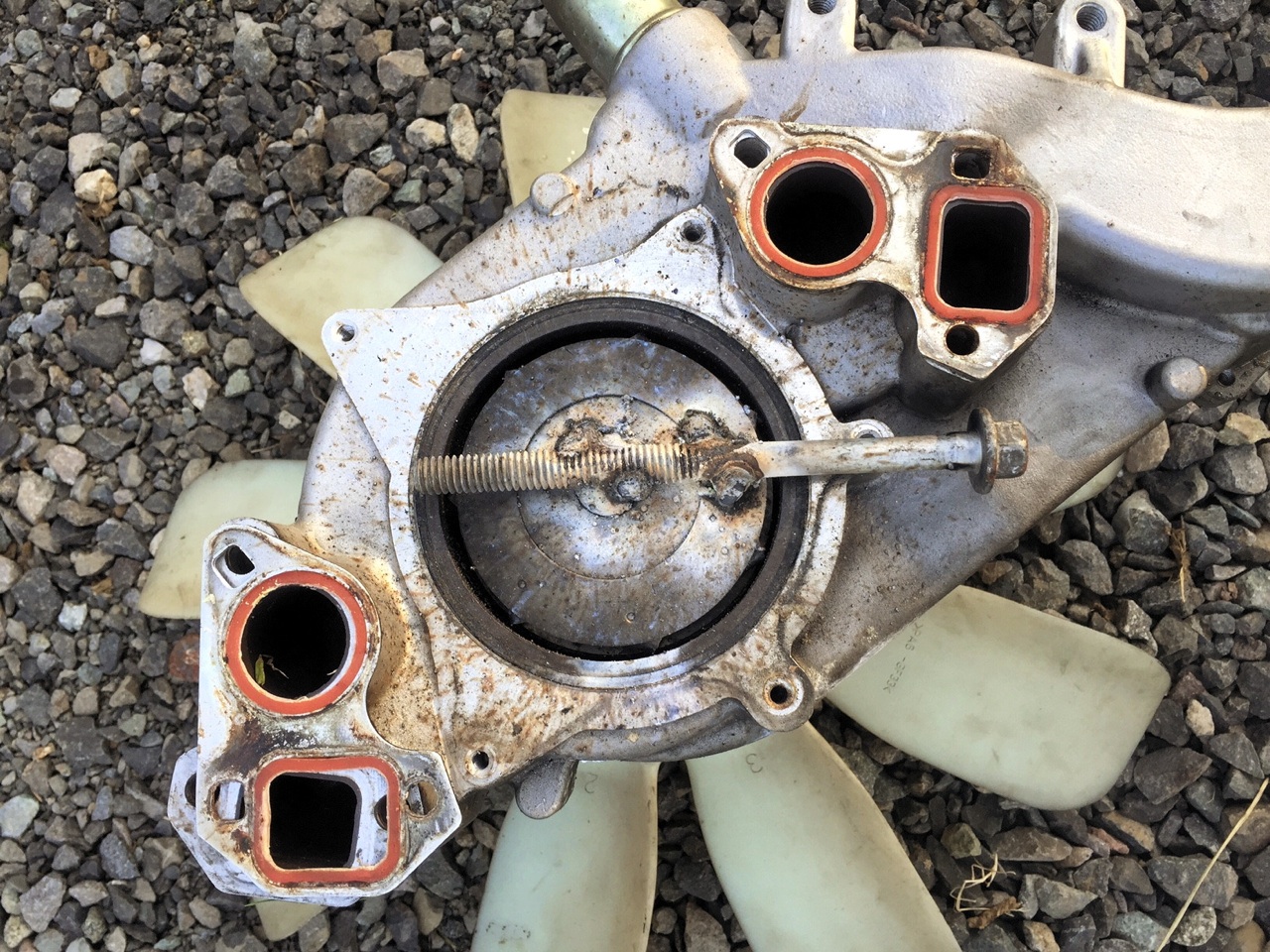

Another tool, this is one-time use only, applies to removing mechanical clutch from a dead Gen III truck water pumps for those still using the mechanical/clutch fan on the water pump.

Need to get that fan off the old dead water pump? Don't have a the Spanner wrench or your strap wrench wont grip tight enough, or wedging piece of wood between the fan belt and a pulley not working to break the fan loose from the water pump?

Remove the pump withe fan attached, unbolt/pry off the back cover of the WP, find an old LSx head bolt or other 9"+ long scrap steel item , weld the bolt to the pump shaft so that as the shaft spins the bolt will catch on the pump legs holding the pump shaft while you break the fan free from the pulley.

Need to get that fan off the old dead water pump? Don't have a the Spanner wrench or your strap wrench wont grip tight enough, or wedging piece of wood between the fan belt and a pulley not working to break the fan loose from the water pump?

Remove the pump withe fan attached, unbolt/pry off the back cover of the WP, find an old LSx head bolt or other 9"+ long scrap steel item , weld the bolt to the pump shaft so that as the shaft spins the bolt will catch on the pump legs holding the pump shaft while you break the fan free from the pulley.