Speedway Alternator relocation bracket install (A-body)

#1

On The Tree

Thread Starter

iTrader: (18)

Join Date: Dec 2006

Location: Twin Cities, MN

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

I thought I would share my experiences / observations of the alternator relocation kit that you can buy from Speedway to date. As I get further into my build, I may add additional information as I complete the swap.

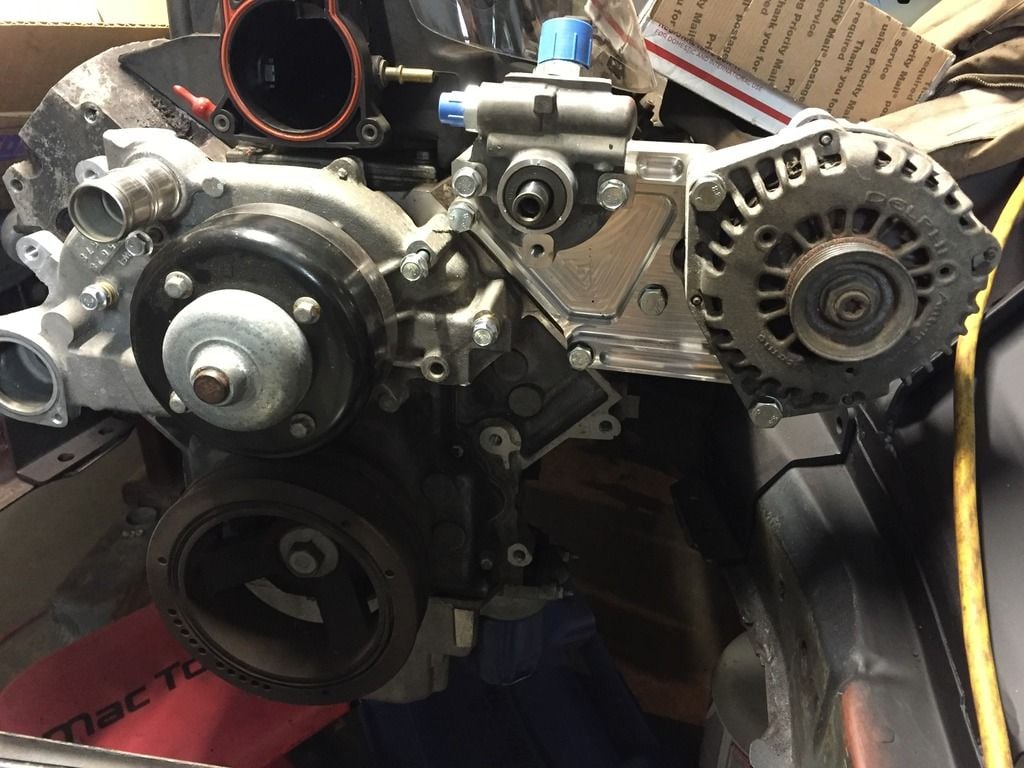

F-Body LS1 High Mount P/S and Alternator Mount Bracket kit

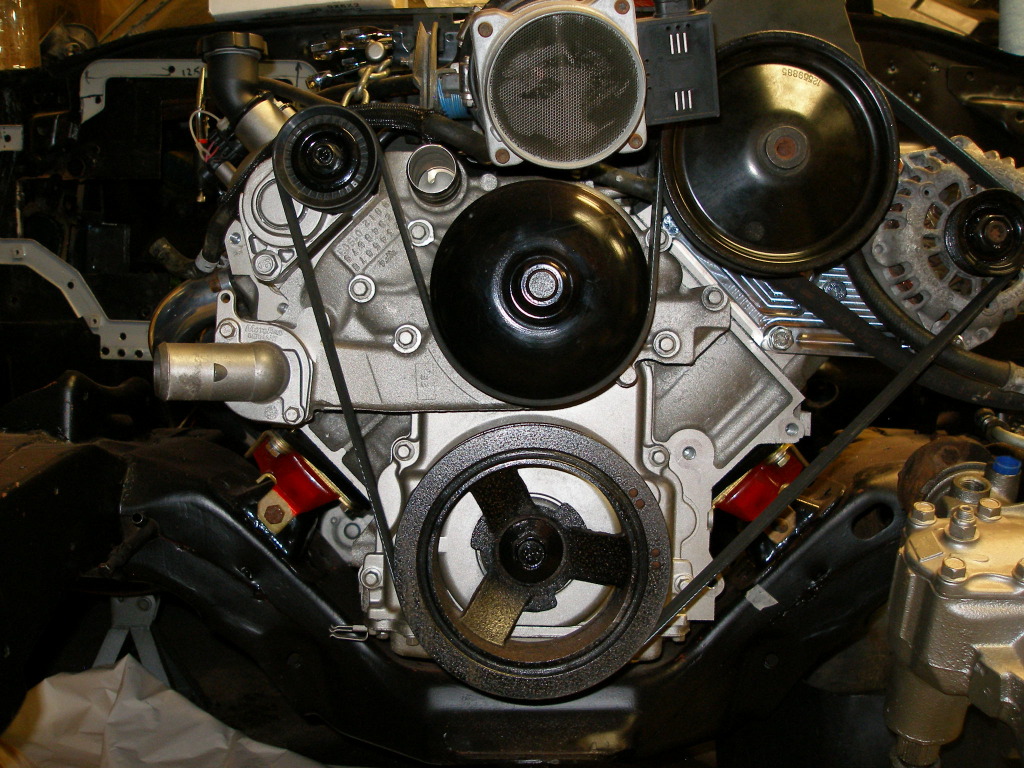

Before

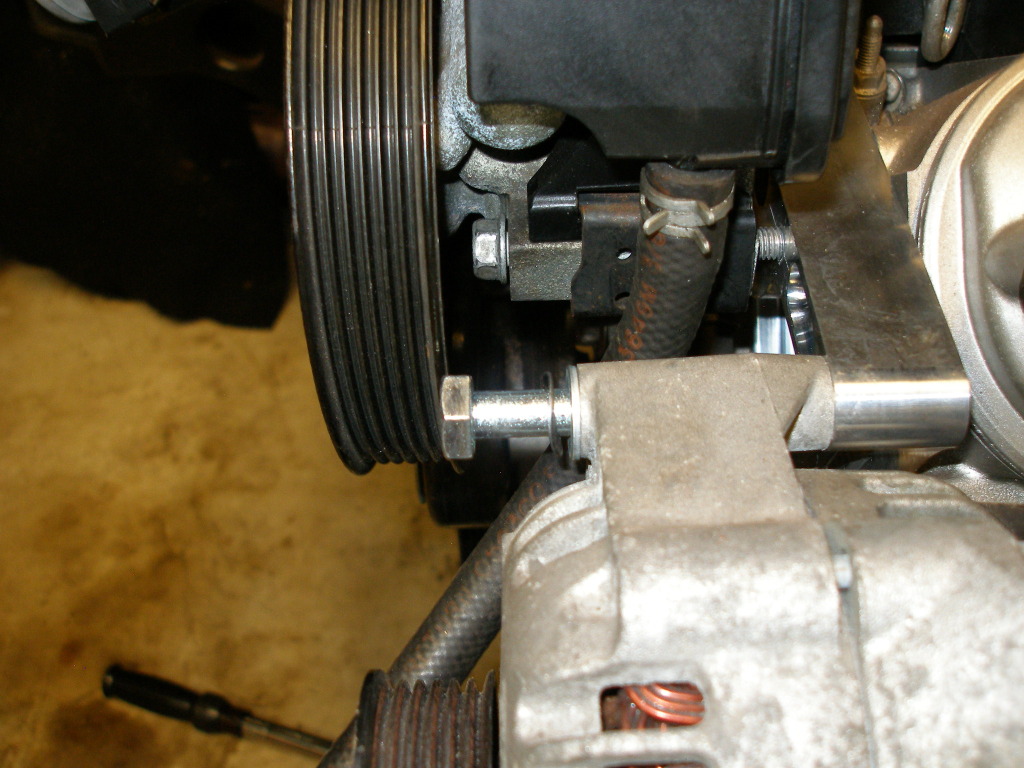

No room to move forward as I could not get the belt on or off the pulley easily.

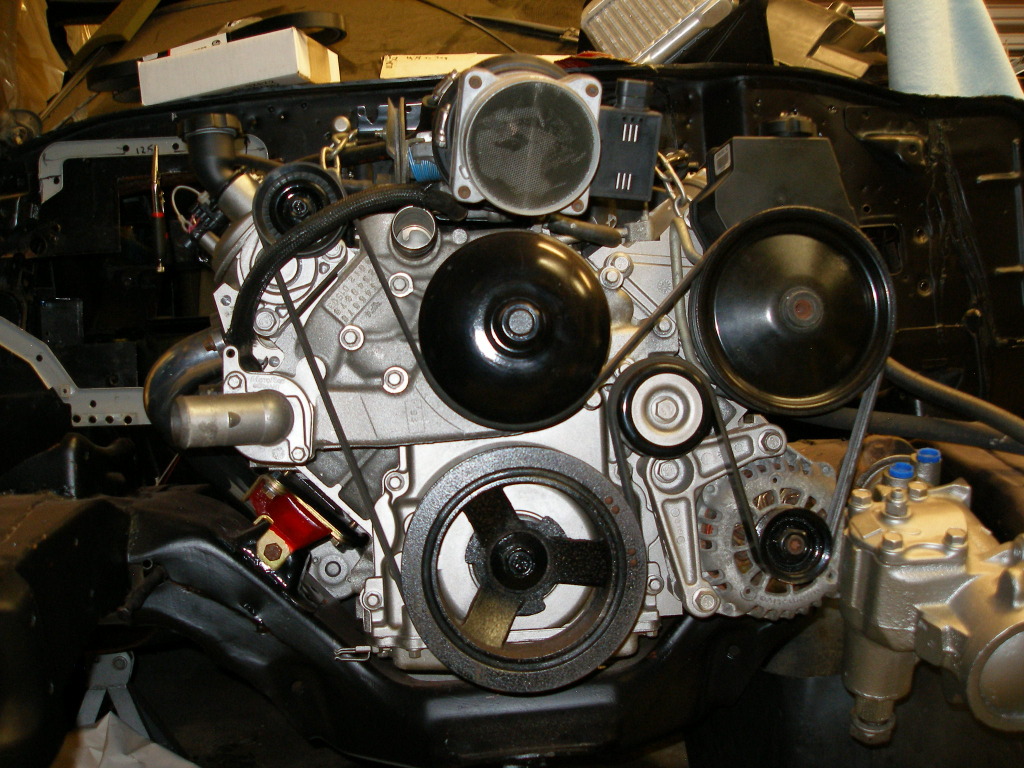

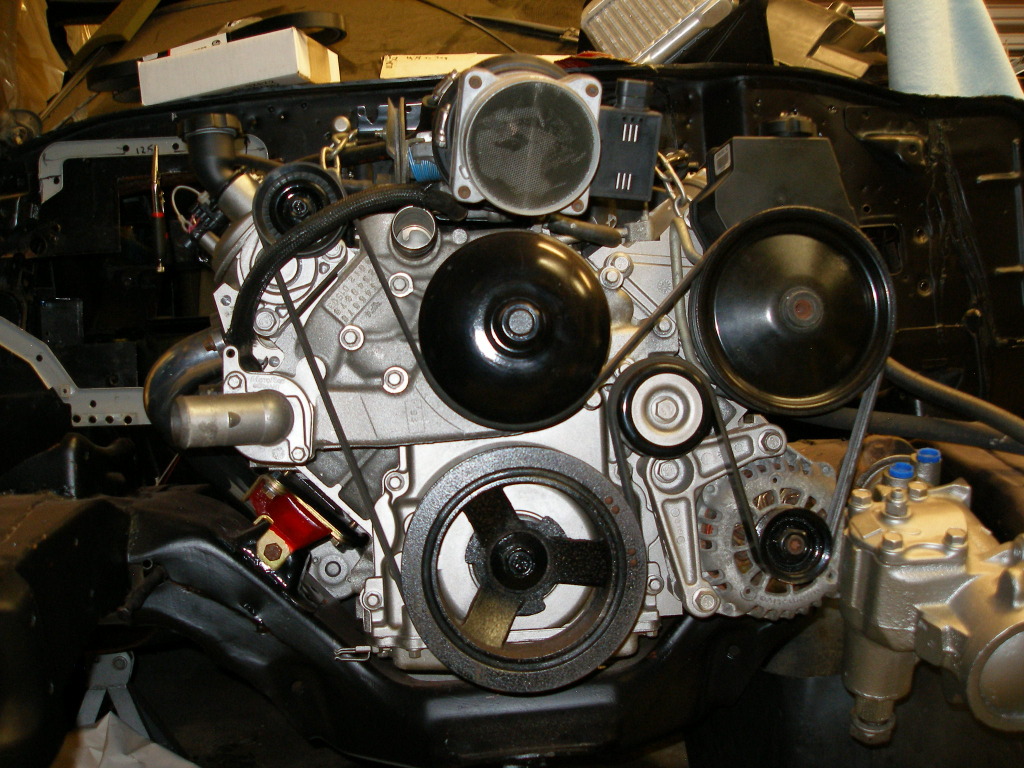

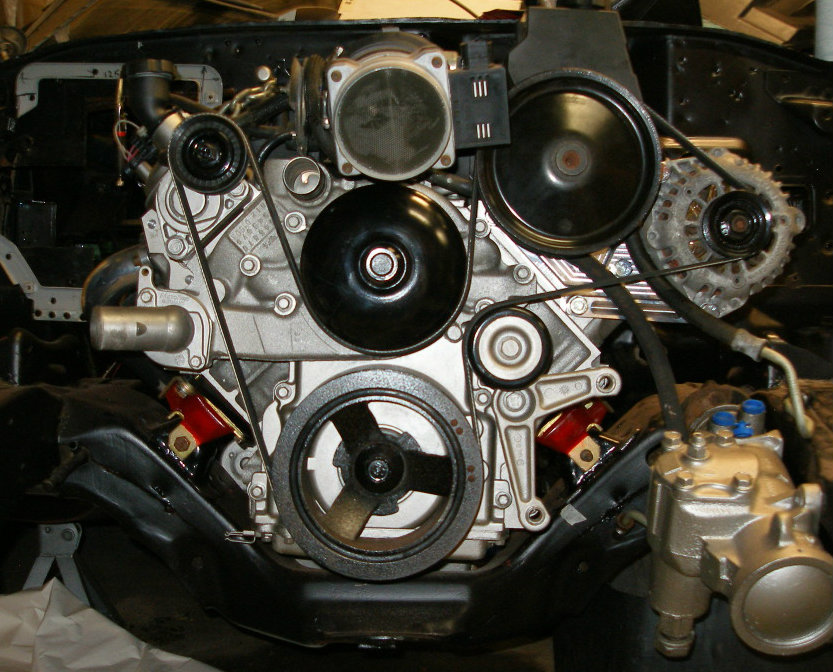

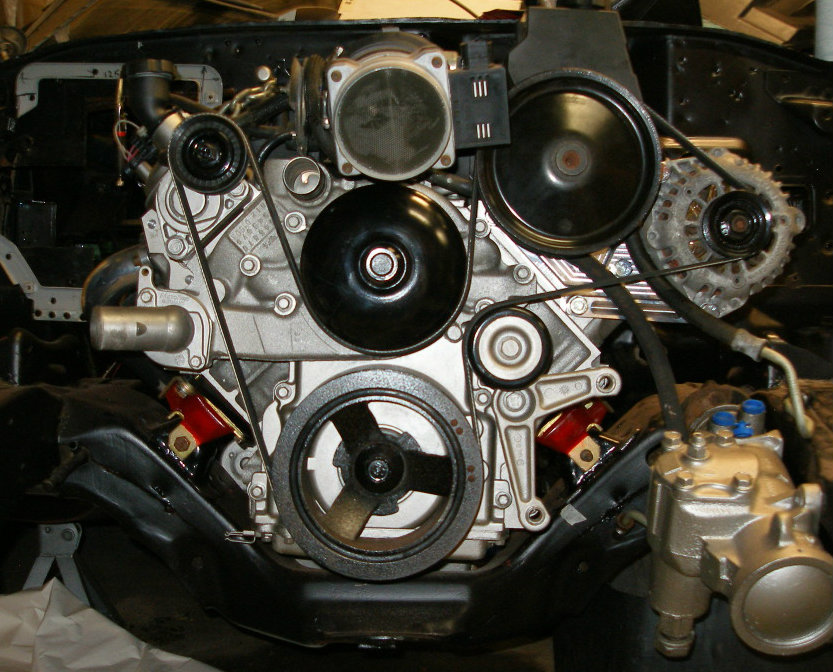

After. Now I can move the engine forward about 1/2"-3/4" for more clearance at the firewall (getting darn close)

Observations

Pro's

Solid aluminum machined bracket

hardware and new belt supplied

Eliminates alternator clearance issues with steering box, allowing more freedom for positioning of the engine.

Cons

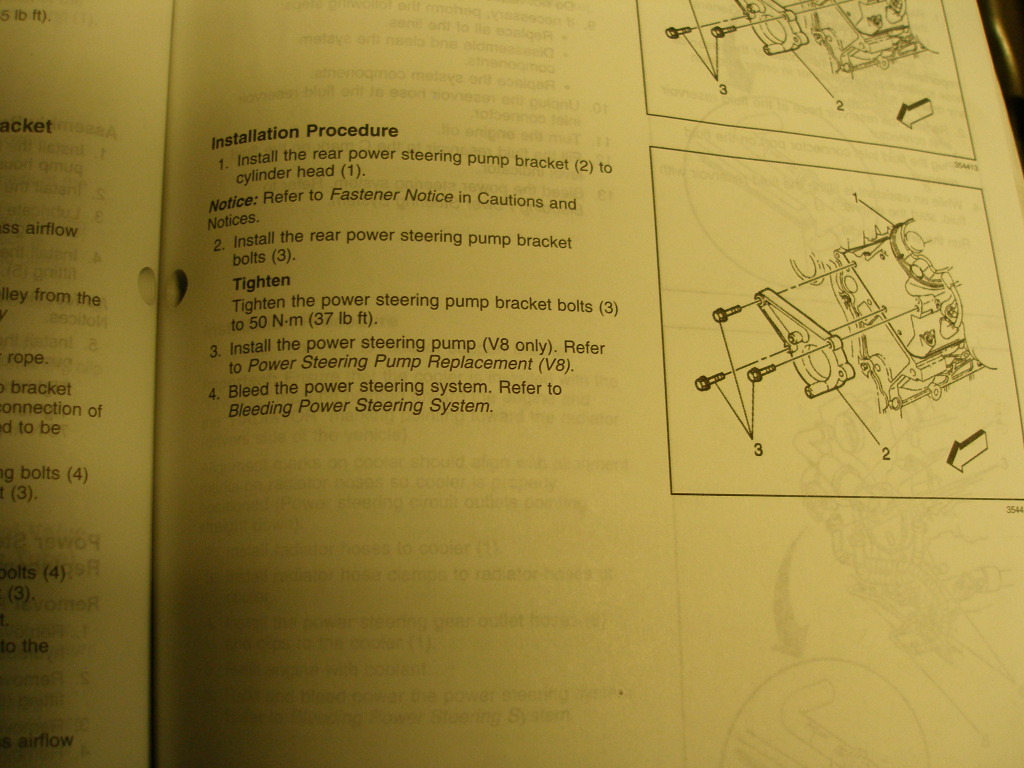

The instructions are absolutely terrible, no torque specs and no pictures or routing diagram of the new belt. You have to look at the parts and try and figure out what should go were and a couple of steps should be reversed.

Fortunaley, there are only four bolts. The longest bolt goes in the lowest hole fyi.

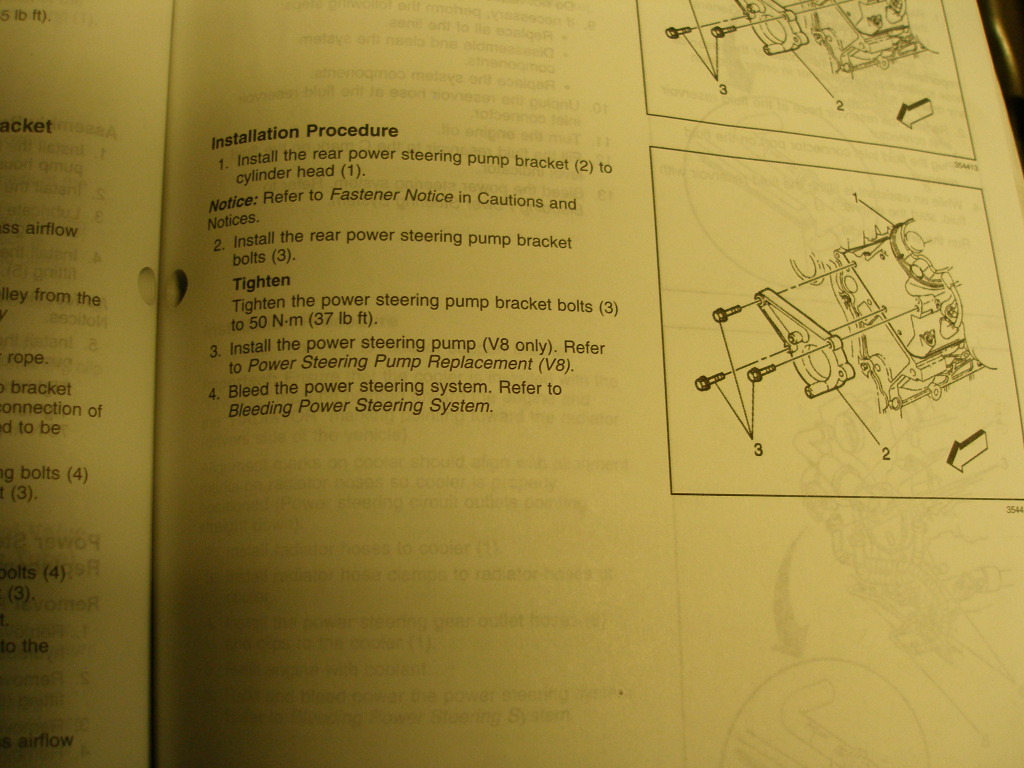

Thank god for a shop manual to get the torque specs.

You will need to tweak one of the power steering line as it want to share the same spot as the coolant line that runs to the throttle body. Nothing mentioned in the instructions.

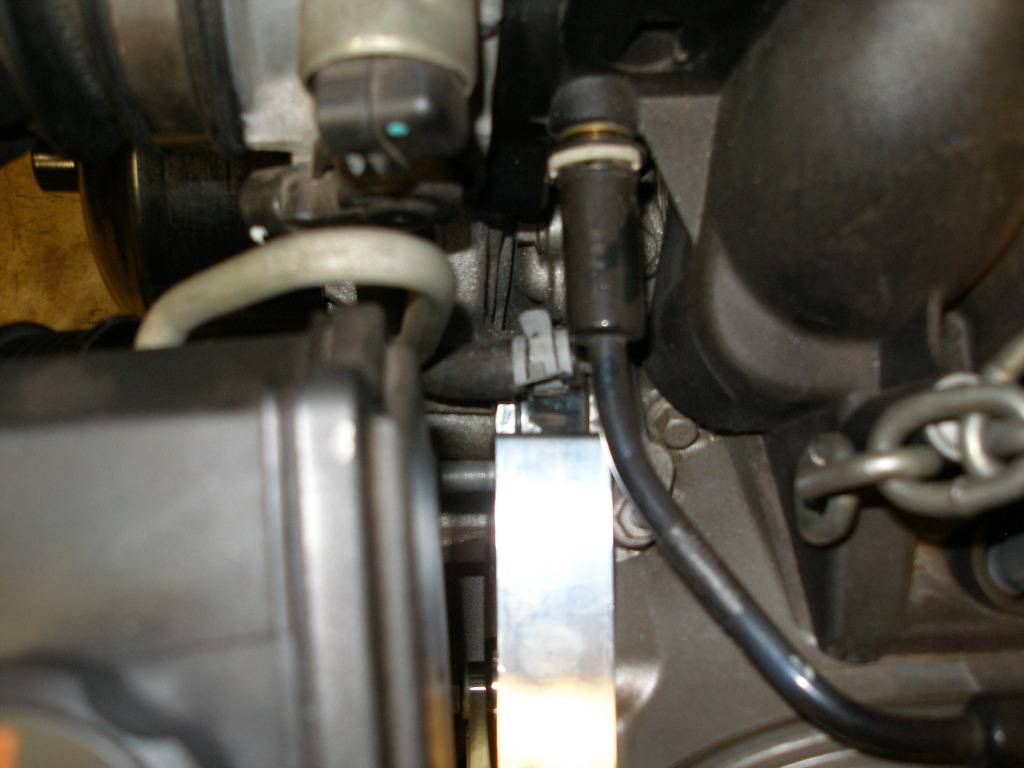

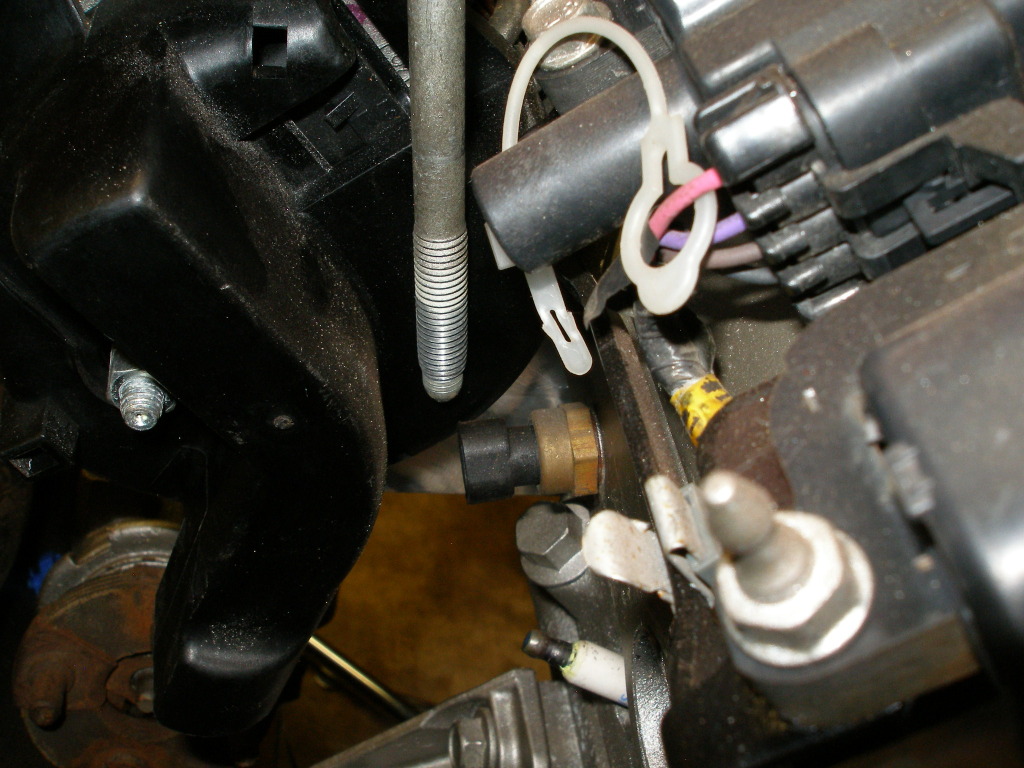

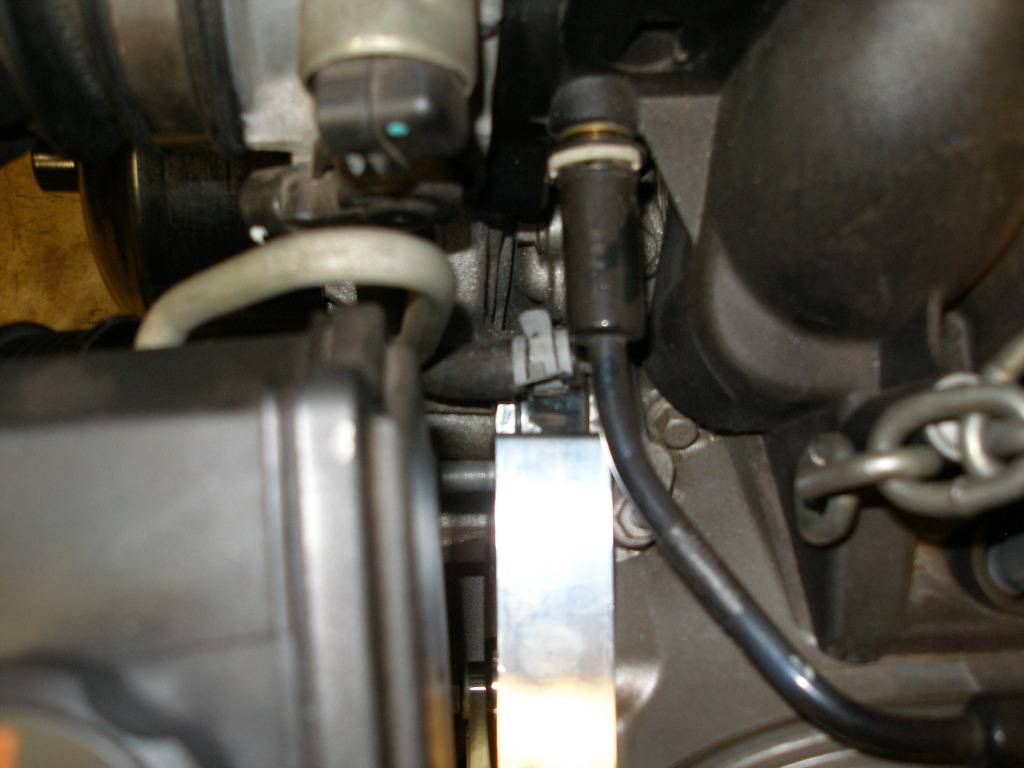

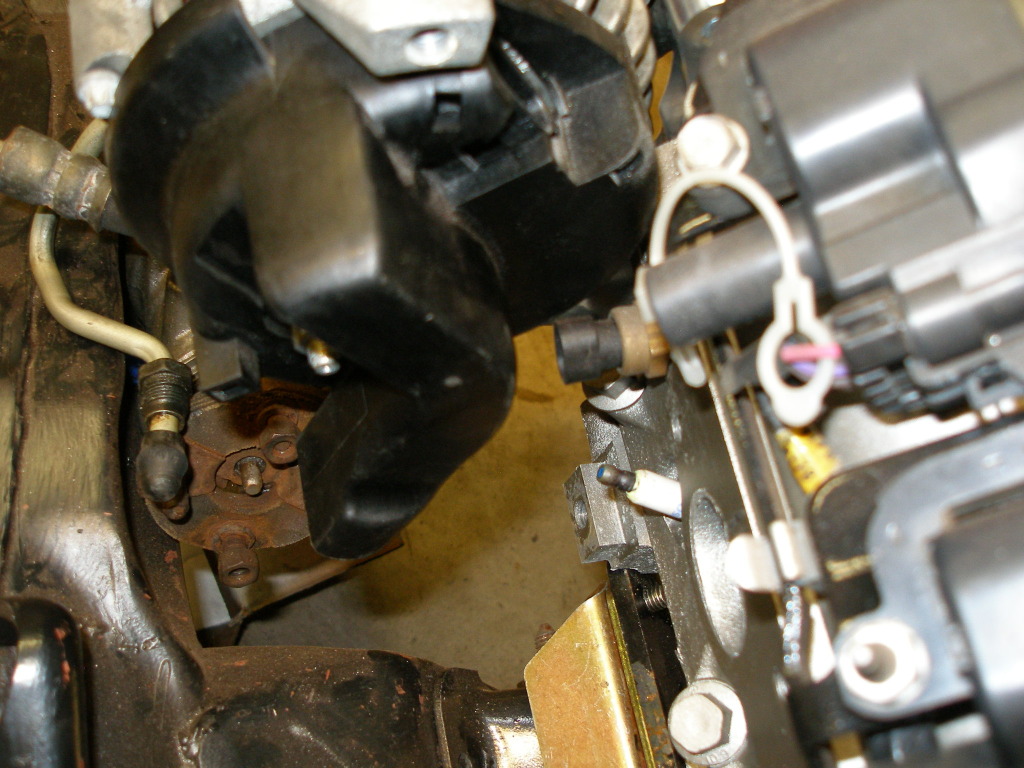

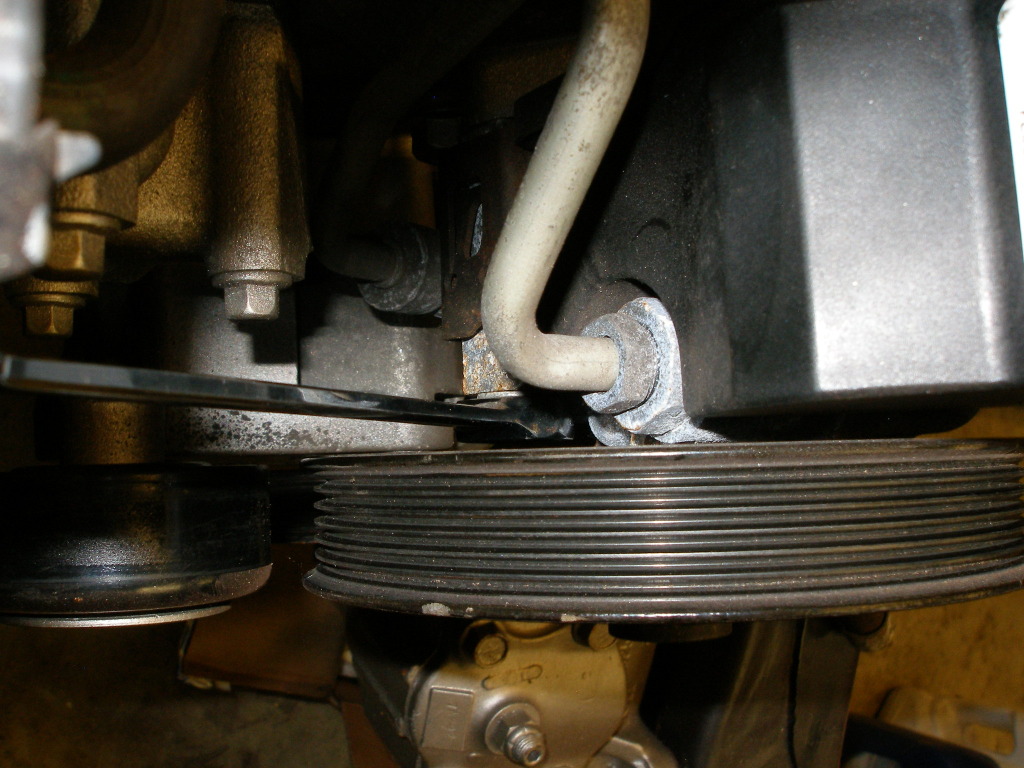

Before - pump is loosely bolted on and the metal line hits the coolant line. The coolant metal 'T' fitting is right there under the hose clamp, so it was not just a matter of pushing the hose away for clearance.

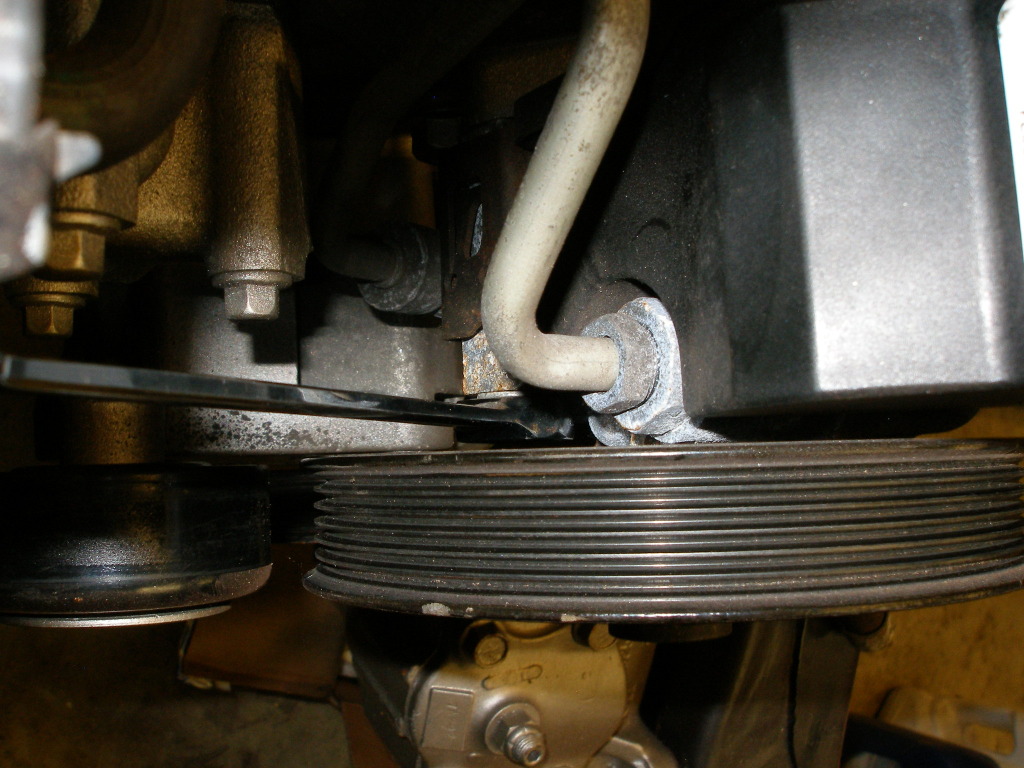

After tweaking - tucking it closer to the pump and pushing the metal line/ hose junction more under the resivoir (versus behind it)

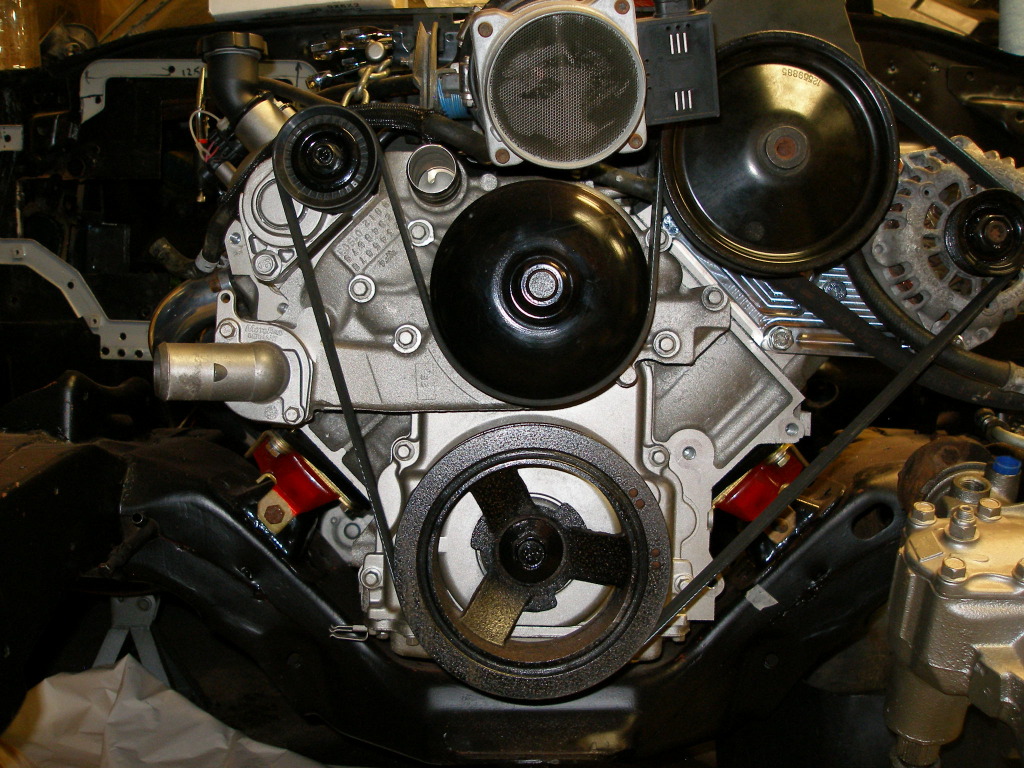

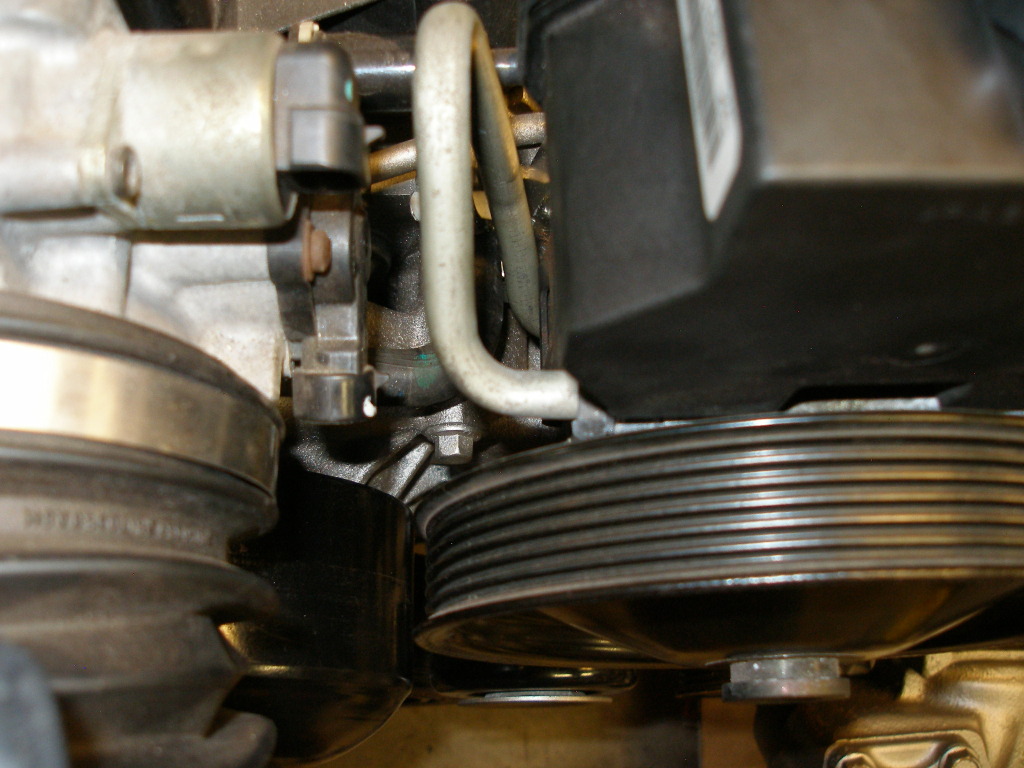

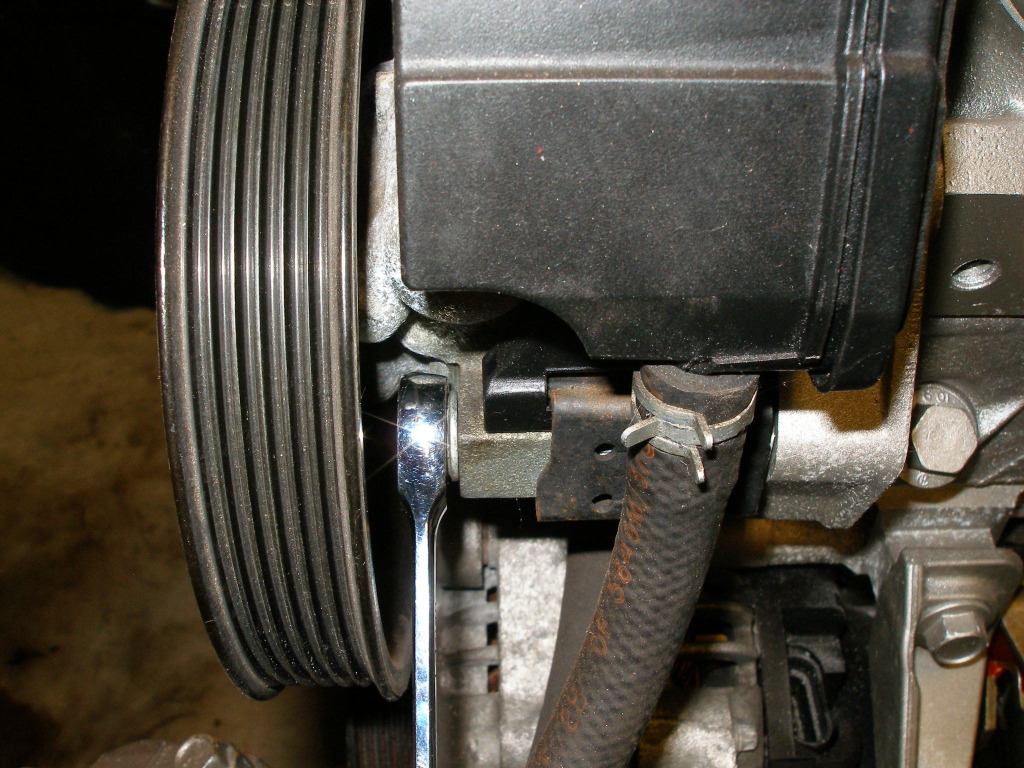

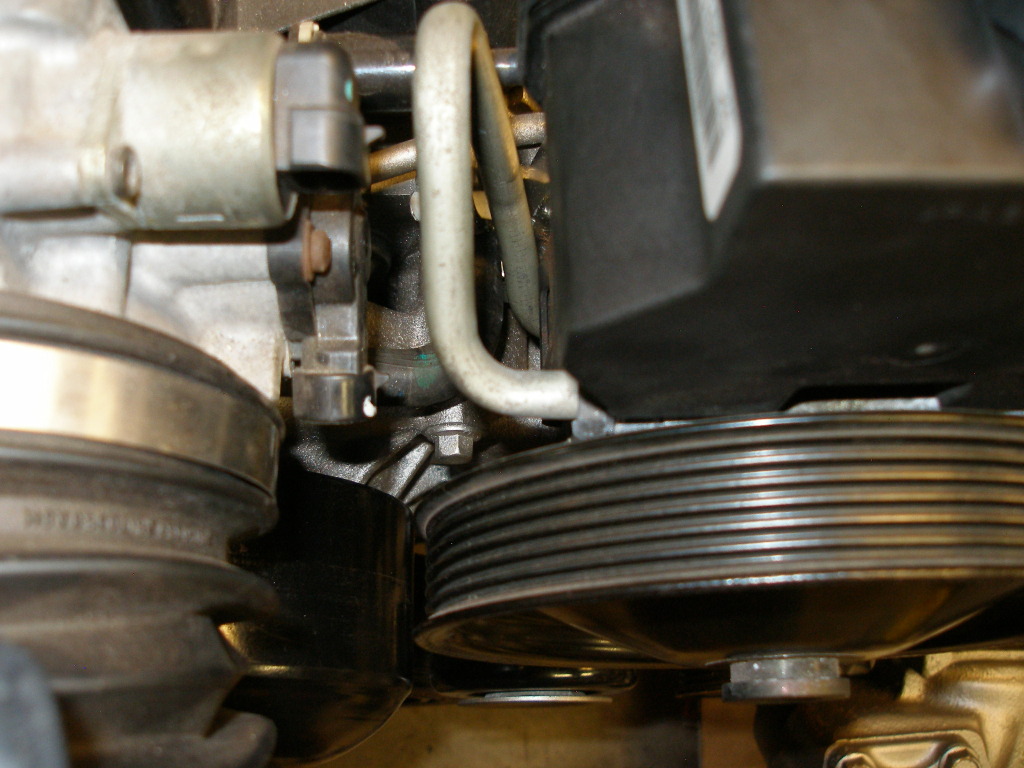

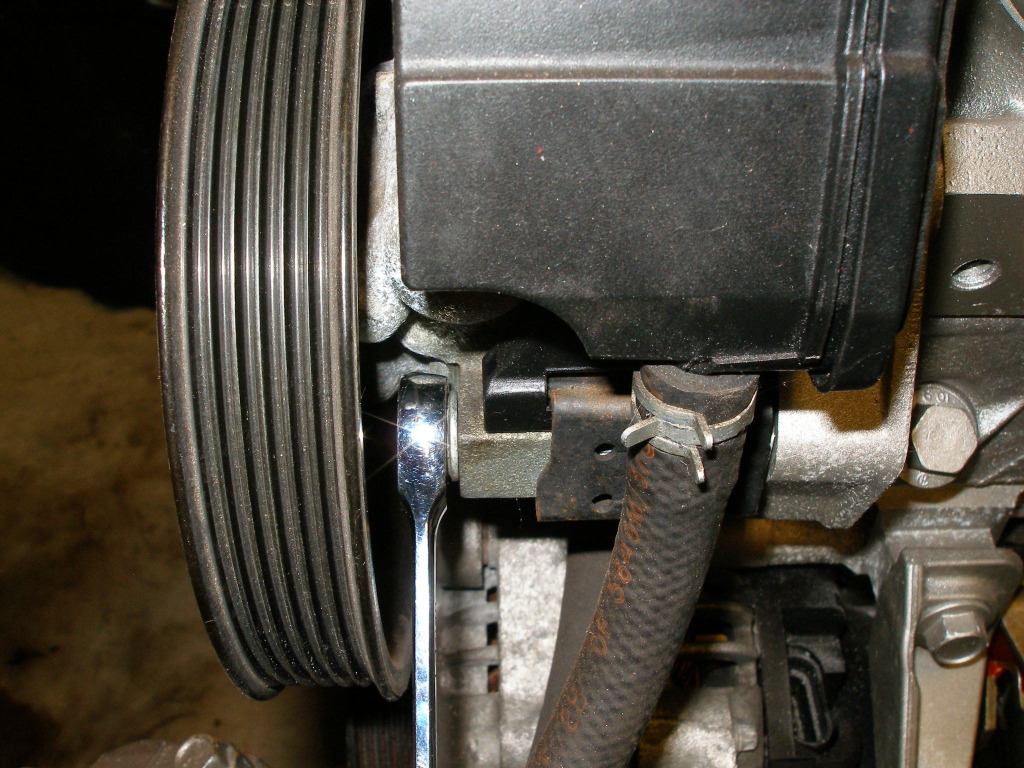

Mount the alternator before the power steering pump. If you do it, per the instructions, the pulley on the power steering pump is too big and the alternator bolt head will not get past it - close but not enough. I ended up re-loosening the power steering pump alot so I could get the alternator mount bolt past.

Power steering pump loosened up and wiggle forward to get past bolt

The belt is about 1/4"-1/2" too small. I have my tensioner maxed in the compressed position and it was still a b!itch to get on...and that was with the engine sitting out in the open and no front clip on...I cannot image trying to do that if the car was assembled with radiator and electric fan.

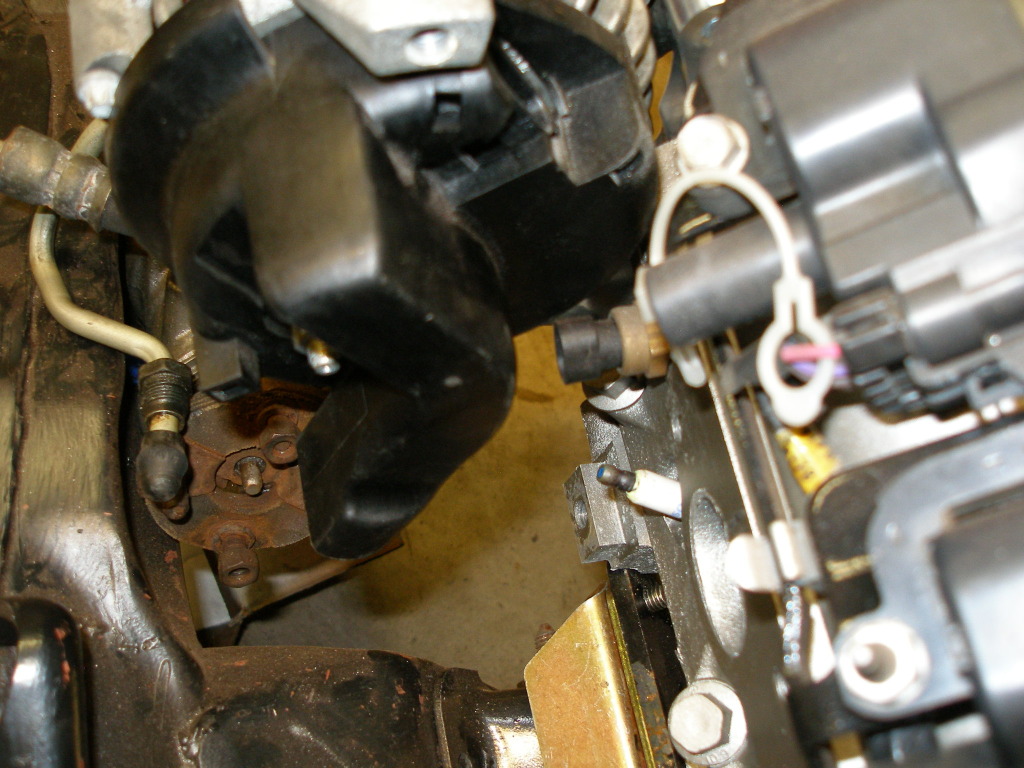

The back of the alternator has a black plastic shrouding that may get too much heat from the header...can't say for sure yet.

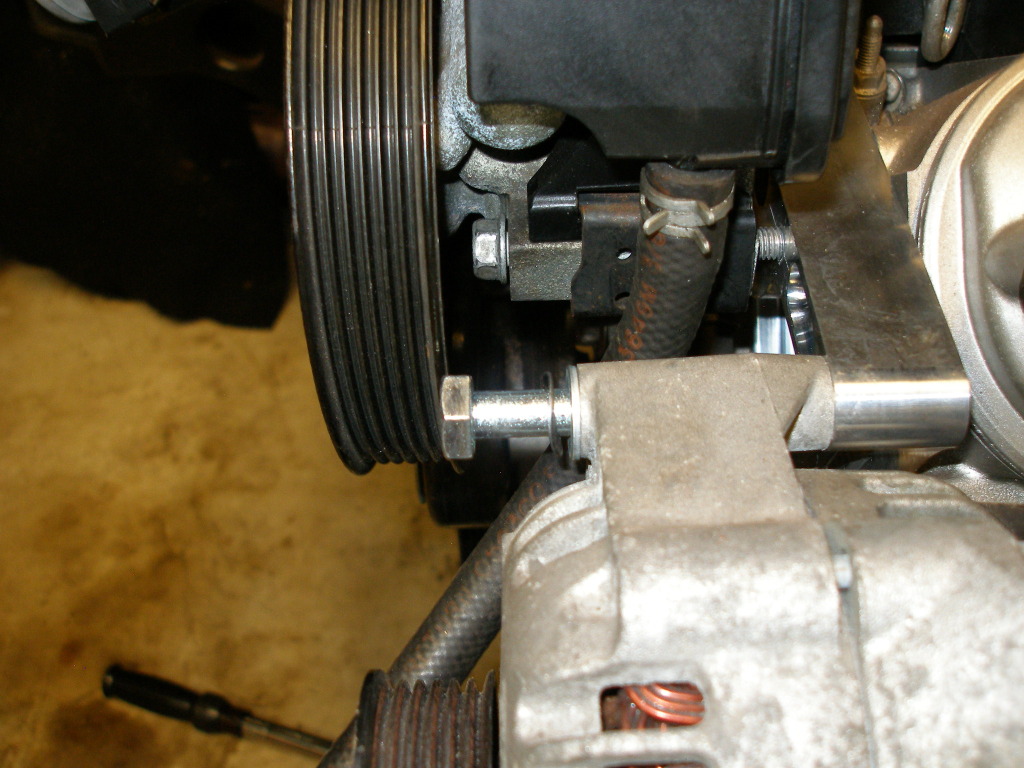

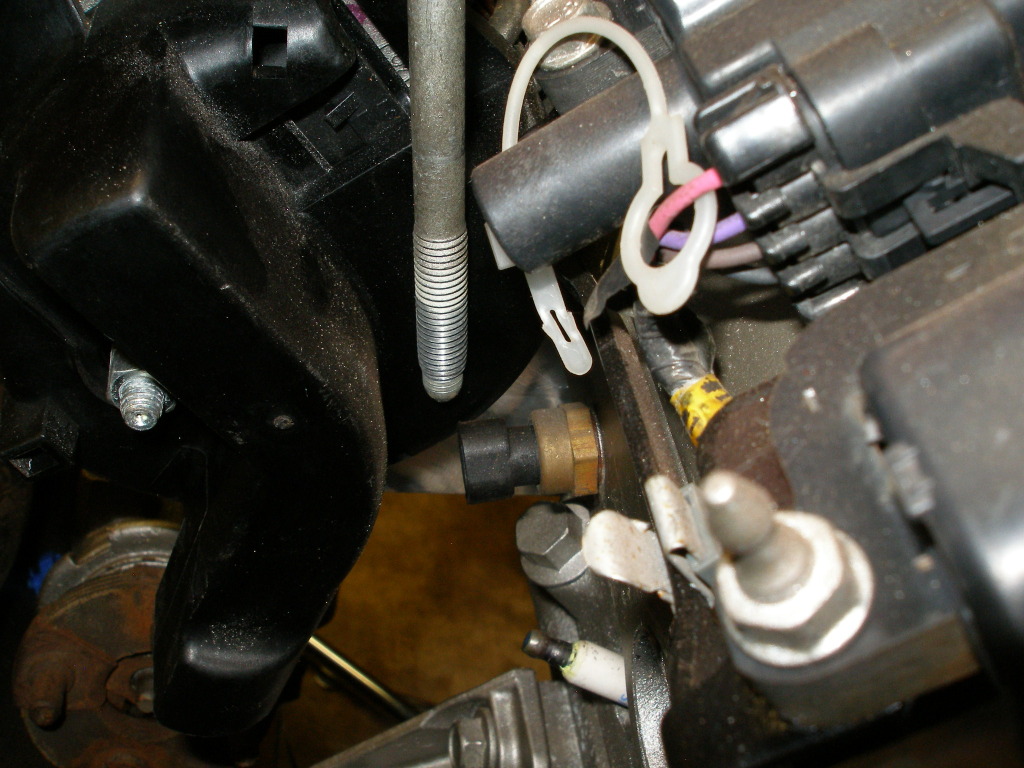

Coolant temp sensor in head maybe a tight fit with the alternator back cover on (see bolt point at it).

I think I will need to replace my power steering pump lines or re-bend them as the alternator sits above the gear box now and does not give you the freedom move them around as before.

Hint:

The power steering bolts are behind the pulley and there is enough space that you can use a gearwrench style wrench loosen and tighten. You may need to come in at different directions when you relocate the pump.

F-Body LS1 High Mount P/S and Alternator Mount Bracket kit

Before

No room to move forward as I could not get the belt on or off the pulley easily.

After. Now I can move the engine forward about 1/2"-3/4" for more clearance at the firewall (getting darn close)

Observations

Pro's

Solid aluminum machined bracket

hardware and new belt supplied

Eliminates alternator clearance issues with steering box, allowing more freedom for positioning of the engine.

Cons

The instructions are absolutely terrible, no torque specs and no pictures or routing diagram of the new belt. You have to look at the parts and try and figure out what should go were and a couple of steps should be reversed.

Fortunaley, there are only four bolts. The longest bolt goes in the lowest hole fyi.

Thank god for a shop manual to get the torque specs.

You will need to tweak one of the power steering line as it want to share the same spot as the coolant line that runs to the throttle body. Nothing mentioned in the instructions.

Before - pump is loosely bolted on and the metal line hits the coolant line. The coolant metal 'T' fitting is right there under the hose clamp, so it was not just a matter of pushing the hose away for clearance.

After tweaking - tucking it closer to the pump and pushing the metal line/ hose junction more under the resivoir (versus behind it)

Mount the alternator before the power steering pump. If you do it, per the instructions, the pulley on the power steering pump is too big and the alternator bolt head will not get past it - close but not enough. I ended up re-loosening the power steering pump alot so I could get the alternator mount bolt past.

Power steering pump loosened up and wiggle forward to get past bolt

The belt is about 1/4"-1/2" too small. I have my tensioner maxed in the compressed position and it was still a b!itch to get on...and that was with the engine sitting out in the open and no front clip on...I cannot image trying to do that if the car was assembled with radiator and electric fan.

The back of the alternator has a black plastic shrouding that may get too much heat from the header...can't say for sure yet.

Coolant temp sensor in head maybe a tight fit with the alternator back cover on (see bolt point at it).

I think I will need to replace my power steering pump lines or re-bend them as the alternator sits above the gear box now and does not give you the freedom move them around as before.

Hint:

The power steering bolts are behind the pulley and there is enough space that you can use a gearwrench style wrench loosen and tighten. You may need to come in at different directions when you relocate the pump.

#4

TECH Senior Member

iTrader: (12)

Just a thought, Could you just try and use the old bracket and idler ? maybe just cut off the un-needed part and leave the upper area with the stock idler and use the use the existing hole or drill a new one to lower the idler a bit.

If not a simple plate, spacer and the old idler would look like it would work.

BC

If not a simple plate, spacer and the old idler would look like it would work.

BC

#5

On The Tree

Thread Starter

iTrader: (18)

Join Date: Dec 2006

Location: Twin Cities, MN

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Rerouted the belt using the existing pulley setup. It has a much better wrap around the pulleys. There is just enough room you can get the bolts into the old alternator bracket, so it did not need cutting;

All you need is:

(2) M10-1.50x50 bolts

(2) 10mm flat washers

(2) 10 mm wave lockwashers

(1) 770K6 belt (77 inch belt)

The tensioner was in the mid range versus max compressed. If you ran under-drive pulleys, the original belt would fit.

All you need is:

(2) M10-1.50x50 bolts

(2) 10mm flat washers

(2) 10 mm wave lockwashers

(1) 770K6 belt (77 inch belt)

The tensioner was in the mid range versus max compressed. If you ran under-drive pulleys, the original belt would fit.

#6

On The Tree

iTrader: (2)

Join Date: Jun 2011

Location: Nashville, TN

Posts: 170

Likes: 0

Received 0 Likes

on

0 Posts

When you get a chance, could you take a picture from higher? An overall shot? It looks like the power steering sits really high.

I have been going back and forth between this setup and the KWIK Performance setup. Your post is very helpful. Thank you very much.

BTW: the change of using the OE idlers was great!

I have been going back and forth between this setup and the KWIK Performance setup. Your post is very helpful. Thank you very much.

BTW: the change of using the OE idlers was great!

Trending Topics

#11

On The Tree

Thread Starter

iTrader: (18)

Join Date: Dec 2006

Location: Twin Cities, MN

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Have you installed the power steering pulley?

I looked at mine (f-body) and there is a fair amount offset back from the nose to the where the serpentine belt is.

I looked at mine (f-body) and there is a fair amount offset back from the nose to the where the serpentine belt is.

#12

No not yet, I am checking to make sure I have the right parts before I press that on. I think there is enough offset in there to make it work.