2000 Black FRC Progress Thread

#62

TECH Enthusiast

iTrader: (1)

got that sweet bumper mod going

photo by Norbert Ogiba, on Flickr

photo by Norbert Ogiba, on Flickr

Coworker was waiting to leave the parking lot onto the street, when a kid on a bike comes whizzing down the sidewalk. Coworker decides to back up to let the kid pass in front of him. Coworker doesn't see my low car and crunches up and over my front bumper.

I hope the bumper can be saved, if not, oh well. This is why we have insurance. If I can buy a used cover I'll toss that on and use the rest of the dough for new tires

I think it's time to get those cutouts finished up so people know where I am, even if they can't see me!

photo by Norbert Ogiba, on Flickr

photo by Norbert Ogiba, on FlickrCoworker was waiting to leave the parking lot onto the street, when a kid on a bike comes whizzing down the sidewalk. Coworker decides to back up to let the kid pass in front of him. Coworker doesn't see my low car and crunches up and over my front bumper.

I hope the bumper can be saved, if not, oh well. This is why we have insurance. If I can buy a used cover I'll toss that on and use the rest of the dough for new tires

I think it's time to get those cutouts finished up so people know where I am, even if they can't see me!

Ouch! Doesn't look to bad, I'm sure it's a easy fix. Thats a good looking vette!

#64

Been driving this thing a ton, trying not to work on it too much, it has needed nothing other than whatever I decide to tinker with for fun.

IMG_1653[1] by Norbert Ogiba, on Flickr

IMG_1653[1] by Norbert Ogiba, on Flickr

IMG_1655[1] by Norbert Ogiba, on Flickr

IMG_1655[1] by Norbert Ogiba, on Flickr

IMG_1681[1] by Norbert Ogiba, on Flickr

IMG_1681[1] by Norbert Ogiba, on Flickr

IMG_1682[1] by Norbert Ogiba, on Flickr

IMG_1682[1] by Norbert Ogiba, on Flickr

Front camber/toe wear finally ruined my front tires

IMG_1666[1] by Norbert Ogiba, on Flickr

IMG_1666[1] by Norbert Ogiba, on Flickr

IMG_1667[1] by Norbert Ogiba, on Flickr

IMG_1667[1] by Norbert Ogiba, on Flickr

So I picked up a new set of Hankook Ventus V12 Evo2, had them on my old BMW and liked them. They are 18/19 compared to the old 17/18, but the overall circumference is the same and will keep the active handling happy.

IMG_1695[1] by Norbert Ogiba, on Flickr

IMG_1695[1] by Norbert Ogiba, on Flickr

I also ordered some Corvette wall art for the garage and an OEM GM tail light lense to replace the one aftermarket one that was a slightly different shade of red than the other 3.

Next up - figuring out how to plumb the vacuum. Been playing with some EGR solenoids. More to come. Also need to pick up a new bumper.

IMG_1653[1] by Norbert Ogiba, on Flickr

IMG_1653[1] by Norbert Ogiba, on Flickr IMG_1655[1] by Norbert Ogiba, on Flickr

IMG_1655[1] by Norbert Ogiba, on Flickr IMG_1681[1] by Norbert Ogiba, on Flickr

IMG_1681[1] by Norbert Ogiba, on Flickr IMG_1682[1] by Norbert Ogiba, on Flickr

IMG_1682[1] by Norbert Ogiba, on FlickrFront camber/toe wear finally ruined my front tires

IMG_1666[1] by Norbert Ogiba, on Flickr

IMG_1666[1] by Norbert Ogiba, on Flickr IMG_1667[1] by Norbert Ogiba, on Flickr

IMG_1667[1] by Norbert Ogiba, on FlickrSo I picked up a new set of Hankook Ventus V12 Evo2, had them on my old BMW and liked them. They are 18/19 compared to the old 17/18, but the overall circumference is the same and will keep the active handling happy.

IMG_1695[1] by Norbert Ogiba, on Flickr

IMG_1695[1] by Norbert Ogiba, on FlickrI also ordered some Corvette wall art for the garage and an OEM GM tail light lense to replace the one aftermarket one that was a slightly different shade of red than the other 3.

Next up - figuring out how to plumb the vacuum. Been playing with some EGR solenoids. More to come. Also need to pick up a new bumper.

#65

Interested to see how you use the vacuum cutout. I have the same idea, just haven't executed it yet. Instead I half-assed tried using a rpm switch to a mini servo so I can dial in the RPM via the rpm switch I want it to open.

Using vacuum setup may get tricky to fine tune when it opens.

Using vacuum setup may get tricky to fine tune when it opens.

#72

Got the new front bumper on, looks good. Whole car needs a paint correction bad, I'll tackle that in the next couple weeks. Need to stick on a new front emblem, too. I did my wife's black A4 a few months ago and hers was in far worse shape to begin with, but turned out nicely - so I have hope for this one.

Threw in a new wheel bearing in the right rear, ahhhhhh, nice and quiet now.

Finally had enough of the stock seats, picked these up on Ebay. Removed from an '02 S2000. All leather, all manual, I will probably clean up the leather with some Leatherique and/or redye the bolsters.

Threw in a new wheel bearing in the right rear, ahhhhhh, nice and quiet now.

Finally had enough of the stock seats, picked these up on Ebay. Removed from an '02 S2000. All leather, all manual, I will probably clean up the leather with some Leatherique and/or redye the bolsters.

#73

Well, 2 steps forward, 1 step back. I plumbed the entire vacuum system for the cutouts - sourcing from the booster line, running along the firewall, through the passenger firewall behind the battery, and through the passenger compartment to the trunk. I mounted the vacuum canister and solenoid in the cargo well next to the CD Changer. Vacuum output from the solenoid ran through a small hole in the cargo well, up and around the diff, and then tee'd to each cutout. Tested it with the engine running and 12V from a wall adapter. Both cutouts open all the way - I was concerned that the vacuum wouldn't be strong enough to overcome the spring pressure of both units, but it works well.

Time to put it all back together and source power from the car - there is an unused harness connector in the passenger footwell that provides a ground, switched power, and constant power - so I wired my power and ground to the switched wire and ran back to my pushbutton switch in the ashtray. Good tips here on where to find it:

http://frankhunt.com/FRANK/hobbies/c...e_install.html

Before putting the dash back together, I yet again tested it with the engine running, now pulling power from that harness inside the car - still worked great.

Put shifter surround trim back in, tested it - blew fuse. Replace fuse, try again, SNAP, blew fuse. Remove console, replace fuse, try again, works. Put shifter surround back in, SNAP, blew fuse. I think I am pinching a wire somewhere. It's a 20A circuit, so I can't see that little vacuum solenoid pulling more current than that, especially since that fuse is not shared with any other circuits. So close to being done! Unfortunately I won't be able to work on the car much this weekend so it will have to sit in the back of my mind and bother me until I can spend some time on it.

On a positive note I did pick up my S2000 seats from the shipping terminal and they look great. Leather needs a quick cleanup and maybe some shoe polish on the bolsters but otherwise like new.

Time to put it all back together and source power from the car - there is an unused harness connector in the passenger footwell that provides a ground, switched power, and constant power - so I wired my power and ground to the switched wire and ran back to my pushbutton switch in the ashtray. Good tips here on where to find it:

http://frankhunt.com/FRANK/hobbies/c...e_install.html

Before putting the dash back together, I yet again tested it with the engine running, now pulling power from that harness inside the car - still worked great.

Put shifter surround trim back in, tested it - blew fuse. Replace fuse, try again, SNAP, blew fuse. Remove console, replace fuse, try again, works. Put shifter surround back in, SNAP, blew fuse. I think I am pinching a wire somewhere. It's a 20A circuit, so I can't see that little vacuum solenoid pulling more current than that, especially since that fuse is not shared with any other circuits. So close to being done! Unfortunately I won't be able to work on the car much this weekend so it will have to sit in the back of my mind and bother me until I can spend some time on it.

On a positive note I did pick up my S2000 seats from the shipping terminal and they look great. Leather needs a quick cleanup and maybe some shoe polish on the bolsters but otherwise like new.

#74

I'm curious, does it tell you how much vacuum you need to pull to close them and overcome the spring?

Love to see some install pics of this if you have any.

I came across your thread on a corvette forum seeing you using a GM EGR solenoid AC Delco 214-329. So if I understand correctly, you have a vacuum line plumbed to a constant source of vacuum (a place where the vacuum is high enough to overcome the spring in the "normally closed" cutout) running to the inlet of the EGR solenoid. Then the outlet of EGR solenoid running to cutout. The solenoid you have powered by a 12V supply via a toggle switch. When no 12V to the solenoid, it remains "normally closed". When you apply 12V it opens and allows motor vacuum to pull cut out open?

Something else you could do is run the 12V supply to the solenoid off a universal RPM switch. You could set the rpm switch to energize the solenoid at say anything above 3000rpm which would open the solenoid and allow cutout to be opened. This would be one step further to something "automatic".

I picked up one of these:

http://www.summitracing.com/parts/su...FQeraQodF5UFmg

Love to see some install pics of this if you have any.

I came across your thread on a corvette forum seeing you using a GM EGR solenoid AC Delco 214-329. So if I understand correctly, you have a vacuum line plumbed to a constant source of vacuum (a place where the vacuum is high enough to overcome the spring in the "normally closed" cutout) running to the inlet of the EGR solenoid. Then the outlet of EGR solenoid running to cutout. The solenoid you have powered by a 12V supply via a toggle switch. When no 12V to the solenoid, it remains "normally closed". When you apply 12V it opens and allows motor vacuum to pull cut out open?

Something else you could do is run the 12V supply to the solenoid off a universal RPM switch. You could set the rpm switch to energize the solenoid at say anything above 3000rpm which would open the solenoid and allow cutout to be opened. This would be one step further to something "automatic".

I picked up one of these:

http://www.summitracing.com/parts/su...FQeraQodF5UFmg

Last edited by smitty2919; 05-27-2016 at 10:55 AM.

#75

I'm curious, does it tell you how much vacuum you need to pull to close them and overcome the spring?

Love to see some install pics of this if you have any.

I came across your thread on a corvette forum seeing you using a GM EGR solenoid AC Delco 214-329. So if I understand correctly, you have a vacuum line plumbed to a constant source of vacuum (a place where the vacuum is high enough to overcome the spring in the "normally closed" cutout) running to the inlet of the EGR solenoid. Then the outlet of EGR solenoid running to cutout. The solenoid you have powered by a 12V supply via a toggle switch. When no 12V to the solenoid, it remains "normally closed". When you apply 12V it opens and allows motor vacuum to pull cut out open?

Something else you could do is run the 12V supply to the solenoid off a universal RPM switch. You could set the rpm switch to energize the solenoid at say anything above 3000rpm which would open the solenoid and allow cutout to be opened. This would be one step further to something "automatic".

I picked up one of these:

http://www.summitracing.com/parts/su...FQeraQodF5UFmg

Love to see some install pics of this if you have any.

I came across your thread on a corvette forum seeing you using a GM EGR solenoid AC Delco 214-329. So if I understand correctly, you have a vacuum line plumbed to a constant source of vacuum (a place where the vacuum is high enough to overcome the spring in the "normally closed" cutout) running to the inlet of the EGR solenoid. Then the outlet of EGR solenoid running to cutout. The solenoid you have powered by a 12V supply via a toggle switch. When no 12V to the solenoid, it remains "normally closed". When you apply 12V it opens and allows motor vacuum to pull cut out open?

Something else you could do is run the 12V supply to the solenoid off a universal RPM switch. You could set the rpm switch to energize the solenoid at say anything above 3000rpm which would open the solenoid and allow cutout to be opened. This would be one step further to something "automatic".

I picked up one of these:

http://www.summitracing.com/parts/su...FQeraQodF5UFmg

Yes, your summary is correct, although I also have a vacuum reservoir in place that allows the cutouts to stay open even when the engine isn't producing vacuum (like when you're WOT).

Yes, you could do the "auto" mode with an RPM switch if you wanted to. That'd be the closest thing to an "NPP" option. But, with how loud my cutouts are, I don't know if I'd want them constantly switching on and off if I'm hovering around 3000 between shifts. All or nothing!

Quick video of a rigged setup, using vacuum from the engine and power from a 12V adapter plugged into the wall. Just testing operation here.

Anyhow, weekend update: I ran the wiring inside the car and tapped into the fused switched power and kept blowing fuses - took the console back apart on Memorial Day and found 2 spots where the console had pinched the power wire, which broke the insulation and grounded it to the metal chassis tunnel. Replaced that section of wire, and got the whole interior finally back together. Test drive went great, works exactly as expected, the nice part is how quickly the cutouts close when you want them off. The spring snaps them shut in about half a second. In car videos to come.

#76

Awesome! That looks like a slick setup/operation. Turns the "electric cutouts" to a more mechanical method which I'm always a fan of...and cheaper!

So for these to "fail" (not open), the solenoid would need to fail or a vacuum leak in the air line would need to occur. Well and or the diaphragm in the cutout fails.

So for these to "fail" (not open), the solenoid would need to fail or a vacuum leak in the air line would need to occur. Well and or the diaphragm in the cutout fails.

#77

If the solenoid fails (doesn't open when 12V is applied), the cutouts just won't open when I push the button.

If the solenoid leaks internally, the cutouts might get pulled open (highly unlikely).

If there is a leak in any of the vacuum lines, the system won't operate and I'll have a vacuum leak from the engine. This is the most likely scenario (still highly unlikely to happen). If that's the case I just plug the line coming off the booster hose until I can get home to inspect it.

If the solenoid leaks internally, the cutouts might get pulled open (highly unlikely).

If there is a leak in any of the vacuum lines, the system won't operate and I'll have a vacuum leak from the engine. This is the most likely scenario (still highly unlikely to happen). If that's the case I just plug the line coming off the booster hose until I can get home to inspect it.

#78

Thanks a lot. Could you PM me the P/N list of what you bought? I have come across a lot of vacuum cutouts online.

I'd like to add this to the "future projects list" at some point LOL.

I'd like to add this to the "future projects list" at some point LOL.

#79

The C5 seats are garbage, I don't care how much you refinish or replace foam, they have poor control and really make the aggressive driving experience terrible. I have not yet autocrossed or road raced my 2000 FRC, only street driven so far. And yet on every highway on/off ramp that I take, I slide either into the center tunnel or smash against the door panel hanging onto the steering wheel for dear life. The C5 chassis is capable of far more - it's an absolute shame the stock seats hold it back so much.

The C5 chassis is supported by a huge aftermarket following, with no lack of gorgeous seating options with bolt-in brackets available. However, I decided not to go with the typical aftermarket options for the following reasons:

-I'm not a millionaire and don't want to spend thousands of dollars on seats and brackets

-I know my way around a wrench and enjoy fabrication projects

-All the aftermarket options I found looked very "boy racer" to me.

- I wanted to keep the "OEM+" look that only factory seats can achieve.

-Had to keep the leather theme - no cheesy aftermarket black foamy cloth with gaudy embroidered lettering for me

As part of the planning phase of the project, I had no intention of keeping the heavy C5 power seat adjustments and adapting the S2000 seat to the C5 rails, so I decided to keep the S2000 seat attached to the Honda rails and adapt them to a bracket, which would be bolted to the stock C5 floor studs. I also did not want to modify the C5 seats or floor mounting points in any way as it would devalue the originality of the chassis.

I did not get any pics of this process, but I simply removed the 4x nuts holding the C5 seat in place and immediately realized that the floor is recessed around the mounting studs. As such I wasn't able to bolt a flat ]rail directly to the floor; it needed to come up at least an inch or more. I bought some hex couplers, washers, and bolts that all matched the factory C5 M10x1.5 studs. The hex couplers threaded onto the studs and provided a raised platform to which I could bolt the new adapter bracket.

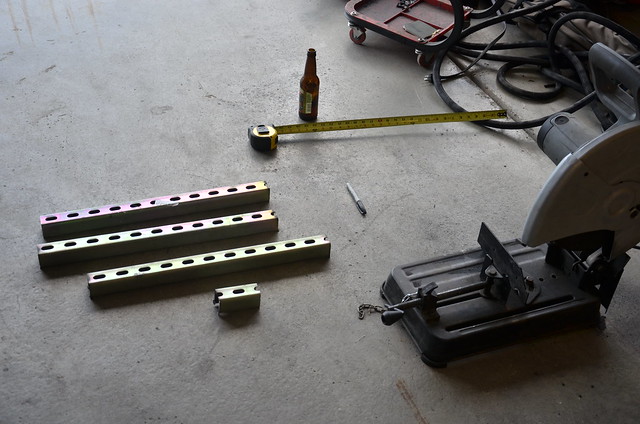

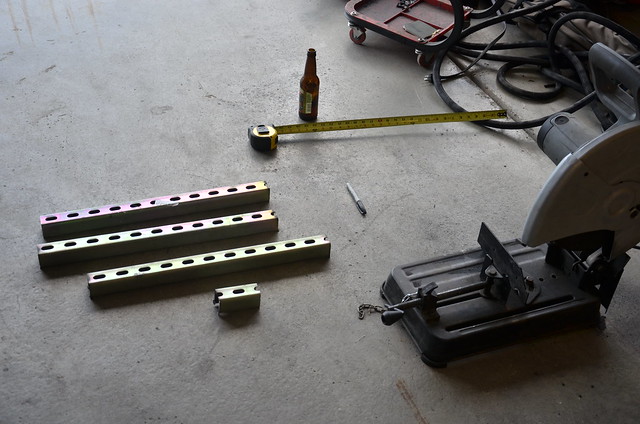

In the fall of '14 I installed a unit heater in my garage and mounted it to the joists in the ceiling using a long stick of zinc-plated Unistrut.

_DSC5115 by Norbert Ogiba, on Flickr

_DSC5115 by Norbert Ogiba, on Flickr

I think the stick was at least 12' long, I only used about 20" of it for the heater install. The remainer collected dust in the corner of the garage for a couple of years until today.

_DSC5118 by Norbert Ogiba, on Flickr

_DSC5118 by Norbert Ogiba, on Flickr

I chopped them to 23" lengths and mounted to the tops of the hex adapters lengthwise in the car. One end of each rail needed to have the slot slightly enlarged to allow it to fit. No pics, will get them next time I take the seat out of the car.

These will get a coat of black paint before final installation and should blend in with the floor nicely.

_DSC5119 by Norbert Ogiba, on Flickr

_DSC5119 by Norbert Ogiba, on Flickr

The S2000 floor mounting points are NOTHING like the C5 so I cut the mounting tabs off the S2000 rails right away. They are riveted AND spot welded to the rails, so some quality time with the cutoff wheel needs to be spent. I tend to enjoy grinding as I can throw in headphones, turn up the tunes, and go to town.

Note 4 shiny corners where brackets are gone.

_DSC5120 by Norbert Ogiba, on Flickr

_DSC5120 by Norbert Ogiba, on Flickr

S2000 mounting tabs cut off.

_DSC5120 by Norbert Ogiba, on Flickr

_DSC5120 by Norbert Ogiba, on Flickr

So now that the unistrut rails were firmly bolted in place, and the S2000 seat had a nice flat bottom to work with, it was time to put the seat in the car and see where I had fitment issues.

These things looks awesome.

_DSC5123 by Norbert Ogiba, on Flickr

_DSC5123 by Norbert Ogiba, on Flickr

_DSC5124 by Norbert Ogiba, on Flickr

_DSC5124 by Norbert Ogiba, on Flickr

However, note how far forward the seat sits in relation to the C5 passenger seat - there is a lot of contact between the S2000 reclining handle cover and the lower C5 seatbelt cover - as well as between the the S2000 seat belt buckle and the center tunnel. To be continued in next post...

The S2000 reclining mechanism and handle cover have serious contact with the C5 lower seatbelt reel cover.

_DSC5125 by Norbert Ogiba, on Flickr

_DSC5125 by Norbert Ogiba, on Flickr

and the S2000 seat belt receptacle is pushed up against the tunnel.

_DSC5126 by Norbert Ogiba, on Flickr

_DSC5126 by Norbert Ogiba, on Flickr

In this position the seat is WAY too far forward (I'm 5'8") and needs to come back.

The S2000 seat came out of the car and onto the bench to have some stuff taken off it. First came the seatbelt buckle

_DSC5128 by Norbert Ogiba, on Flickr

_DSC5128 by Norbert Ogiba, on Flickr

...along with the related Z-shaped harness. I won't need this as it doesn't interface with the C5 seatbelt OR the C5 electrical seat harness.

_DSC5129 by Norbert Ogiba, on Flickr

_DSC5129 by Norbert Ogiba, on Flickr

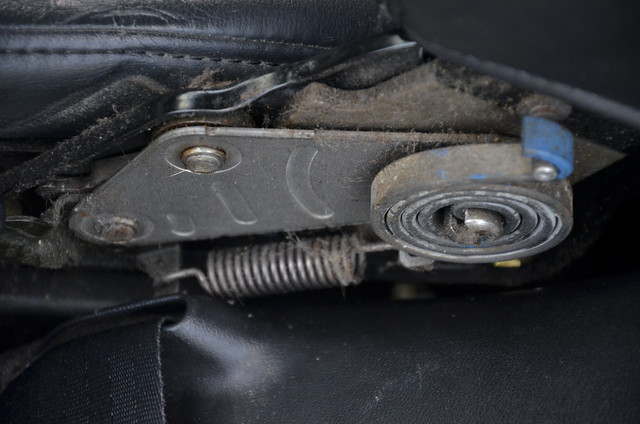

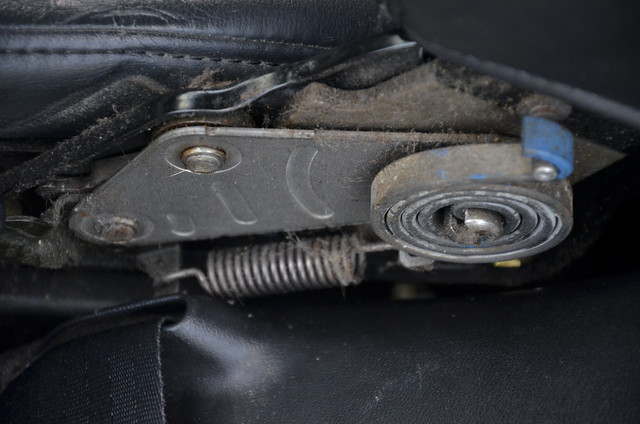

You're now looking at the rear of the S2000 seat, driver's side, reclining mechanism plastic cover. It sticks out WAY past the rail, which is already far wide than the C5 bolt spacing. It will have to go.

_DSC5130 by Norbert Ogiba, on Flickr

_DSC5130 by Norbert Ogiba, on Flickr

Firmly pull on the cool looking reclining handle to remove it

_DSC5131 by Norbert Ogiba, on Flickr

_DSC5131 by Norbert Ogiba, on Flickr

now that the 2 items that were in the way are now gone, I stuck the seat back in the car to see what it looked like. The good news is that the seat can now slide all the way back. This keeps with the OEM+ theme, keeping full functionality of adjustment. Note the absolute lack of shoulder bolsters on the C5 seat, compared to the S2000. I still can't get over how much better these seats look than the stockers.

_DSC5132 by Norbert Ogiba, on Flickr

_DSC5132 by Norbert Ogiba, on Flickr

_DSC5133 by Norbert Ogiba, on Flickr

_DSC5133 by Norbert Ogiba, on Flickr

Now we can see just how close that mechanism is to the C5 seatbelt retractor

_DSC5134 by Norbert Ogiba, on Flickr

_DSC5134 by Norbert Ogiba, on Flickr

_DSC5135 by Norbert Ogiba, on Flickr

_DSC5135 by Norbert Ogiba, on Flickr

_DSC5136 by Norbert Ogiba, on Flickr

_DSC5136 by Norbert Ogiba, on Flickr

18mm thin nut and a connector, and the buckle comes out

_DSC5138 by Norbert Ogiba, on Flickr

_DSC5138 by Norbert Ogiba, on Flickr

Here's where I left off for the night. S2000 buckle on bottom with goofy Z offset, C5 on top with straight shot

_DSC5140 by Norbert Ogiba, on Flickr

_DSC5140 by Norbert Ogiba, on Flickr

The C5 chassis is supported by a huge aftermarket following, with no lack of gorgeous seating options with bolt-in brackets available. However, I decided not to go with the typical aftermarket options for the following reasons:

-I'm not a millionaire and don't want to spend thousands of dollars on seats and brackets

-I know my way around a wrench and enjoy fabrication projects

-All the aftermarket options I found looked very "boy racer" to me.

- I wanted to keep the "OEM+" look that only factory seats can achieve.

-Had to keep the leather theme - no cheesy aftermarket black foamy cloth with gaudy embroidered lettering for me

As part of the planning phase of the project, I had no intention of keeping the heavy C5 power seat adjustments and adapting the S2000 seat to the C5 rails, so I decided to keep the S2000 seat attached to the Honda rails and adapt them to a bracket, which would be bolted to the stock C5 floor studs. I also did not want to modify the C5 seats or floor mounting points in any way as it would devalue the originality of the chassis.

I did not get any pics of this process, but I simply removed the 4x nuts holding the C5 seat in place and immediately realized that the floor is recessed around the mounting studs. As such I wasn't able to bolt a flat ]rail directly to the floor; it needed to come up at least an inch or more. I bought some hex couplers, washers, and bolts that all matched the factory C5 M10x1.5 studs. The hex couplers threaded onto the studs and provided a raised platform to which I could bolt the new adapter bracket.

In the fall of '14 I installed a unit heater in my garage and mounted it to the joists in the ceiling using a long stick of zinc-plated Unistrut.

_DSC5115 by Norbert Ogiba, on Flickr

_DSC5115 by Norbert Ogiba, on FlickrI think the stick was at least 12' long, I only used about 20" of it for the heater install. The remainer collected dust in the corner of the garage for a couple of years until today.

_DSC5118 by Norbert Ogiba, on Flickr

_DSC5118 by Norbert Ogiba, on FlickrI chopped them to 23" lengths and mounted to the tops of the hex adapters lengthwise in the car. One end of each rail needed to have the slot slightly enlarged to allow it to fit. No pics, will get them next time I take the seat out of the car.

These will get a coat of black paint before final installation and should blend in with the floor nicely.

_DSC5119 by Norbert Ogiba, on Flickr

_DSC5119 by Norbert Ogiba, on FlickrThe S2000 floor mounting points are NOTHING like the C5 so I cut the mounting tabs off the S2000 rails right away. They are riveted AND spot welded to the rails, so some quality time with the cutoff wheel needs to be spent. I tend to enjoy grinding as I can throw in headphones, turn up the tunes, and go to town.

Note 4 shiny corners where brackets are gone.

_DSC5120 by Norbert Ogiba, on Flickr

_DSC5120 by Norbert Ogiba, on FlickrS2000 mounting tabs cut off.

_DSC5120 by Norbert Ogiba, on Flickr

_DSC5120 by Norbert Ogiba, on FlickrSo now that the unistrut rails were firmly bolted in place, and the S2000 seat had a nice flat bottom to work with, it was time to put the seat in the car and see where I had fitment issues.

These things looks awesome.

_DSC5123 by Norbert Ogiba, on Flickr

_DSC5123 by Norbert Ogiba, on Flickr _DSC5124 by Norbert Ogiba, on Flickr

_DSC5124 by Norbert Ogiba, on FlickrHowever, note how far forward the seat sits in relation to the C5 passenger seat - there is a lot of contact between the S2000 reclining handle cover and the lower C5 seatbelt cover - as well as between the the S2000 seat belt buckle and the center tunnel. To be continued in next post...

The S2000 reclining mechanism and handle cover have serious contact with the C5 lower seatbelt reel cover.

_DSC5125 by Norbert Ogiba, on Flickr

_DSC5125 by Norbert Ogiba, on Flickrand the S2000 seat belt receptacle is pushed up against the tunnel.

_DSC5126 by Norbert Ogiba, on Flickr

_DSC5126 by Norbert Ogiba, on FlickrIn this position the seat is WAY too far forward (I'm 5'8") and needs to come back.

The S2000 seat came out of the car and onto the bench to have some stuff taken off it. First came the seatbelt buckle

_DSC5128 by Norbert Ogiba, on Flickr

_DSC5128 by Norbert Ogiba, on Flickr...along with the related Z-shaped harness. I won't need this as it doesn't interface with the C5 seatbelt OR the C5 electrical seat harness.

_DSC5129 by Norbert Ogiba, on Flickr

_DSC5129 by Norbert Ogiba, on FlickrYou're now looking at the rear of the S2000 seat, driver's side, reclining mechanism plastic cover. It sticks out WAY past the rail, which is already far wide than the C5 bolt spacing. It will have to go.

_DSC5130 by Norbert Ogiba, on Flickr

_DSC5130 by Norbert Ogiba, on FlickrFirmly pull on the cool looking reclining handle to remove it

_DSC5131 by Norbert Ogiba, on Flickr

_DSC5131 by Norbert Ogiba, on Flickrnow that the 2 items that were in the way are now gone, I stuck the seat back in the car to see what it looked like. The good news is that the seat can now slide all the way back. This keeps with the OEM+ theme, keeping full functionality of adjustment. Note the absolute lack of shoulder bolsters on the C5 seat, compared to the S2000. I still can't get over how much better these seats look than the stockers.

_DSC5132 by Norbert Ogiba, on Flickr

_DSC5132 by Norbert Ogiba, on Flickr _DSC5133 by Norbert Ogiba, on Flickr

_DSC5133 by Norbert Ogiba, on FlickrNow we can see just how close that mechanism is to the C5 seatbelt retractor

_DSC5134 by Norbert Ogiba, on Flickr

_DSC5134 by Norbert Ogiba, on Flickr _DSC5135 by Norbert Ogiba, on Flickr

_DSC5135 by Norbert Ogiba, on Flickr _DSC5136 by Norbert Ogiba, on Flickr

_DSC5136 by Norbert Ogiba, on Flickr18mm thin nut and a connector, and the buckle comes out

_DSC5138 by Norbert Ogiba, on Flickr

_DSC5138 by Norbert Ogiba, on FlickrHere's where I left off for the night. S2000 buckle on bottom with goofy Z offset, C5 on top with straight shot

_DSC5140 by Norbert Ogiba, on Flickr

_DSC5140 by Norbert Ogiba, on Flickr