Intake manifold reversal on AFM/DOD engine

#1

Guys I have an Gen IV LC9 5.3 with an LS2 intake manifold for a project of mine. Problem is I need to reverse the intake manifold on it (180 degrees) but if I do that the Oil pressure sender is in the way along with the plug for the DOD/AFM I have not lifted the valley cover yet, but is there an easy way around this??

I want to retain the use of the AFM/DOD too.

I want to retain the use of the AFM/DOD too.

#4

TECH Resident

iTrader: (1)

Here is my LS2 intake on a DoD 5.3 with it flipped around... (transverse installation with a 6 speed manual in the back of a fiero)

Even with the OPSU boss cut down about 1/2" in this picture, you can see the valley cover needs to come down another 3/8" to be able to fit... this is going to take a bunch of work!

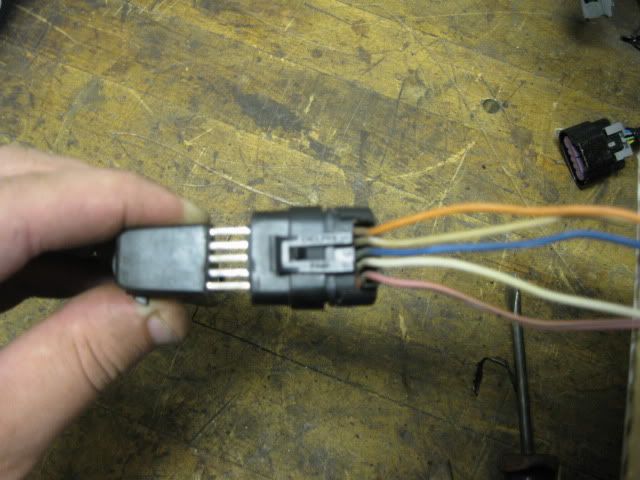

First thing under the knife was the connector. Right behind the flange for the connector, I gently cut through the plastic and eventually was able to pry the end off exposing the 5 terminals:

Call me finicky... but I wanted to know the OEM wire colors for this connection so the new wires (recycled from other GM harnesses) can match.

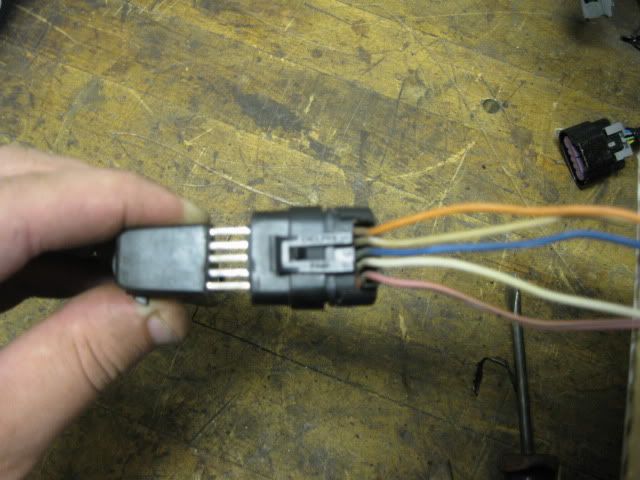

New wires (about 24" in length - way too long) soldered to the appropriate terminals:

Heat shrink x2:

Now onto the OPSU - it will be relocated entirely: I had already cut it down about 1/2" and cut it down another 3/8" to expose the oil passage while still leaving material to drill a new oil passage.

New oil passage:

Then the top side of the OPSU boss was welded up to close up the passages. Here is a finished pic of the welded OPSU and the modified connector:

Sadly, the LS2 intake isn't going to accept installation without a fight! Even with the modifications above, it still would not fit and it was time to modify the intake.

Lower ribs flattened and the area of the connector and OPSU was cut open:

But now the bastard can be installed w/o interference:

Even with the OPSU boss cut down about 1/2" in this picture, you can see the valley cover needs to come down another 3/8" to be able to fit... this is going to take a bunch of work!

First thing under the knife was the connector. Right behind the flange for the connector, I gently cut through the plastic and eventually was able to pry the end off exposing the 5 terminals:

Call me finicky... but I wanted to know the OEM wire colors for this connection so the new wires (recycled from other GM harnesses) can match.

New wires (about 24" in length - way too long) soldered to the appropriate terminals:

Heat shrink x2:

Now onto the OPSU - it will be relocated entirely: I had already cut it down about 1/2" and cut it down another 3/8" to expose the oil passage while still leaving material to drill a new oil passage.

New oil passage:

Then the top side of the OPSU boss was welded up to close up the passages. Here is a finished pic of the welded OPSU and the modified connector:

Sadly, the LS2 intake isn't going to accept installation without a fight! Even with the modifications above, it still would not fit and it was time to modify the intake.

Lower ribs flattened and the area of the connector and OPSU was cut open:

But now the bastard can be installed w/o interference:

#6

TECH Resident

iTrader: (1)

You could remove the DoD connector entirely and test fit the intake to see if the intake would fit w/o it there.

If it does (and it should), then you could cut the DoD connector below the valley cover and solder on the wires below the cover. Then have just the wires come out the valley cover hole, or even drill a new hole for the wires off to the side to clear the intake.

If it does (and it should), then you could cut the DoD connector below the valley cover and solder on the wires below the cover. Then have just the wires come out the valley cover hole, or even drill a new hole for the wires off to the side to clear the intake.

Trending Topics

#8

TECH Resident

iTrader: (1)

By block is an LS4 with the smaller metric bellhousing, so I drilled and tapped the block to mount the oil pressure sender about 3" lower than the original location. You could drill/tap the oil bypass plate on the oil pan and mount it there, but that is where I am placing the sender for the gauges.