Project: 84' Blazer - LQ4/4L60e Swap

#1

Hey guys,

I've been posting in the LSx section of S10forum but there isn't much help over there...

It's a 1984 S10 Blazer (Tahoe) with a 2.8L/700r4 that has become very tired and is in need of an LSx Swap!

Parts Bought:

KWik - Alt and PS bracket

Kwik - A/C mount w/ sanden compressor

Stainless Works - 1-7/8 LT Headers

CPW - Radiator w/Fans, Shroud & A/C Condenser

CPW - A/C condenser and lines

Shift Works: Mechanical Speedometer Kit Tailhousing

Holley LS Valve Covers - Black

Holley - 302-1 GM LS Retro-fit Aluminum Oil Pan

Parts to buy:

Fuel System - pump, regulator AN fittings

Lokar - Midnight Series Shifter

Rad Mounts from new S10

LS3 Dipstick/tube for Holley pan

Energy susp body mounts (Mine are all deteriorated)

Trans dipstick

Shiftworks tailhousing or Dakota digital gauges (To work with VSS)

Trans and Fuel lines 20ft of each with AN fittings

Steam vent hose.

Lokar 36" throttle cable

Ball joints

Hydroboost brake set up

PS pump pully with access holes

Type II Remote resivoir PS pump

02 Z28 Camaro A/C tensionner

Air filter

Oil, Coolant, Trans filter and fluid

Anyways, on to pictures!

What I started with:

Goodbye 2.8L

2001 6.0L LQ4 from a Suburban

When it was delivered:

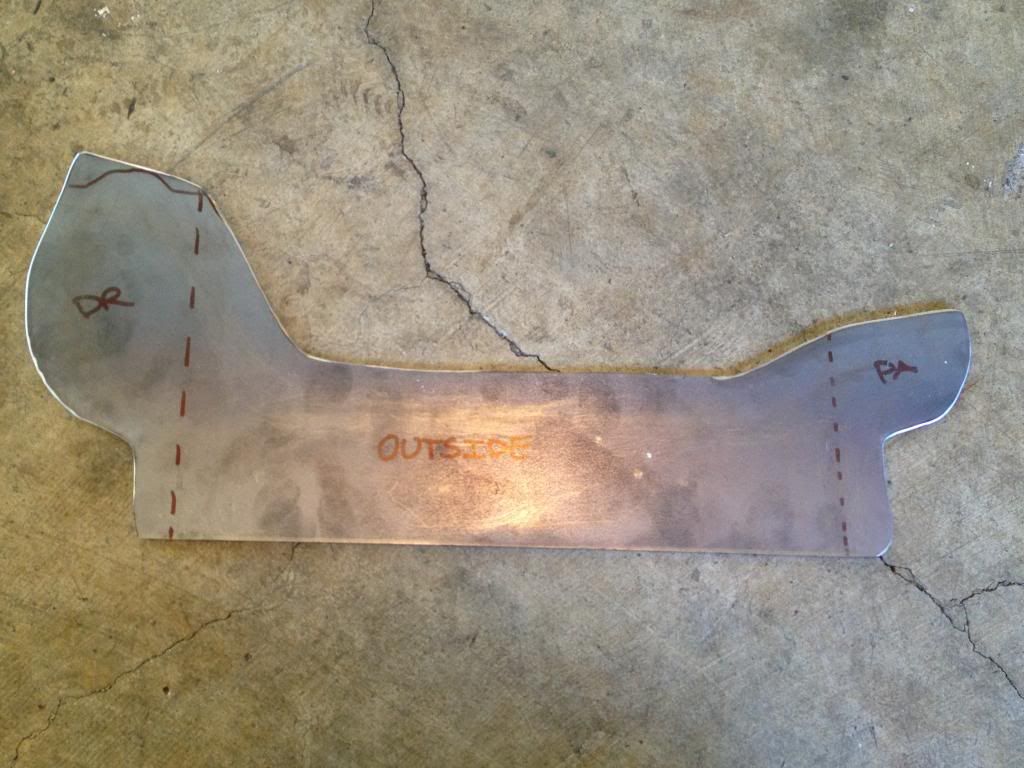

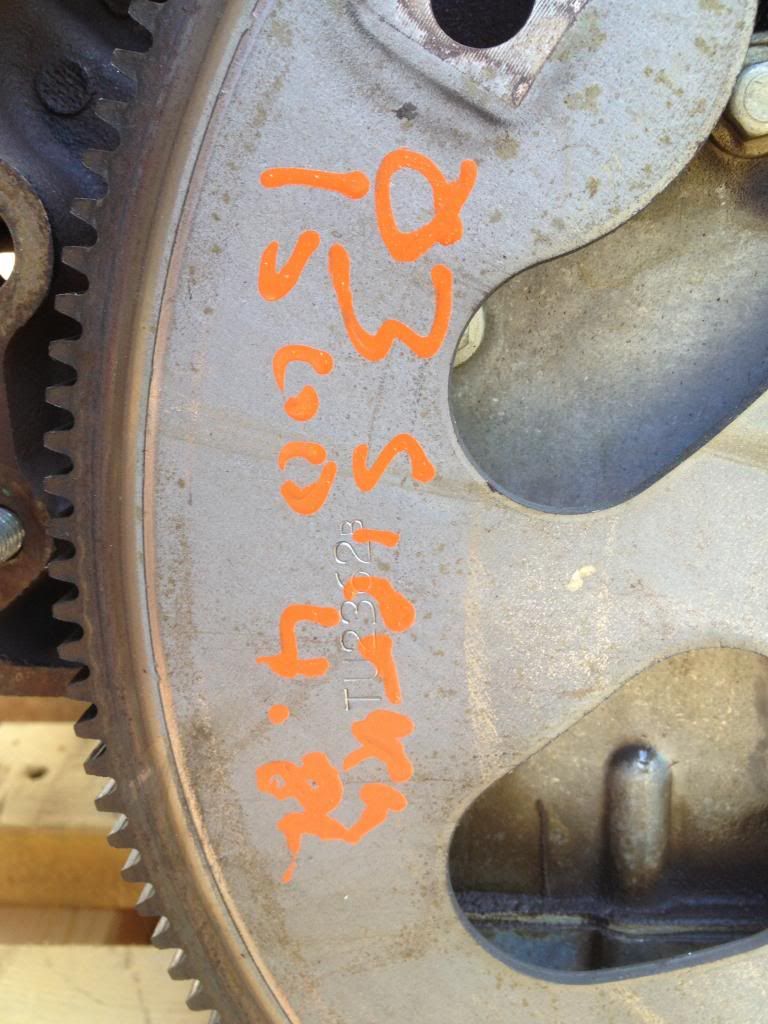

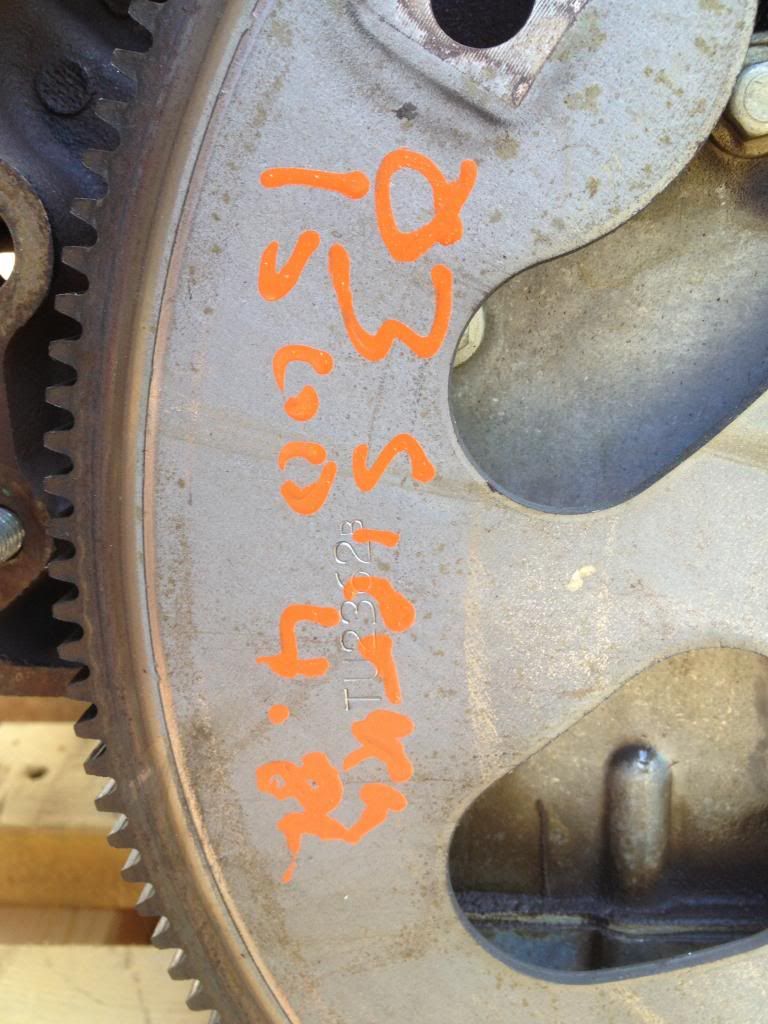

Using a 4.8L dished flexplate to work with the 4L60e

4L60e

I've been posting in the LSx section of S10forum but there isn't much help over there...

It's a 1984 S10 Blazer (Tahoe) with a 2.8L/700r4 that has become very tired and is in need of an LSx Swap!

Parts Bought:

KWik - Alt and PS bracket

Kwik - A/C mount w/ sanden compressor

Stainless Works - 1-7/8 LT Headers

CPW - Radiator w/Fans, Shroud & A/C Condenser

CPW - A/C condenser and lines

Shift Works: Mechanical Speedometer Kit Tailhousing

Holley LS Valve Covers - Black

Holley - 302-1 GM LS Retro-fit Aluminum Oil Pan

Parts to buy:

Fuel System - pump, regulator AN fittings

Lokar - Midnight Series Shifter

Rad Mounts from new S10

LS3 Dipstick/tube for Holley pan

Energy susp body mounts (Mine are all deteriorated)

Trans dipstick

Shiftworks tailhousing or Dakota digital gauges (To work with VSS)

Trans and Fuel lines 20ft of each with AN fittings

Steam vent hose.

Lokar 36" throttle cable

Ball joints

Hydroboost brake set up

PS pump pully with access holes

Type II Remote resivoir PS pump

02 Z28 Camaro A/C tensionner

Air filter

Oil, Coolant, Trans filter and fluid

Anyways, on to pictures!

What I started with:

Goodbye 2.8L

2001 6.0L LQ4 from a Suburban

When it was delivered:

Using a 4.8L dished flexplate to work with the 4L60e

4L60e

Last edited by 84blaze; 09-13-2013 at 11:44 AM.

#2

#3

#5

Now you guys can see where I'm at after that big photo dump. I'm now at school until Christmas. I plan to put in a big order for the remaining parts I need to get this bitch running. I'm probably looking at another $2000 and $3000 in parts to get it going.

I want to keep all factory gauges, which is why I have that tailhousing or I may go with the Dakota Digital Gauges which are in my parts list. My main priority is to get the truck running and able to move under its own power by Xmas this year. Once that is done, I will work on the cosmetic touches, such as valve covers, tailhousing, A/C, trans rebuild etc... As the engine has about 120,000miles I wouldn't be surprised if I rebuild down the road, but like I said, the main priority is to get it running.

The truck is sitting at my parents place ATM and my Dad told me he would help prep the frame rails control arms, finish the notch, add tome exhaust cutouts in the stock trans crossmember and paint it all up before I get back in December. He also plans to tackle the wiring harness. If it is too difficult, I will buy a CPW harness.

I removed the engine and all front end components prior to leaving so it should all get cleaned up nicely. Sorry no pictures of this at this time...

Thats all for now.

Hopefully someone can answer some of my questions...

1- My transmission cooler lines are on the passenger side but the rad fittings are on the driver side. What is the best way to route these lines? I was going to route them over the trans and into the frame rail exiting where the fuel lines used to exit near the steering box. Should I run some flexible braided line and AN fittings for this as well, or is there a better material I should use?

2 - My plan is to run AN fittings and Russell ProClassic braided line from the break on the stock hard fuel lines (near forward leaf spring hanger). As I have "return style" fuel rails I will need to run about 20 feet of fuel line; 10 feet of feed and 10 to return.

Does anyone have any suggestions on what pump I should buy?

Do I need a fuel filter/regulator?

What else do I need for this system?

What size line should I purchase for feed? and for return? 6AN?

I would like to run an inline pump rather than an in tank pump. What's my best option for this?

3 - Are there any good sites that give a tutorial on how to create a wiring harness from the stock one?

I want to keep all factory gauges, which is why I have that tailhousing or I may go with the Dakota Digital Gauges which are in my parts list. My main priority is to get the truck running and able to move under its own power by Xmas this year. Once that is done, I will work on the cosmetic touches, such as valve covers, tailhousing, A/C, trans rebuild etc... As the engine has about 120,000miles I wouldn't be surprised if I rebuild down the road, but like I said, the main priority is to get it running.

The truck is sitting at my parents place ATM and my Dad told me he would help prep the frame rails control arms, finish the notch, add tome exhaust cutouts in the stock trans crossmember and paint it all up before I get back in December. He also plans to tackle the wiring harness. If it is too difficult, I will buy a CPW harness.

I removed the engine and all front end components prior to leaving so it should all get cleaned up nicely. Sorry no pictures of this at this time...

Thats all for now.

Hopefully someone can answer some of my questions...

1- My transmission cooler lines are on the passenger side but the rad fittings are on the driver side. What is the best way to route these lines? I was going to route them over the trans and into the frame rail exiting where the fuel lines used to exit near the steering box. Should I run some flexible braided line and AN fittings for this as well, or is there a better material I should use?

2 - My plan is to run AN fittings and Russell ProClassic braided line from the break on the stock hard fuel lines (near forward leaf spring hanger). As I have "return style" fuel rails I will need to run about 20 feet of fuel line; 10 feet of feed and 10 to return.

Does anyone have any suggestions on what pump I should buy?

Do I need a fuel filter/regulator?

What else do I need for this system?

What size line should I purchase for feed? and for return? 6AN?

I would like to run an inline pump rather than an in tank pump. What's my best option for this?

3 - Are there any good sites that give a tutorial on how to create a wiring harness from the stock one?

#7

TECH Junkie

iTrader: (18)

Get an intank Walbro 255 pump, just make sure it's not from ebay. Most of those are fake clones and won't last three months. You will need to make sure you have an inline filter somewhere. If you have the return style fuel rail, then it should have the regulator built into it. Post some close up pic's of the rail and we can see if you have the regulator.

Trending Topics

#8

It did technically "fit" with out the notch but I wanted to give myself some more room to run the brake lines and I would have had other header and steering clearance issues if I had mounted it in that rearward position. From what I've seen most S10's require a small notch with the Holley pan but some can get away without one.

#9

Get an intank Walbro 255 pump, just make sure it's not from ebay. Most of those are fake clones and won't last three months. You will need to make sure you have an inline filter somewhere. If you have the return style fuel rail, then it should have the regulator built into it. Post some close up pic's of the rail and we can see if you have the regulator.

Do you have a part number for the inline filter? I know WIX makes some for corvettes and camaros.

My fuel rails have have 2 lines coming off the intake.

Here are some photos. They are the best I have ATM (being across the country from it) of my fuel rails:

Hope you can tell me what exactly I need!

Last edited by 84blaze; 09-14-2013 at 08:34 AM.

#11

Launching!

iTrader: (10)

Join Date: Oct 2008

Location: Winnipeg Manitoba Canada

Posts: 293

Likes: 0

Received 0 Likes

on

0 Posts

If I had to do my swap over I would change the location of the a/c compressor and knotch the fram and move it down to the factory location and keep the factory brackets. With the rad hose there it just seems so crowded, and it allows for more room up top. But nice job otherwise. I like those white bricks. ( 1st gen s series)

#12

#13

If I had to do my swap over I would change the location of the a/c compressor and knotch the fram and move it down to the factory location and keep the factory brackets. With the rad hose there it just seems so crowded, and it allows for more room up top. But nice job otherwise. I like those white bricks. ( 1st gen s series)

Can't wait till its all put together!

#16

#17

TECH Regular

iTrader: (2)

Join Date: Oct 2004

Location: Struble, IA

Posts: 443

Likes: 0

Received 0 Likes

on

0 Posts

On the transmission lines, I would run them to the core support and over to the other side from that point.

#18

On The Tree

iTrader: (1)

Join Date: Apr 2009

Location: 201 NJ

Posts: 153

Likes: 0

Received 0 Likes

on

0 Posts

The engine already has a pressure regulator on the fuel rail. Pick up a Walbro 255, it can be mounted on the frame or in the tank. For filters, you need 100 microns before the pump (a pickup sock is fine) and 10 microns after the filter. Summit and Jeg's both have serviceable inline filters for a reasonable price. Run -6 lines supply and return.

#19

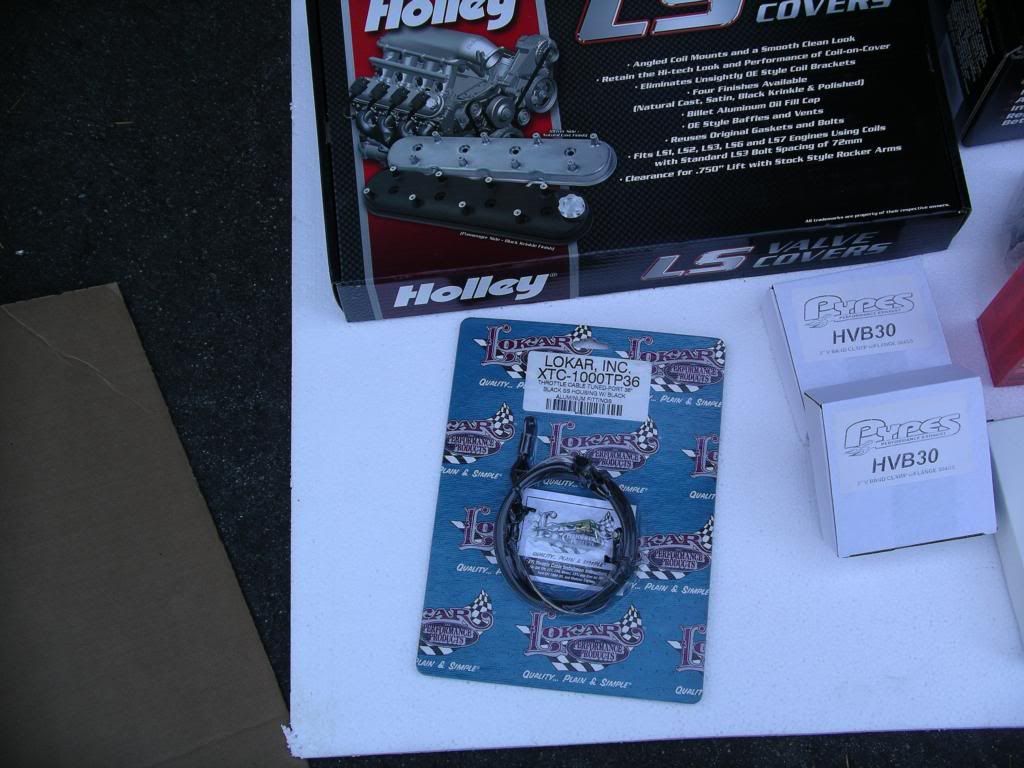

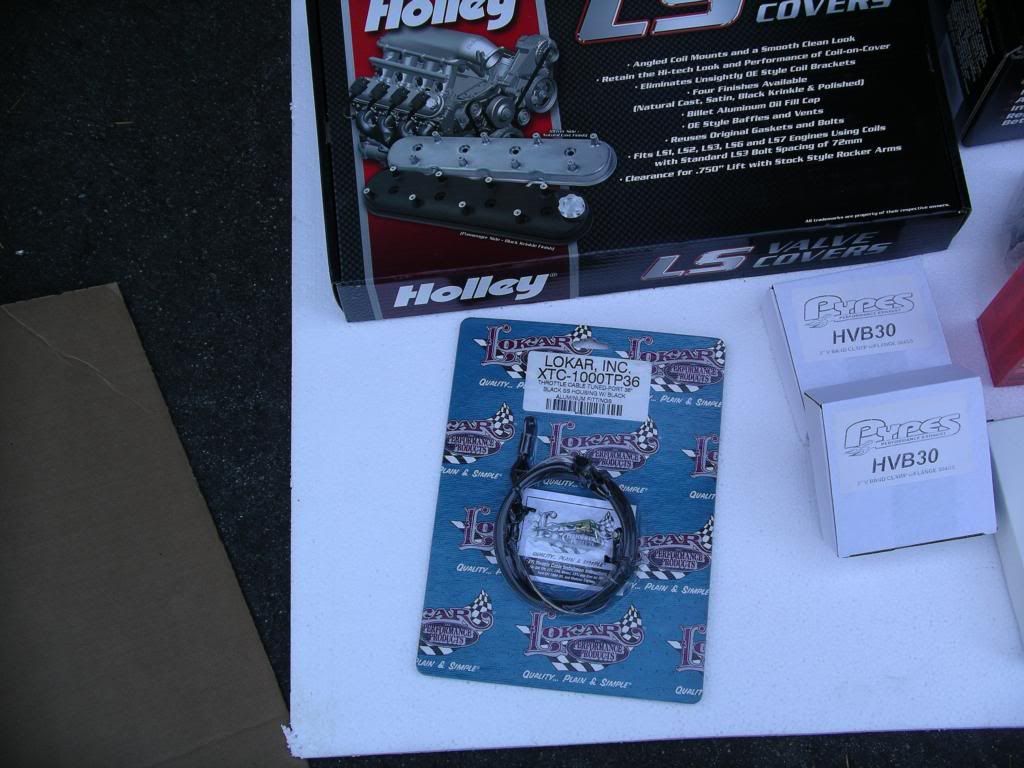

I ordered some parts:

Random Orders

Rock Auto: Spectra tank (GM18B) and Spectra sending unit (FG03A)

eBay: EGR billet block off

KWiK Performance: Type II PS pump/pulley/reservoir,

eBay: Dorman 924-424 rad bushings,

eBay: Hydroboost S10 mounting plate,

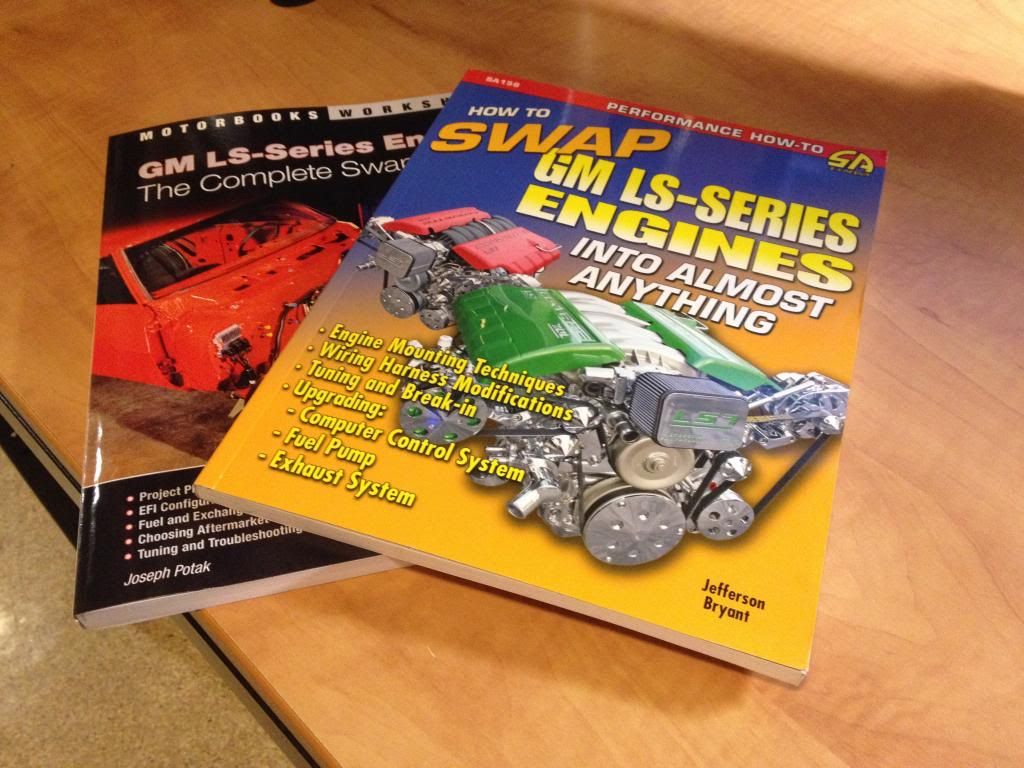

Amazon: 2 - LS Swap Books .

Summit Order:

Holley Aluminum LS Valve Covers X1

Lokar Midnight Series Throttle Cable - 36" X1

Billet Specialities radiator cap X1

Dakota Digital Gauges X1

Energy Suspension Body mount kit X1

Chevrolet Performance Drive Belt Tensioner - Z28 X1

Fuel System:

Edelbrock In-tank fuel pump X1

Fram inline filter X1

Russell ProClassic -6AN hose - 50ft X1

Fittings:

Russell - 6 AN Hose to Female -6 AN X6

Fragola - Male -6 AN to 16mm x 1.5 Male X2

Russell - M14 x 1.5 to -6AN Flare X1

Russell - M16 x 1.5 to -6AN Flare X1

Russell - Push on EFI fitting - 5/16 X1

Russell - Push on EFI fitting - 3/8 X1

Exhaust:

Summit Racing® Universal X-Pipe Kit - Stainless Steel X1

Pypes SS V-Bands X2

Once all these parts come in I should be able to get this thing going by Christmas!

Random Orders

Rock Auto: Spectra tank (GM18B) and Spectra sending unit (FG03A)

eBay: EGR billet block off

KWiK Performance: Type II PS pump/pulley/reservoir,

eBay: Dorman 924-424 rad bushings,

eBay: Hydroboost S10 mounting plate,

Amazon: 2 - LS Swap Books .

Summit Order:

Holley Aluminum LS Valve Covers X1

Lokar Midnight Series Throttle Cable - 36" X1

Billet Specialities radiator cap X1

Dakota Digital Gauges X1

Energy Suspension Body mount kit X1

Chevrolet Performance Drive Belt Tensioner - Z28 X1

Fuel System:

Edelbrock In-tank fuel pump X1

Fram inline filter X1

Russell ProClassic -6AN hose - 50ft X1

Fittings:

Russell - 6 AN Hose to Female -6 AN X6

Fragola - Male -6 AN to 16mm x 1.5 Male X2

Russell - M14 x 1.5 to -6AN Flare X1

Russell - M16 x 1.5 to -6AN Flare X1

Russell - Push on EFI fitting - 5/16 X1

Russell - Push on EFI fitting - 3/8 X1

Exhaust:

Summit Racing® Universal X-Pipe Kit - Stainless Steel X1

Pypes SS V-Bands X2

Once all these parts come in I should be able to get this thing going by Christmas!

Last edited by 84blaze; 10-06-2013 at 06:35 PM.

#20

On with the pictures!

Some Mr Gasket -6AN straight and 90* as well as some Russell Transmission fittings:

Billet EGR block off:

Dorman rad bushings:

Hydroboost S10 firewall mounting plate:

GM LS3 dipstick and tube:

LS Swap books:

More parts:

While I'm away at school my Dad has been busy doing the dirty work for me.

He's managed to finish welding the oil pan and header notches while also grind down and somewhat smooth out the front frame rails.

Here are some pictures.

Some pictures of the firewall that needs to be beat un to clean the SW LTs:

Ill be home in 3 weeks and then the progress will be almost daily. Once I get home I'll have 30 days to complete the project. Hopefully I'll be able to get it running by then!

More photos to follow.

Some Mr Gasket -6AN straight and 90* as well as some Russell Transmission fittings:

Billet EGR block off:

Dorman rad bushings:

Hydroboost S10 firewall mounting plate:

GM LS3 dipstick and tube:

LS Swap books:

More parts:

While I'm away at school my Dad has been busy doing the dirty work for me.

He's managed to finish welding the oil pan and header notches while also grind down and somewhat smooth out the front frame rails.

Here are some pictures.

Some pictures of the firewall that needs to be beat un to clean the SW LTs:

Ill be home in 3 weeks and then the progress will be almost daily. Once I get home I'll have 30 days to complete the project. Hopefully I'll be able to get it running by then!

More photos to follow.