1937 Ford Sedan

#562

TECH Regular

Thread Starter

#563

TECH Regular

Thread Starter

I was finally able to get back on here! It was good to run into you the other day. You have been busy since I was last on here, Just about a year ago.

Here is an idea for keeping you fuel cool, how about a length of 3/8" spine fin tubing? Do y'all even still make that stuff?

Once I get this divorce finalized and have some sense of what I can afford to do, I hope to get back on my '65.

Here is an idea for keeping you fuel cool, how about a length of 3/8" spine fin tubing? Do y'all even still make that stuff?

Once I get this divorce finalized and have some sense of what I can afford to do, I hope to get back on my '65.

.

.

#564

Thanks for identifying the tubing. I'm considering using steel tubing on my 39 Chev LS2 (in progress) and wondered what fitting you were going to use to connect to the EFI fuel rails and the Corvette filter/regulator. I don't have that Classic Tube kit that can put the EFI flare on the tube. I used some steel 6AN fittings counterbored .375 that I heli-brazed to my trans cooler lines. Now I don't remember where I got them and can't find them at Earls or Russell.

#566

As usual...……. Freak'in AWSUM !!!!!!!!!!

#567

TECH Regular

Thread Starter

Got a few things finalized on the exhaust system today. Brackets, hangers, and prepped all the joints for welding. I forgot to mention in the previous exhaust post thanks to Bill Arnold for the idea of using the 4 hole flanges to be able to remove the sections from the car. Taking all the pieces to my Tig welding buddy tomorrow. I couldn't do the last tailpipe without the body being back on the car, but I'll finish that later. Also down the road after the car runs I'll check for any exhaust leaks and eventually get all the sections ceramic coated.

I didn't point this out before, but the Fab Director had the idea of running the inside pipe past the joint where the gasket will be to keep some heat off of it. So all the joints are done this way. I just had to machine the flanges a little larger where they slide over the belled end of the pipe. Looks like a good idea - time will tell

I didn't point this out before, but the Fab Director had the idea of running the inside pipe past the joint where the gasket will be to keep some heat off of it. So all the joints are done this way. I just had to machine the flanges a little larger where they slide over the belled end of the pipe. Looks like a good idea - time will tell

#568

TECH Senior Member

Man, I love a clean, well-though-out exhaust system! Should be fairly quiet with converters and big mufflers too. Lookin' GOOD!

#570

TECH Regular

Thread Starter

[QUOTE=aggie91;20051970]Exhaust looks good. Kinda surprised you did not use V-Band clamps for the sections. One fastener to tighten and no gasket.

Karl I did a lot of research on V band clamps. I love the way they look and the concept. There are many out there and I studied everything I could find. I also visited 2 exhaust shops to learn more about them. The way my exhaust is sectioned it was going to have 8 connection points. After looking at how the V band design has a machined surface where the sealing would be done, I was not comfortable about all 8 of them sealing after initial welding AND then still sealing after the car is driven a few thousand miles. I just couldn't get comfortable with that in my mind. I knew Bill Arnold built his exhaust system with the 4 bolt flanges with gaskets, and he told me he put a couple of extra gaskets in his road trip kit and has never used a single one even after chugging up Pikes Peak ! If someone has good experience with V bands please post so the rest of us can learn for next time......

! If someone has good experience with V bands please post so the rest of us can learn for next time......

Karl I did a lot of research on V band clamps. I love the way they look and the concept. There are many out there and I studied everything I could find. I also visited 2 exhaust shops to learn more about them. The way my exhaust is sectioned it was going to have 8 connection points. After looking at how the V band design has a machined surface where the sealing would be done, I was not comfortable about all 8 of them sealing after initial welding AND then still sealing after the car is driven a few thousand miles. I just couldn't get comfortable with that in my mind. I knew Bill Arnold built his exhaust system with the 4 bolt flanges with gaskets, and he told me he put a couple of extra gaskets in his road trip kit and has never used a single one even after chugging up Pikes Peak

! If someone has good experience with V bands please post so the rest of us can learn for next time......

! If someone has good experience with V bands please post so the rest of us can learn for next time......

#571

TECH Veteran

iTrader: (4)

[quote=Kharp;20052066] I've never used V band clamps, but have messed with them at work on big trucks, so I don't think you would have had any issues with them, but the way you're going should work just fine too. But what I want to know is, what was your friend driving that was "chugging" up Pikes Peak? He needs to put an LS in whatever it is! LOL! You wont have that problem, I can guarantee that, I made due with an outdated LS1.  And for a little inspiration, here's a quick video I made last summer, and yes, its not as fun since it's been all paved...

And for a little inspiration, here's a quick video I made last summer, and yes, its not as fun since it's been all paved...

Exhaust looks good. Kinda surprised you did not use V-Band clamps for the sections. One fastener to tighten and no gasket.

Karl I did a lot of research on V band clamps. I love the way they look and the concept. There are many out there and I studied everything I could find. I also visited 2 exhaust shops to learn more about them. The way my exhaust is sectioned it was going to have 8 connection points. After looking at how the V band design has a machined surface where the sealing would be done, I was not comfortable about all 8 of them sealing after initial welding AND then still sealing after the car is driven a few thousand miles. I just couldn't get comfortable with that in my mind. I knew Bill Arnold built his exhaust system with the 4 bolt flanges with gaskets, and he told me he put a couple of extra gaskets in his road trip kit and has never used a single one even after chugging up Pikes Peak ! If someone has good experience with V bands please post so the rest of us can learn for next time......

! If someone has good experience with V bands please post so the rest of us can learn for next time......

Karl I did a lot of research on V band clamps. I love the way they look and the concept. There are many out there and I studied everything I could find. I also visited 2 exhaust shops to learn more about them. The way my exhaust is sectioned it was going to have 8 connection points. After looking at how the V band design has a machined surface where the sealing would be done, I was not comfortable about all 8 of them sealing after initial welding AND then still sealing after the car is driven a few thousand miles. I just couldn't get comfortable with that in my mind. I knew Bill Arnold built his exhaust system with the 4 bolt flanges with gaskets, and he told me he put a couple of extra gaskets in his road trip kit and has never used a single one even after chugging up Pikes Peak

! If someone has good experience with V bands please post so the rest of us can learn for next time......

! If someone has good experience with V bands please post so the rest of us can learn for next time...... And for a little inspiration, here's a quick video I made last summer, and yes, its not as fun since it's been all paved...

And for a little inspiration, here's a quick video I made last summer, and yes, its not as fun since it's been all paved...

#572

TECH Regular

Thread Starter

Eric COOL video on Pikes Peak! I'd really like to see that someday.

Got all the exhaust welded up this week and reinstalled. Fab director put his signature on this exhaust hanger. Look closely at the 90 degree rod going from the rubber to the mounting plate. It is threaded going through the plate so you can adjust it just right .

.

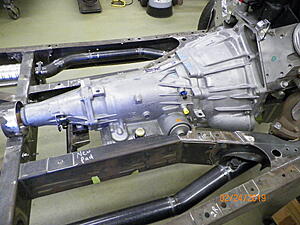

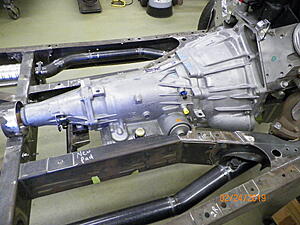

Installed the new trans. I had been using a mock up case up to this point. Dropped a few plumb bobs and established a center line and it was right on the money so I nailed the cross member.

Thanks to Bevis for welding my exhaust. Chassis starting to look like something. Moving on to some plumbing..........

Got all the exhaust welded up this week and reinstalled. Fab director put his signature on this exhaust hanger. Look closely at the 90 degree rod going from the rubber to the mounting plate. It is threaded going through the plate so you can adjust it just right

.

.

Installed the new trans. I had been using a mock up case up to this point. Dropped a few plumb bobs and established a center line and it was right on the money so I nailed the cross member.

Thanks to Bevis for welding my exhaust. Chassis starting to look like something. Moving on to some plumbing..........

#573

TECH Apprentice

Your work is looking good. Don't take my comments on the V-bands as you did a bod thing, I just know you street rod guys are about looks as you are about function. Plus you can say, Hey I even made my out flanges to take it apart if I need too!

#575

#576

TECH Regular

Thread Starter

Started plumbing the fuel system, but when I got to the front I realized I didn't have enough things nailed down in the engine compartment to be able to go all the way to the fuel rail, so I put that on hold for now. Then I started plumbing brakes and have the rear lines done. I'll post the highlights of that eventually, but as of this moment I started putting the front brakes together tonight only to discover they don't fit. Wilwood only listed one part number for a TCI spindle, BUT they sure don't fit. The bearings fit fine, but the brackets don't fit the spindles at all. Grrrrrrrrrrrrrrrrrrrrrr Calling the tech folks tomorrow..........

#577

Check the spring rate on the front springs.... The ones sent with my kit were way to stiff, had to change them out for softer ones...… Can't remember what the rates were though....

Ken

Ken

#578

The springs sent with the kit were 350# lbs...…… Way too stiff.... Switched to 275# and everything was good......

#580

TECH Regular

Thread Starter

Since my friend Stan owns a good flaring tool I bought a straightener to go with it. Kinda pricey but works pretty good. Just running some mild galvanized steel from Classic Tube that comes in coils.

Starting from the master cylinder to the rear brakes.....

Found some neat banjo fittings for the master cylinder and cut a window for access to tighten the fitting. Thank you Bill A !

Using aluminum wire and cardboard to figure out if I could get the line in and out.

Had a few obstacles to work around.

Found some pipe with just the right radius.

Really like the little plastic line clips I found made by Notchead.

Talked to TCI, Wilwood, Billet Specialties, and Speedway today about my front brakes. I hope we figured out the issue and can get my kit exchanged for one that will still fit the car nicely and have caliper clearance

Starting from the master cylinder to the rear brakes.....

Found some neat banjo fittings for the master cylinder and cut a window for access to tighten the fitting. Thank you Bill A !

Using aluminum wire and cardboard to figure out if I could get the line in and out.

Had a few obstacles to work around.

Found some pipe with just the right radius.

Really like the little plastic line clips I found made by Notchead.

Talked to TCI, Wilwood, Billet Specialties, and Speedway today about my front brakes. I hope we figured out the issue and can get my kit exchanged for one that will still fit the car nicely and have caliper clearance

Last edited by Kharp; 04-19-2019 at 07:01 PM.