DOMN8R's 2000 TransAm 4L80E Build

#1

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

Did the M6 ---> 4L80E Swap

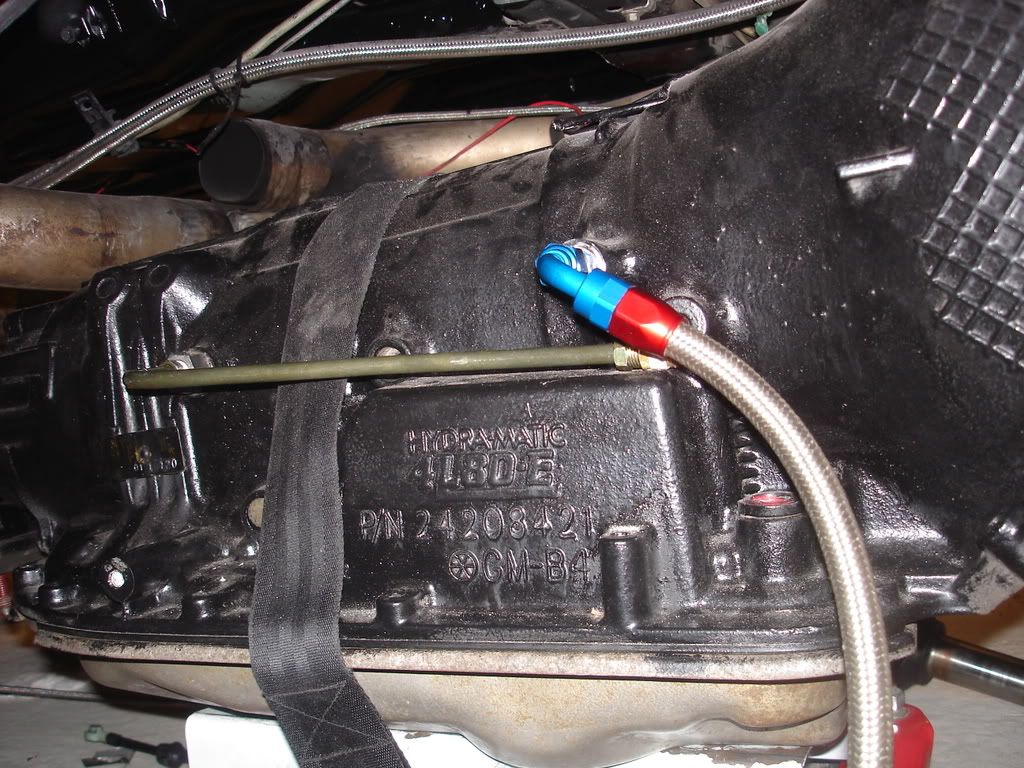

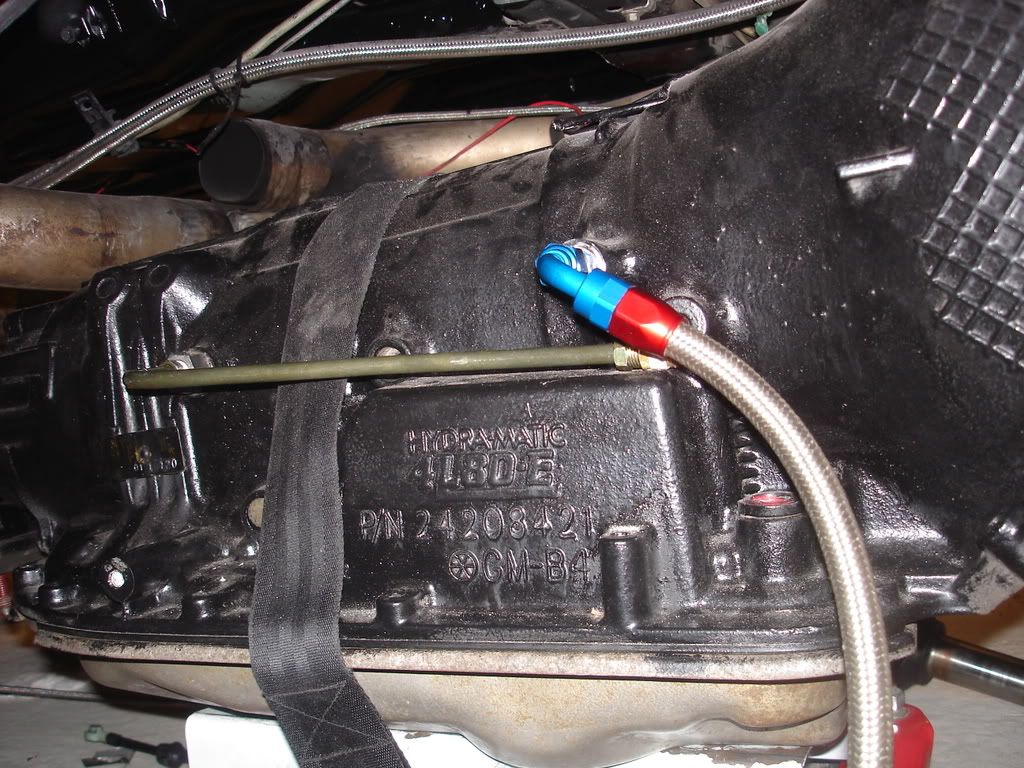

I bought a used 4l80E from junkyard with 45k miles on it. It is from a 2001 Chevy Van and is the later style in 2001. I bought a Yank PY3400 and ran the transmission stock for a season and when 2-3 shift became slow I installed a TransGo Stage II shift kit, that helped a lot.

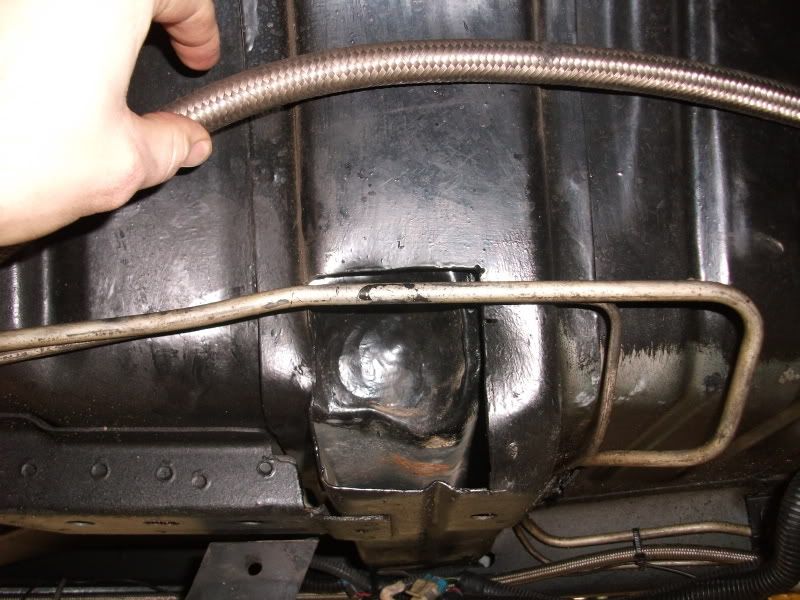

I painted the case with Por-15 and cut the passenger ear off as shown on the pictures. See the tunnel modifications to make it fit. I cut an aluminum plate and used a hammer to shape it to fit the hole in the tunnel.

Driver Side

Passenger Side

Aluminum plate with stock 4l60e shifter mounted on it.

Shifter Assembly from 4l60e

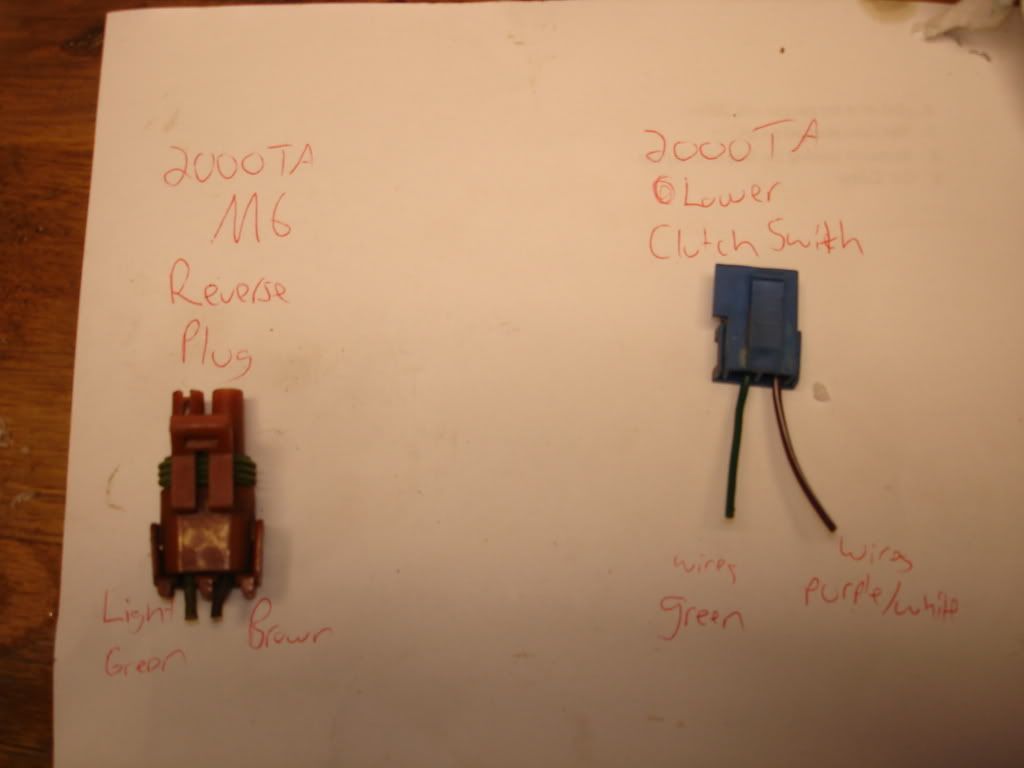

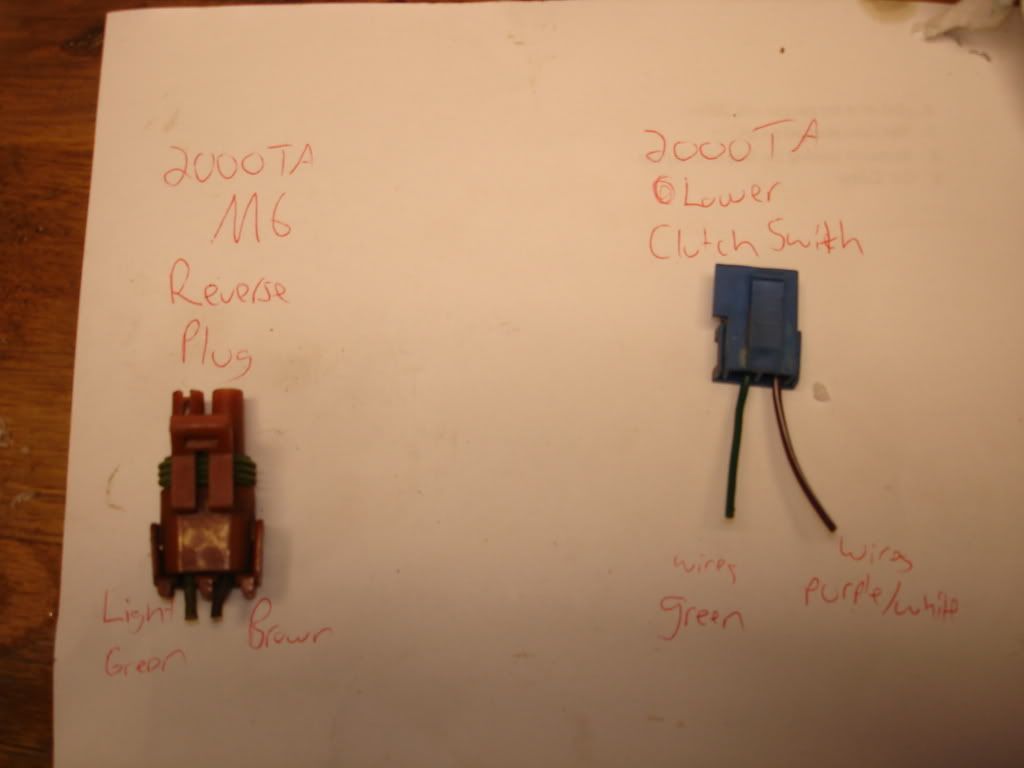

Wired in the reverse lights to the shifter assembly and the old clutch switch for the park/neutral safety switch. I forget which pins but there are other posts where I got my information from that explain that.

I bought a TCI SFI flexplate P/N: 399753 and used all six bolts for the converter. The converter comes with three so buy additional 10mmx1.5 bolts.

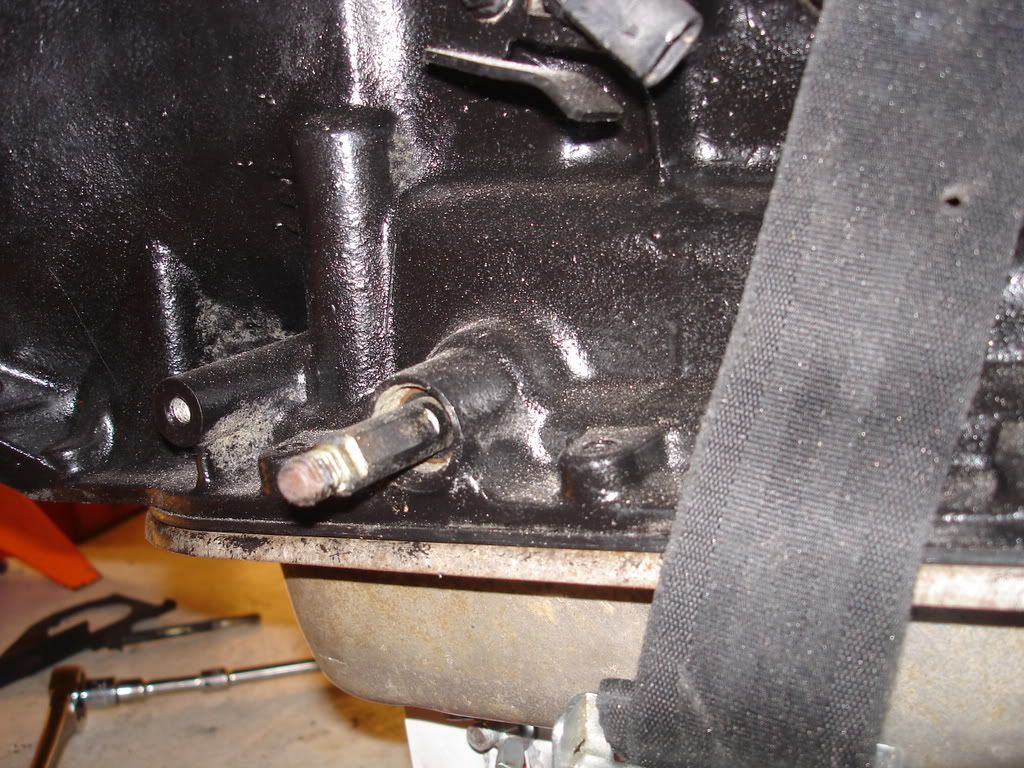

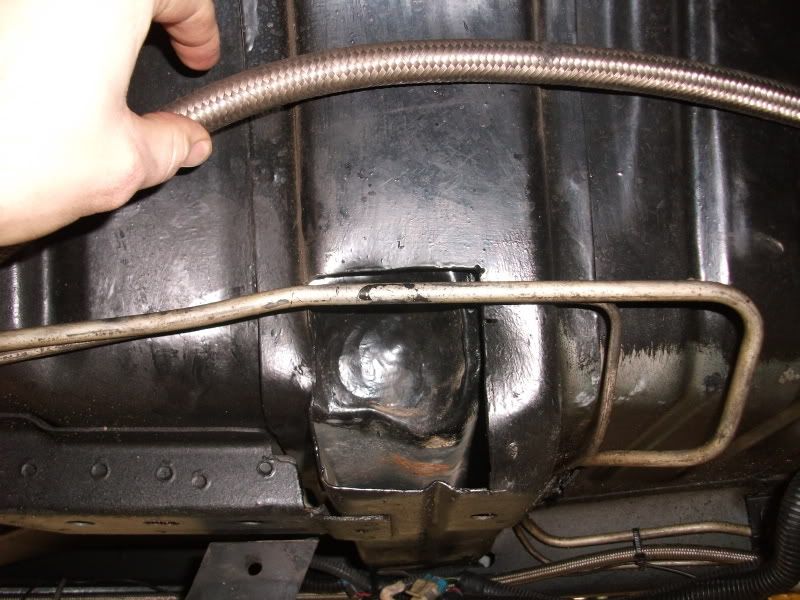

I removed the oring on the inside of this housing and bought a slip yoke with 1350 u joint for the 4L80e.

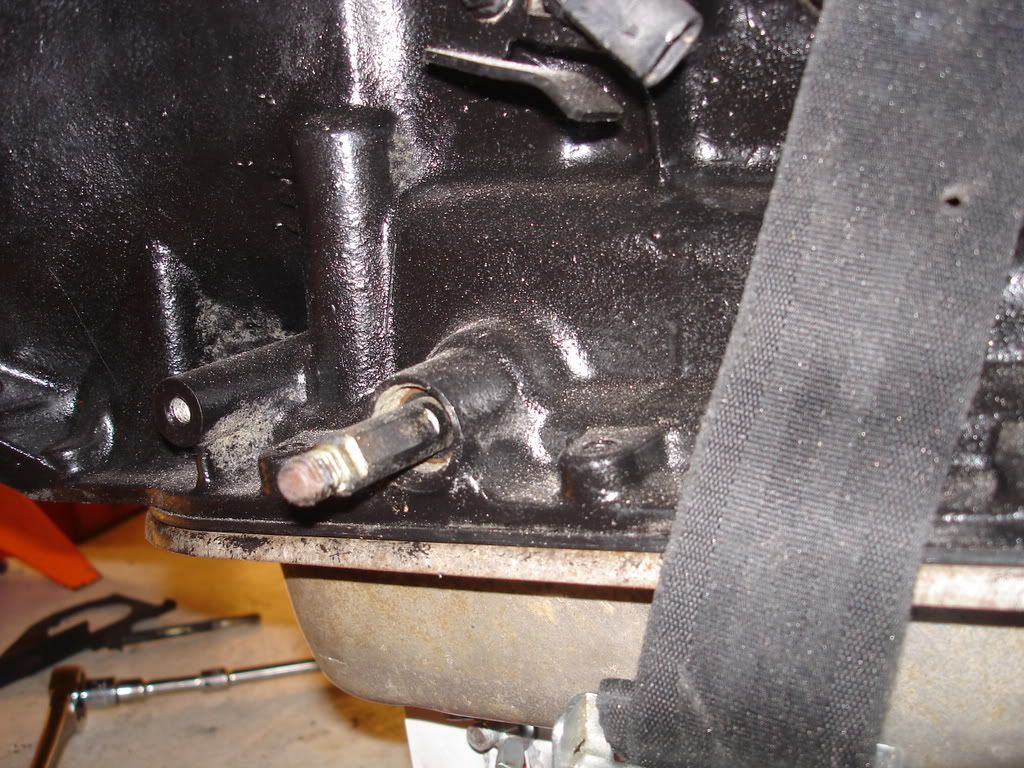

Stock slip yoke compared to one i ordered. Notice the new one didnt have the splines all the way to the end, i sent it back and got one with the splines to the end.

Bought this case cooler line assembly online.

BMR 4l80E Trany Crossmember P/N: TCC021

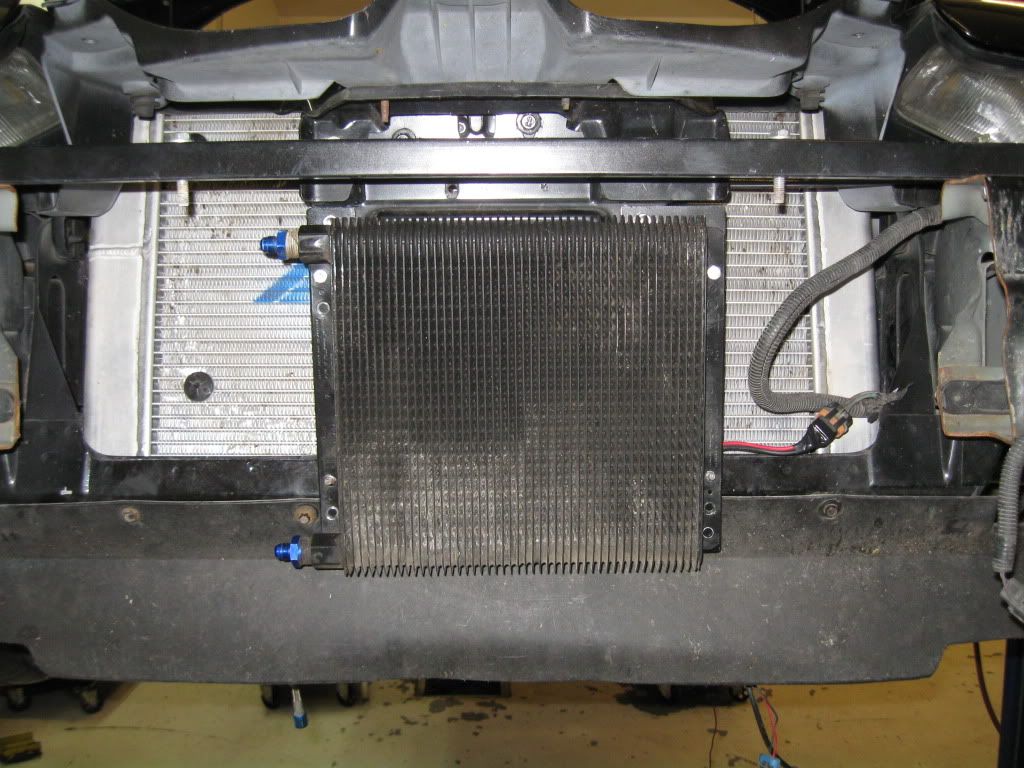

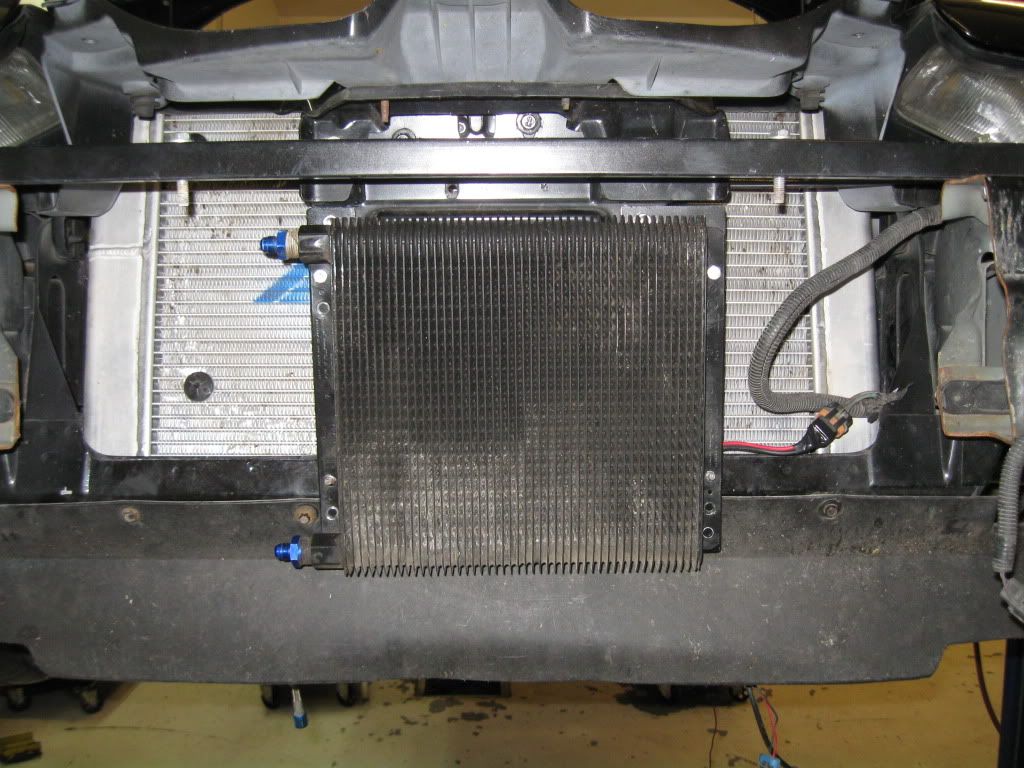

B&M Tranny Cooler (Old Mounting)

Mounting last year after turbo kit install (didnt work well, but also it should have been turned 90 degrees to let air flow thru it better)

Current Mount

M6--->4L80E Swap Parts List

TCI SFI flexplate P/N: 399753

4l80E Lokar Tranny Dipstick P/N: LOK-TD34L80FM36

Speartech Wiring Harness

BMR Replacement Torque Arm Bushing P/N: U-69112

BMR 4l80E Trany Crossmember P/N: TCC021

Tranny Bellhousing bolts from GM P/N: 11515767*

4l80E Dust Shield from GM P/N: 15765623*

1350 Slipyoke (to match 1350 ujoint on driveshaft)

Tranny Temp Gauge Autometer P/N: ATM-4457

B&M Tranny Cooler P/N: BMM-70274

I bought a used 4l80E from junkyard with 45k miles on it. It is from a 2001 Chevy Van and is the later style in 2001. I bought a Yank PY3400 and ran the transmission stock for a season and when 2-3 shift became slow I installed a TransGo Stage II shift kit, that helped a lot.

I painted the case with Por-15 and cut the passenger ear off as shown on the pictures. See the tunnel modifications to make it fit. I cut an aluminum plate and used a hammer to shape it to fit the hole in the tunnel.

Driver Side

Passenger Side

Aluminum plate with stock 4l60e shifter mounted on it.

Shifter Assembly from 4l60e

Wired in the reverse lights to the shifter assembly and the old clutch switch for the park/neutral safety switch. I forget which pins but there are other posts where I got my information from that explain that.

I bought a TCI SFI flexplate P/N: 399753 and used all six bolts for the converter. The converter comes with three so buy additional 10mmx1.5 bolts.

I removed the oring on the inside of this housing and bought a slip yoke with 1350 u joint for the 4L80e.

Stock slip yoke compared to one i ordered. Notice the new one didnt have the splines all the way to the end, i sent it back and got one with the splines to the end.

Bought this case cooler line assembly online.

BMR 4l80E Trany Crossmember P/N: TCC021

B&M Tranny Cooler (Old Mounting)

Mounting last year after turbo kit install (didnt work well, but also it should have been turned 90 degrees to let air flow thru it better)

Current Mount

M6--->4L80E Swap Parts List

TCI SFI flexplate P/N: 399753

4l80E Lokar Tranny Dipstick P/N: LOK-TD34L80FM36

Speartech Wiring Harness

BMR Replacement Torque Arm Bushing P/N: U-69112

BMR 4l80E Trany Crossmember P/N: TCC021

Tranny Bellhousing bolts from GM P/N: 11515767*

4l80E Dust Shield from GM P/N: 15765623*

1350 Slipyoke (to match 1350 ujoint on driveshaft)

Tranny Temp Gauge Autometer P/N: ATM-4457

B&M Tranny Cooler P/N: BMM-70274

Last edited by nahasapeemapetalon; 03-29-2011 at 06:52 AM.

#3

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

This last summer the transmission started slipping and wouldn't consistently shift at WOT from 2--->3. I did quite a bit of research on here and the net for what parts to upgrade. My buddy is rebuilding my transmission and found that most of the parts were in pretty good shape with exception of the direct clutches, they were shot and worn down. The pump didnt show signs of wear so I am reusing it.

Direct Clutches

I sent in my Yank PY3400 and had the bearings replaced and they found that the clutch should be replaced as well so I did that.

The internals looked good but while it was apart i decided to go with a few hard parts. I bought a billet input shaft, intermediate shaft, and billet forward rollerized hub from c k performance.

I bought a master rebuild kit online with borg warner (stock type) clutches. The direct clutch kit is coming with 6 clutches instead of the stock five and thinner steels to leave proper clearances.

The endplay for the rear case was .015" before the rebuild.

I ordered a TCI 224400 rear case bearing (made for th400's but works for 4l80e's) and my buddy said the endplay is .008" now.

I am waiting on one more direct clutch and the steels, then the tranny get get put together and i can take it for a rip.

I already had a transgo stage II shiftkit previously installed.

My transmission is the later model of the 2001 and came with the 34 element drum. I decided to not upgrade the drum.

Direct Clutches

I sent in my Yank PY3400 and had the bearings replaced and they found that the clutch should be replaced as well so I did that.

The internals looked good but while it was apart i decided to go with a few hard parts. I bought a billet input shaft, intermediate shaft, and billet forward rollerized hub from c k performance.

I bought a master rebuild kit online with borg warner (stock type) clutches. The direct clutch kit is coming with 6 clutches instead of the stock five and thinner steels to leave proper clearances.

The endplay for the rear case was .015" before the rebuild.

I ordered a TCI 224400 rear case bearing (made for th400's but works for 4l80e's) and my buddy said the endplay is .008" now.

I am waiting on one more direct clutch and the steels, then the tranny get get put together and i can take it for a rip.

I already had a transgo stage II shiftkit previously installed.

My transmission is the later model of the 2001 and came with the 34 element drum. I decided to not upgrade the drum.

#4

The direct clutch failure you experienced is common on a unmodded 4L80E.

The transgo kit addresses the issue but we use a different method while rebuilding them.

This is why a typical wrecking yard unit, even if in excellent shape, isn't really ideal. ~450 flywheel HP will slowly kill the directs without hydraulic mods.

The transgo kit addresses the issue but we use a different method while rebuilding them.

This is why a typical wrecking yard unit, even if in excellent shape, isn't really ideal. ~450 flywheel HP will slowly kill the directs without hydraulic mods.

#5

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

I probably did most of the clutch damage prior to the HD2 shift kit then....

Interesting, thanks for your input. You have also posted helpful information that helped me out during this build, thanks a bunch!

Interesting, thanks for your input. You have also posted helpful information that helped me out during this build, thanks a bunch!

Trending Topics

#8

Staging Lane

Join Date: Apr 2007

Location: Melbourne, Australia

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

Are you sure you can use that new slip yoke with the splines to the end ?

I have a simular setup in my car and I stuck with the old one , Because I though there was an O ring seal at the end inside the box that needed that flat spot ?

I'm also using the bolt in the shaft too to bolt it together .

I have a simular setup in my car and I stuck with the old one , Because I though there was an O ring seal at the end inside the box that needed that flat spot ?

I'm also using the bolt in the shaft too to bolt it together .

#10

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

Are you sure you can use that new slip yoke with the splines to the end ?

I have a simular setup in my car and I stuck with the old one , Because I though there was an O ring seal at the end inside the box that needed that flat spot ?

I'm also using the bolt in the shaft too to bolt it together .

I have a simular setup in my car and I stuck with the old one , Because I though there was an O ring seal at the end inside the box that needed that flat spot ?

I'm also using the bolt in the shaft too to bolt it together .

In 08' I was making about 385rwhp on motor and 550rwhp on spray, it took its abuse on the street and strip. Later in the summer 2-3 shifts were taking too long and I ran 11.00. I put in a shift kit and came back on a cooler day and ran 10.46@130. Over half of track runs were on slicks. Probably 30+ passes that year.

I ran the tranny with shift kit all of 09' with a handful of 10 second passes and quite a few 11 second passes as well. It got a workout on the street as well. Power was the same 385rwhp-560rwhp. Over half of track runs were on slicks. Probably 15-20 track runs.

10' I did the turbo and 408 swap. Power was probably between 550-700rwhp on most races with highway pulls more than that.

Raced it on power tour in bowling green ran 10.9@131 then mid summer with slicks i pulled off a 10.52@133 and the next pass it didnt make the 2-3 shift, hit the limiter.

Raceweight this year was 42xx

That gives you a good idea on how long it lasted with the heavy weight and abuse, very impressed.

Last edited by nahasapeemapetalon; 03-29-2011 at 09:26 PM.

#14

11 Second Club

iTrader: (22)

I'm doing nearly the exact swap now too. 01 van tranny into a '98 TA, Circle D 4k stall. I found a rear 6an fitting that made the install way easier, though the main trans electrical plug seems pulled a little too tight for comfort.

Sounds like yours has been in a little bit already, did you have any issues with the shifter positioning? I've seen a few posts about not being able to get to get the 80's to fully engage in every gear due to shifter detent spacing. Not sure if that's just aftermarket shifters or stock ones too...

Sounds like yours has been in a little bit already, did you have any issues with the shifter positioning? I've seen a few posts about not being able to get to get the 80's to fully engage in every gear due to shifter detent spacing. Not sure if that's just aftermarket shifters or stock ones too...

#15

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

I checked out my yoke and I did get a longer yoke splined all the way. My transmission didnt have an oring on the shaft going into the back of the trans. The new yoke p/n: Spicer 70914.

I didnt have any problems with the shifter, stock shifter is working great. When I installed it i ran it through the gears to make sure it worked. Good luck! I'd recommend doing stage II transgo shift kit right away and a good cooler mounted up front.

I didnt have any problems with the shifter, stock shifter is working great. When I installed it i ran it through the gears to make sure it worked. Good luck! I'd recommend doing stage II transgo shift kit right away and a good cooler mounted up front.

#18

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

Transmission is working excellent! Shifts quickly, almost dont notice it!

Very happy so far. I will have to make sure i have the transmission tables setup properly.

Very happy so far. I will have to make sure i have the transmission tables setup properly.