Camaro and Firebird: Rattle Noise When Accelerating

The powerplants found in the fourth generation F-body cars, as well as the C5 Corvette, are inherently noisy. If you are noticing a rattling or ticking noise, especially under acceleration, it is a good idea to inspect your car for potential issues.

This article applies to the Chevrolet Camaro, Pontiac Firebird (1993-2002), as well as Chevrolet Corvette (1997-2004).

Noises that clatter and rattle from the engine bay are enough to worry any driver. More often than not, Camaro, Firebird, and Corvette owners will experience certain noises during normal driving or under acceleration that would lead them to believe their car is falling apart. Fortunately, much of the racket produced is considered to be normal inherent traits of the engines fitted in these cars. With a bit of probing, owners are often able to easily pinpoint the source of a noise and fix it, if necessary. With such a large following, common noises have been well documented for the F-body and Corvette platforms. This article will outline some of those usual noises that Camaro, Firebird and Corvette owners experience and the best course of action to take if there is a problem.

Materials Needed

- Mechanic's stethoscope

- Floor jack and jack stands

Step 1 – Check for loose components

The first step in diagnosing a rattling noise is to inspect underhood components to ensure they are securely fastened in place. Most individuals assume the worst case scenario when a rattling noise develops; however, a loose bracket or bolt can make some serious racket caused by the harmonics of the engine/exhaust. If a visual inspection does not turn up any results, have a friend work the throttle with the car in park to achieve the engine rpm at which the rattle occurs while you listen under the hood. Be sure to thoroughly inspect around the firewall area, as any rattling or vibrating components will be directly transferred into the cab. A mechanic's stethoscope can come in handy when searching for rattles, ticks, and vibration noises.

Step 2 – Check for exhaust leaks

A common problem that many F-body cars and Corvettes experience is an exhaust leak. Exhaust leaks tend to develop around the exhaust manifold (header) to cylinder head flanges or at the mid-pipe connections. An exhaust leak will be most noticeable when the engine is under load and accelerating, and will create a sharp ticking noise. Minor exhaust leaks may only be present when the engine is cold and will disappear as components heat up and expand. On the other hand, a severe leak will be present at all times. Inspecting for exhaust leaks is best completed by starting a cold engine and using a mechanic's stethoscope or small length of hose to probe various joints of the exhaust. Leaks are quite apparent by simply listening for them, but can sometimes be visually spotted by looking for soot buildup. Year models equipped with OBD-II diagnostics systems will often trip the check engine light if the exhaust leak is upstream of the oxygen sensors, so scan for any trouble codes to see if they are related to the exhaust system.

Pro Tip

If exhaust leaks are found and gaskets need to be replaced, it is best to use the high quality factory multi-layer steel gaskets to prevent future leaks.

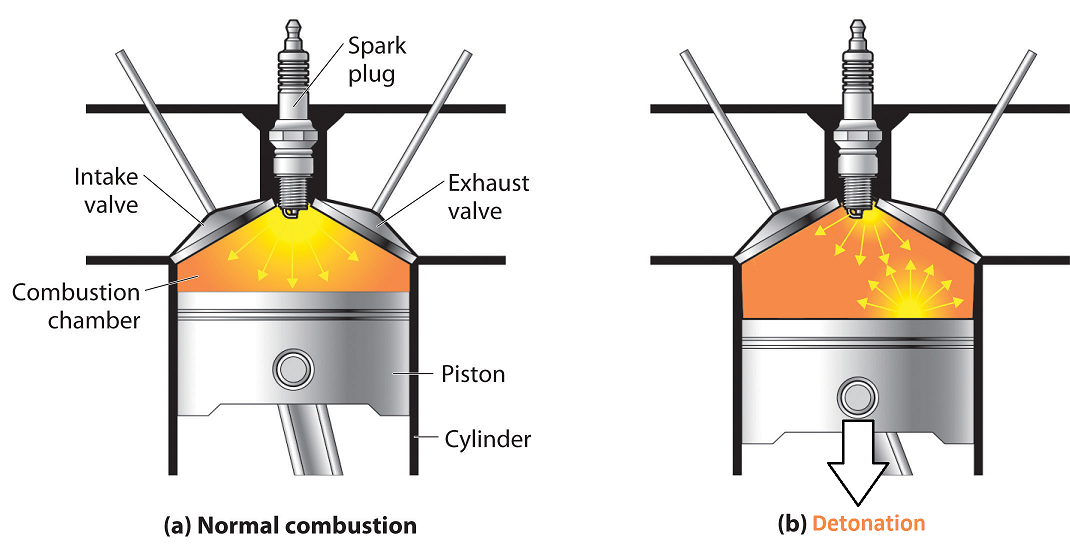

Step 3 – Check for detonation (knock)

Octane ratings in today's fuels is crucial in preventing engine knock, also known as detonation. In basic terms, detonation takes place when an uncontrolled explosion occurs in the combustion chamber(s) and creates a flame from opposite the spark plug. These opposing pressures typically produce a rattling or ticking sound under acceleration. Using a poor quality gasoline or a lower octane rating than required by the engine equipped in your car can cause regular detonation to occur. If using 87 octane fuel, try switching to a higher octane level from a quality fuel supplier and monitor the performance of the car. If the problem persists, the knock sensors, which help to monitor for detonation and allow for ignition timing adjustments, may be faulty and require replacement. It is well known that various GM vehicles produced during the 90's and early 2000's suffer from knock sensor problems that cause a loss of performance and subsequent rattling under acceleration. For additional information on knock sensor replacement, see How to Replace Knock Sensors.

Step 4 – Check for piston slap

The LS1 engine is notoriously noisy from piston slap with four out of five cars typically experiencing this issue. Piston slap occurs from excessive piston to cylinder wall clearance and allows the piston to rock back and forth in the bore. While this is normally associated with high mileage engines that have excessive wear, LS series engines have fairly loose tolerances from the factory to allow for thermal expansion of the pistons once the engine has warmed up. Generally, piston slap should only occur when the engine is cold and subside once operating temperatures have been reached, so it is a good idea to drive your car at a modest pace until fully warmed up. Many have had their engines rebuilt to eliminate this issue, but the problem always seems to persist. If your oil/oil filter is free of debris and you only experience this noise with the engine is cold, there is no need for concern, as cars experiencing piston slap since new have lasted well over 250,000 miles.

Step 5 – Check for lifter tick

A number of owners have experienced valvetrain noises, most notably lifter ticking. Generally, most explain this noise as sounding much like a "sewing machine" under acceleration. There have been numerous discussion about lifter pre-load settings and valve adjustments pertaining to lifter noises as well as collapsed lifters being the noisy culprits, but many have solved the issue by replacing the oil pick-up tube O-ring. GM released a technical service bulletin and subsequently a redesigned O-ring for the oil pick-up tube to prevent aeration of the oil. Apparently, the old design would not seal properly and allowed small amounts of air to be sucked in, thus allowing the oil to foam and the lifters to partially collapse under load. The result is excessive valve lash and a ticking or clattering valvetrain.

Related Discussions

- LS1 Lifter Noise - LS1Tech.com

- Engine Rattle and Clack - LS1Tech.com

- LS1 Piston Slap Issues - LS1Tech.com