ProCharger guys...anyone ever have issues w/ stock crank?

#1

11 Second Truck Club

Thread Starter

iTrader: (34)

Join Date: Mar 2006

Location: Dallas, Georgia

Posts: 2,858

Likes: 0

Received 0 Likes

on

0 Posts

New build has less than 2k miles on it...

fought belt tensioner issues for quite a while...

resolved that and finally got it tuned...

went to pick it up from tuner, let it run for a while while chatting with tuner, had him load an "emissions tune" and e-mail me the dyno tune...

got ready to leave and noticed I had no oil pressure...like 15-20lbs @ idle in Park and 10lbs or less when put into gear...low oil pressure warning flashing.

Tuner had multiple WOT dyno runs while tuning...all w/ perfectly fine OP.

Changed oil and filter...pan and cut-open filter had copper in it.

Towed it back to shop that installed everything...hoping that new oil pump's relief valve may be stuck, I bought a new one and we dropped the pan.

Some metal in pan...rod bearings showed slight wear...thinking P series bearings needed to be replaced with H series and that we may be able to roll new ones in, I exchanged new pump for a new set of H's.

When checking clearances and about to install new rod bearings, we checked a main to be sure there was no wear there and discovered major bearing wear...even some copper transferred to the main journals.

No knocking...no audible signs of this at all...low oil pressure was first and only sign.

I noticed that the current bearings were 0.010's and remembered that the last build we polished the 0.010 crank and used P series 0.010's.

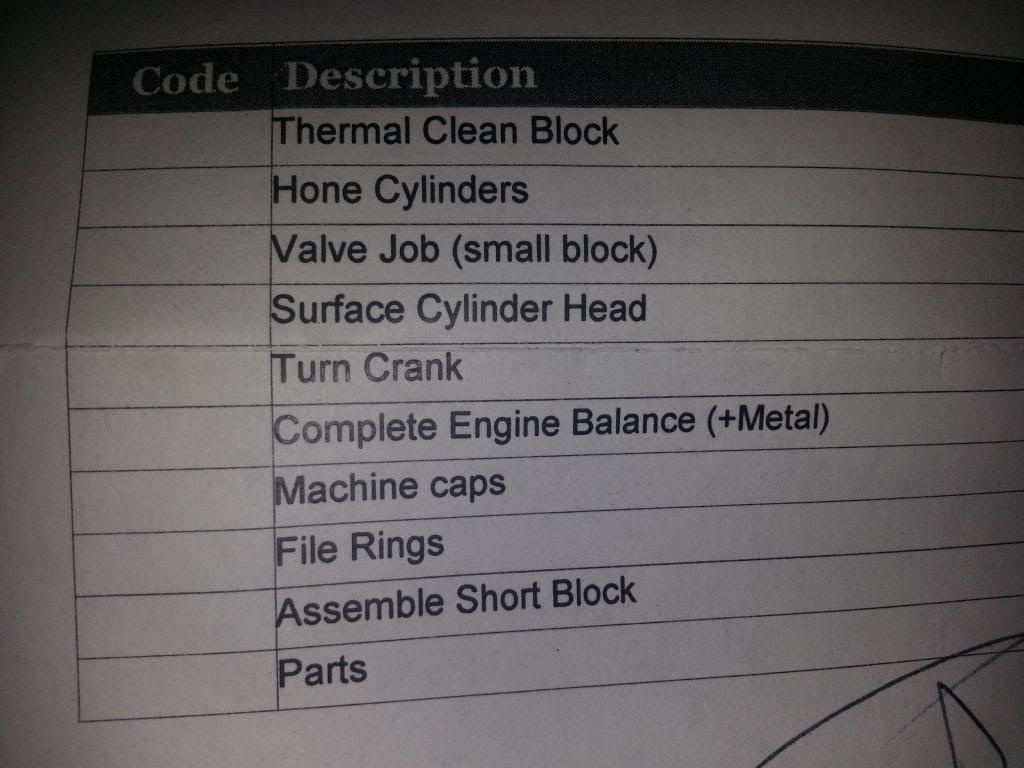

I checked the invoice from the machine shop and it listed "turn crank - $125".

Could they have possibly turned it to 0.020 and installed 0.010's?

The bearings are the only items that I didn't supply.

Three machinists, including the one I used, have looked at this and claim that from what they see that it couldn't have been that.

Journals have not been measured since the motor is still in the truck.

The only thing that makes me agree with them is the thought that it would have been making a racket from the beginning with that much excess clearance. Would it have...w/o a doubt?

I have NO clue what has caused this.

They are claiming the stock crank being the issue...which I know is known to be good to 1k+ rwhp...even with crank driven superchargers.

I'm no where near that level.

Any thoughts?

Thanks!

fought belt tensioner issues for quite a while...

resolved that and finally got it tuned...

went to pick it up from tuner, let it run for a while while chatting with tuner, had him load an "emissions tune" and e-mail me the dyno tune...

got ready to leave and noticed I had no oil pressure...like 15-20lbs @ idle in Park and 10lbs or less when put into gear...low oil pressure warning flashing.

Tuner had multiple WOT dyno runs while tuning...all w/ perfectly fine OP.

Changed oil and filter...pan and cut-open filter had copper in it.

Towed it back to shop that installed everything...hoping that new oil pump's relief valve may be stuck, I bought a new one and we dropped the pan.

Some metal in pan...rod bearings showed slight wear...thinking P series bearings needed to be replaced with H series and that we may be able to roll new ones in, I exchanged new pump for a new set of H's.

When checking clearances and about to install new rod bearings, we checked a main to be sure there was no wear there and discovered major bearing wear...even some copper transferred to the main journals.

No knocking...no audible signs of this at all...low oil pressure was first and only sign.

I noticed that the current bearings were 0.010's and remembered that the last build we polished the 0.010 crank and used P series 0.010's.

I checked the invoice from the machine shop and it listed "turn crank - $125".

Could they have possibly turned it to 0.020 and installed 0.010's?

The bearings are the only items that I didn't supply.

Three machinists, including the one I used, have looked at this and claim that from what they see that it couldn't have been that.

Journals have not been measured since the motor is still in the truck.

The only thing that makes me agree with them is the thought that it would have been making a racket from the beginning with that much excess clearance. Would it have...w/o a doubt?

I have NO clue what has caused this.

They are claiming the stock crank being the issue...which I know is known to be good to 1k+ rwhp...even with crank driven superchargers.

I'm no where near that level.

Any thoughts?

Thanks!

Last edited by Superado; 02-25-2013 at 04:17 PM.

#4

11 Second Truck Club

Thread Starter

iTrader: (34)

Join Date: Mar 2006

Location: Dallas, Georgia

Posts: 2,858

Likes: 0

Received 0 Likes

on

0 Posts

Lower half bearings have the most wear...

Middle ones worse than others...

All top halves have minimal wear, in comparison...

Stock crank, Howard rods, Diamond pistons (higher CR than last build, 9.5CR)

Last edited by Superado; 02-25-2013 at 11:58 AM.

Trending Topics

#14

TECH Regular

iTrader: (8)

Join Date: May 2002

Location: Tampa FL

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

Any evidence of detonation on the ring lands or piston tops? Maybe the tuner got a little too aggressive with timing while on the dyno? Just a thought, especially if it was only the lower half of the bearing.

#17

Closed ex-Sponsor Account

iTrader: (55)

Mic the journals and check by I highly doubt there were .010" bearings on a .020" crank. Would have never carried good oil pressure from the get go. Sounds like you possibly had some detonation issues but would need to see the rod bearings. How do the plugs look. Any shiny sepcks?

#18

11 Second Truck Club

Thread Starter

iTrader: (34)

Join Date: Mar 2006

Location: Dallas, Georgia

Posts: 2,858

Likes: 0

Received 0 Likes

on

0 Posts

Mic the journals and check by I highly doubt there were .010" bearings on a .020" crank. Would have never carried good oil pressure from the get go. Sounds like you possibly had some detonation issues but would need to see the rod bearings. How do the plugs look. Any shiny sepcks?

couple of rod bearings can be seen in pic of main cap & bearing in earlier post...

plugs look fine...

#19

TT-TECH Veteran

iTrader: (29)

Stock cranks have held over 1K for me with a Procharger quite a few times. Seen guys with a manual tensioner bend cranks multiple times before swapping to a spring loaded tensioner and solved the issue. Looks to me that there wasn't enough clearance on the bearings for sure. Especially the thrust bearing that thing looks bad lol! GL! Oh BTW I'm not saying that an aftermarket crank isn't better for these types of setups, just that they work fine when set up right.

#20

11 Second Truck Club

Thread Starter

iTrader: (34)

Join Date: Mar 2006

Location: Dallas, Georgia

Posts: 2,858

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by kp

If the upper rod bearings and pistons look OK most likely the main cap line bore was off or something silly like the main caps got mixed up. It will take 10 seconds to check and see of the crank is bent once its apart.

All you can do now is take it apart, measure everything to see what happened and try again..

I really doubt you bent the crank, but it may have been bent when it was put in.

All you can do now is take it apart, measure everything to see what happened and try again..

I really doubt you bent the crank, but it may have been bent when it was put in.

guess we'll see what may have happened when we get it apart.