Anyone using Cerakote Coating on Engine Internals?

#1

On The Tree

Thread Starter

I am working on a new build and been doing research on friction and thermal coatings.

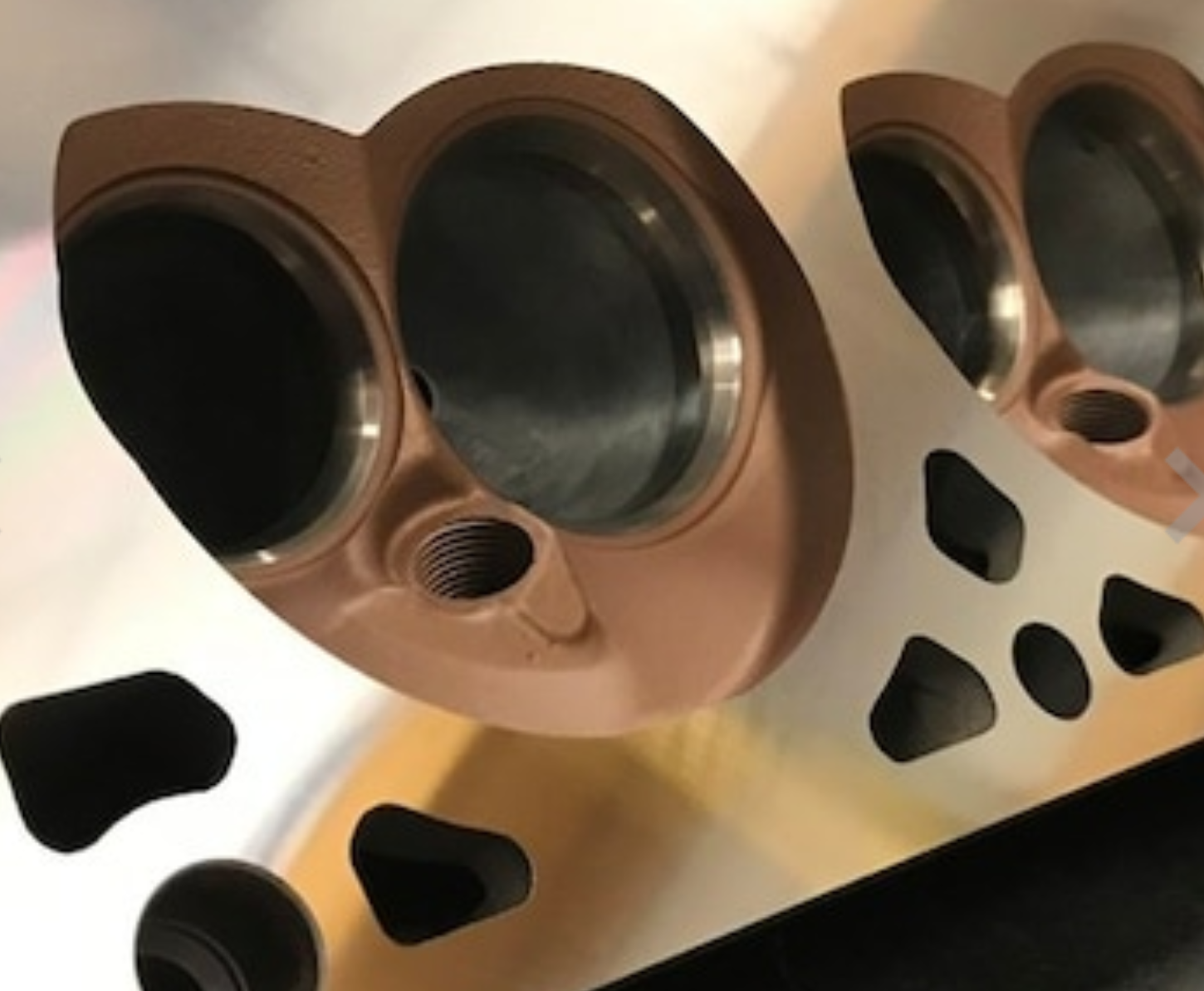

The coating on Top of the piston greatly reduces the crank case temperatures, the side skirt coating reduces scuffing and friction, I have even seen combustion chambers coated with cerakote.

They have this stuff called micro slick that you can coat your engine bearings with and builders say it greatly reduces wear and friction.

Have you guys ever had any experience using this method with good results? Thanks.

The coating on Top of the piston greatly reduces the crank case temperatures, the side skirt coating reduces scuffing and friction, I have even seen combustion chambers coated with cerakote.

They have this stuff called micro slick that you can coat your engine bearings with and builders say it greatly reduces wear and friction.

Have you guys ever had any experience using this method with good results? Thanks.

#5

I've used both the Micro Slick and the Piston Coat on pistons. It holds up really well. I've also used their Glacier Silver and Chrome on exhaust manifolds in both the air cure and the oven cure variants. I may have had a bad or older batch of the air cure Silver or it's possible I didn't put the coats on thick enough, but I have some rust spots that show through on the last manifolds I did (unfortunately, these are the manifolds on my LQ9 in my Tahoe). The literature does say it should actually flow in such a manner that it fills in dips and imperfections and looks smooth, but the manifolds I have coated still show the "as cast" texture even after several coats were applied. I did use an airbrush to spray this time instead of a touch up gun, though. The oven cure stuff I have used fills everything in extremely well. It seems to be a bit thicker, but takes high temps to cure. The manifolds I have coated using the oven cure stuff with either the airbrush or a touch up gun look and feel smooth to the touch. None of the "cast" texture remains. The Chrome needs polishing and will become dull over time, so you have to polish it every now and then. I use them on turbo manifolds and they hold up very well to the heat and keep a significant amount of the heat in the manifold. On my turbo cars, it reduced underhood temps to the point they were cooler than they were with the factory manifold and heat shield in place.

I also do powdercoating on pretty much anything I get my hands on while working on something. Haha! It's an illness, I think.

I also do powdercoating on pretty much anything I get my hands on while working on something. Haha! It's an illness, I think.

#6

TECH Fanatic

iTrader: (20)

https://ls1tech.com/forums/conversio...le-2-9l-5.html

^that build thread OP has applied thermal coatings to the valve springs, pistons, oil pump, cam, valves, retainers, combustion chambers etc...hasnt fired the engine yet tho

^that build thread OP has applied thermal coatings to the valve springs, pistons, oil pump, cam, valves, retainers, combustion chambers etc...hasnt fired the engine yet tho

#9

On The Tree

Thread Starter

I am also curious if Coating the Inside of a Aluminum intake manifold with Cerakote would Knock down the Intake Air Temperatures and help alot with heat soak.

The following users liked this post:

GSAWYERS (04-29-2021)

#11

It is very effective at blocking heat transfer. You could use it to prevent heat soak as long as the heat wasnít coming from elevated intake air temps in the first place like in boosted applications.

On the exhaust side, the inside and outside are coated. It keeps a significant amount of the heat moving down the exhaust. Manifolds I have done on turbo cars used to glow red after a hard run. Now you can almost touch them after. I would imagine it helps with spool a bit, but have no back to back info since I usually am changing something at the same time. Haha!

The Cerakote line isnít really a DIY product. It just happens that it is easy to use and sample sizes were made available to everyone. The oven cure versions need 500 and then up to 750 degrees to fully cure, but they are very resilient. I use industrial infrared heat lamps for this. The air cure line is relatively new by comparison, but does well.

On the exhaust side, the inside and outside are coated. It keeps a significant amount of the heat moving down the exhaust. Manifolds I have done on turbo cars used to glow red after a hard run. Now you can almost touch them after. I would imagine it helps with spool a bit, but have no back to back info since I usually am changing something at the same time. Haha!

The Cerakote line isnít really a DIY product. It just happens that it is easy to use and sample sizes were made available to everyone. The oven cure versions need 500 and then up to 750 degrees to fully cure, but they are very resilient. I use industrial infrared heat lamps for this. The air cure line is relatively new by comparison, but does well.

#12

On The Tree

Thread Starter

Yeah its easy to use as long as your Prep work is good. My friend has coated lots of parts for the gun store he works at with Great results, He uses Oven Cure so that will be what I do. Seems to be some very good stuff.