Horsepower vs Torque.. My Theory

#21

TECH Senior Member

just a little trivia.the mid 50's buick century was pretty peppy for a large ,heavy car to the extent that they were used as police pursuit vehicles.this was with an automatic transmission that was not too kindly called the dynaslush.actually,the dynaflow was a really hi-tech piece.it had drive and low for forward gears.in drive,it did notstart out in low and then shift to high.it remained in high the whole time.so how did the buick engineers quickly accelerate a heavy car without using low gear ? the dynaflow was essentially continuously variable transmission via a variable pitch torque converter.now,the point of all this is that the buick engineers tuned the converter to keep the engine rpm at peak horsepower--not peak torque,while the vehicle accelerated.you stepped on the gas pedal and the revs shot up to a little over 4000 and stayed there while the torque converter continuously changed ratios (stall speeds ).

Its already been established, in a given gear you're car's acceleration follows the torque curve exactly. You pull hardest in that gear at torque peak. So why change at peak hp, or in the CVT's case, stay at peak hp? Because you want to run that gear (or ratio in the CVT's case) out as long as you can because after you change you are not going to accelerate as hard in the next gear (or ratio). Switching at (or staying at) peak torque will have you changing gears or ratios too soon and not utilize that gear ratio to its fullest.

#22

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Modern day CVT's do this, I don't think you are going to be blowing any minds here.

Its already been established, in a given gear you're car's acceleration follows the torque curve exactly. You pull hardest in that gear at torque peak. So why change at peak hp, or in the CVT's case, stay at peak hp? Because you want to run that gear (or ratio in the CVT's case) out as long as you can because after you change you are not going to accelerate as hard in the next gear (or ratio). Switching at (or staying at) peak torque will have you changing gears or ratios too soon and not utilize that gear ratio to its fullest.

Its already been established, in a given gear you're car's acceleration follows the torque curve exactly. You pull hardest in that gear at torque peak. So why change at peak hp, or in the CVT's case, stay at peak hp? Because you want to run that gear (or ratio in the CVT's case) out as long as you can because after you change you are not going to accelerate as hard in the next gear (or ratio). Switching at (or staying at) peak torque will have you changing gears or ratios too soon and not utilize that gear ratio to its fullest.

#23

Horsepower is a magnitude, torque the cross product of the connecting rod length and rotational combustion force. Horsepower is a number of efficiency in total energy that can be dissipated at a certain point. Torque is a vector that has magnitude and direction which is measured as the greatest difference of angular velocity possible over a given RPM band.

That is why torque is what eats transmissions and rear gears and is what you want to move down the track as fast as possible. The greater the delta in torque the quicker you can accelerate a given mass down the track. The horsepower of a vehicle involves the efficiency to get there and the total power a combination is capable of making which is how fast you're making that torque and where in the RPM band you're going to be doing it best.

#24

Banned

Join Date: Mar 2013

Location: Studewood/Acres-Homes TX.

Posts: 1,137

Likes: 0

Received 2 Likes

on

2 Posts

Try this for kicks. The next time you’re surrounded by your gearhead buddies, ask them to explain the difference between horsepower and torque. The participants will immediately divide into “pro torque” and “pro horsepower” camps, and at the end of two hours—or two years—worth of arguing, all you’ll have to show for it are a bunch of lame clichés.

Raging debates and a healthy discourse of divergent opinions is part of what makes building hot rods so much fun, but the key issue at hand here is the lack of knowledge or history per se. Few people seem to truly understand the difference between the two units of measurement, and those who do can be hard pressed to explain it in a way that most people can understand. Fortunately, we know some really smart dudes who have both the knowledge and ability to lay it all out in a palatable fashion. Our cast includes Jon Kaase of Jon Kaase Racing Engines, Judson Massingill of the School of Automotive Machinists, Scott Shafiroff of Shafiroff Racing Engines, and Harold Bettes of Power Technology Consultants. Depending on your preconceived biases, the truth might be difficult to accept, but the experts have spoken once and for all.

Horsepower Defined

Harold Bettes: An engine produces a twisting force at the flywheel, typically measured in lb-ft of torque. One lb-ft of torque is equivalent to the force of a 1-pound weight pulling down on a 1-foot-long lever. Horsepower, by definition, is torque times rpm divided by 5,252. In a running engine, you can’t have torque without horsepower and horsepower without torque because they’re interrelated. The horsepower formula was invented by Scottish engineer James Watt in the late 18th century to help him market his newly invented steam engine. Since his new invention was competing with horses, he had to come up with a way to relate the output of his steam engine to horses. The problem was that his engine produced a twisting force, or torque, while horses performed work. In other words, horses performed work and therefore made power, not torque. If he told potential buyers that his steam engine made more torque than their horses, no one would have known what he was talking about. Watt determined that the typical horse could pull 33,000 pounds of weight 1 foot in one minute, and he had to figure out a way to relate the rotary motion of his steam engine to the linear motion performed by horses. To do this, he divided 33,000 by 6.28, since the circular distance a 1-foot lever travels in one revolution of a crankshaft is equal to 2 pi. By dividing 33,000 by 6.28, Watt came up with the constant of 5,252 that’s now used universally in the horsepower formula. Consequently, an engine that’s producing 33,000 lb-ft of torque per minute—or 550 lb-ft of torque per second—is producing 1 hp, and the constant 5,252 is used to convert the rotational motion of a crankshaft into linear motion.

Force vs. Work

Judson Massingill: There is a distinct difference between force and work. You can push against a wall with incredible force, but if the wall doesn’t move then you haven’t performed any work. You may have worn yourself out, but you still haven’t performed any work. The same applies to an engine. Torque is just a force, and horsepower is a unit of work that measures the rate at which torque is applied. That means that an engine that produces half as much torque as another engine needs to turn twice as many rpm to produce the same amount of horsepower. For instance, let’s say I need a ditch dug on both sides of my desk. On one side I have Arnold Schwarzenegger with a big shovel, and on the other side I have a skinny guy with a small shovel. If Schwarzenegger throws out 3 cubic feet of dirt with each scoop, and the skinny guy takes out 11/2 cubic feet of dirt with each scoop but works twice as fast, they’ll both dig a ditch the same depth in the same amount of time. Therefore, they’ve accomplished the same amount of work.

This example shows why you can have a big engine that makes much more torque than a smaller engine, but doesn’t produce any more horsepower. Torque is important, but it’s not nearly as important as the rpm at which that torque is produced. To illustrate the point, let’s compare a ’70 Buick 455 to a ’70 LS6 big-block Chevy. The Buick made 510 lb-ft of torque compared to the Chevy’s 500 lb-ft. If you thought that the Buick could outrun the Chevy because it made more torque, you were living in a dream world. Since the Chevy made peak torque at 3,600 rpm instead of 2,800 rpm, it made 450 hp compared to the Buick’s 350 hp. Torque is directly related to displacement, and in the last 40 years, torque output per cubic inch has only gone up 10 percent at most. On the other hand, horsepower per cubic inch has gone up dramatically, nearly 30 percent, in that time. That’s because today’s engines aren’t producing that much more torque, but they’re maintaining that torque at a much higher rpm before it drops off.

Torque Rules

Jon Kaase: Horsepower is just a figure that’s calculated from math. When you put the gas pedal to the floorboard, torque is what you feel. In a street car, you want lots of torque. Let’s say you have a small-block V-8 that makes 250 hp at 5,500 rpm and a small Japanese V-6 that makes 250 hp at 7,000 rpm. If you drove both of them back to back, there would be no comparison on how much faster the V-8 would feel because the smaller motor makes far less torque. Having too much torque is like having too much money. You don’t want any less of it. You just have to learn how to manage your account better. If you’re making so much torque that your car is blowing off the tires, either get some bigger tires or manage the power more efficiently with better electronics.

Horsepower is King

Judson Massingill: The 433ci LS small-block in our ’99 Camaro drag car makes 1,050 hp naturally aspirated, and has an 8,000- to 9,600-rpm powerband. We don’t even know what the peak torque output is because the motor never turns that low rpm. The reason I quit paying attention to peak torque in race motors is because the vast majority of them operate at rpm that are above peak torque the entire run, whether it’s in NHRA Pro Stock or circle track. If peak torque was more important than peak power, we’d be better off putting our turbo diesel in our race car instead of in our tow rig since it makes more torque than our race engine. If torque is all that matters, why not put some taller gears in our Camaro so the rpm drops down to 7,000 rpm between shifts instead of 8,000? Our 433 small-block might make more torque at 7,000 rpm than at 8,000, but it makes far less power at 7,000 so the car would fall on its face and slow way down. Gearing multiplies torque, and turning more rpm enables you to run shorter gears. In many road racing and circle track applications, a high-rpm motor with lots of gear will make more torque at the rear wheels than a low-rpm motor with less gear since they’ll be turning more rpm and getting more torque multiplication coming off of a corner.

From our racing experience, it’s our opinion that the minimum rpm at which you can go wide-open throttle without breaking the tires loose is the most important part of the power curve. With our Camaro, that point happens to be right around 8,000 rpm. In some respects, the horsepower it makes at 8,000 rpm is more important than peak horsepower. That’s because if the engine speed drops down to 8,000 between shifts, the motor better have some beans at that rpm to keep the car moving down the track. At the end of the day, I am a “bottom end” kind of guy. I just refer to it as horsepower instead of torque.

Harold Bettes: For people who say that they would rather have torque than horsepower, you have to think about where in the rpm range that torque is produced. Torque multiplication with the transmission in Reverse is greater than in any of the forward gears. If that’s the case, a car will produce the most torque at the rear wheels while in Reverse, so shouldn’t you just leave it in Reverse and mash the gas? Of course not. Likewise, if you prefer torque over horsepower, maybe you should try leaving a car in First gear all the way down the dragstrip. Let’s say you have a motor that makes 400 lb-ft of torque that’s matched with a 2.50:1 First gear ratio and 4.00:1 ring-and-pinion set. That equates to 4,000 lb-ft of torque that’s being applied to the axles at the engine’s torque peak. However, since the transmission gear ratios get taller with every upshift that means the torque applied to the axles drops significantly in each successive gear. Obviously, if you leave the car in First gear just to maximize the torque that’s applied to the axles and wheels, you’re not going to go very fast. This example clearly illustrates that it’s not torque that pushes a vehicle down the road, but rather horsepower.

Raging debates and a healthy discourse of divergent opinions is part of what makes building hot rods so much fun, but the key issue at hand here is the lack of knowledge or history per se. Few people seem to truly understand the difference between the two units of measurement, and those who do can be hard pressed to explain it in a way that most people can understand. Fortunately, we know some really smart dudes who have both the knowledge and ability to lay it all out in a palatable fashion. Our cast includes Jon Kaase of Jon Kaase Racing Engines, Judson Massingill of the School of Automotive Machinists, Scott Shafiroff of Shafiroff Racing Engines, and Harold Bettes of Power Technology Consultants. Depending on your preconceived biases, the truth might be difficult to accept, but the experts have spoken once and for all.

Horsepower Defined

Harold Bettes: An engine produces a twisting force at the flywheel, typically measured in lb-ft of torque. One lb-ft of torque is equivalent to the force of a 1-pound weight pulling down on a 1-foot-long lever. Horsepower, by definition, is torque times rpm divided by 5,252. In a running engine, you can’t have torque without horsepower and horsepower without torque because they’re interrelated. The horsepower formula was invented by Scottish engineer James Watt in the late 18th century to help him market his newly invented steam engine. Since his new invention was competing with horses, he had to come up with a way to relate the output of his steam engine to horses. The problem was that his engine produced a twisting force, or torque, while horses performed work. In other words, horses performed work and therefore made power, not torque. If he told potential buyers that his steam engine made more torque than their horses, no one would have known what he was talking about. Watt determined that the typical horse could pull 33,000 pounds of weight 1 foot in one minute, and he had to figure out a way to relate the rotary motion of his steam engine to the linear motion performed by horses. To do this, he divided 33,000 by 6.28, since the circular distance a 1-foot lever travels in one revolution of a crankshaft is equal to 2 pi. By dividing 33,000 by 6.28, Watt came up with the constant of 5,252 that’s now used universally in the horsepower formula. Consequently, an engine that’s producing 33,000 lb-ft of torque per minute—or 550 lb-ft of torque per second—is producing 1 hp, and the constant 5,252 is used to convert the rotational motion of a crankshaft into linear motion.

Force vs. Work

Judson Massingill: There is a distinct difference between force and work. You can push against a wall with incredible force, but if the wall doesn’t move then you haven’t performed any work. You may have worn yourself out, but you still haven’t performed any work. The same applies to an engine. Torque is just a force, and horsepower is a unit of work that measures the rate at which torque is applied. That means that an engine that produces half as much torque as another engine needs to turn twice as many rpm to produce the same amount of horsepower. For instance, let’s say I need a ditch dug on both sides of my desk. On one side I have Arnold Schwarzenegger with a big shovel, and on the other side I have a skinny guy with a small shovel. If Schwarzenegger throws out 3 cubic feet of dirt with each scoop, and the skinny guy takes out 11/2 cubic feet of dirt with each scoop but works twice as fast, they’ll both dig a ditch the same depth in the same amount of time. Therefore, they’ve accomplished the same amount of work.

This example shows why you can have a big engine that makes much more torque than a smaller engine, but doesn’t produce any more horsepower. Torque is important, but it’s not nearly as important as the rpm at which that torque is produced. To illustrate the point, let’s compare a ’70 Buick 455 to a ’70 LS6 big-block Chevy. The Buick made 510 lb-ft of torque compared to the Chevy’s 500 lb-ft. If you thought that the Buick could outrun the Chevy because it made more torque, you were living in a dream world. Since the Chevy made peak torque at 3,600 rpm instead of 2,800 rpm, it made 450 hp compared to the Buick’s 350 hp. Torque is directly related to displacement, and in the last 40 years, torque output per cubic inch has only gone up 10 percent at most. On the other hand, horsepower per cubic inch has gone up dramatically, nearly 30 percent, in that time. That’s because today’s engines aren’t producing that much more torque, but they’re maintaining that torque at a much higher rpm before it drops off.

Torque Rules

Jon Kaase: Horsepower is just a figure that’s calculated from math. When you put the gas pedal to the floorboard, torque is what you feel. In a street car, you want lots of torque. Let’s say you have a small-block V-8 that makes 250 hp at 5,500 rpm and a small Japanese V-6 that makes 250 hp at 7,000 rpm. If you drove both of them back to back, there would be no comparison on how much faster the V-8 would feel because the smaller motor makes far less torque. Having too much torque is like having too much money. You don’t want any less of it. You just have to learn how to manage your account better. If you’re making so much torque that your car is blowing off the tires, either get some bigger tires or manage the power more efficiently with better electronics.

Horsepower is King

Judson Massingill: The 433ci LS small-block in our ’99 Camaro drag car makes 1,050 hp naturally aspirated, and has an 8,000- to 9,600-rpm powerband. We don’t even know what the peak torque output is because the motor never turns that low rpm. The reason I quit paying attention to peak torque in race motors is because the vast majority of them operate at rpm that are above peak torque the entire run, whether it’s in NHRA Pro Stock or circle track. If peak torque was more important than peak power, we’d be better off putting our turbo diesel in our race car instead of in our tow rig since it makes more torque than our race engine. If torque is all that matters, why not put some taller gears in our Camaro so the rpm drops down to 7,000 rpm between shifts instead of 8,000? Our 433 small-block might make more torque at 7,000 rpm than at 8,000, but it makes far less power at 7,000 so the car would fall on its face and slow way down. Gearing multiplies torque, and turning more rpm enables you to run shorter gears. In many road racing and circle track applications, a high-rpm motor with lots of gear will make more torque at the rear wheels than a low-rpm motor with less gear since they’ll be turning more rpm and getting more torque multiplication coming off of a corner.

From our racing experience, it’s our opinion that the minimum rpm at which you can go wide-open throttle without breaking the tires loose is the most important part of the power curve. With our Camaro, that point happens to be right around 8,000 rpm. In some respects, the horsepower it makes at 8,000 rpm is more important than peak horsepower. That’s because if the engine speed drops down to 8,000 between shifts, the motor better have some beans at that rpm to keep the car moving down the track. At the end of the day, I am a “bottom end” kind of guy. I just refer to it as horsepower instead of torque.

Harold Bettes: For people who say that they would rather have torque than horsepower, you have to think about where in the rpm range that torque is produced. Torque multiplication with the transmission in Reverse is greater than in any of the forward gears. If that’s the case, a car will produce the most torque at the rear wheels while in Reverse, so shouldn’t you just leave it in Reverse and mash the gas? Of course not. Likewise, if you prefer torque over horsepower, maybe you should try leaving a car in First gear all the way down the dragstrip. Let’s say you have a motor that makes 400 lb-ft of torque that’s matched with a 2.50:1 First gear ratio and 4.00:1 ring-and-pinion set. That equates to 4,000 lb-ft of torque that’s being applied to the axles at the engine’s torque peak. However, since the transmission gear ratios get taller with every upshift that means the torque applied to the axles drops significantly in each successive gear. Obviously, if you leave the car in First gear just to maximize the torque that’s applied to the axles and wheels, you’re not going to go very fast. This example clearly illustrates that it’s not torque that pushes a vehicle down the road, but rather horsepower.

#25

Banned

Join Date: Mar 2013

Location: Studewood/Acres-Homes TX.

Posts: 1,137

Likes: 0

Received 2 Likes

on

2 Posts

RPM = Power

Judson Massingill: In the racing world, the motor that makes the most explosions going down the track is going to win the race. In other words, the motor than turns the most rpm is probably going to win. Again, that’s because torque per cubic inch is difficult to increase, so the next option is turning more rpm. Not surprisingly, unless the rule book restricts it, engines in every form of racing turn more rpm every year. With today’s cylinder head technology, torque curves stay flat even at high rpm so turning more rpm is the key to making power. In most race engines, horsepower will continue climbing even after peak torque, and as long as rpm increases faster than the rate at which torque drops off after its peak, horsepower will continue to increase. An extreme example is Formula 1. Since the rules limit displacement to 2.4 liters, the motors barely make more than 200 lb-ft. By revving them up to 18,000 rpm, however, they make an incredible 800 hp.

Jon Kaase: Horsepower is torque multiplied by rpm, so if you have a drag car with flat torque curve, the horsepower will keep climbing for a while because of the way the math works out. In other words, if an engine produces lots of torque at high rpm, it will make a ton of power. A Pro Stock motor makes about 1.7 lb-ft per cubic inch, while a very healthy street engine can make as much as 1.5 lb-ft per cubic inch. The big difference is that a race engine will continue to maintain high torque output even after its torque peak. All they’re doing in a Pro Stock engine is raising the rpm where torque is made, and they don’t make that much more peak torque than they did six to eight years ago. Most engines will usually turn a couple thousand rpm past their torque peaks. If horsepower drops off any quicker than that, it usually indicates a problem with the motor. Either the heads, camshaft, intake manifold, carb, or headers are too small, or it’s running out of valvetrain. Scott Shafiroff: In racing, rpm is critical. If you think about it, the greater the number of explosions per second an engine produces, the better it will accelerate a car down the track. In race cars, you look at the horsepower an engine makes and the rpm it turns, and gear it accordingly. You never want a motor to be below peak torque, which requires keeping the rpm up. On each gear change, you want the rpm to drop down to the torque peak and then accelerate beyond power peak. Engine design is about making compromises. You don’t want to trade a lot of torque for only 2 hp, but you do need to sacrifice some torque in order to make horsepower up top.

Area Under the Curve

Harold Bettes: People like to argue over torque and horsepower, but in the process they often overlook the area under the curve. That refers to the average horsepower an engine produces throughout its operating range. Let’s say one engine produces a power curve that looks like a church steeple, while another engine has a power curve shaped like the top of a balloon. Even if both engines produce the same peak power, the engine with the broader curve will be both more fun to drive and substantially faster at the track. That’s because when you shift gears, the engine with the balloon-shaped torque curve will be making more horsepower. For this reason, the area under the curve, or average horsepower, is a much more effective way of gauging how well an engine will perform than peak torque or horsepower.

Scott Shafiroff: People want to see a big peak horsepower number, but average horsepower is much more important. It’s not just the peak number that counts, but rather the horsepower that’s produced over an engine’s rpm range. Some people think that building street motors is easier than building race motors, but that’s not always the case. In some ways it’s harder to build a street motor since they have to operate in a broad rpm range. Whether it’s a street motor or a race motor, the goal is to maximize the average horsepower output.

Low End vs. Top End

Judson Massingill: In America, we tend to look at low-rpm engine output in units of torque and high-rpm output in units of horsepower. However, the truth of the matter is that you can’t separate the two since horsepower is a derivative of torque that’s mathematically calculated from torque and rpm. People are familiar with the formula horsepower equals torque times rpm divided by 5,252. So if you have more torque at, say, 5,000 rpm, than the guy in the other lane, you’ll have more horsepower as well. Likewise, if an engine is producing lots of torque at 3,000 rpm, it’s also producing lots of horsepower at 3,000 rpm. Another way to look at it is that if you’re building an engine to maximize torque output at low rpm, you’re also building an engine that makes lots of horsepower at low rpm. People tend to get very passionate about the horsepower versus torque topic, and some people are torque guys while others are horsepower guys. I’ve been at engine conferences where people got so riled up about this debate that they had to be escorted out of the room by security. The funny thing is that they’re arguing about the same thing.

Judson Massingill: In the racing world, the motor that makes the most explosions going down the track is going to win the race. In other words, the motor than turns the most rpm is probably going to win. Again, that’s because torque per cubic inch is difficult to increase, so the next option is turning more rpm. Not surprisingly, unless the rule book restricts it, engines in every form of racing turn more rpm every year. With today’s cylinder head technology, torque curves stay flat even at high rpm so turning more rpm is the key to making power. In most race engines, horsepower will continue climbing even after peak torque, and as long as rpm increases faster than the rate at which torque drops off after its peak, horsepower will continue to increase. An extreme example is Formula 1. Since the rules limit displacement to 2.4 liters, the motors barely make more than 200 lb-ft. By revving them up to 18,000 rpm, however, they make an incredible 800 hp.

Jon Kaase: Horsepower is torque multiplied by rpm, so if you have a drag car with flat torque curve, the horsepower will keep climbing for a while because of the way the math works out. In other words, if an engine produces lots of torque at high rpm, it will make a ton of power. A Pro Stock motor makes about 1.7 lb-ft per cubic inch, while a very healthy street engine can make as much as 1.5 lb-ft per cubic inch. The big difference is that a race engine will continue to maintain high torque output even after its torque peak. All they’re doing in a Pro Stock engine is raising the rpm where torque is made, and they don’t make that much more peak torque than they did six to eight years ago. Most engines will usually turn a couple thousand rpm past their torque peaks. If horsepower drops off any quicker than that, it usually indicates a problem with the motor. Either the heads, camshaft, intake manifold, carb, or headers are too small, or it’s running out of valvetrain. Scott Shafiroff: In racing, rpm is critical. If you think about it, the greater the number of explosions per second an engine produces, the better it will accelerate a car down the track. In race cars, you look at the horsepower an engine makes and the rpm it turns, and gear it accordingly. You never want a motor to be below peak torque, which requires keeping the rpm up. On each gear change, you want the rpm to drop down to the torque peak and then accelerate beyond power peak. Engine design is about making compromises. You don’t want to trade a lot of torque for only 2 hp, but you do need to sacrifice some torque in order to make horsepower up top.

Area Under the Curve

Harold Bettes: People like to argue over torque and horsepower, but in the process they often overlook the area under the curve. That refers to the average horsepower an engine produces throughout its operating range. Let’s say one engine produces a power curve that looks like a church steeple, while another engine has a power curve shaped like the top of a balloon. Even if both engines produce the same peak power, the engine with the broader curve will be both more fun to drive and substantially faster at the track. That’s because when you shift gears, the engine with the balloon-shaped torque curve will be making more horsepower. For this reason, the area under the curve, or average horsepower, is a much more effective way of gauging how well an engine will perform than peak torque or horsepower.

Scott Shafiroff: People want to see a big peak horsepower number, but average horsepower is much more important. It’s not just the peak number that counts, but rather the horsepower that’s produced over an engine’s rpm range. Some people think that building street motors is easier than building race motors, but that’s not always the case. In some ways it’s harder to build a street motor since they have to operate in a broad rpm range. Whether it’s a street motor or a race motor, the goal is to maximize the average horsepower output.

Low End vs. Top End

Judson Massingill: In America, we tend to look at low-rpm engine output in units of torque and high-rpm output in units of horsepower. However, the truth of the matter is that you can’t separate the two since horsepower is a derivative of torque that’s mathematically calculated from torque and rpm. People are familiar with the formula horsepower equals torque times rpm divided by 5,252. So if you have more torque at, say, 5,000 rpm, than the guy in the other lane, you’ll have more horsepower as well. Likewise, if an engine is producing lots of torque at 3,000 rpm, it’s also producing lots of horsepower at 3,000 rpm. Another way to look at it is that if you’re building an engine to maximize torque output at low rpm, you’re also building an engine that makes lots of horsepower at low rpm. People tend to get very passionate about the horsepower versus torque topic, and some people are torque guys while others are horsepower guys. I’ve been at engine conferences where people got so riled up about this debate that they had to be escorted out of the room by security. The funny thing is that they’re arguing about the same thing.

#26

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

You always have a torque curve during acceleration. Torque is the angular equivalent to a vector force and involves any change in speed. If you're changing speeds laterally there is a torque involved which increases linear speed.

Horsepower is a magnitude, torque the cross product of the connecting rod length and rotational combustion force. Horsepower is a number of efficiency in total energy that can be dissipated at a certain point. Torque is a vector that has magnitude and direction which is measured as the greatest difference of angular velocity possible over a given RPM band.

That is why torque is what eats transmissions and rear gears and is what you want to move down the track as fast as possible. The greater the delta in torque the quicker you can accelerate a given mass down the track. The horsepower of a vehicle involves the efficiency to get there and the total power a combination is capable of making which is how fast you're making that torque and where in the RPM band you're going to be doing it best.

Horsepower is a magnitude, torque the cross product of the connecting rod length and rotational combustion force. Horsepower is a number of efficiency in total energy that can be dissipated at a certain point. Torque is a vector that has magnitude and direction which is measured as the greatest difference of angular velocity possible over a given RPM band.

That is why torque is what eats transmissions and rear gears and is what you want to move down the track as fast as possible. The greater the delta in torque the quicker you can accelerate a given mass down the track. The horsepower of a vehicle involves the efficiency to get there and the total power a combination is capable of making which is how fast you're making that torque and where in the RPM band you're going to be doing it best.

#27

What you are talking about is matching where in the RPM band the difference of load and torque in magnitude matches HP. The input is not constant and varies depending on RPM and the load against the transmission as well as many other factors like kinetic rotational energy and kinetic linear energy. Transmissions do multiply torque but also remember the load the transmission sees multiplies work required against a transmission as the multiplication approaches 1:1 and becomes lower than 1:1. As the load increases inertia and torque become more important than HP.

#28

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

What you are talking about is matching where in the RPM band the difference of load and torque in magnitude matches HP. The input is not constant and varies depending on RPM and the load against the transmission as well as many other factors like kinetic rotational energy and kinetic linear energy. Transmissions do multiply torque but also remember the load the transmission sees multiplies work required against a transmission as the multiplication approaches 1:1 and becomes lower than 1:1. As the load increases inertia and torque become more important than HP.

#29

If you think in terms of actual imperial units (horsepower and lb/ft) it's so much more confusing because they always cross at 5252. So you can get them mixed up more. If you look at it in curves of metric units, you can see that if torque is flat, power is still rising. Power is directly related to the rate of change of torque as rpm rises. If torque is rising quickly as rpms go up, power will rise quickly. If torque is flat, power will continue to increase. When torque starts dropping, power will flatten out and eventually drop.

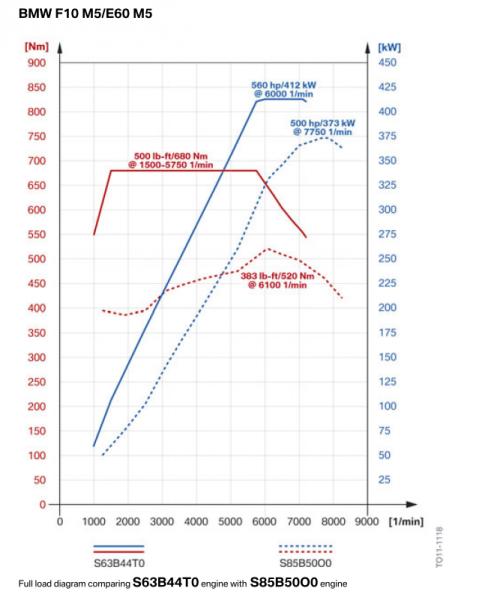

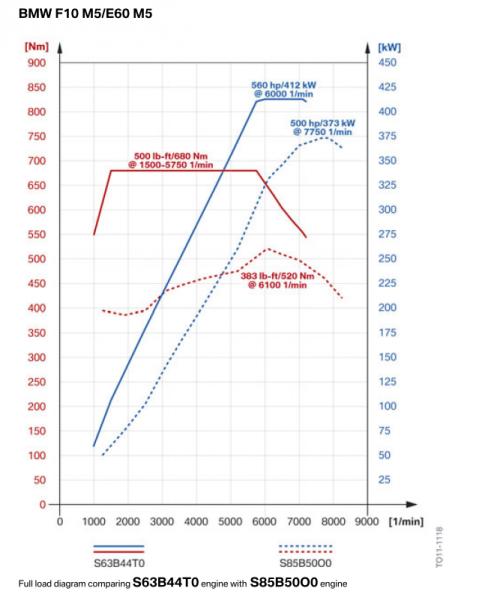

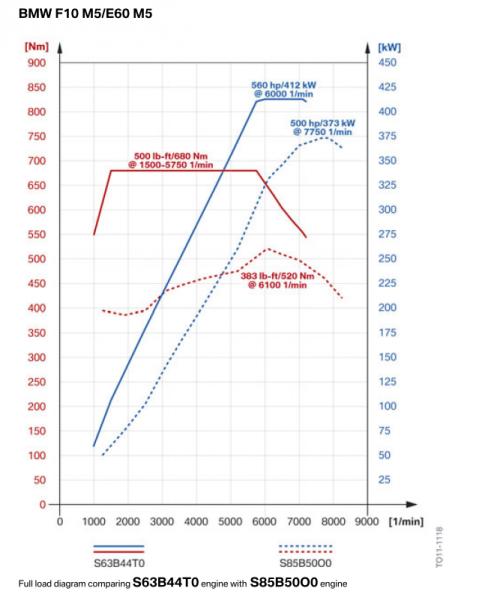

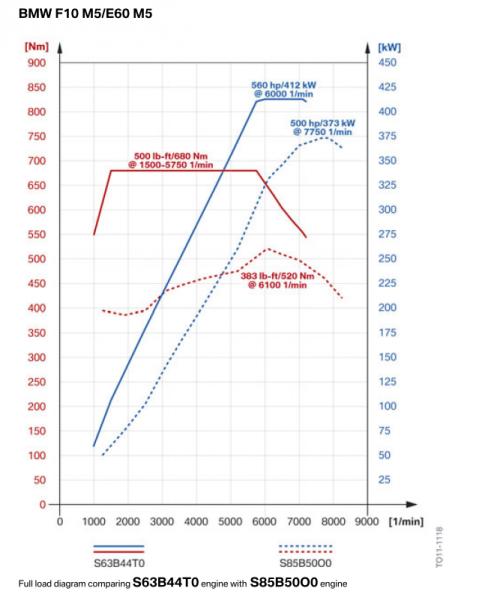

Compare the power and torque curves of the twin turbo direct injected V8 (solid line) in the current BMW M5 to the high revving n/a port injected V10 in the old M5 (dotted line).

You can see that on a modern turbo engine you can have a flat portions of the power curve and flat portions of the torque curve. Obviously those are smoothed engine dyno curves but it gets to be a pretty messy issue when you talk about shift points in the vehicle. Nowadays you have so many gears, and so many actuators (throttle, cam phasers, maybe turbo and valve lift control) that it's complicated.

Compare the power and torque curves of the twin turbo direct injected V8 (solid line) in the current BMW M5 to the high revving n/a port injected V10 in the old M5 (dotted line).

You can see that on a modern turbo engine you can have a flat portions of the power curve and flat portions of the torque curve. Obviously those are smoothed engine dyno curves but it gets to be a pretty messy issue when you talk about shift points in the vehicle. Nowadays you have so many gears, and so many actuators (throttle, cam phasers, maybe turbo and valve lift control) that it's complicated.

Last edited by arghx7; 10-15-2013 at 09:12 PM.

#30

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

If you think in terms of actual imperial units (horsepower and lb/ft) it's so much more confusing because they always cross at 5252. So you can get them mixed up more. If you look at it in curves of metric units, you can see that if torque is flat, power is still rising. Power is directly related to the rate of change of torque as rpm rises. If torque is rising quickly as rpms go up, power will rise quickly. If torque is flat, power will continue to increase. When torque starts dropping, power will flatten out and eventually drop.

Compare the power and torque curves of the twin turbo direct injected V8 (solid line) in the current BMW M5 to the high revving n/a port injected V10 in the old M5 (dotted line).

You can see that on a modern turbo engine you can have a flat portions of the power curve and flat portions of the torque curve. Obviously those are smoothed engine dyno curves but it gets to be a pretty messy issue when you talk about shift points in the vehicle. Nowadays you have so many gears, and so many actuators (throttle, cam phasers, maybe turbo and valve lift control) that it's complicated.

Compare the power and torque curves of the twin turbo direct injected V8 (solid line) in the current BMW M5 to the high revving n/a port injected V10 in the old M5 (dotted line).

You can see that on a modern turbo engine you can have a flat portions of the power curve and flat portions of the torque curve. Obviously those are smoothed engine dyno curves but it gets to be a pretty messy issue when you talk about shift points in the vehicle. Nowadays you have so many gears, and so many actuators (throttle, cam phasers, maybe turbo and valve lift control) that it's complicated.

#31

When you apply a load that resists torque, It is possible to have a force that is less than the force being applied to the tires but equal to the sum of frictional losses + inertia of the drivetrain + the force of movement.

For example you can push your car and it will change direction or speed. If the force was greater than what the engine could produce at any RPM then the engine would stall and lockup violently. Likewise, if you try to push the vehicle up a hill with the wheels cocked, you wont be getting very far. The force required to move the vehicle is far greater than that you can produce.

The engine is trying to move the object to a certain speed and applying a torque to get there while velocity of the vehicle itself also increases. The larger the amount of torque, the faster the vehicle will reach that speed and the less time it will take to get there. However there becomes a point where the change in linear velocity gets smaller and smaller as the transmission changes ratios to stay within the torque band of the motor and limit the RPM's required to turn the vehicle. As torque multiplication decreases, the load of the object that the valvetrain sees increases. As you're going through the RPM's at this point the amount of torque, which has units (N)(m) is equal to the amount of force measured in Newtons required to increase the speed of the vehicle minus the difference of inertia the drivetrain has. Whatever RPM this happens at greatly depends on motor design, vehicle weight, gear ratios, etc.

Also remember that torque converter work by fluid dynamics. The angle of the fins determine the flash RPM that moves the vehicle. So if the TC is designed to flash at 4000RPM then some fluid force is moving the dispersed as heat instead of rotational force since fluid is being pumped through the TC. When 4000RPM is met the force the fluid can turn the transmission by pushing on the fins is greatest and the motor then sees the load of the force required to move the vehicle forward.

#32

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

I am assuming you're talking about an automatic transmission but i'll keep this simple in terms of the engines output.

When you apply a load that resists torque, It is possible to have a force that is less than the force being applied to the tires but equal to the sum of frictional losses + inertia of the drivetrain + the force of movement.

For example you can push your car and it will change direction or speed. If the force was greater than what the engine could produce at any RPM then the engine would stall and lockup violently. Likewise, if you try to push the vehicle up a hill with the wheels cocked, you wont be getting very far. The force required to move the vehicle is far greater than that you can produce.

The engine is trying to move the object to a certain speed and applying a torque to get there while velocity of the vehicle itself also increases. The larger the amount of torque, the faster the vehicle will reach that speed and the less time it will take to get there. However there becomes a point where the change in linear velocity gets smaller and smaller as the transmission changes ratios to stay within the torque band of the motor and limit the RPM's required to turn the vehicle. As torque multiplication decreases, the load of the object that the valvetrain sees increases. As you're going through the RPM's at this point the amount of torque, which has units (N)(m) is equal to the amount of force measured in Newtons required to increase the speed of the vehicle minus the difference of inertia the drivetrain has. Whatever RPM this happens at greatly depends on motor design, vehicle weight, gear ratios, etc.

Also remember that torque converter work by fluid dynamics. The angle of the fins determine the flash RPM that moves the vehicle. So if the TC is designed to flash at 4000RPM then some fluid force is moving the dispersed as heat instead of rotational force since fluid is being pumped through the TC. When 4000RPM is met the force the fluid can turn the transmission by pushing on the fins is greatest and the motor then sees the load of the force required to move the vehicle forward.

When you apply a load that resists torque, It is possible to have a force that is less than the force being applied to the tires but equal to the sum of frictional losses + inertia of the drivetrain + the force of movement.

For example you can push your car and it will change direction or speed. If the force was greater than what the engine could produce at any RPM then the engine would stall and lockup violently. Likewise, if you try to push the vehicle up a hill with the wheels cocked, you wont be getting very far. The force required to move the vehicle is far greater than that you can produce.

The engine is trying to move the object to a certain speed and applying a torque to get there while velocity of the vehicle itself also increases. The larger the amount of torque, the faster the vehicle will reach that speed and the less time it will take to get there. However there becomes a point where the change in linear velocity gets smaller and smaller as the transmission changes ratios to stay within the torque band of the motor and limit the RPM's required to turn the vehicle. As torque multiplication decreases, the load of the object that the valvetrain sees increases. As you're going through the RPM's at this point the amount of torque, which has units (N)(m) is equal to the amount of force measured in Newtons required to increase the speed of the vehicle minus the difference of inertia the drivetrain has. Whatever RPM this happens at greatly depends on motor design, vehicle weight, gear ratios, etc.

Also remember that torque converter work by fluid dynamics. The angle of the fins determine the flash RPM that moves the vehicle. So if the TC is designed to flash at 4000RPM then some fluid force is moving the dispersed as heat instead of rotational force since fluid is being pumped through the TC. When 4000RPM is met the force the fluid can turn the transmission by pushing on the fins is greatest and the motor then sees the load of the force required to move the vehicle forward.

#33

Either you use variable gears to keep the motor within the band the engine creates maximum horsepower in effort to multiply angular momentum and inertia into torque, or you're variably changing the load with fluid dynamics inside a torque converter to keep the maximum HP and torque the motor can produce within a tight band as linear speed increases. Obviously when you have the most torque and horsepower you accelerate much quicker.

Regardless of how it is done the same laws apply.

#34

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Regardless of how it is done the same laws apply.

how about the fact that newton-meters cant equal newtons ? your intire post was full of eroneous statements. if you dont read the other posts,at least proofread your own,

how about the fact that newton-meters cant equal newtons ? your intire post was full of eroneous statements. if you dont read the other posts,at least proofread your own,

#35

Edit:

Just so there are absolutely zero questions about units, a Nm is not a N/m. When you divide a Nm by a N you are left with meters which is the distance covered. The Nm is taking into consideration rotational mass which includes the rotating assembly/drivetrain moment of inertia (mass in angular form), and the Newtons of the load is taking into consideration the mass of the vehicle and the distance you're covering over a specific amount of time which is real world time. All units cancel but meters which is the resultant distance covered.

Last edited by SS10Tech; 10-16-2013 at 12:24 AM.

#36

why is it called horse power? ask james watt, he made all this stuff up to replace horses with steam engines. His pitch was to tell horse owners that his engine would replace x amount of horses, walla horse power Yes he made up all the math also.

#37

Staging Lane

iTrader: (1)

Join Date: Aug 2008

Location: central michigan

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Just so there are absolutely zero questions about units, a Nm is not a N/m. When you divide a Nm by a N you are left with meters which is the distance covered. The Nm is taking into consideration rotational mass which includes the rotating assembly/drivetrain moment of inertia (mass in angular form), and the Newtons of the load is taking into consideration the mass of the vehicle and the distance you're covering over a specific amount of time which is real world time. All units cancel but meters which is the resultant distance covered.

ok,you went to a different physics school than me. NM is a unit of torque and does not involve any travel. also,measuring load as a distance traveled is a whole new concept . but ,it appears you dont want to be confused by fact --so no further comment.

ok,you went to a different physics school than me. NM is a unit of torque and does not involve any travel. also,measuring load as a distance traveled is a whole new concept . but ,it appears you dont want to be confused by fact --so no further comment.

#40

TECH Enthusiast

Join Date: Feb 2007

Location: Raleigh, NC

Posts: 625

Likes: 0

Received 0 Likes

on

0 Posts

When the vehicle is moving you're traveling a certain distance of meters. The load is seen as how much distance you're trying to travel in a certain amount of time which also involves gravity and frictional constants. A Newton is a kg * m/s^2. How about applying a little common sense instead of being a smart ***?

Edit:

Just so there are absolutely zero questions about units, a Nm is not a N/m. When you divide a Nm by a N you are left with meters which is the distance covered. The Nm is taking into consideration rotational mass which includes the rotating assembly/drivetrain moment of inertia (mass in angular form), and the Newtons of the load is taking into consideration the mass of the vehicle and the distance you're covering over a specific amount of time which is real world time. All units cancel but meters which is the resultant distance covered.

Edit:

Just so there are absolutely zero questions about units, a Nm is not a N/m. When you divide a Nm by a N you are left with meters which is the distance covered. The Nm is taking into consideration rotational mass which includes the rotating assembly/drivetrain moment of inertia (mass in angular form), and the Newtons of the load is taking into consideration the mass of the vehicle and the distance you're covering over a specific amount of time which is real world time. All units cancel but meters which is the resultant distance covered.

Angular force is a vector (T=rxF, matrix meaning r CROSS F) which results in units of magnitude being length*Force, you already posted this. Work is force multiplied by distance, which is in no way the same as rotational force. The units of the magnitude of the two (torque and work) are coincidentally the same but they are not interchangeable .

Sorry, but I (took the other guy's advice and) really tried reading your post several times and I can make no sense of it.