79 RX7 LS 5.3 Turbo. (8.93 @ 153mph)

#501

9 Second Club

If the fastener is designed to stretch to maintain clamp loads as the metal expands/contracts with heat, then yes it could very well work better than a bolt that does not offer the same behaviour.

ARP's are not designed as stretch bolts in that manner....hence are fully re-usable.

Many OEM head bolts, flywheel bolts etc are not deemed re-usable, so there are clearly differences.

So it isnt static clamp force and one simple moment in time....it's how they behave under stress, heat, etc etc etc and of course cooling.

ARP's are not designed as stretch bolts in that manner....hence are fully re-usable.

Many OEM head bolts, flywheel bolts etc are not deemed re-usable, so there are clearly differences.

So it isnt static clamp force and one simple moment in time....it's how they behave under stress, heat, etc etc etc and of course cooling.

#502

I wouldn't think TTY head bolts that have been reused multiple times would retain that same "stretchy clamping force". But the used headbolts seem to put up with the abuse on Denmah's build which was making ALOT more power than I was.

The ARP bolt does stretch, as does any fastener. The fact that it can be reused does not mean it's ridged. If that were the case, the ARP studs would suffer form the same lack of TTY style clamping force, no? Same with the china studs that are so popular these days?

I'm not saying I know, just discussing. Something let go for sure, and at this point I sure can't tell you what it was at this point.

The ARP bolt does stretch, as does any fastener. The fact that it can be reused does not mean it's ridged. If that were the case, the ARP studs would suffer form the same lack of TTY style clamping force, no? Same with the china studs that are so popular these days?

I'm not saying I know, just discussing. Something let go for sure, and at this point I sure can't tell you what it was at this point.

#503

9 Second Club

You're trying to compare totally different fasteners as the same though

TTY bolts are not supposed to be re-used.

A little google that maybe explains some better ? ( And I dont know all about it myself either, I just know that the fasteners are very different )

http://www.enginebuildermag.com/2005...head-bolt-use/

TTY bolts are not supposed to be re-used.

A little google that maybe explains some better ? ( And I dont know all about it myself either, I just know that the fasteners are very different )

http://www.enginebuildermag.com/2005...head-bolt-use/

#504

I’m aware they are supposed to be one time use bolts and appreciate the input. My point is Denmah did reuse stock TTY bolts and made over 1000whp doing so. Not only were they reused, but they are the same head bolts that had been reused multiple times on the same motor making 700-900whp many many times. My rational is if the OEM TTY head bolts that have already been stretched to their yield point many times can keep the heads down without issue, than an ARP bolt *should* be able to do the same job, if not better.

Maybe there’s some magic I’m not familiar with on the stock head bolts that makes them better. But my common sense tells me there isn’t. If a bolt stretches, it is loosening the clamp load placed on the gasket. I can think of no instance where a “stretchy” fastener would be better at keeping a head down. The ability of the gasket to flex/shift as the deck/head deforms is a different story, and can be a good thing.

Maybe there’s some magic I’m not familiar with on the stock head bolts that makes them better. But my common sense tells me there isn’t. If a bolt stretches, it is loosening the clamp load placed on the gasket. I can think of no instance where a “stretchy” fastener would be better at keeping a head down. The ability of the gasket to flex/shift as the deck/head deforms is a different story, and can be a good thing.

#505

Old School Heavy

iTrader: (16)

If a bolt stretches, it is loosening the clamp load placed on the gasket. I can think of no instance where a “stretchy” fastener would be better at keeping a head down. The ability of the gasket to flex/shift as the deck/head deforms is a different story, and can be a good thing.

#506

That’s my point. The ARP bolt does stretch like any other head fastener. I’d think it would be able to maintain a higher clamping load in that stretch range than the factory bolt as well, making it a better part to use. Which is the whole purpose of running it over a factory bolt.

#508

9 Second Club

Thatís my point. The ARP bolt does stretch like any other head fastener. Iíd think it would be able to maintain a higher clamping load in that stretch range than the factory bolt as well, making it a better part to use. Which is the whole purpose of running it over a factory bolt.

Generally we use studs etc because they're stronger and we can tighten the **** out of things, and ignore any stretch aspect simply be pre-loading everything instead.

it's also like buying aftermarket gaskets because they should be better.....lets face it, few if any are better than the LS9 !

#509

Old School Heavy

iTrader: (16)

I wouldn't think TTY head bolts that have been reused multiple times would retain that same "stretchy clamping force". But the used headbolts seem to put up with the abuse on Denmah's build which was making ALOT more power than I was.

The ARP bolt does stretch, as does any fastener. The fact that it can be reused does not mean it's ridged. If that were the case, the ARP studs would suffer form the same lack of TTY style clamping force, no? Same with the china studs that are so popular these days?

I'm not saying I know, just discussing. Something let go for sure, and at this point I sure can't tell you what it was at this point.

The ARP bolt does stretch, as does any fastener. The fact that it can be reused does not mean it's ridged. If that were the case, the ARP studs would suffer form the same lack of TTY style clamping force, no? Same with the china studs that are so popular these days?

I'm not saying I know, just discussing. Something let go for sure, and at this point I sure can't tell you what it was at this point.

http://www.felpro-only.com/blog/prop...e-t-t-y-bolts/

People cite examples all the time of "getting away with" this or that. That is fine, but I not would exactly call that empirical evidence. A CFO that I used to work with had a saying that is both amusing and insightful. When people in the company would argue that they had not followed company procedure in the past and nothing blew up, he would say: "I have never been thrown through the windshield of a car, but I still wear my seatbelt". Always a show stopper.

#510

The bolts are pretty cheap compared to the studs! I went with the $106 ARP bolts for the re-usability and better quality control over the china studs.

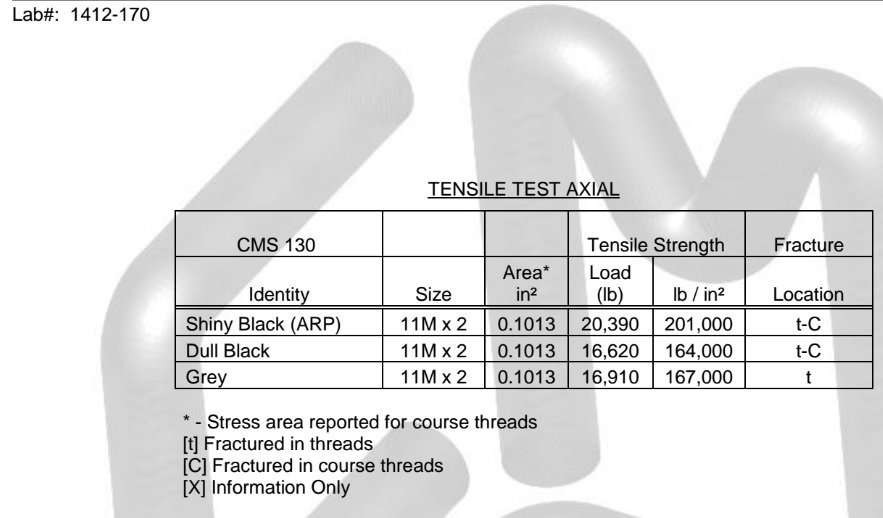

Seems to me like ARP is made from a better material for the job. Was an independent test awhile back where they tested the tensile stretch and failure loads of china studs, OEM bolts, and ARP 2000 studs. It showed that the china stud and OEM bolt were VERY similar and the ARP material was clearly better than both.

So the debate here is whether or not the OEM head bolt with less tensile strength is a better head fastener than the ARP? I know a stud is a better design, but comparing bolt to bolt here I don’t see how anyone could think the OEM bolt is more qualified in a performance application.

Seems to me like ARP is made from a better material for the job. Was an independent test awhile back where they tested the tensile stretch and failure loads of china studs, OEM bolts, and ARP 2000 studs. It showed that the china stud and OEM bolt were VERY similar and the ARP material was clearly better than both.

So the debate here is whether or not the OEM head bolt with less tensile strength is a better head fastener than the ARP? I know a stud is a better design, but comparing bolt to bolt here I don’t see how anyone could think the OEM bolt is more qualified in a performance application.

#511

9 Second Club

At what level does something become a "performance" application though to warrant a different fastener design ?

None of us here have the ability to do all the testing needed and state which fastener is better or not. But if the OEM bolts work...then they work.

Which is a better material ? and for what job exactly ? Again, I doubt any of us could answer that one.

Head bolts etc are not clamped down to the point of fastener failure, so is that test valid ? Probably not.

None of us here have the ability to do all the testing needed and state which fastener is better or not. But if the OEM bolts work...then they work.

Which is a better material ? and for what job exactly ? Again, I doubt any of us could answer that one.

Head bolts etc are not clamped down to the point of fastener failure, so is that test valid ? Probably not.

#512

You may have seen this already, but it is worth a read:

http://www.felpro-only.com/blog/prop...e-t-t-y-bolts/

People cite examples all the time of "getting away with" this or that. That is fine, but I not would exactly call that empirical evidence. A CFO that I used to work with had a saying that is both amusing and insightful. When people in the company would argue that they had not followed company procedure in the past and nothing blew up, he would say: "I have never been thrown through the windshield of a car, but I still wear my seatbelt". Always a show stopper.

http://www.felpro-only.com/blog/prop...e-t-t-y-bolts/

People cite examples all the time of "getting away with" this or that. That is fine, but I not would exactly call that empirical evidence. A CFO that I used to work with had a saying that is both amusing and insightful. When people in the company would argue that they had not followed company procedure in the past and nothing blew up, he would say: "I have never been thrown through the windshield of a car, but I still wear my seatbelt". Always a show stopper.

#513

At what level does something become a "performance" application though to warrant a different fastener design ?

None of us here have the ability to do all the testing needed and state which fastener is better or not. But if the OEM bolts work...then they work.

Which is a better material ? and for what job exactly ? Again, I doubt any of us could answer that one.

Head bolts etc are not clamped down to the point of fastener failure, so is that test valid ? Probably not.

None of us here have the ability to do all the testing needed and state which fastener is better or not. But if the OEM bolts work...then they work.

Which is a better material ? and for what job exactly ? Again, I doubt any of us could answer that one.

Head bolts etc are not clamped down to the point of fastener failure, so is that test valid ? Probably not.

#515

Old School Heavy

iTrader: (16)

They are talking about "typical bolts" snapping. The ARP fasteners are designed specifically to stretch and use on heads. They are not a typical hardened bolt. I've yet to hear of any ARP hardware snapping due to head expansion. If this were the case the "Pro's" would be using one time use TTY fasteners. Yet none do? I'm still not buying it guys. No stink'n way an OEM bolt is a better part for this application. Obviously they can work... that doesn't make them superior in any way to an ARP.

To me one big advantage of the ARP head bolts is that they can be re-used. When customers ask me if they are worth it, I tell them that they start to become worth it the minute you take your engine apart again. Then there is the additional clamping force that they are capable of if you need it.

#516

The examples are out there. Look at the L19, Custom Aged 625, and Aermet head fasteners ARP offers. The difference is in the tensile strength. More the better apparently?

Top fuel guys use the Aermet studs mainly because they are rated to 310,000psi tensile loads. Guys spend the big bucks on the aged stuff thatís rated at 280,000psi.

Pretty easy to see why youíd think the ARP 2000 bolts rated at 220,000psi would be better than a factory bolt. Here are the independent test results I was talking about.

I must have missed something in this thread. I am not sure who you are disagreeing with. I thought we were talking about whether it was wise to re-use TTY bolts because somebody "got away with it".

To me one big advantage of the ARP head bolts is that they can be re-used. When customers ask me if they are worth it, I tell them that they start to become worth it the minute you take your engine apart again. Then there is the additional clamping force that they are capable of if you need it.

To me one big advantage of the ARP head bolts is that they can be re-used. When customers ask me if they are worth it, I tell them that they start to become worth it the minute you take your engine apart again. Then there is the additional clamping force that they are capable of if you need it.

I was simply mentioning that the TTY bolts that have been reused multiple times seem to hold up to big power. So in theory I think an ARP bolt would provide at least as much clamping force and be just as good as a factory bolt if not better.

#517

Old School Heavy

iTrader: (16)

Somebody shared another LS headbolt test recently on Facebook. I looked for it to share, but did not find it. In their test, used TTY bolts actually had some favorable attributes over the Ebay studs. Where the used TTY bolts did poorly was their bolt to bolt consistently varied substantially more that the ARP or Ebay bolts. In fact, not only were their clamping force consistency all over the place, a couple used TTY bolts broke during the test. Conversely, the new TTY had extremely consistent clamping force.

#520

Had the injectors flowed. All within 2% of each other so that wasn’t the problem.

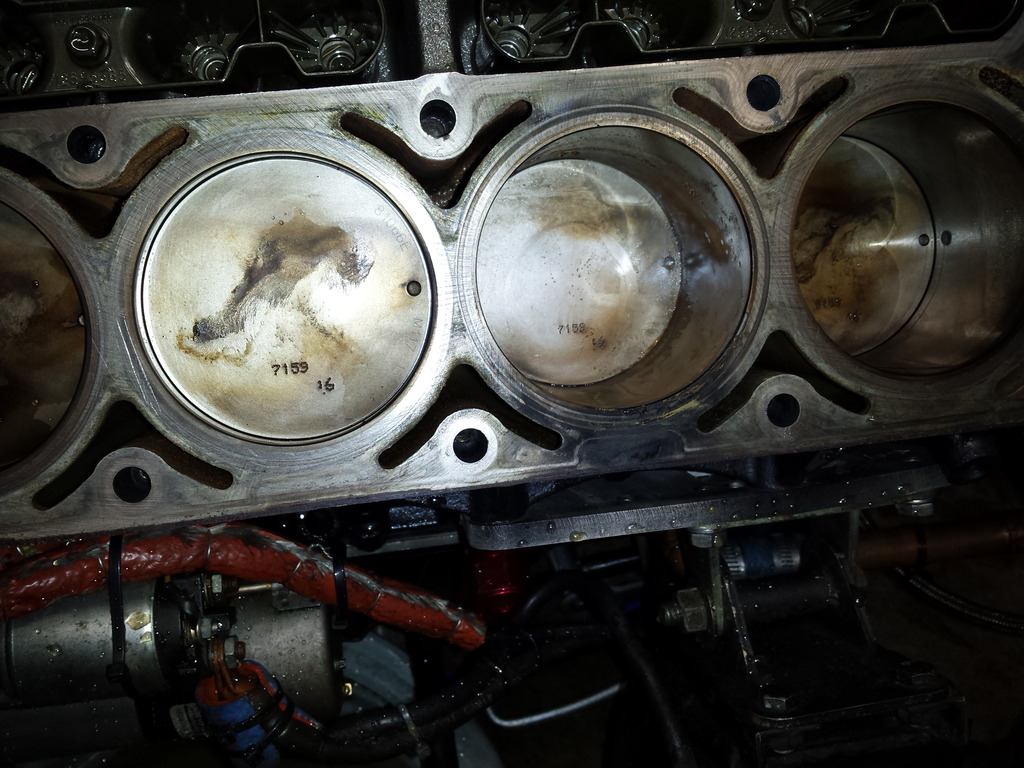

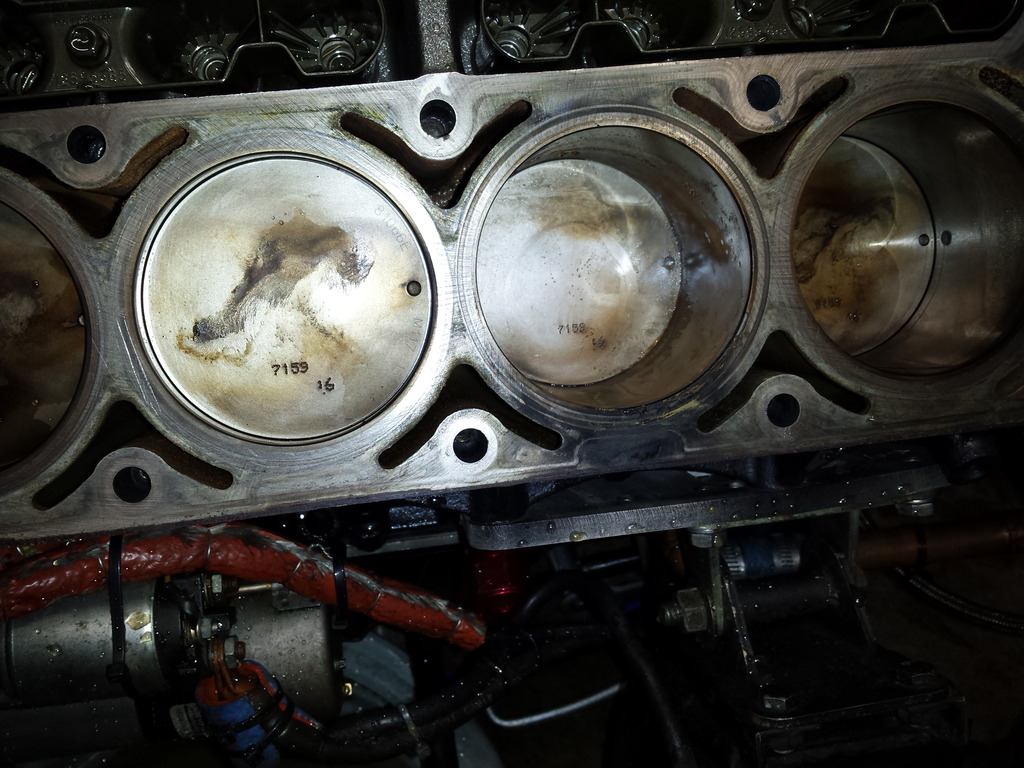

Checked the torqe on the head bolts before pulling and they all seemed to still be at 78 ft lb. Yanked the Pas side head off. #4 was blown huge. Head and deck seemed straight. No idea what/why this let loose. Plugs were oldish so I couldn’t get a great read, but there were no signs of detonation and the heat marks I could see on the strap looked conservative about half way down the strap. 10.8 AFR peaked around 5800 25lbs 13* of timing. This is with E85 7gph of water/meth (washer fluid) and 100* IAT’s.

Cylinder looked like it had a little galling. 90% sure none of the cylinders had any markings when I put the engine together. Rings gapped at 22/24 same as I’ve done on all my LS stuff. Figure I might have knocked the ring land out of that piston. Not sure what else would cause it, unless the ring was just cocked goofy.

Can’t pull the pan on this setup without removing the engine and I wasn’t ready to pull the motor yet. So I copper sprayed a used LS9 gasket and put the head back on. Torqued to 80ftlb. Cranking compression is the same as it was prior, so I threw everything back together. Started right up and seems ok. Cruised around quite a bit. The tune was reading really rich all of a sudden. Dropped a bunch of fuel out and it seems fine. Ordered a new WB02 sensor to be sure. I’ve had the same Bosch 4.2 sensor for 6-7 years now. I think it’s fine, but I want to be sure.

Checked the torqe on the head bolts before pulling and they all seemed to still be at 78 ft lb. Yanked the Pas side head off. #4 was blown huge. Head and deck seemed straight. No idea what/why this let loose. Plugs were oldish so I couldn’t get a great read, but there were no signs of detonation and the heat marks I could see on the strap looked conservative about half way down the strap. 10.8 AFR peaked around 5800 25lbs 13* of timing. This is with E85 7gph of water/meth (washer fluid) and 100* IAT’s.

Cylinder looked like it had a little galling. 90% sure none of the cylinders had any markings when I put the engine together. Rings gapped at 22/24 same as I’ve done on all my LS stuff. Figure I might have knocked the ring land out of that piston. Not sure what else would cause it, unless the ring was just cocked goofy.

Can’t pull the pan on this setup without removing the engine and I wasn’t ready to pull the motor yet. So I copper sprayed a used LS9 gasket and put the head back on. Torqued to 80ftlb. Cranking compression is the same as it was prior, so I threw everything back together. Started right up and seems ok. Cruised around quite a bit. The tune was reading really rich all of a sudden. Dropped a bunch of fuel out and it seems fine. Ordered a new WB02 sensor to be sure. I’ve had the same Bosch 4.2 sensor for 6-7 years now. I think it’s fine, but I want to be sure.