E85 & Static compression ratio with regards to 3 different engine types.

#1

My question is this, can you achieve the same static compression ratio with a typical fuel injected SBC, aluminum heads, using E85, as you could with either a reverse cooled engine such as the 2nd gen LT1 or a current Direct Injection LT1? This of course using the same cam.

I'm asking this because of the excellent cooling properties of E85. Or if using a typical SBC, would you have to lower the Static CR?

I'm asking because one of the mechanics I know is running a carbed 468ci with a CR of 14:1 using E85 and I didn't think that was possible.

Thanks

I'm asking this because of the excellent cooling properties of E85. Or if using a typical SBC, would you have to lower the Static CR?

I'm asking because one of the mechanics I know is running a carbed 468ci with a CR of 14:1 using E85 and I didn't think that was possible.

Thanks

#2

E85 can run on 14:1 compression no problem, it has been ran even 15:1+ by some with the right setup. It does burn cooler, so the engine does run a few degrees cooler than when on gas, all other things being equal. I ran 13.1:1 on my 385 LT1 with stock ported/milled heads before I upgraded to the AFR's, which cost me .5 compression due to a few more cc chamber volume. I plan on fixing that though by freshening it up next year with some small flat dome pistons to put it just over 14.1.

#3

I've done big boost and 13:1.

Typically, small blocks like more timing as well. They get away with (probably the wrong phrase) more timing in most situations because it is needed to build cylinder pressure.

On a given amount of timing, TYPICALLY a small block is safer than an LS engine. Once the aftermarket heads reach a certain point though, the different is negligible.

Engine type doesn't matter nearly as much as things like rod/stroke ratio (TDC dwell), dynamic compression, chamber design, among others.

Typically, small blocks like more timing as well. They get away with (probably the wrong phrase) more timing in most situations because it is needed to build cylinder pressure.

On a given amount of timing, TYPICALLY a small block is safer than an LS engine. Once the aftermarket heads reach a certain point though, the different is negligible.

Engine type doesn't matter nearly as much as things like rod/stroke ratio (TDC dwell), dynamic compression, chamber design, among others.

#4

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,835 Likes

on

1,145 Posts

Originally Posted by AwesomeAuto

I've done big boost and 13:1.

Typically, small blocks like more timing as well. They get away with (probably the wrong phrase) more timing in most situations because it is needed to build cylinder pressure.

On a given amount of timing, TYPICALLY a small block is safer than an LS engine. Once the aftermarket heads reach a certain point though, the different is negligible.

Engine type doesn't matter nearly as much as things like rod/stroke ratio (TDC dwell), dynamic compression, chamber design, among others.

Typically, small blocks like more timing as well. They get away with (probably the wrong phrase) more timing in most situations because it is needed to build cylinder pressure.

On a given amount of timing, TYPICALLY a small block is safer than an LS engine. Once the aftermarket heads reach a certain point though, the different is negligible.

Engine type doesn't matter nearly as much as things like rod/stroke ratio (TDC dwell), dynamic compression, chamber design, among others.

#5

Its not uncommon to see small blocks running upper 30s for timing N/A and 6-10 degrees more under boost than a compariable LS setup.

Once you get into low degree SBC heads, things change.

#6

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,835 Likes

on

1,145 Posts

Mostly, yes. The head design differences between an LS and a small block cause differences in cylinder mixing, fuel atomization, quench, cylinder filling, camshaft duration/lift ratio (cylinder filling vs dynamic compression).

Its not uncommon to see small blocks running upper 30s for timing N/A and 6-10 degrees more under boost than a compariable LS setup.

Once you get into low degree SBC heads, things change.

Its not uncommon to see small blocks running upper 30s for timing N/A and 6-10 degrees more under boost than a compariable LS setup.

Once you get into low degree SBC heads, things change.

The following users liked this post:

G Atsma (01-02-2020)

#7

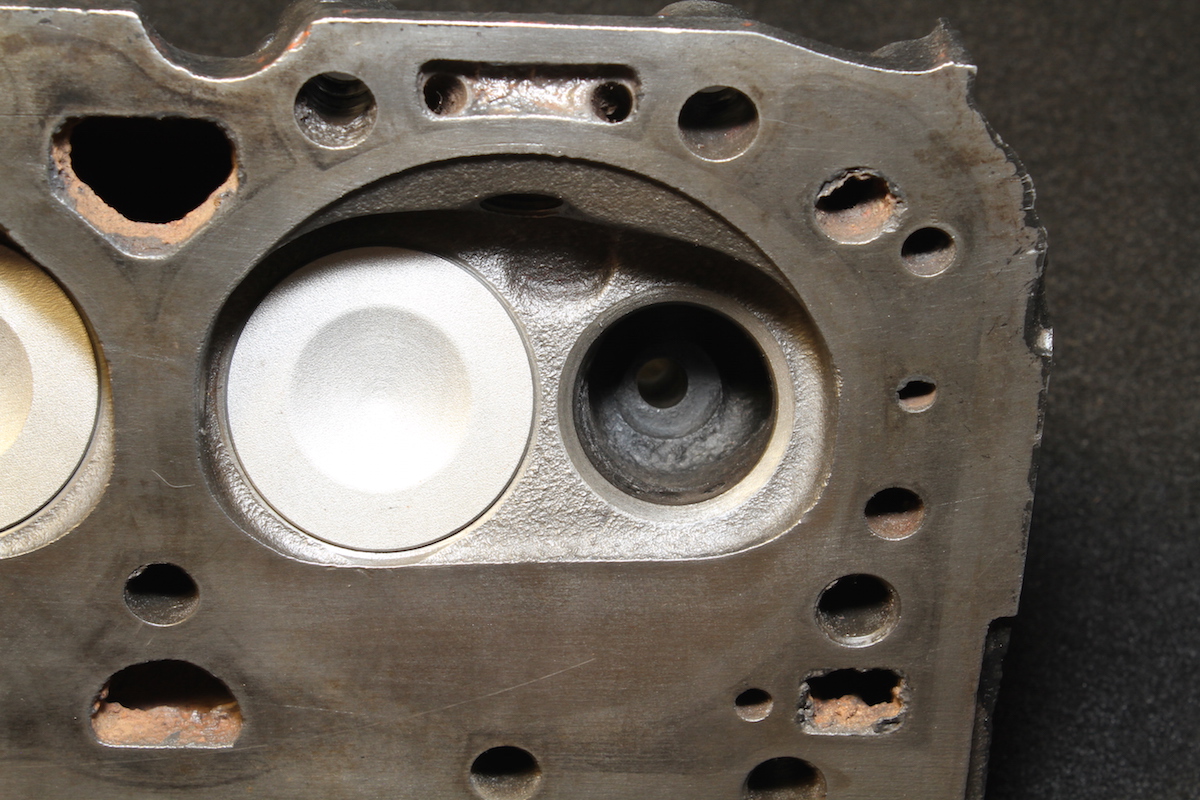

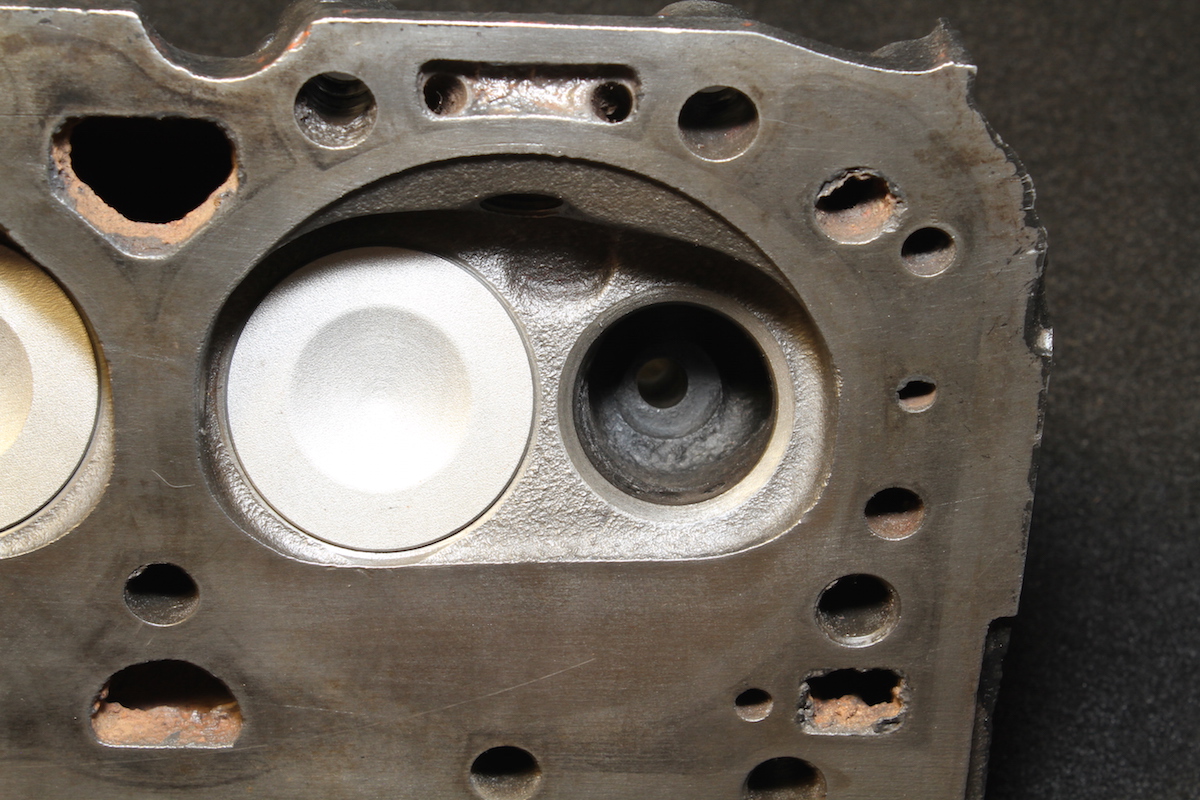

The higher angle changes the chamber quite a bit.

A more angled valve typically requires the chamber to be "deeper".

To keep the chambers lower volume, they would either have to move the lowest point of the valve closer to the deck, reducing PTV clearance, or shroud the valves and reduce the overall area of the chamber size while still maintaining volume.

I'm on my phone so searching for an image isn't much fun, but this should give you an idea of the valve angle, chamber depth, and opening area/shrouding solution to keep CCs low.

A more angled valve typically requires the chamber to be "deeper".

To keep the chambers lower volume, they would either have to move the lowest point of the valve closer to the deck, reducing PTV clearance, or shroud the valves and reduce the overall area of the chamber size while still maintaining volume.

I'm on my phone so searching for an image isn't much fun, but this should give you an idea of the valve angle, chamber depth, and opening area/shrouding solution to keep CCs low.

The following users liked this post:

G Atsma (01-02-2020)

Trending Topics

#8

Camshafts for small blocks compound the problems.

You can't run much lift with stock style valvetrain, so they typically run wide durations, more wide than what we are used to with LS engines (24x/24x can be considered mild or common by most on your average 350 small block).

You end up with low dynamic compression on a cylinder that was poorly filled to begin with. Extra timing is used to generate cylinder pressure.

The smog era heads were designed to be used with small camshafts and 87 octane. When you try to build a performance engine out of them and run 93, you can get away with boatloads of timing.

Aftermarket heads for small blocks solve SO many problems.

You can't run much lift with stock style valvetrain, so they typically run wide durations, more wide than what we are used to with LS engines (24x/24x can be considered mild or common by most on your average 350 small block).

You end up with low dynamic compression on a cylinder that was poorly filled to begin with. Extra timing is used to generate cylinder pressure.

The smog era heads were designed to be used with small camshafts and 87 octane. When you try to build a performance engine out of them and run 93, you can get away with boatloads of timing.

Aftermarket heads for small blocks solve SO many problems.

The following users liked this post:

G Atsma (01-02-2020)

#9

Late model in engines LT1. LS1 And newer have reverse flow cooling which directly enables them to run higher compression.. So you can get away with higher compressions in a older engine with E85 but you should be able to Have even higher compression in a newer engine.

#10

Late model in engines LT1. LS1 And newer have reverse flow cooling which directly enables them to run higher compression.. So you can get away with higher compressions in a older engine with E85 but you should be able to Have even higher compression in a newer engine.

The following users liked this post:

G Atsma (05-28-2020)