Foxbody notch lq4 turbo build

#81

On The Tree

I actually started to pull the fuel pump assembly out of my 2003 mustang to put in a Walbro 450. Realized the pump body is much larger than the OEM pump and would not fit into the bucket. Are you planning on using the OEM bucket, or are you going to make a fixture that the pumps attach to?

#82

I actually started to pull the fuel pump assembly out of my 2003 mustang to put in a Walbro 450. Realized the pump body is much larger than the OEM pump and would not fit into the bucket. Are you planning on using the OEM bucket, or are you going to make a fixture that the pumps attach to?

#83

On The Tree

Not gunna lie, I saw the threaded rod in one of the pictures and had an AHA! moment. Run a threaded rod through the hat and just make a couple of half circle brackets with the ID being the same as the pump OD to hold them together.

#87

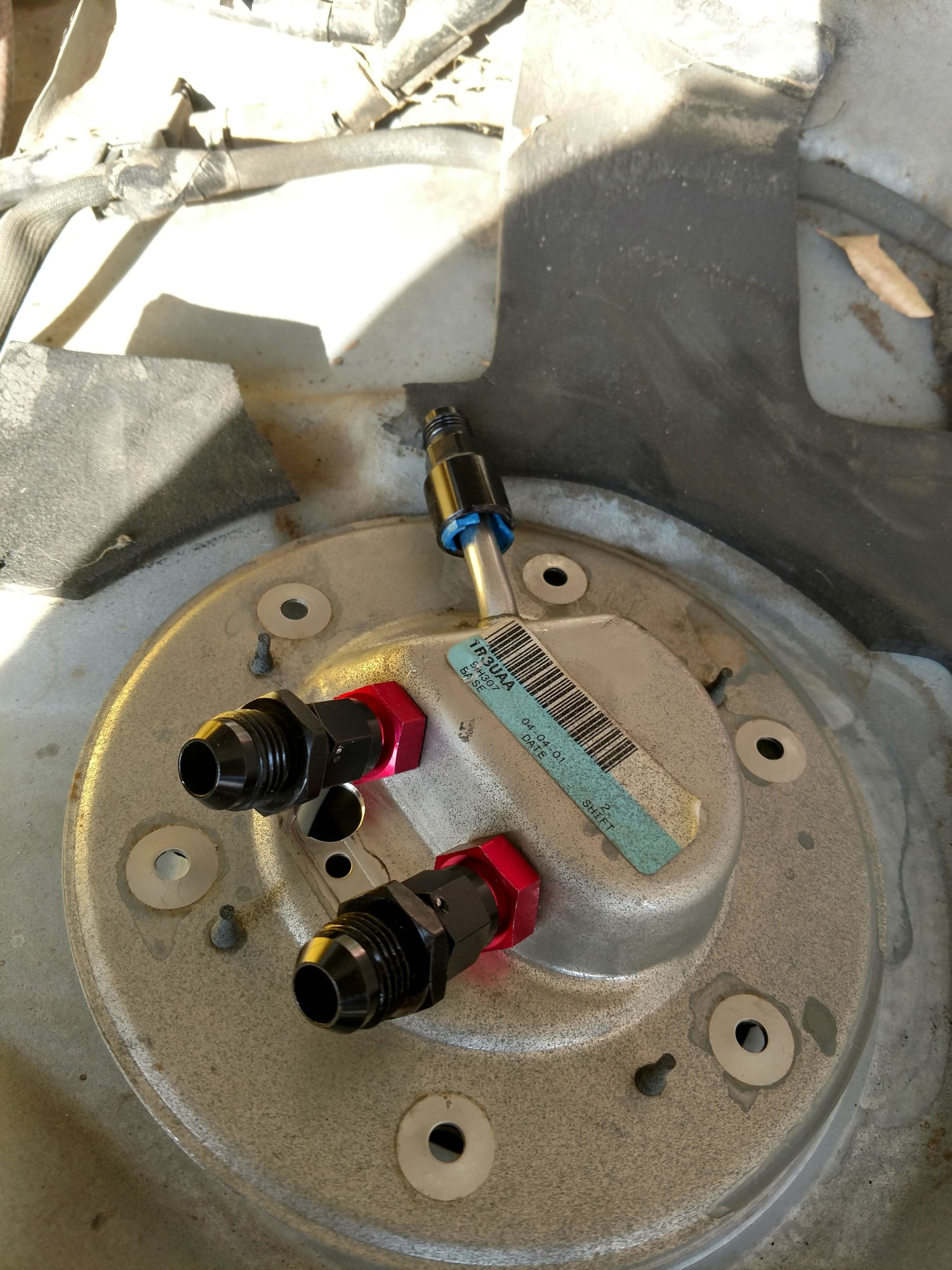

I'm trying to build the fuel system large enough so I don't have to change things down the road. I'm using a -10 feed to Holley high flow rails and FIC 127lbs injectors. Should be good for 1000 wheel on e85 from the reading I've been doing. Here's on of the y blocks two -8 lines from the pumps to a -10 feed. Still waiting on more pieces to come in.

#88

TECH Resident

iTrader: (26)

IMO, making 1000rwhp on E85 with FIC 127s will be a stretch unless you are willing to run them over 90% DC and a leaner AFR. You don't have the option to jack up the FP since the 127# flow is at 4bar. For 1000rwhp you will have to run 20+psi putting the FP at 80psi or more, so make sure the pumps can flow what you need at 80psi and remember to factor in flow loss from the lines, fittings, filters, voltage, etc. Here's what I mean. The Walbro flow chart show the flow as ~87gph @ 80psi / 13.5V. That's about 1070 lb/hr for the 2 pumps. If you use a BSFC of .8 for E85 and apply driveline loss and flow loss, there's not a lot margin left at 1000rwhp.

Not saying it can't be done, just make sure you calculate and know exactly what the injs and pumps will do at the boost/FP you plan to run AND make sure you have at least 13.5V at full load. Just passing on my experiences.

I see my car every time I look at your build. Good luck.

Not saying it can't be done, just make sure you calculate and know exactly what the injs and pumps will do at the boost/FP you plan to run AND make sure you have at least 13.5V at full load. Just passing on my experiences.

I see my car every time I look at your build. Good luck.

#89

IMO, making 1000rwhp on E85 with FIC 127s will be a stretch unless you are willing to run them over 90% DC and a leaner AFR. You don't have the option to jack up the FP since the 127# flow is at 4bar. For 1000rwhp you will have to run 20+psi putting the FP at 80psi or more, so make sure the pumps can flow what you need at 80psi and remember to factor in flow loss from the lines, fittings, filters, voltage, etc. Here's what I mean. The Walbro flow chart show the flow as ~87gph @ 80psi / 13.5V. That's about 1070 lb/hr for the 2 pumps. If you use a BSFC of .8 for E85 and apply driveline loss and flow loss, there's not a lot margin left at 1000rwhp.

Not saying it can't be done, just make sure you calculate and know exactly what the injs and pumps will do at the boost/FP you plan to run AND make sure you have at least 13.5V at full load. Just passing on my experiences.

I see my car every time I look at your build. Good luck.

Not saying it can't be done, just make sure you calculate and know exactly what the injs and pumps will do at the boost/FP you plan to run AND make sure you have at least 13.5V at full load. Just passing on my experiences.

I see my car every time I look at your build. Good luck.

#93

TECH Senior Member

Bigger injectors, or bigger pump? OR both??

#95

TECH Senior Member

How much ET you think you were cheated out of with the present fuel system?

Oh, it looks like your answer to my question is BOTH! PLUS some stuff! lol

Best of luck, and have a Joyful Christmas and Prosperous New Year!

Oh, it looks like your answer to my question is BOTH! PLUS some stuff! lol

Best of luck, and have a Joyful Christmas and Prosperous New Year!

Last edited by G Atsma; 12-23-2017 at 04:18 PM.

#100

Couldn't use the threaded rod to secure the pumps. They have to sit at an angle so the hose won't kink. The plastic piece that the stock bucket sits in does the job of holding them from moving around too much.

-6 adapter on the stock feed for the return fit on I re used it from the factory fuel rail I was using for fuel supply.