Darth Vader 454 Project....LIVES AGAIN!!

#81

LS1Tech Sponsor

Thread Starter

Good to hear from you....we need to catch up one of these days!

-Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#84

LS1Tech Sponsor

Thread Starter

Thanks guys....I appreciate all the positive comments etc. To be honest, this project got a little stressful in the 9th hour but it turned out as good as I could have hoped and then some and it was worth every minute I invested in it.

Regarding some of the previous commentary regarding RPM I have a few things to add.

This engine is every bit a 7300 RPM player which is impressive considering its displacement, stroke, and the modest size of the cam (some would call this cam downright small for this much engine), but the better the rest of the combination is (especially a really killer set of heads), the less cam you need to make big power and ultimately that situation gives you the have your cake and eat it too scenario....a really wide extremely usable power band similar to what this engine produced.

Smaller motors need RPM to crutch lower TQ figures in hopes of seeing a larger HP figure.....this beast does it with brutal TQ figures not requiring the RPM multiplier to make a big HP number that a smaller motor would be forced to turn (making it that much less appealing as a street engine due to having to cam it much larger which hurts drivability, responsiveness, and low/midrange TQ and HP output).

I always tell people to build the largest shortblock they can afford to.....this combination is proof positive of how that can work for you....LOL (naturally costs go up associated with building larger cubes not to mention buying the better parts required to feed all those inches).

In fact I recently added this to my stable of high performance (mind blowing) rides....the Kawasaki ZX14R....basically the fastest production motorcycle on the planet at this point in time. It's notably faster and more powerful than the Hayabusa which handed the crown to Kawasaki in 2012 when the 14R was launched.

While only having two wheels, its approach to dominance is very similar to this engine and is the reason I bring it up. In fact in this market (high performance sport bikes), high revs are usually always the ticket to big power and performance, but the ZX14R smashes the competition with cubes, really good cylinder heads and a very sorted out thoughtful approach to the rest of the engine's components as well (a perfect parallel to what I just built in the automotive world featured here). It's factory redline is "only" 11,000 RPM (which is actually impressive at this size engine) but it generates almost 200 RWHP right off the showroom floor and almost 120 RWTQ!! It traps 150 MPH in the quarter (un corrected) and is just a freaking rocketship....it accelerates harder than anything I've ever experienced....its downright scary and it wants to rip the arms out of your sockets as it tries to leave you behind it. The fact anyone with a few bucks can buy one of these that strolls into a dealership is actually insane....you should really need a special licence to pilot something like this but Im getting off topic....LOL (I drove a ZX11 for many years which used to be the top dog in the 90's.....the 14R makes that bike feel like a 600!).

In fact once again to draw a meaningful parallel to this discussion....the ZX14R makes more torque at 3000 RPM than the peak torque output of Kawi's flagship literbike the ZX10R and that's a modern tour de force of an engine also, only smaller in size and not quite as fast (160 ish RWHP but the bike is 100 lbs lighter). This bike pulls like a locomotive at any RPM much like this 454 will certainly do in a car with almost 600 ft/lbs on tap at 4000 ish RPMs

Guys.....cubes.....the right heads.....the right approach to the rest of the build and you have yourself one hell of a street engine....the beauty of not having to turn it so high to see the Godzilla part of the power band just makes it more reliable over the long haul and a much more tractable combination with huge grunt at almost any RPM!!

That old adage there is no replacement for displacement....its corny but its true if we are discussing naturally aspirated engines....the other "replacement" choices being boost and nitrous but that's really a very different engine....nothing like a really stout N/A engine if the output of that N/A engine can accomplish for you what your looking to achieve. The power is instantaneous and explosive....very different than boosted stuff....especially the fun factor at part and mid throttle....boosted engines are lazy there in comparison (off boost) while N/A engines are like race horses that are just dying for you to feed out the reins and respond instantly.

I leave you with these words once again....Build the largest engine you can afford to build properly. BUT....don't spend your money on a shortblock and put ported OEM heads on it.....that's a disaster....you have to properly feed a big engine for this to work or they just make a bunch of bottom end and fall on their face.....not a desirable power curve for a performance engine! In fact a smaller motor with better heads will always make more power than a larger motor with so so heads. You have to get the entire combination right so budget accordingly

Hope some of you guys enjoyed reading this....learned something and maybe someday would consider having me build you something similar!

Catch you guys later!

-Tony

Regarding some of the previous commentary regarding RPM I have a few things to add.

This engine is every bit a 7300 RPM player which is impressive considering its displacement, stroke, and the modest size of the cam (some would call this cam downright small for this much engine), but the better the rest of the combination is (especially a really killer set of heads), the less cam you need to make big power and ultimately that situation gives you the have your cake and eat it too scenario....a really wide extremely usable power band similar to what this engine produced.

Smaller motors need RPM to crutch lower TQ figures in hopes of seeing a larger HP figure.....this beast does it with brutal TQ figures not requiring the RPM multiplier to make a big HP number that a smaller motor would be forced to turn (making it that much less appealing as a street engine due to having to cam it much larger which hurts drivability, responsiveness, and low/midrange TQ and HP output).

I always tell people to build the largest shortblock they can afford to.....this combination is proof positive of how that can work for you....LOL (naturally costs go up associated with building larger cubes not to mention buying the better parts required to feed all those inches).

In fact I recently added this to my stable of high performance (mind blowing) rides....the Kawasaki ZX14R....basically the fastest production motorcycle on the planet at this point in time. It's notably faster and more powerful than the Hayabusa which handed the crown to Kawasaki in 2012 when the 14R was launched.

While only having two wheels, its approach to dominance is very similar to this engine and is the reason I bring it up. In fact in this market (high performance sport bikes), high revs are usually always the ticket to big power and performance, but the ZX14R smashes the competition with cubes, really good cylinder heads and a very sorted out thoughtful approach to the rest of the engine's components as well (a perfect parallel to what I just built in the automotive world featured here). It's factory redline is "only" 11,000 RPM (which is actually impressive at this size engine) but it generates almost 200 RWHP right off the showroom floor and almost 120 RWTQ!! It traps 150 MPH in the quarter (un corrected) and is just a freaking rocketship....it accelerates harder than anything I've ever experienced....its downright scary and it wants to rip the arms out of your sockets as it tries to leave you behind it. The fact anyone with a few bucks can buy one of these that strolls into a dealership is actually insane....you should really need a special licence to pilot something like this but Im getting off topic....LOL (I drove a ZX11 for many years which used to be the top dog in the 90's.....the 14R makes that bike feel like a 600!).

In fact once again to draw a meaningful parallel to this discussion....the ZX14R makes more torque at 3000 RPM than the peak torque output of Kawi's flagship literbike the ZX10R and that's a modern tour de force of an engine also, only smaller in size and not quite as fast (160 ish RWHP but the bike is 100 lbs lighter). This bike pulls like a locomotive at any RPM much like this 454 will certainly do in a car with almost 600 ft/lbs on tap at 4000 ish RPMs

Guys.....cubes.....the right heads.....the right approach to the rest of the build and you have yourself one hell of a street engine....the beauty of not having to turn it so high to see the Godzilla part of the power band just makes it more reliable over the long haul and a much more tractable combination with huge grunt at almost any RPM!!

That old adage there is no replacement for displacement....its corny but its true if we are discussing naturally aspirated engines....the other "replacement" choices being boost and nitrous but that's really a very different engine....nothing like a really stout N/A engine if the output of that N/A engine can accomplish for you what your looking to achieve. The power is instantaneous and explosive....very different than boosted stuff....especially the fun factor at part and mid throttle....boosted engines are lazy there in comparison (off boost) while N/A engines are like race horses that are just dying for you to feed out the reins and respond instantly.

I leave you with these words once again....Build the largest engine you can afford to build properly. BUT....don't spend your money on a shortblock and put ported OEM heads on it.....that's a disaster....you have to properly feed a big engine for this to work or they just make a bunch of bottom end and fall on their face.....not a desirable power curve for a performance engine! In fact a smaller motor with better heads will always make more power than a larger motor with so so heads. You have to get the entire combination right so budget accordingly

Hope some of you guys enjoyed reading this....learned something and maybe someday would consider having me build you something similar!

Catch you guys later!

-Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 08-16-2017 at 04:56 PM.

#85

LS1Tech Sponsor

Thread Starter

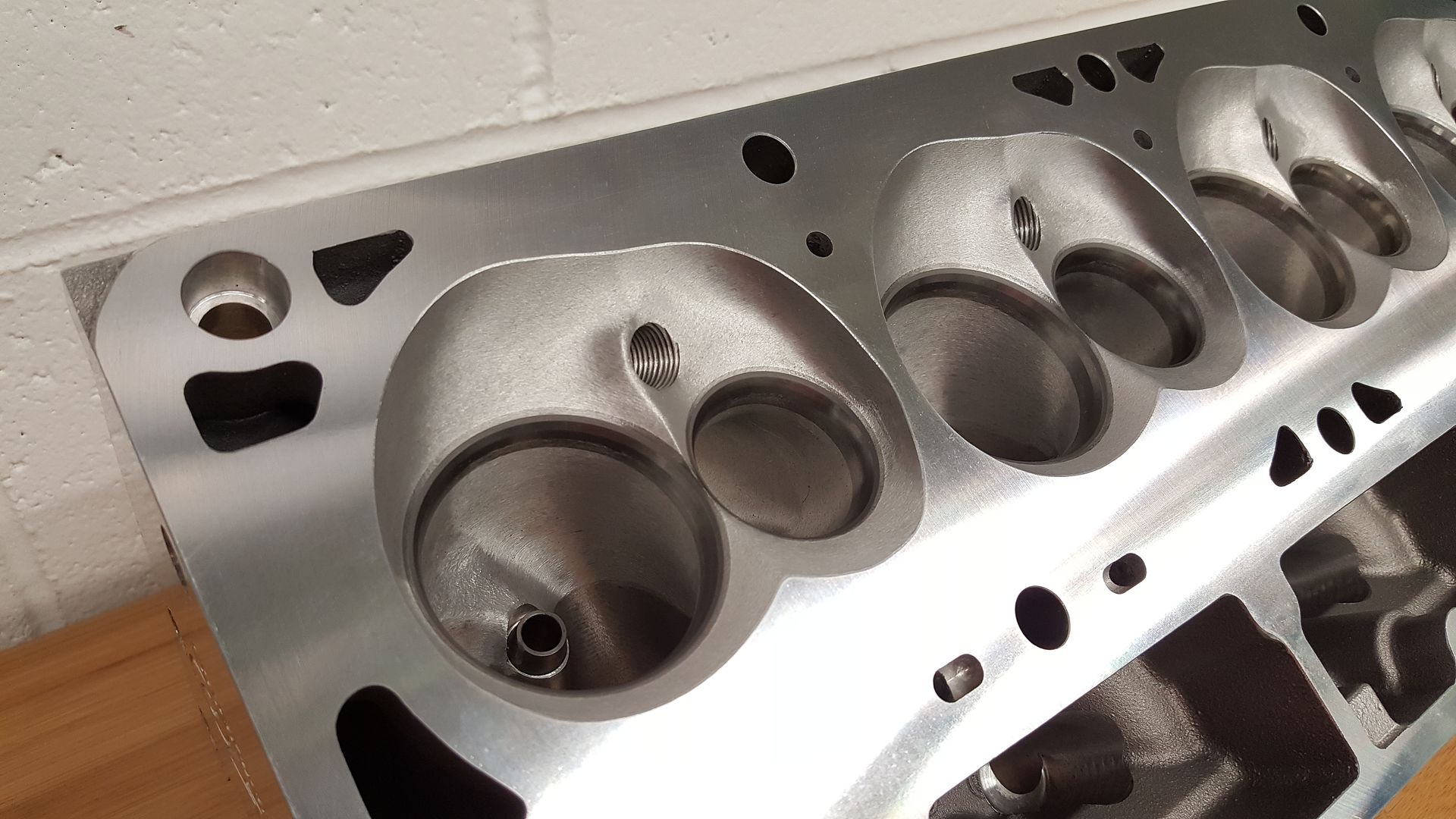

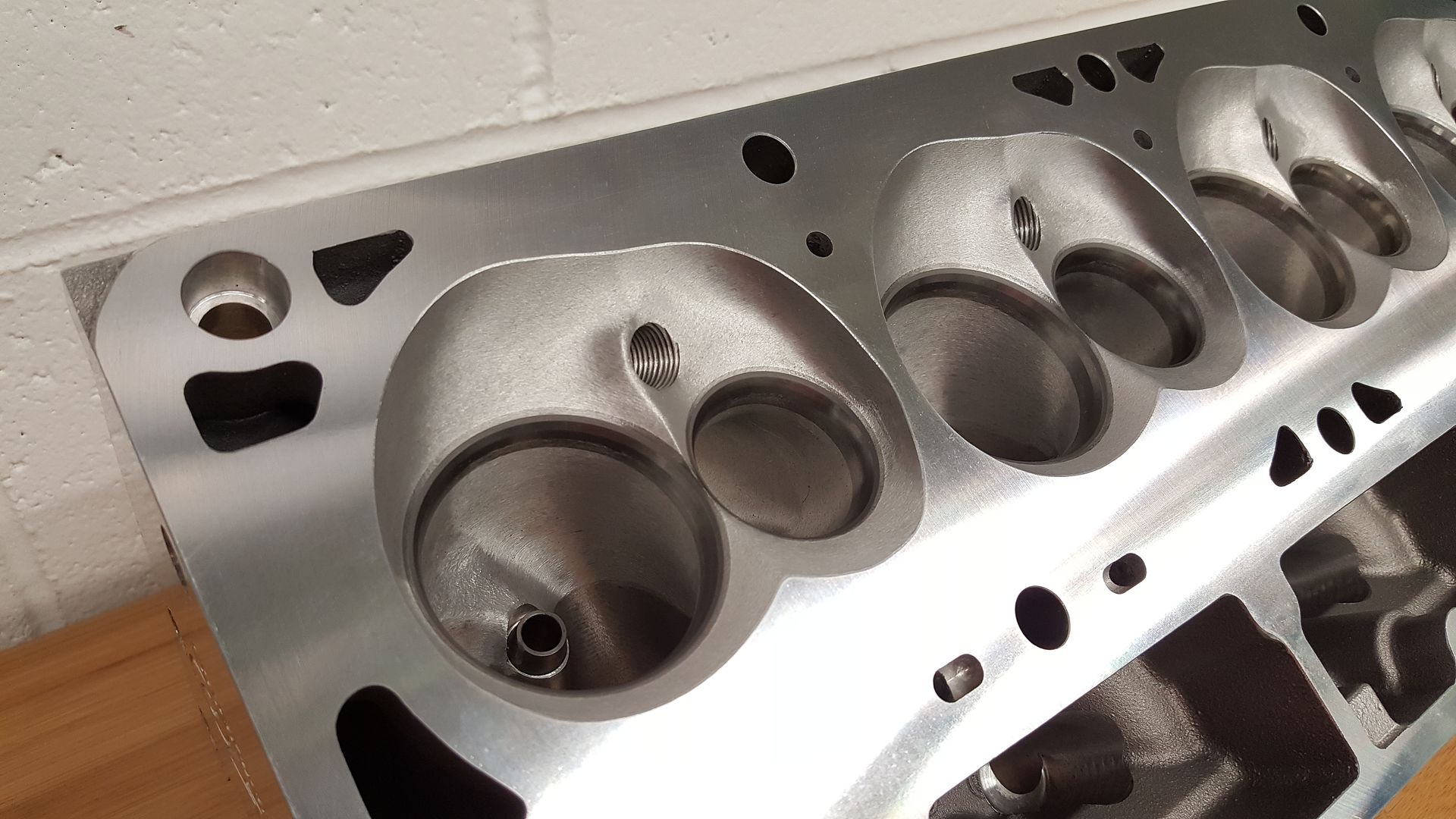

Thought I would show you guys the business end of what really made most of this happen....I have a retarded amount of hours invested in my LS7 program and this is the cornerstone of all of it. The real secret....huge airflow thru a conservative (relative to the LS7 platform) sized runner.

In fact my finished intake port (after the CNC porting and hand finishing) is 5 cc's smaller than an unported OEM head yet it flows about 40 CFM stronger!! Major win going on right there as not only do you have a really big peak number to tap into (which somewhat dictates how much peak HP you can make) at 410 CFM, the fact the port is still modestly sized gets you that airflow with a bunch of airspeed and that helps really pack the cylinder and adds dramatically to cylinder fill in the lower and middle RPM's. The exhaust port is also extremely important in a head like this (you need a really good one to exhale that deep intake charge) and it flows around 270 CFM which while very good for a (smallblock) LS cylinder head, it is still light in flow when considering you have to exhale the intake volume of a decent Bigblock Chevy head hence the big split I put on the exhaust side to crutch that situation some. This is not so much a function of my heads as it is the LS7 platform in general but this is the trend in race heads (and killer street heads) that are producing more power. Its always easier to get the exhaust out under enormous cylinder pressure but getting it in is inherently more difficult (without the aid of a blower naturally).

Here are some pics of my LS7 program....the quality is pretty evident....every set I ship looks exactly the same. Only difference is how much I mill the chambers based on my customer's individual needs (the quarter in the intake port photo a few pics down is for the purpose of "scale" btw....LOL It looks like a nickel but I assure you its not!)

In fact my finished intake port (after the CNC porting and hand finishing) is 5 cc's smaller than an unported OEM head yet it flows about 40 CFM stronger!! Major win going on right there as not only do you have a really big peak number to tap into (which somewhat dictates how much peak HP you can make) at 410 CFM, the fact the port is still modestly sized gets you that airflow with a bunch of airspeed and that helps really pack the cylinder and adds dramatically to cylinder fill in the lower and middle RPM's. The exhaust port is also extremely important in a head like this (you need a really good one to exhale that deep intake charge) and it flows around 270 CFM which while very good for a (smallblock) LS cylinder head, it is still light in flow when considering you have to exhale the intake volume of a decent Bigblock Chevy head hence the big split I put on the exhaust side to crutch that situation some. This is not so much a function of my heads as it is the LS7 platform in general but this is the trend in race heads (and killer street heads) that are producing more power. Its always easier to get the exhaust out under enormous cylinder pressure but getting it in is inherently more difficult (without the aid of a blower naturally).

Here are some pics of my LS7 program....the quality is pretty evident....every set I ship looks exactly the same. Only difference is how much I mill the chambers based on my customer's individual needs (the quarter in the intake port photo a few pics down is for the purpose of "scale" btw....LOL It looks like a nickel but I assure you its not!)

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 08-16-2017 at 01:18 AM.

#86

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,835 Likes

on

1,145 Posts

BUT....don't spend your money on a shortblock and put ported OEM heads on it.....that's a disaster....you have to properly feed a big engine for this to work or they just make a bunch of bottom end and fall on their face.

And 410 CFM through that port is retarded. Honestly, those heads should run great even on a "smaller" engine as long as they fit the bore. Wouldn't be "lazy" on airflow at lower engine speeds.

What's the smallest bore you think you could run these on?

#87

TECH Senior Member

Amazing! That kind of flow thru a port 5cc's SMALLER than OEM! Gotta be some CRAZY velocity at full tilt! I guess I should NOT be surprised; it's what you do, Tony!

#89

TECH Fanatic

Join Date: Aug 2009

Location: Coast of San Mateo County Between Pacifica & HMB

Posts: 1,815

Received 215 Likes

on

128 Posts

LOL, yeah - make a nice tow truck engine that way.

And 410 CFM through that port is retarded. Honestly, those heads should run great even on a "smaller" engine as long as they fit the bore. Wouldn't be "lazy" on airflow at lower engine speeds.

What's the smallest bore you think you could run these on?

And 410 CFM through that port is retarded. Honestly, those heads should run great even on a "smaller" engine as long as they fit the bore. Wouldn't be "lazy" on airflow at lower engine speeds.

What's the smallest bore you think you could run these on?

I would have run them on my 396" if they had been available

When I purchased my Heads, would have used adapter to

Run FAST LS3 with Mid Lengths VS MSD.

AWESOME Heads BTW

"Hands Down Best LS7 Heads"

Especially for Plastic Intakes.

#91

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,835 Likes

on

1,145 Posts

Originally Posted by NAVYBLUE210

Any Bore 4.125"/+

I would have run them on my 396" if they had been available

When I purchased my Heads, would have used adapter to

Run FAST LS3 with Mid Lengths VS MSD.

AWESOME Heads BTW

"Hands Down Best LS7 Heads"

Especially for Plastic Intakes.

I would have run them on my 396" if they had been available

When I purchased my Heads, would have used adapter to

Run FAST LS3 with Mid Lengths VS MSD.

AWESOME Heads BTW

"Hands Down Best LS7 Heads"

Especially for Plastic Intakes.

#93

LS1Tech Sponsor

Thread Starter

Its all a matter of what your really trying to build and accomplish but IMO unless your purposely building a smaller motor (with a big bore) that your setting up for 8K or more, I would prefer to see a minimum bore of 4.125 and a minimum displacement of 427 cubes....and the more the merrier from there!! A 440 is an awesome combo for this platform also....for guys that will give up a little torque (about 20 ft/lbs) for the ability to get more revs up top and want it to carry better past peak. In fact I'm building one now for a customer.....or collecting parts at this point that will be a real showstopper....Ultralite Callies crank, lightweight Dyers steel rods, tricked out custom Wiseco pistons....Ti intake valves.....etc. etc. Its a road race build so it will still have conservative cam timing but I'm hoping it generates similar power to this build but that one I do plan to spin to 7500 RPM's and its being designed with that target clearly in mind. Its four months or more away from the dyno but I will share the results with you guys when I'm finished with it. Its one of those "if you have to ask its probably too expensive" type builds but this customer is fortunate enough to have the means and is very excited about the project as am I....should be awesome in his C6Z track car!

Regards,

Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 08-16-2017 at 05:24 PM.

#94

10 Second Club

There are guys that are successfully running 4.100 on an ls3 block. Sonic checking is recommended though as ls3 blocks are known for having crooked cylinders

#97

LS1Tech Sponsor

Thread Starter

If your spending all that money anyway on a killer top end and want to do it right suck it up and sleeve your stock block or go aftermarket.....no compromise and a bunch more power and torque from the larger combination (with the sleeved block). Its almost a crime to put these heads on an engine that cant take full advantage of them. Your better off in my MMS 260 LS3 heads meant to operate efficiently on a smaller bore....they flow 390+ CFM.....not far off of my LS7 stuff with similar levels of efficiency!

-Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

#98

10 Second Club

In an NA application and if your ls3 core is good then 4.100 isn't really an issue. Guys take 6.0 blocks out .040 fairly often and the liners are the same thickness. If you ever came across an ls3 block with a very scored cylinder it's worth a try for sure

#99

Did the FRH Ls3 heads on a 408 and not willing to do a expensive big bore. The Ls7 I speak of has been done already for the same engine. Looks better or as good as any small bore Ls7 heads just on CSA and flow alone. Not to worried about the exhaust. We shrunk it. Also Cheaper than any aftermarket small bore available. They would still need to send them off to someone like yourself to help which at the end will run around 3k plus just for bare heads. I spent 2300. Also don't like having what everyone and there mother can just call and have. 1 of 1 ! Heck even had my name engraved on them.

Driving trying to get back home from out of state.

Driving trying to get back home from out of state.

Last edited by Patron; 08-17-2017 at 10:27 AM.