1963 Chevy Nova LS6 Swap

#41

Staging Lane

Join Date: Jul 2007

Location: Chicago, Sw Subs

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

Not sure what you did is a good thing cutting the bushing ...i have done two of these with TCI clips and never had a problem with the rack YOU should be using a F Body pan and possibly a different set of motor plates the other issue could be you have your trans tail shaft to high which is tilting the front of the motor down make it hit the rack.

Heres a picture of my clearance not real great pictures, if your interested in a better i could take some ...seems like you made it work ?

Heres a picture of my clearance not real great pictures, if your interested in a better i could take some ...seems like you made it work ?

#42

Here's the challenge to the 1st and 2nd gen front clip suppliers. Heidt, TCI or Church Brothers or anyone.

Show me or us the consumers pics of the their clips with an LS engine either with the Fbody pan or aftermarket pan clearing the power rack.

No rant but if using the "typical" short wide SBC mount conversion plates will their clips accomodate the LS swap using a Fbody pan without raising the motor mounts to clear the power rack? The short wide mounts move the LS back within 1/2" of the head to firewall.

Heidt's with the rear mount sway bar on the super ride show me it clearing the Fbody pan.

The point being as we order parts, suppliers just let us know what it takes. Don't guess. If you don't know just say so. Most of us as we are building cars would be more than happy to show you what we have run into as far as problems go. Nothing worse than sliding that LS engine in on Friday late and the pan hits the rack then waiting till Monday morning calling the supplier and hearing "well it should fit".

If an aftermarket pan is required just say so or change your design so it's not required.

Maybe a bit of a rant but my .02 worth.

Show me or us the consumers pics of the their clips with an LS engine either with the Fbody pan or aftermarket pan clearing the power rack.

No rant but if using the "typical" short wide SBC mount conversion plates will their clips accomodate the LS swap using a Fbody pan without raising the motor mounts to clear the power rack? The short wide mounts move the LS back within 1/2" of the head to firewall.

Heidt's with the rear mount sway bar on the super ride show me it clearing the Fbody pan.

The point being as we order parts, suppliers just let us know what it takes. Don't guess. If you don't know just say so. Most of us as we are building cars would be more than happy to show you what we have run into as far as problems go. Nothing worse than sliding that LS engine in on Friday late and the pan hits the rack then waiting till Monday morning calling the supplier and hearing "well it should fit".

If an aftermarket pan is required just say so or change your design so it's not required.

Maybe a bit of a rant but my .02 worth.

#43

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

Not sure what you did is a good thing cutting the bushing ...i have done two of these with TCI clips and never had a problem with the rack YOU should be using a F Body pan and possibly a different set of motor plates the other issue could be you have your trans tail shaft to high which is tilting the front of the motor down make it hit the rack.

The problem with my front end is that I have one of the very first front clips TCI ever designed (back in 2002). Since then, they have made several changes in their design according toÖ (I think I talked to Evan at TCI). Iíve had two sets of motor mount plates of varying thicknesses and what you see in the pics is the F-body oil pan. Iím using the standard gm polyurethane trans mount, but my other issue is the fact that my exhaust may hit if I go any lower than I am right now by the trans mount. HmmmmÖ.??

If need be, I can always replace the bushings no sweat. The only thing that it could possibly mess with is the alignment since vibration is not an issue at those reaction points. Shouldnít be a big deal if I get it re-aligned when Iím done with the install.

Not sure what else I could have done?

Here's the challenge to the 1st and 2nd gen front clip suppliers. Heidt, TCI or Church Brothers or anyone.

Show me or us the consumers pics of the their clips with an LS engine either with the Fbody pan or aftermarket pan clearing the power rack.

No rant but if using the "typical" short wide SBC mount conversion plates will their clips accomodate the LS swap using a Fbody pan without raising the motor mounts to clear the power rack? The short wide mounts move the LS back within 1/2" of the head to firewall.

Heidt's with the rear mount sway bar on the super ride show me it clearing the Fbody pan.

The point being as we order parts, suppliers just let us know what it takes. Don't guess. If you don't know just say so. Most of us as we are building cars would be more than happy to show you what we have run into as far as problems go. Nothing worse than sliding that LS engine in on Friday late and the pan hits the rack then waiting till Monday morning calling the supplier and hearing "well it should fit".

If an aftermarket pan is required just say so or change your design so it's not required.

Maybe a bit of a rant but my .02 worth.

Show me or us the consumers pics of the their clips with an LS engine either with the Fbody pan or aftermarket pan clearing the power rack.

No rant but if using the "typical" short wide SBC mount conversion plates will their clips accomodate the LS swap using a Fbody pan without raising the motor mounts to clear the power rack? The short wide mounts move the LS back within 1/2" of the head to firewall.

Heidt's with the rear mount sway bar on the super ride show me it clearing the Fbody pan.

The point being as we order parts, suppliers just let us know what it takes. Don't guess. If you don't know just say so. Most of us as we are building cars would be more than happy to show you what we have run into as far as problems go. Nothing worse than sliding that LS engine in on Friday late and the pan hits the rack then waiting till Monday morning calling the supplier and hearing "well it should fit".

If an aftermarket pan is required just say so or change your design so it's not required.

Maybe a bit of a rant but my .02 worth.

#44

Here's the challenge to the 1st and 2nd gen front clip suppliers. Heidt, TCI or Church Brothers or anyone.

Show me or us the consumers pics of the their clips with an LS engine either with the Fbody pan or aftermarket pan clearing the power rack.

No rant but if using the "typical" short wide SBC mount conversion plates will their clips accomodate the LS swap using a Fbody pan without raising the motor mounts to clear the power rack? The short wide mounts move the LS back within 1/2" of the head to firewall.

Heidt's with the rear mount sway bar on the super ride show me it clearing the Fbody pan.

The point being as we order parts, suppliers just let us know what it takes. Don't guess. If you don't know just say so. Most of us as we are building cars would be more than happy to show you what we have run into as far as problems go. Nothing worse than sliding that LS engine in on Friday late and the pan hits the rack then waiting till Monday morning calling the supplier and hearing "well it should fit".

If an aftermarket pan is required just say so or change your design so it's not required.

Maybe a bit of a rant but my .02 worth.

Show me or us the consumers pics of the their clips with an LS engine either with the Fbody pan or aftermarket pan clearing the power rack.

No rant but if using the "typical" short wide SBC mount conversion plates will their clips accomodate the LS swap using a Fbody pan without raising the motor mounts to clear the power rack? The short wide mounts move the LS back within 1/2" of the head to firewall.

Heidt's with the rear mount sway bar on the super ride show me it clearing the Fbody pan.

The point being as we order parts, suppliers just let us know what it takes. Don't guess. If you don't know just say so. Most of us as we are building cars would be more than happy to show you what we have run into as far as problems go. Nothing worse than sliding that LS engine in on Friday late and the pan hits the rack then waiting till Monday morning calling the supplier and hearing "well it should fit".

If an aftermarket pan is required just say so or change your design so it's not required.

Maybe a bit of a rant but my .02 worth.

First two are of a power set up and the engine sitting forward 1" from neutral.

These two photos are with a manual rack and the engine sitting just as you described....as close to the firewall without contact.

In the first two photos with the power set up the engine is actually sitting farther forward than what we provide with motor plates, when purchasing our headers. With the engine further ahead the clearance would be tighter however this customer has zero issue with clearance. Both cars are using the F-body oil pan.

Now back to our regular scheduled, informative thread.

#46

Didn't mean to flame any supplier. Looks like the Chuch Boys fits great and that's what we need to see.

Great selling point for Church Boys.

Anyone with a power rack with a MII type clip and power rack?

Great selling point for Church Boys.

Anyone with a power rack with a MII type clip and power rack?

#47

Amen. I just heard this the other day on the phone from BTO..."well it should fit" was not enough for me to spend $300 bucks on their trans crossmember with an adapter.

Hey 67 church, the ls1 in my 63 chevy II sits back toward the firewall like you mentioned. Do you make a trans crossmember that will work with a 4l60e?

Hey 67 church, the ls1 in my 63 chevy II sits back toward the firewall like you mentioned. Do you make a trans crossmember that will work with a 4l60e?

#48

Yes I have one in the works. Here is a mock up of what I used when we designed the headers and 3" exhaust.

That is 3" tubing with approximately 3/8" spacer between the pipe and cross member. Here is a link showing the rest of the mock up. The first few photos shows a Chassis works clip with our headers...after that is the initial mock up of the LS and a stock clip with our rack.

http://s274.photobucket.com/albums/j...cpZZ1QQtppZZ16

That is 3" tubing with approximately 3/8" spacer between the pipe and cross member. Here is a link showing the rest of the mock up. The first few photos shows a Chassis works clip with our headers...after that is the initial mock up of the LS and a stock clip with our rack.

http://s274.photobucket.com/albums/j...cpZZ1QQtppZZ16

#49

#50

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

#51

Haha, That's BTO's "go to" answer. I decided to take the chance and well, I paid for it in the pocketbook and frustration with them. This is the crossmember that another Nova guy, Tom, recommended Adjustable crossmember. I remember he said it fit nicely with his 4L60E since it was adjustable.

#52

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

My passenger side head is about an inch from the firewall. If the CW positions your engine in the same spot, I suppose it could work? Either way, hope you find something that works!

#53

I have been working on both cross members. 700 and 4l60. I had hoped that one could be used for both. However, that is not the case they are completely different.

As far as moving the engine back. You can not go any further back with the engine than when using the mounts that allow the bottom bolt on the engine mount to pass thru the adapter plate and into the block. I tried the plates that allow you to move the engine an 1" further back. It puts the engine in contact with the fire wall. In my opinion if the lower motor mount shares the same bolt hole as the adapter plate, this would be a neutral position.

The adapter plates that Chevykid has with his headers are what I am referring to.

As far as moving the engine back. You can not go any further back with the engine than when using the mounts that allow the bottom bolt on the engine mount to pass thru the adapter plate and into the block. I tried the plates that allow you to move the engine an 1" further back. It puts the engine in contact with the fire wall. In my opinion if the lower motor mount shares the same bolt hole as the adapter plate, this would be a neutral position.

The adapter plates that Chevykid has with his headers are what I am referring to.

#54

I'm waiting on you

...let me know if you need any pictures or measurements

...let me know if you need any pictures or measurements

#55

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

#57

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

August 10, 2011

Money in my pocket, It's gonna be Christmas in August for parts!

Ordered all my fuel system parts and starting to look into wiring harnesses. Tom, another nova guy on the site, recommends Techrods for a custom wiring harness. I'll post more info when I research that. Meanwhile, here is a link to my fuel system thread. Hope this is helpful!

FUEL SYSTEM DIAGRAM

Money in my pocket, It's gonna be Christmas in August for parts!

Ordered all my fuel system parts and starting to look into wiring harnesses. Tom, another nova guy on the site, recommends Techrods for a custom wiring harness. I'll post more info when I research that. Meanwhile, here is a link to my fuel system thread. Hope this is helpful!

FUEL SYSTEM DIAGRAM

#58

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

December 18, 2011

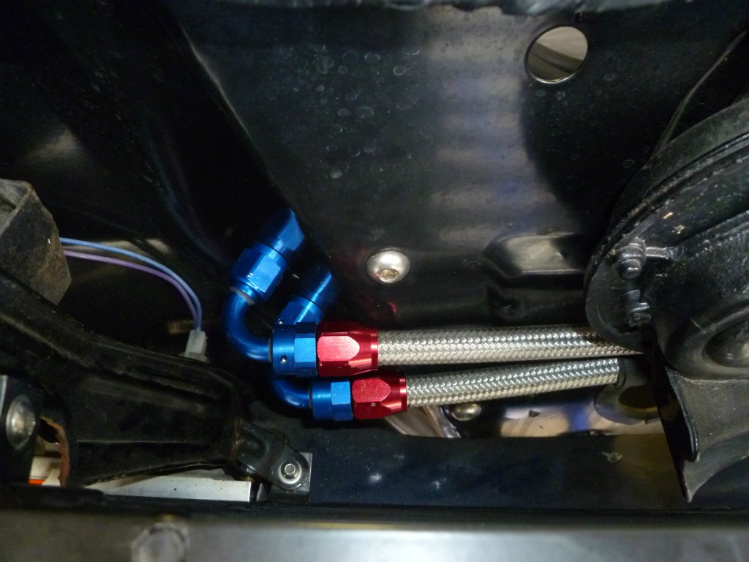

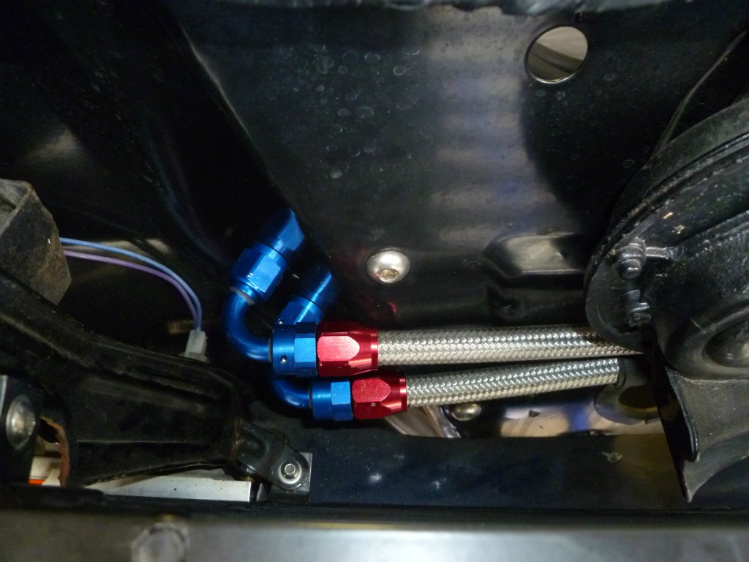

Sooo... a lot of work is getting done, I've just been slacking on the updates lately. The fuel system diagram link above was more of a guide than anything else. I ended up using a bunch of different AN fittings. Anyway, I'll start where I left off with the fuel system.

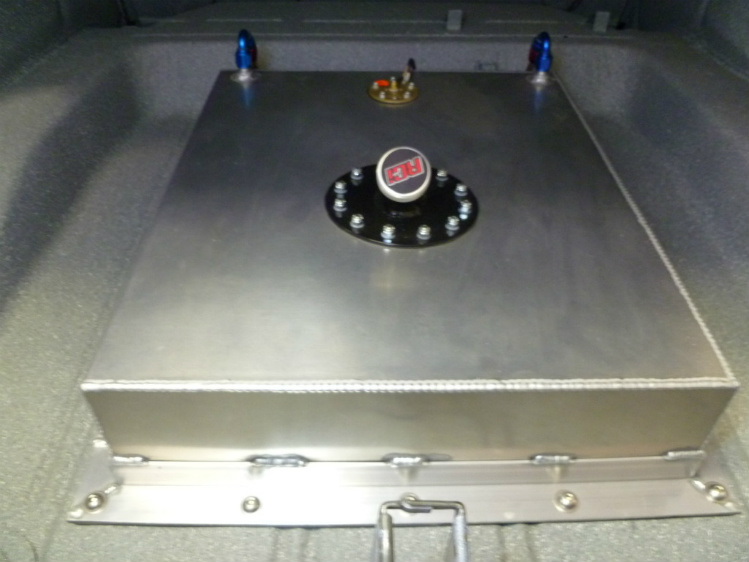

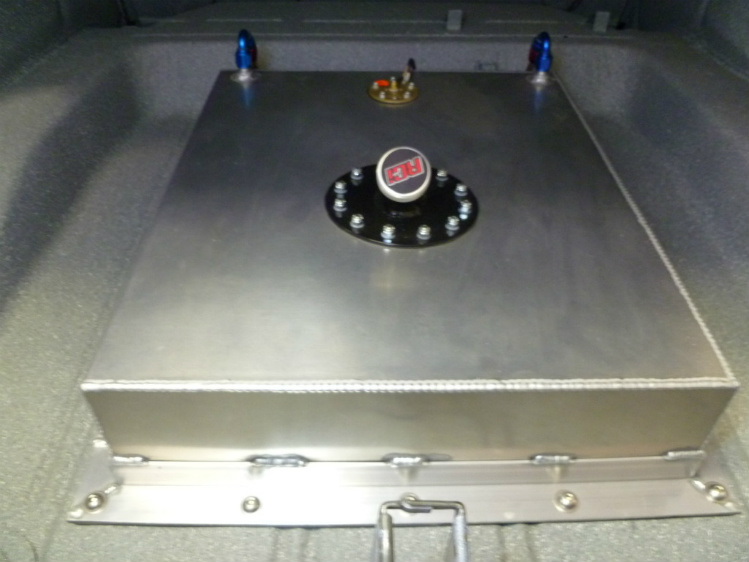

The 16 gallon stock tank was not working for me so I opted for a larger fuel cell.

Made up some brackets, cut the trunk floor out, painted, and put in a new battery box.

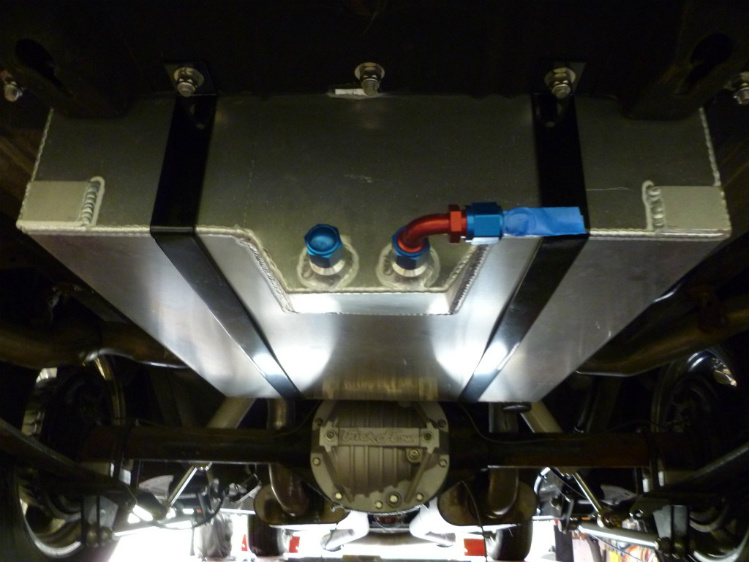

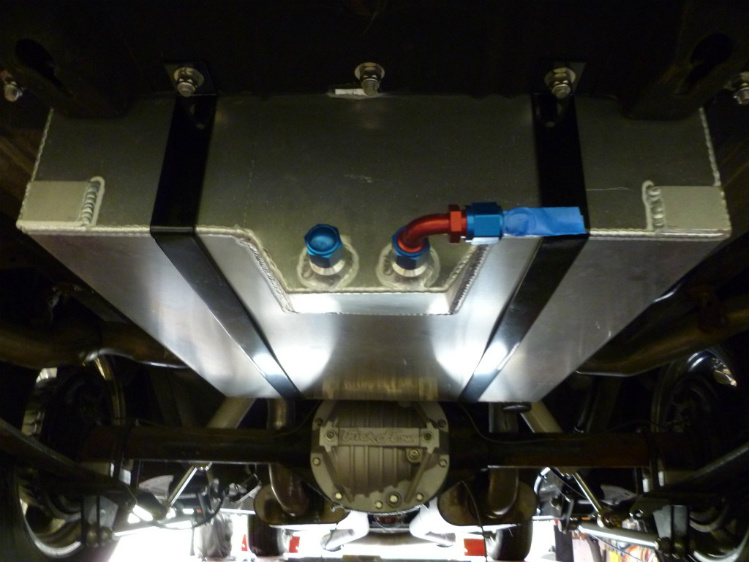

Bent up some steel straps, had them powder coated, and installed them under the tank for some support.

Walbro fuel pump and Earls pre-filter installed

Corvette filter regulator mounted next to the passenger side rear wheel along the frame rail. See the link above for the part number.

Return line routed through the floor to the tank from the filter regulator

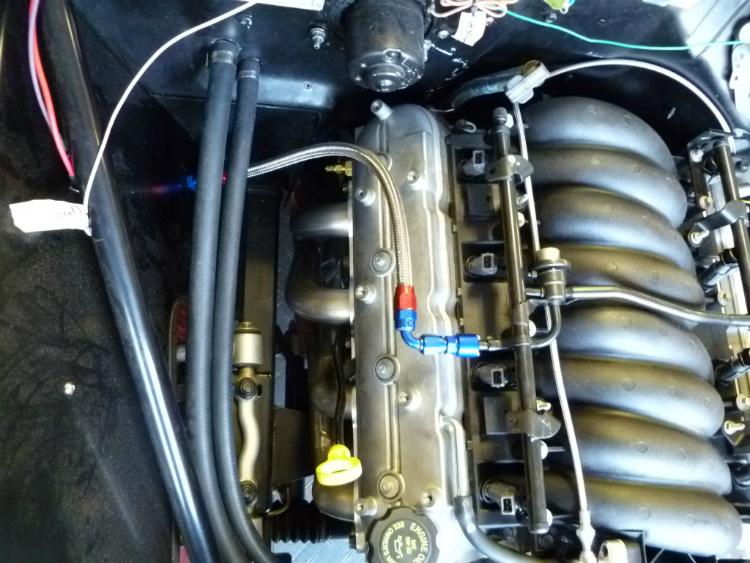

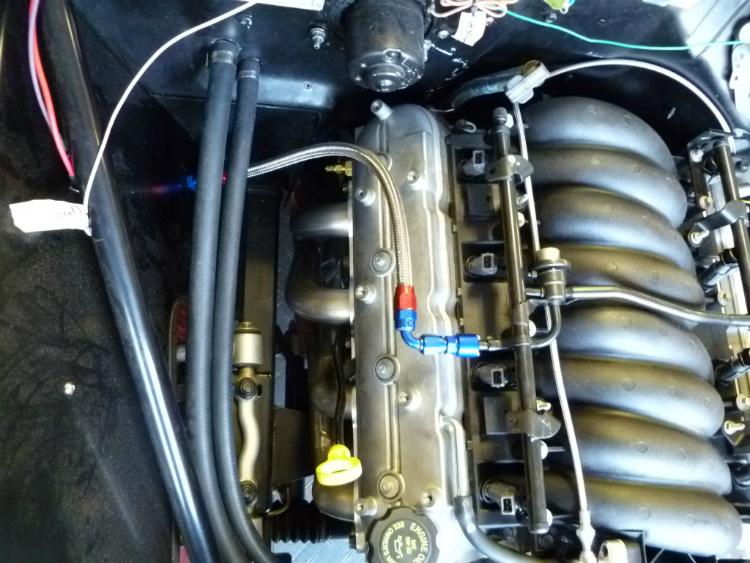

I turned the fuel rail around to plumb all the fuel lines on the passenger side. I used the braided stainless line only for the engine compartment, then back to the twist lok fittings. Again, part numbers are listed on the fuel system diagram link above.

When I was installing the fuel rail fitting to 6AN adapter, I didn't have the little, plastic, locking piece in the adapter. I wasn't sure if it was missing from the manufacturer, I lost it, or broke it so I called up Russell Performance (talked to a guy named "Smitty") and they sent one out to me free of charge. Great customer service. They'll definitely keep me as a customer.

Sooo... a lot of work is getting done, I've just been slacking on the updates lately. The fuel system diagram link above was more of a guide than anything else. I ended up using a bunch of different AN fittings. Anyway, I'll start where I left off with the fuel system.

The 16 gallon stock tank was not working for me so I opted for a larger fuel cell.

Made up some brackets, cut the trunk floor out, painted, and put in a new battery box.

Bent up some steel straps, had them powder coated, and installed them under the tank for some support.

Walbro fuel pump and Earls pre-filter installed

Corvette filter regulator mounted next to the passenger side rear wheel along the frame rail. See the link above for the part number.

Return line routed through the floor to the tank from the filter regulator

I turned the fuel rail around to plumb all the fuel lines on the passenger side. I used the braided stainless line only for the engine compartment, then back to the twist lok fittings. Again, part numbers are listed on the fuel system diagram link above.

When I was installing the fuel rail fitting to 6AN adapter, I didn't have the little, plastic, locking piece in the adapter. I wasn't sure if it was missing from the manufacturer, I lost it, or broke it so I called up Russell Performance (talked to a guy named "Smitty") and they sent one out to me free of charge. Great customer service. They'll definitely keep me as a customer.

Last edited by NovaKid; 01-01-2012 at 05:06 PM. Reason: Updates

#59

On The Tree

Thread Starter

Join Date: Sep 2010

Location: San Luis Obispo CA

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

December 18, 2011

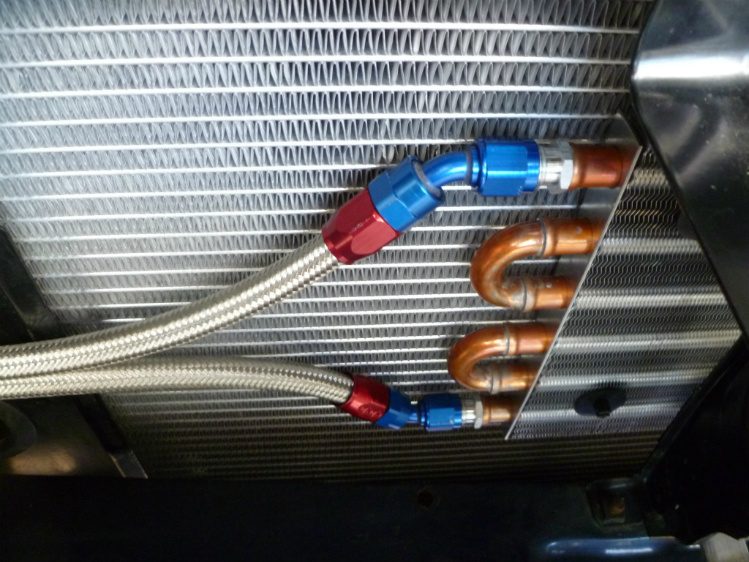

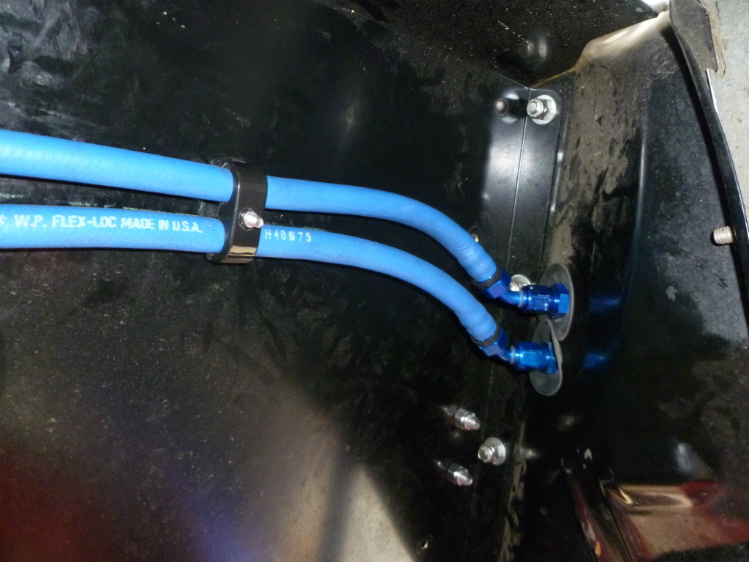

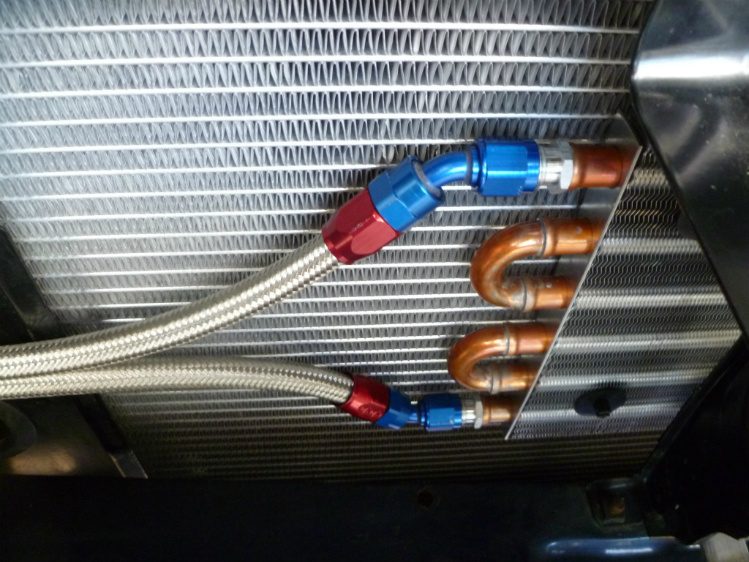

I installed all the transmission cooler lines a month ago and for the most part, everything went smoothly. The hardest part was trying to figure out where to route them.

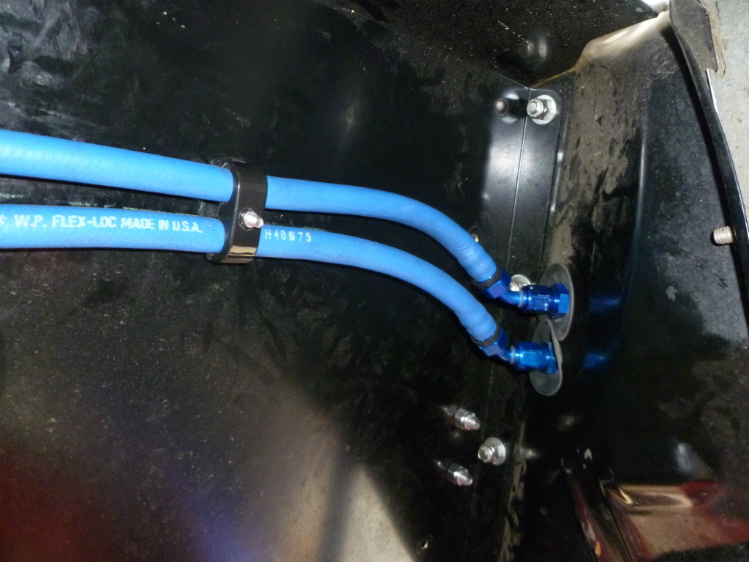

I was debating whether to use the "twist tite/twist lok" fittings, or braided stainless AN fittings. After talking to several transmission shops and the manufacturer themselves, they said the twist lok fittings would withstand the temperatures and pressures of the transmission cooler lines without a problem. When installing the the twist lok fittings, I would definitely recommend heating the end of the hose with a heat gun and adding a little oil to the inside of the hose before sliding/twisting it onto the barbed fitting... it makes life a lot easier! Here are a few pics:

Since the trans cooler was visible behind the grille, I wanted a cleaner look so I only used AN fittings for this part.

Ran the lines into the inner fender area.

Twist Lok hose and fittings mounted under the passenger side fender.

I installed all the transmission cooler lines a month ago and for the most part, everything went smoothly. The hardest part was trying to figure out where to route them.

I was debating whether to use the "twist tite/twist lok" fittings, or braided stainless AN fittings. After talking to several transmission shops and the manufacturer themselves, they said the twist lok fittings would withstand the temperatures and pressures of the transmission cooler lines without a problem. When installing the the twist lok fittings, I would definitely recommend heating the end of the hose with a heat gun and adding a little oil to the inside of the hose before sliding/twisting it onto the barbed fitting... it makes life a lot easier! Here are a few pics:

Since the trans cooler was visible behind the grille, I wanted a cleaner look so I only used AN fittings for this part.

Ran the lines into the inner fender area.

Twist Lok hose and fittings mounted under the passenger side fender.