'89 S-10 LQ4 4L80E Project

#22

Hey Jay! I'm JT (LOL), gathering parts to for just about the same swap. I'll be running a stg3 4l60e from Extreme Automatics. Your alot futher than me so I'll be learning from you so don't f@#k up bro. Clean dimes are hard to come by in the upper midwest, so we both lucked out in that aspect. Good luck on your build and hopefully if these last parts come in, I'll catch up to you at the finish line.

#23

TECH Apprentice

Thread Starter

Ha! Honestly, the green truck I had was in better shape (except for the roof) but this is pretty solid. It's got some rust in some weird places (like high on the firewall?!) The floors look great from underneath, tho the driver's side is a little thin.

I've never done this before. I just spend a lot of time on here, Pro-touring.com, S10forum, etc. and doing a lot of Google searching. lol

I'm not trying to do anything ground breaking, but I am trying to do everything right and eventually have a clean nice weather driver.

My GF keeps asking if the engine/trans will fit, and I keep telling her it's been done many times that's why I'm doing it. lol

I've been doing car audio/alarms/automotive electrical for 23 years now, so I plan to do my own harness.

One thing I would do different, is I think I would have held out for a Silverado donor in better shape (or maybe a 4th gen Camaro/Firebird)...the engine in this thing looks like it was underwater, everything is rusty, but it ran well enough (one of the power steering hoses popped at some point so there's oil and PS fluid caked all over it.

I plan to clean it up as best I can, but I'll pull it out later for a freshening up after all the bugs are worked out.

Would love to see your project!

Jay

I've never done this before. I just spend a lot of time on here, Pro-touring.com, S10forum, etc. and doing a lot of Google searching. lol

I'm not trying to do anything ground breaking, but I am trying to do everything right and eventually have a clean nice weather driver.

My GF keeps asking if the engine/trans will fit, and I keep telling her it's been done many times that's why I'm doing it. lol

I've been doing car audio/alarms/automotive electrical for 23 years now, so I plan to do my own harness.

One thing I would do different, is I think I would have held out for a Silverado donor in better shape (or maybe a 4th gen Camaro/Firebird)...the engine in this thing looks like it was underwater, everything is rusty, but it ran well enough (one of the power steering hoses popped at some point so there's oil and PS fluid caked all over it.

I plan to clean it up as best I can, but I'll pull it out later for a freshening up after all the bugs are worked out.

Would love to see your project!

Jay

#24

TECH Apprentice

Thread Starter

#26

TECH Apprentice

Thread Starter

I don't even know if *I* can use it for my 4L80E, but I wanted to give it a shot. It was relatively inexpensive, and only weighs like 6 lbs. A lot of guys just mod the stock one, but my truck didn't have one when I bought it. It will probably be a couple weeks before I get it in, but I'll let you know how it works out.

Jay

Jay

#27

TECH Apprentice

Thread Starter

#28

TECH Apprentice

Thread Starter

So, um, yeah...it's been a while. My motivation has been up lately, so I finally got the engine trans out of the bed and put in the right end of the truck. lol

OK. I fought with this thing for a couple of days. Clearly, the Current Performance mounts were NOT mean to be used when the trans is still attached. lol

I tried lifting and lowering the transmission, adjusting where the hook for my engine hoist was on my chains, etc.

My GF tried to help, but her descriptions "The top thing is about an inch from lining up with the bottom thingie" made it difficult. lol

All in all, I had to remove the transmission dipstick, use shorter bolts on the back of the head where I had my chain attached, remove 3 brackets, and remove the bolts that hold the gas pedal on to the firewall....then there was a lot of rocking and prying. But it's in (sans oilpan/pickup tube) for mockup.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

Bolt on the back of the head stuck out about an inch too far. Kinda blurry, obviously auto focus picked the bolt higher on the firewall focus on. lol

by https://www.flickr.com/photos/152771097@N08/, on Flickr

Heads are touching the gas pedal mounting bolts.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

So, after I got it in. I have the trans supported, the pan is sitting about 5/8" below the frame. Since I don't know exactly where things need to sit for proper driveline angles, I figured that's a good start, because I can always raise it.

So, then I removed the old trans mount...

by https://www.flickr.com/photos/152771097@N08/, on Flickr

Then replaced it with a urethane Energy Suspension mount.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

So I could bolt on the main part of my transmission crossmember. My truck didn't have a driveline in it when I bought this one, so I needed to mod a stock one or fab one or a combination. So I picked up a Stiffler's crossmember for a Mustang (I think it was -04 Cobra, but I can't remember for sure.) for it's clean look and exhaust clearance. So, I'll need to fab mounts that go from the frame to it. It was also reasonably priced at around $138 at the time.

Out of curiosity, isn't steering shaft supposed to compress? I was going to take the stock one off, and swap on my Jeep steering shaft for engine clearance, but it wouldn't compress enough to get it off?

Jay

OK. I fought with this thing for a couple of days. Clearly, the Current Performance mounts were NOT mean to be used when the trans is still attached. lol

I tried lifting and lowering the transmission, adjusting where the hook for my engine hoist was on my chains, etc.

My GF tried to help, but her descriptions "The top thing is about an inch from lining up with the bottom thingie" made it difficult. lol

All in all, I had to remove the transmission dipstick, use shorter bolts on the back of the head where I had my chain attached, remove 3 brackets, and remove the bolts that hold the gas pedal on to the firewall....then there was a lot of rocking and prying. But it's in (sans oilpan/pickup tube) for mockup.

Bolt on the back of the head stuck out about an inch too far. Kinda blurry, obviously auto focus picked the bolt higher on the firewall focus on. lol

Heads are touching the gas pedal mounting bolts.

So, after I got it in. I have the trans supported, the pan is sitting about 5/8" below the frame. Since I don't know exactly where things need to sit for proper driveline angles, I figured that's a good start, because I can always raise it.

So, then I removed the old trans mount...

Then replaced it with a urethane Energy Suspension mount.

So I could bolt on the main part of my transmission crossmember. My truck didn't have a driveline in it when I bought this one, so I needed to mod a stock one or fab one or a combination. So I picked up a Stiffler's crossmember for a Mustang (I think it was -04 Cobra, but I can't remember for sure.) for it's clean look and exhaust clearance. So, I'll need to fab mounts that go from the frame to it. It was also reasonably priced at around $138 at the time.

Out of curiosity, isn't steering shaft supposed to compress? I was going to take the stock one off, and swap on my Jeep steering shaft for engine clearance, but it wouldn't compress enough to get it off?

Jay

#29

Teching In

Join Date: May 2009

Location: igloo's and skidoo's

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

It should but since it would never happen until an accident it's probably a bit crusty and siezed. Just pry up on the rag joint or losses up the steering box.

#30

TECH Apprentice

Thread Starter

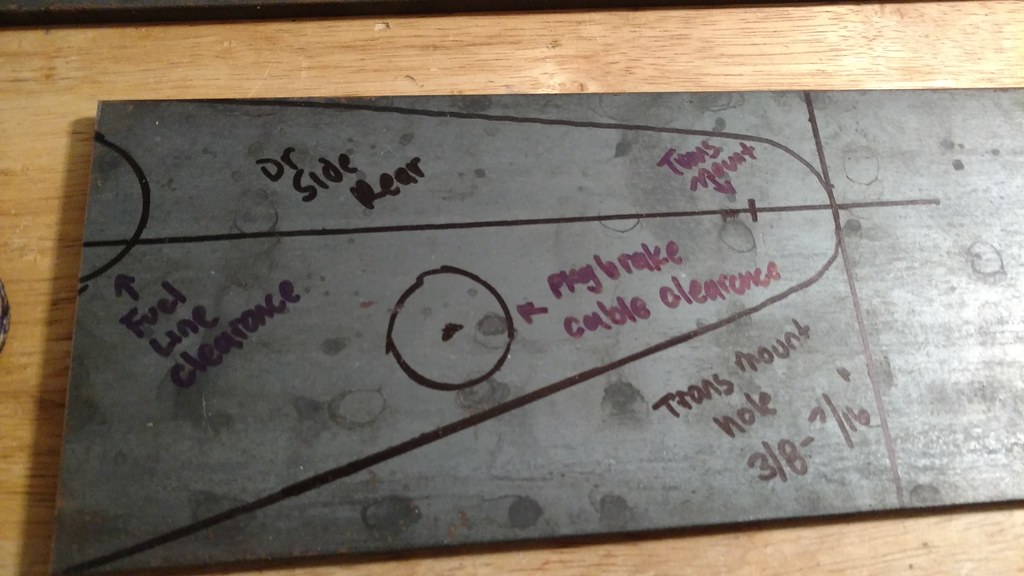

I worked on my trans crossmember mounts today. I think I got them figured out.

They're going to be 1/4" steel, and then I'm going to use some 3/16" to connect/reinforce them.

A little Carboard Aided Design helped verify my measurements.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

by https://www.flickr.com/photos/152771097@N08/, on Flickr

Probably going to cut them and weld them up on Wednesday.

Once I verify they fit, I plan to weld these directly to the frame. The Stiffler's 94-98 Mustang crossmember will bolt right up and drop out as needed. It has humps to allow for the exhaust to pass through.

Jay

They're going to be 1/4" steel, and then I'm going to use some 3/16" to connect/reinforce them.

A little Carboard Aided Design helped verify my measurements.

Probably going to cut them and weld them up on Wednesday.

Once I verify they fit, I plan to weld these directly to the frame. The Stiffler's 94-98 Mustang crossmember will bolt right up and drop out as needed. It has humps to allow for the exhaust to pass through.

Jay

#31

I'm doing an 87 S10, 6.0, 4L80e...my biggest issue right now is the steering shaft and headers...what are you going to use for the steering shaft? I like the trans crossmember you're doing!

#32

TECH Apprentice

Thread Starter

I've got a Jeep Cherokee steering shaft I intended to use, but I'm not 100%

Even with the seats all the way back the steering wheel kind of encroaches on my personal space, and since I intend to build my own interior, I'm thinking of switching to something like a Grand Am steering column for more space. Assuming it's shorter. But that won't be until spring, I don't think.

My other reason for the steering column change is because I have a Push to Start/Proximity key system I am going to install and I want a column w/o the key cylinder on it.

Glad you like the crossmember. I couldn't justify the $265 one that CPW sells, and I hadn't seen anyone else do it this way, so I figured I'd give it a shot. I have a welder, why not? lol

Jay

Even with the seats all the way back the steering wheel kind of encroaches on my personal space, and since I intend to build my own interior, I'm thinking of switching to something like a Grand Am steering column for more space. Assuming it's shorter. But that won't be until spring, I don't think.

My other reason for the steering column change is because I have a Push to Start/Proximity key system I am going to install and I want a column w/o the key cylinder on it.

Glad you like the crossmember. I couldn't justify the $265 one that CPW sells, and I hadn't seen anyone else do it this way, so I figured I'd give it a shot. I have a welder, why not? lol

Jay

#33

TECH Apprentice

Thread Starter

I started with an '87, but the convertible conversion led me to a replacement cab...which turned out to be a better option to start with. lol

#34

TECH Addict

iTrader: (47)

JayinMI, I should have mentioned its SOOOOO much easier to drop the engine/trans as a unit if you unbolt the cab, and lift the front up and slide a 4x4 under the front of it. Progress is looking good!

As far as Blacks10 asked, there are a lot of options for headers, but IMO the best bet is either the Sanderson knock offs on Ebay that are stainless shortys or go all the way and buy the Stainless Works long tubes if you want a real, high quality part that supports high HP. I still have a stock steering shaft in my truck, with a aftermarket 9" brake booster, soon to be hydroboost.

As far as Blacks10 asked, there are a lot of options for headers, but IMO the best bet is either the Sanderson knock offs on Ebay that are stainless shortys or go all the way and buy the Stainless Works long tubes if you want a real, high quality part that supports high HP. I still have a stock steering shaft in my truck, with a aftermarket 9" brake booster, soon to be hydroboost.

#36

TECH Apprentice

Thread Starter

Was fighting a bad (possibly caffeine withdrawal) headache all day, but I made some progress.

I updated my crossmember mount design to be height adjustable, and drew them out on the 4" wide, 1/4" thick plate I had. I was at home depot in the morning, and was considering buying an 20V Dewalt drill for this, because I didn't know if my little 12V Milwaukee Hammer Drill would be able to cut it, but it worked like a champ.

Passenger side went off (so far) without a hitch. Driver side, not so much. lol

by https://www.flickr.com/photos/152771097@N08/, on Flickr

by https://www.flickr.com/photos/152771097@N08/, on Flickr

by https://www.flickr.com/photos/152771097@N08/, on Flickr

On the driver's side, someone ran a rubber hose of some kind (that's kinda in the way) and there's a fuel or brake line that sticks out of the fram right about where I DON'T need it to. I had to leave a spot for it in the mount, and the other issue is the parking brake cable is in the way.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

With it rough cut, it touches the line, but sits flat agains the frame, so I just need to shape the opening different for clearance.

With the parking brake cable, my issue was when I tried to take the slack out of the cable so I could disconnect them, is that if I tighten the bolt it gives me some slack (but not enough) and if I loosen it, the cable get tighter.

The bolt you need to turn seems to be frozen on. Let it soak most of the day in penetrating oil, but it still held fast.

So I think my next option is to cut the intermediate cable that attached the left and right cables, I think. That's the cheapest part to replace. I realized the cables won't go anywhere near the trans crossmember mounts after I set up my hand brake handle, so I'll have to find shorter cables to use later on. Much shorter.

Anyway, I'm doing this as a hobby and I'm not in a hurry, so I don't push it. I don't want to get frustrated and quit. That's happened before. lol

Jay

I updated my crossmember mount design to be height adjustable, and drew them out on the 4" wide, 1/4" thick plate I had. I was at home depot in the morning, and was considering buying an 20V Dewalt drill for this, because I didn't know if my little 12V Milwaukee Hammer Drill would be able to cut it, but it worked like a champ.

Passenger side went off (so far) without a hitch. Driver side, not so much. lol

On the driver's side, someone ran a rubber hose of some kind (that's kinda in the way) and there's a fuel or brake line that sticks out of the fram right about where I DON'T need it to. I had to leave a spot for it in the mount, and the other issue is the parking brake cable is in the way.

With it rough cut, it touches the line, but sits flat agains the frame, so I just need to shape the opening different for clearance.

With the parking brake cable, my issue was when I tried to take the slack out of the cable so I could disconnect them, is that if I tighten the bolt it gives me some slack (but not enough) and if I loosen it, the cable get tighter.

The bolt you need to turn seems to be frozen on. Let it soak most of the day in penetrating oil, but it still held fast.

So I think my next option is to cut the intermediate cable that attached the left and right cables, I think. That's the cheapest part to replace. I realized the cables won't go anywhere near the trans crossmember mounts after I set up my hand brake handle, so I'll have to find shorter cables to use later on. Much shorter.

Anyway, I'm doing this as a hobby and I'm not in a hurry, so I don't push it. I don't want to get frustrated and quit. That's happened before. lol

Jay

#37

TECH Apprentice

Thread Starter

Oh, btw, here's the area I have to work in.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

About 3 feet on the passenger side, and

by https://www.flickr.com/photos/152771097@N08/, on Flickr

and about 18" on the driver's side...at least until I get the transmission supported, then I can push it out and move it over. Then I'll have about 2.5 feet on either side! lol

Jay

About 3 feet on the passenger side, and

and about 18" on the driver's side...at least until I get the transmission supported, then I can push it out and move it over. Then I'll have about 2.5 feet on either side! lol

Jay

#38

TECH Apprentice

Thread Starter

As I was getting close to welding up my trans crossmember mounts, the temperatures took a nose dive.

I don't think it's been above 25F in my garage in over a month. So, that hasn't happened yet.

In the meantime, I've been researching and ordering parts since I can do that inside. lol

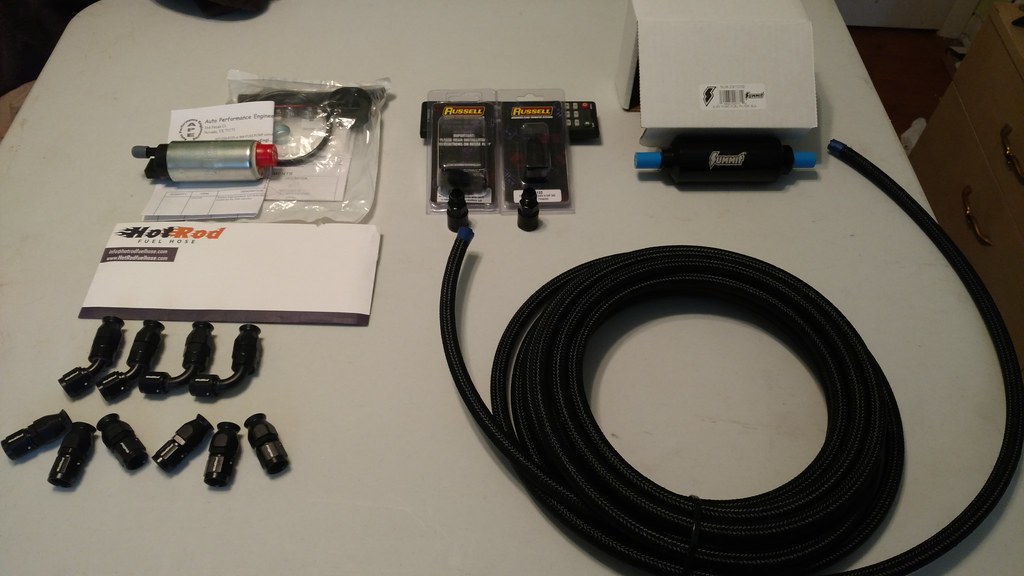

I ordered my main parts for my fuel system.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

by https://www.flickr.com/photos/152771097@N08/, on Flickr

Which consists of a Walbro 255 pump and install kit from APE, Russel fuel line adapters (not the ones with the plastic clips), Summit racing 10 Micron fuel filter and AN wrenches, and PTFE -6AN nylon braided hose (and hose ends) from HotRod Fuel Hose.

by https://www.flickr.com/photos/152771097@N08/, on Flickr

by https://www.flickr.com/photos/152771097@N08/, on Flickr

Justin at Hot Rod Fuel Hose was great to work with. Great communication and even refunded a little of my money because of a shipping SNAFU on his end.

I ordered 30ft of hose so I can use some of it for the trans cooler as well.

Future plans are Sweet Performance Banjo ends for the 4L80E to clear the trans tunnel.

Currently debating on using the Superior Radiator I planned on using (No trans cooler) or a 4.3HD/Corvette radiator.

A lot of people have good luck with the latter, and I don't plan to have ridiculous HP and I don't live where it's stupid hot. But I DO want to retain A/C.

I've also been looking at Restomod Air stuff. But that's a ways off.

I've also been trying to find a crimping tool that will do all the ends I need to do, if possible.

It looks like GM uses Weatherpack, Metripack and possible open end barrel connectors on a typical LS harness.

My current thought was to depin from the PCM, route everything and repin the PCM side. Not 100% sure what connectors they use in those, tho.

Jay

I don't think it's been above 25F in my garage in over a month. So, that hasn't happened yet.

In the meantime, I've been researching and ordering parts since I can do that inside. lol

I ordered my main parts for my fuel system.

Which consists of a Walbro 255 pump and install kit from APE, Russel fuel line adapters (not the ones with the plastic clips), Summit racing 10 Micron fuel filter and AN wrenches, and PTFE -6AN nylon braided hose (and hose ends) from HotRod Fuel Hose.

Justin at Hot Rod Fuel Hose was great to work with. Great communication and even refunded a little of my money because of a shipping SNAFU on his end.

I ordered 30ft of hose so I can use some of it for the trans cooler as well.

Future plans are Sweet Performance Banjo ends for the 4L80E to clear the trans tunnel.

Currently debating on using the Superior Radiator I planned on using (No trans cooler) or a 4.3HD/Corvette radiator.

A lot of people have good luck with the latter, and I don't plan to have ridiculous HP and I don't live where it's stupid hot. But I DO want to retain A/C.

I've also been looking at Restomod Air stuff. But that's a ways off.

I've also been trying to find a crimping tool that will do all the ends I need to do, if possible.

It looks like GM uses Weatherpack, Metripack and possible open end barrel connectors on a typical LS harness.

My current thought was to depin from the PCM, route everything and repin the PCM side. Not 100% sure what connectors they use in those, tho.

Jay

#40

TECH Apprentice

Thread Starter

I started a thread here listing all the Delphi part numbers for the connector in my engine harness. Hopefully it'll be helpful to some other people.

Finally got the trans crossmember mounts welded in (not pretty, but I got decent penetration), and put the truck on the ground. I'll get pics this weekend.

Started mocking up my DWB gas pedal today as well.

Jay

Finally got the trans crossmember mounts welded in (not pretty, but I got decent penetration), and put the truck on the ground. I'll get pics this weekend.

Started mocking up my DWB gas pedal today as well.

Jay