Garage Built AWD Camaro

#61

its there or at least close to enough room for it. look at the level where the governor cover is. then look at the finished floor.. it caries over

#62

I was actually researching about doing a similar project and ran across this page. Good job with the build so far. I am going to do a tube frame awd rear engine car using the bw 4472 t case. Im still going to gamble with the front bias due to the history of that case being in some awesome trucks. However I would look into the nvg 149 transfer case it's full time awd and places up to 100% of the torque where its needed but is going to be front biased under normal driving conditions in rear engine. I'm going to have one as a backup. Haven't done much research on it but so far looks promising.

#63

On The Tree

Thread Starter

I had looked at the NVG 149 as well. Both that and the BW 4472 are identical in function, torque bias and input shaft spline count. Both should be able to handle 500+ hp that I am shooting for and my estimated final curb weight of 3900 lbs.

I went with the BW 4472 simply to save $$$. I picked mine up for $100.00, and in my area I could easily get another for the same. NVG 149's are holding strong at $800.00. Since they have simular torque bias and function the same, I cut my cost by using the more readily avalible unit.

Plus, the sy/ty guys don't modify these at all in 10 sec builds. A BW 4472 will be plenty strong for what I have in mind....

I went with the BW 4472 simply to save $$$. I picked mine up for $100.00, and in my area I could easily get another for the same. NVG 149's are holding strong at $800.00. Since they have simular torque bias and function the same, I cut my cost by using the more readily avalible unit.

Plus, the sy/ty guys don't modify these at all in 10 sec builds. A BW 4472 will be plenty strong for what I have in mind....

#64

I'll plan on getting started with this project once I get home from the outage season then I will hopefully have the funds and plenty of time to work on it. I might start with the 149 just to have a different angle though I have much respect for the 4472. Ill probably run both on the 1/4 to see if times change drastically. We will see this summer for sure. Im going tube frame to try and keep it under 3000lbs and so I can have a custom design. It could also be a huge failure too so I'll keep ya posted.

#66

On The Tree

Thread Starter

Good luck with your project, I look forward to seeing what you come up with.

#67

On The Tree

Thread Starter

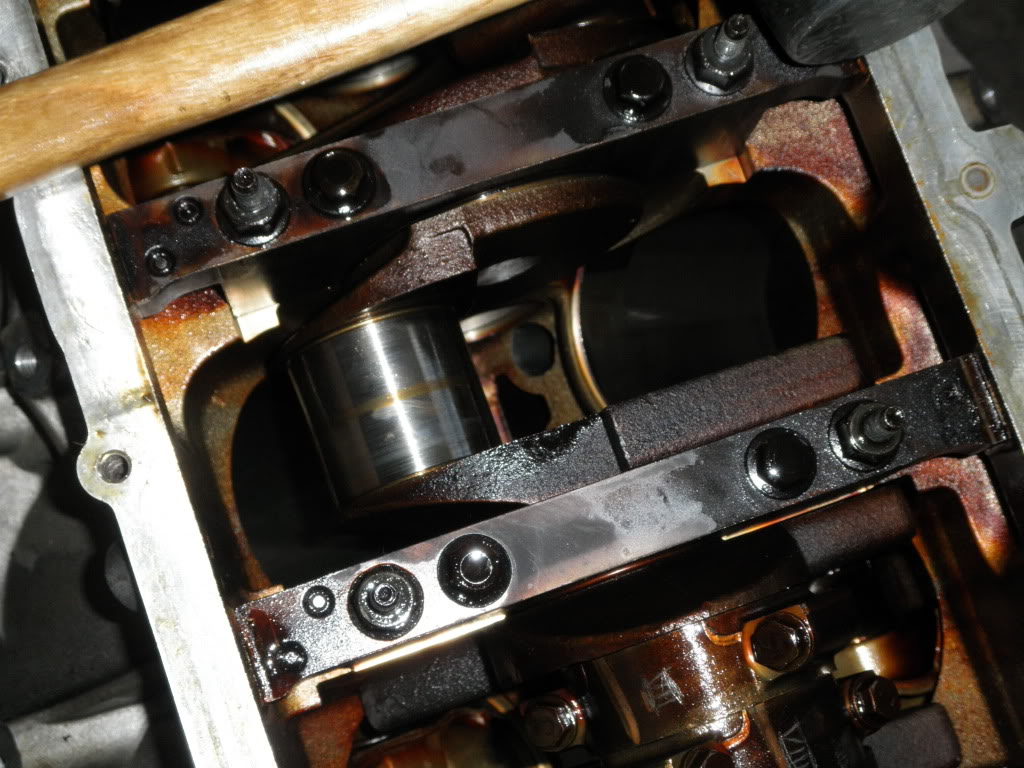

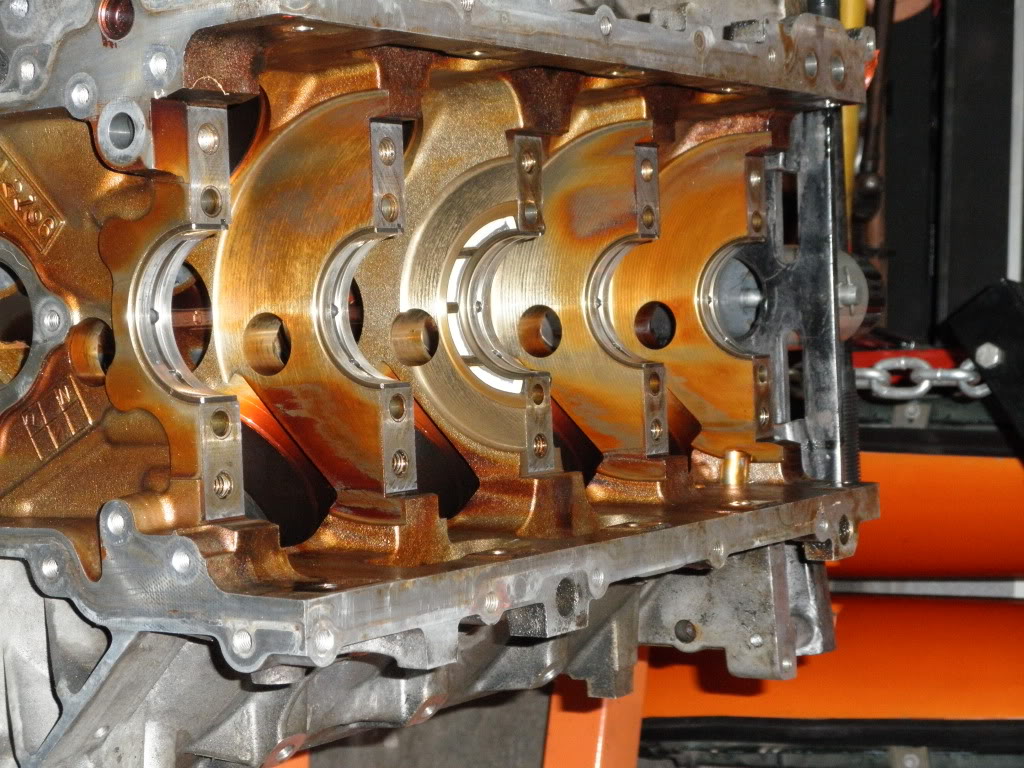

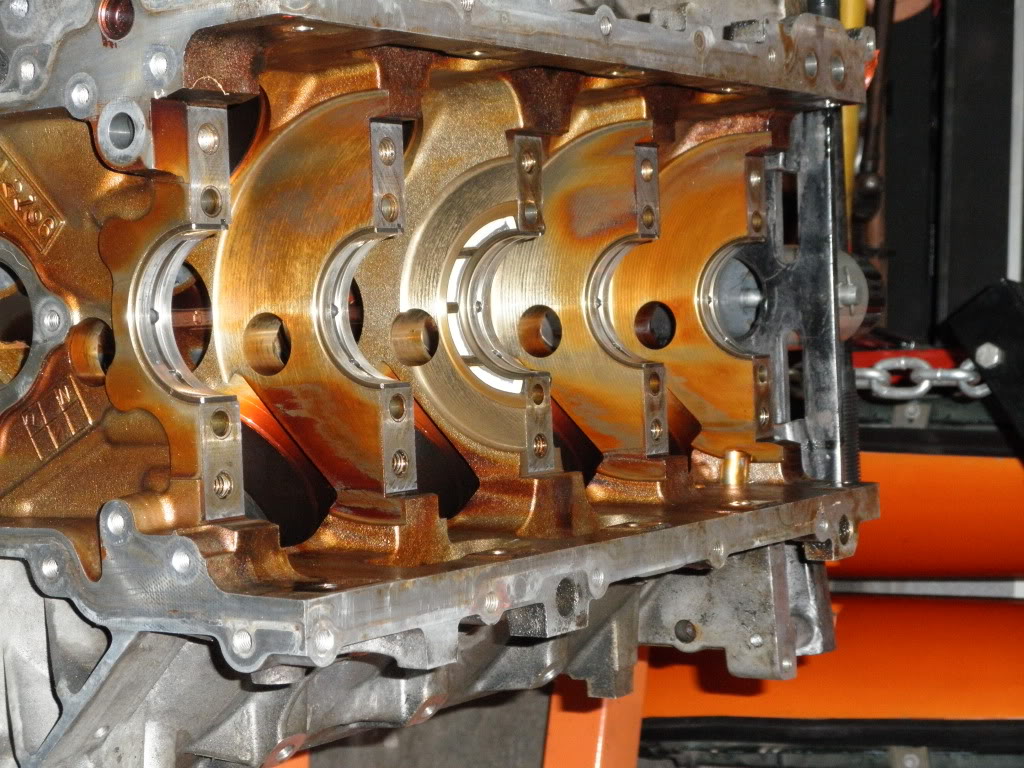

Kept busy this past weekend by tearing down my LS1 and 4L-80E for the project. I knew both needed rebuilt when I picked them up, which is fine with me. I like doing my own work.

The thrust bearing has minor wear, and the journals look great.

Starting to think the marks in #8 can be honed out, walls are pretty thick yet. I can still see factory hone marks in most of the cylinders.

Will send it out to the machinist later. If honing fixes it; new pistons, LS6 heads, and an Edlebrock XT intake. If it needs sleeved; Darton MID system, LS3 heads, and a holley tunnel ram intake. Regardless of the block; reusing the crank, stronger rods, and a cam and computer from MAST.

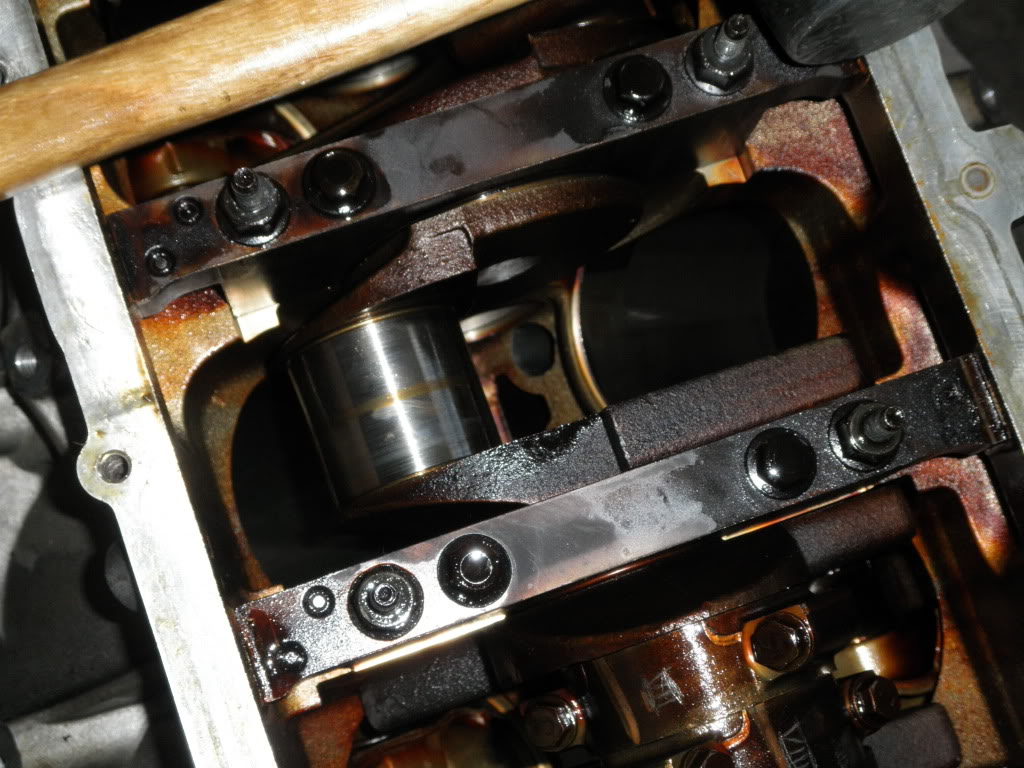

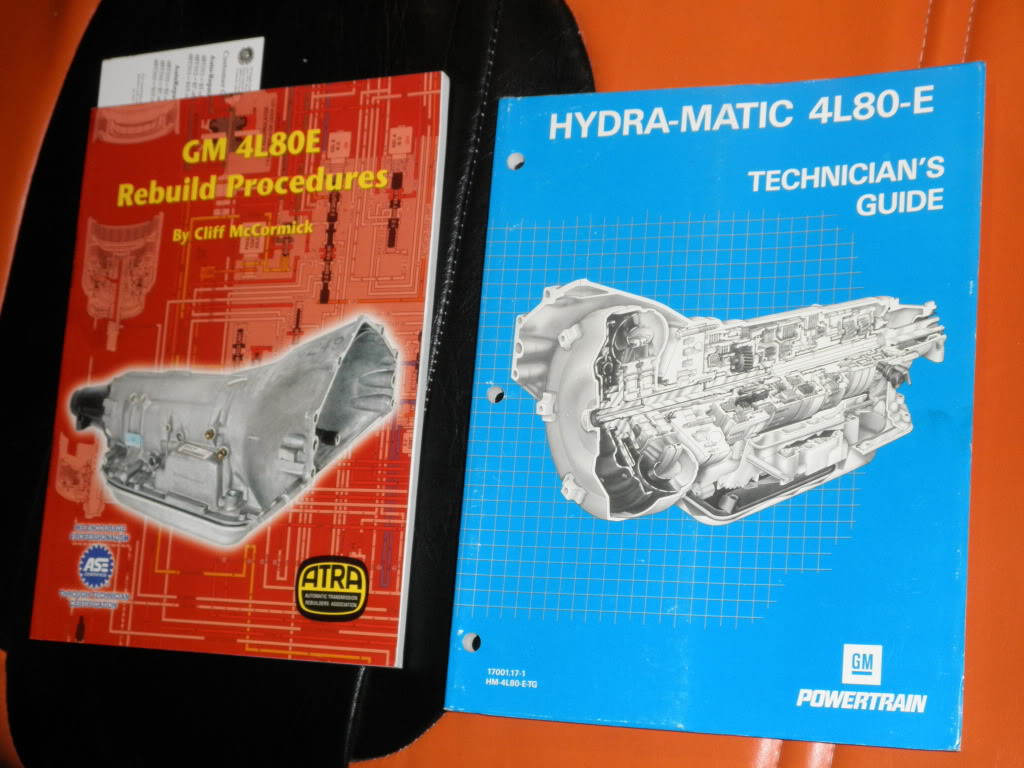

And on to the 4L-80E, this thing definetly needed a rebuild...

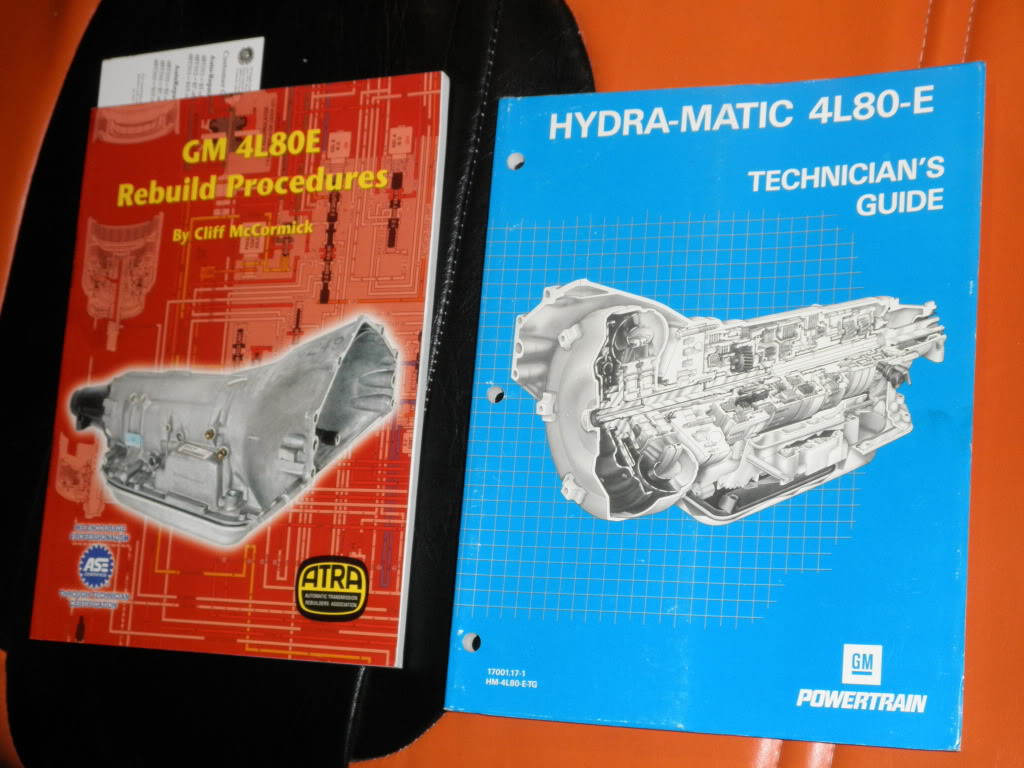

If you can get them, these are great guides to use for a rebuild.

And tear-down complete.

I didn't find any show stoppers, looks like the clutches were burnt out. Since I'm only shooting for 500-ish hp, this rebuild will be pretty basic. Match a converter to the cam, manual valve body, basic rebuild kit, and the adapter set for the transfer case.

Depending on how the block turns out, I think I can drop $2,000.00 and 1 year from my project estimates. I had initially assumed the block would need re-sleeved. The last owner was pretty sure the rings were causing the cylinder damage, turns out that was not the case.

Well, back to the chassis.....

The thrust bearing has minor wear, and the journals look great.

Starting to think the marks in #8 can be honed out, walls are pretty thick yet. I can still see factory hone marks in most of the cylinders.

Will send it out to the machinist later. If honing fixes it; new pistons, LS6 heads, and an Edlebrock XT intake. If it needs sleeved; Darton MID system, LS3 heads, and a holley tunnel ram intake. Regardless of the block; reusing the crank, stronger rods, and a cam and computer from MAST.

And on to the 4L-80E, this thing definetly needed a rebuild...

If you can get them, these are great guides to use for a rebuild.

And tear-down complete.

I didn't find any show stoppers, looks like the clutches were burnt out. Since I'm only shooting for 500-ish hp, this rebuild will be pretty basic. Match a converter to the cam, manual valve body, basic rebuild kit, and the adapter set for the transfer case.

Depending on how the block turns out, I think I can drop $2,000.00 and 1 year from my project estimates. I had initially assumed the block would need re-sleeved. The last owner was pretty sure the rings were causing the cylinder damage, turns out that was not the case.

Well, back to the chassis.....

#68

9 Second Club

iTrader: (12)

I think you should make that statement your signature line. How many of the pessimists who took the liberty of spewing their negative comments in your build thread have ever disassembled/built an automatic transmission? Certainly your vision is not for everyone, but who am I or anyone else to try to pursuade you to to simply follow a mainstream LS1 engine swap.

Good luck with your build. Keep it fun. Take a break when you need to, and don't let yourself feel guilty on the days when you don't work on it. But most of all, stay active on the forums with detailed progress posts. It will help you stay motivated and focused and it shares knowledge both ways.

Good luck with your build. Keep it fun. Take a break when you need to, and don't let yourself feel guilty on the days when you don't work on it. But most of all, stay active on the forums with detailed progress posts. It will help you stay motivated and focused and it shares knowledge both ways.

#70

On The Tree

Thread Starter

Interesting idea for the signature...... will definetly think about it.

And as for the comments, good or bad, they are welcome here. They help me with the details, and keep me motivated. Some of the bad ones are funny, and they get funnier with the more work I get done.

And if you can't tell, this is not my 1st auto tran rebuild. Got more than afew 4L-60E's, 4T-60E's, and TH-400's behind my belt. The same can be said with engine rebuilds, I would say I've done about 9 every year since '98. Afew of those were even for a car instead of a helicopter

I plan on taking my time, and take plenty of notes too. I noticed their isn't a sticky in the tranny section for a 4L-80E rebuild. I just might have to post mine later on.....

And as for the comments, good or bad, they are welcome here. They help me with the details, and keep me motivated. Some of the bad ones are funny, and they get funnier with the more work I get done.

And if you can't tell, this is not my 1st auto tran rebuild. Got more than afew 4L-60E's, 4T-60E's, and TH-400's behind my belt. The same can be said with engine rebuilds, I would say I've done about 9 every year since '98. Afew of those were even for a car instead of a helicopter

I plan on taking my time, and take plenty of notes too. I noticed their isn't a sticky in the tranny section for a 4L-80E rebuild. I just might have to post mine later on.....

#73

Staging Lane

Join Date: Sep 2010

Location: Perth / Australia

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

This has been done by the factory in a GTO, 2004 year. Parts are avaliable in Australia there where 3 or 4 models that shared the drivetrain.......

Having one of these cars sitting in my drive I would say to anyone one the Forum is a AWD LS swap worth it??? Honestly NO!!!!!

Yes I see your engine in a different location, I talking mainly about the AWD concept, over this system how much extra weight will your design be?

Heavy steering, good in the wet but worth the effort, no not for the end result. Holden spent 125 million developing this system it keep it for 3 or 4 years.

I not trying to rain on your parade but $18,000 and 6 years, I would not finish it for what you'll get in the end.

Look at my F100 I'm not stopping anyone from thinking outside the square, but you have to ask what will all the work give???

The guys are saying Mid Engine , I say yes, parts are avaliable. It is different and yes its is a unique conversion.

check these links, its up to you just a thought from someone who is driving something you are trying to build.

http://www.italiaspeed.com/2007/moto.../prologue.html

http://youtu.be/E-RBwcbWs-k

Having one of these cars sitting in my drive I would say to anyone one the Forum is a AWD LS swap worth it??? Honestly NO!!!!!

Yes I see your engine in a different location, I talking mainly about the AWD concept, over this system how much extra weight will your design be?

Heavy steering, good in the wet but worth the effort, no not for the end result. Holden spent 125 million developing this system it keep it for 3 or 4 years.

I not trying to rain on your parade but $18,000 and 6 years, I would not finish it for what you'll get in the end.

Look at my F100 I'm not stopping anyone from thinking outside the square, but you have to ask what will all the work give???

The guys are saying Mid Engine , I say yes, parts are avaliable. It is different and yes its is a unique conversion.

check these links, its up to you just a thought from someone who is driving something you are trying to build.

http://www.italiaspeed.com/2007/moto.../prologue.html

http://youtu.be/E-RBwcbWs-k

Last edited by Thomo5150; 01-22-2012 at 04:34 AM.

#74

On The Tree

Thread Starter

Interesting car, I hadn't found that one during my research. Thanks for the post. I did find the holden AWD system when I was laying down my concept, and I passed on it.

I was concerned about having the space needed to fab up my suspension, with the engine and front diff all under the hood of the already tight 4th gen engine bay. Plus I found that the torsen t-3 t-case it comes with is expensive here, and doesn't have the track history the BW 4472 does. I found reverse cut ring and pinion gears, and my set-up ended up how it is.

Heavy steering, I think that is a relative issue. Heavy steering in a 3900lb car may be an issue for some, but is hardly noticable to guys like me who spend a part of the day driving Hemmits and LMTVs. That is heavy steering! I acually prefer firm steering, helps me feel the road.

BTW, nice F100. definetly an "outside the box" build! Look forward to seeing it finished.

I was concerned about having the space needed to fab up my suspension, with the engine and front diff all under the hood of the already tight 4th gen engine bay. Plus I found that the torsen t-3 t-case it comes with is expensive here, and doesn't have the track history the BW 4472 does. I found reverse cut ring and pinion gears, and my set-up ended up how it is.

Heavy steering, I think that is a relative issue. Heavy steering in a 3900lb car may be an issue for some, but is hardly noticable to guys like me who spend a part of the day driving Hemmits and LMTVs. That is heavy steering! I acually prefer firm steering, helps me feel the road.

BTW, nice F100. definetly an "outside the box" build! Look forward to seeing it finished.

#75

Staging Lane

Join Date: Sep 2010

Location: Perth / Australia

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

No problem, glad you took my opinion onboard, good luck with the build, BTW the Holden drivetrain has had 500hp motors running thru them for years now they are very strong......

#76

On The Tree

Join Date: Mar 2008

Location: Acworth, GA

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

Good luck! I've never heard of an AWD camaro before. That thing will be sweet when you get it finished!

I saw your pictures of the yarn where the bracing will get welded in and I have a question. If you'd have to service the engine/transmission later would it fit through the rear hatch or would it drop out from the bottom? I assume the bracing would get welded in but I guess they could be bolted in. Then again I would imagine feeding that thing through the door into the back would be a bear as well. Your project has my curiousity peaked.

Subscribed !!!

I saw your pictures of the yarn where the bracing will get welded in and I have a question. If you'd have to service the engine/transmission later would it fit through the rear hatch or would it drop out from the bottom? I assume the bracing would get welded in but I guess they could be bolted in. Then again I would imagine feeding that thing through the door into the back would be a bear as well. Your project has my curiousity peaked.

Subscribed !!!

#78

yeah irs needs to be part of it. irs would prevent the rear driveshaft from smashing the bottom of the oil pan. most truck front ends would do nicely flipped with the partial solid axle making the half shafts equal in length.

#79

though I guess you could incorporate some form of bump stop deal or mount the diff with a rotating arm that allows the diff to rotate but keeps it away from the engine. the offset diff. produces an issue there because there would be a lack of suspension travel on one side. truck front end allows usage of the original suspension which would save time and money