2 years, 80 passes L33 SBE teardown

#1

Hey all,

After the season ended last year I decided to add forged rods and pistons to the L33. Basically so I could quit saying "don't blow up" as I approached the finish line every pass.

And I thought I might to really turn it up someday.

I bought the LJMS pistons and Compstar rods.

So thought I'd share what I found on disassembly.

Valvetrain all good. Stock rockers, Comp Trunions BTR springs.

I do have a couple of guides that have become sloppy.

The LS9 heads gaskets showed no signs of even thinking about leaking. Great to see after losing LS1 gaskets and then Felpro gaskets.

Cloyes chain a touch loose as compared to the tight it was when new. Still tighter than an LS2 chain. I am also running the chain damper as this block is drilled for one.

Cam and lifters look good.

Pistons all good. Rings all free.

No bent rods. :-)

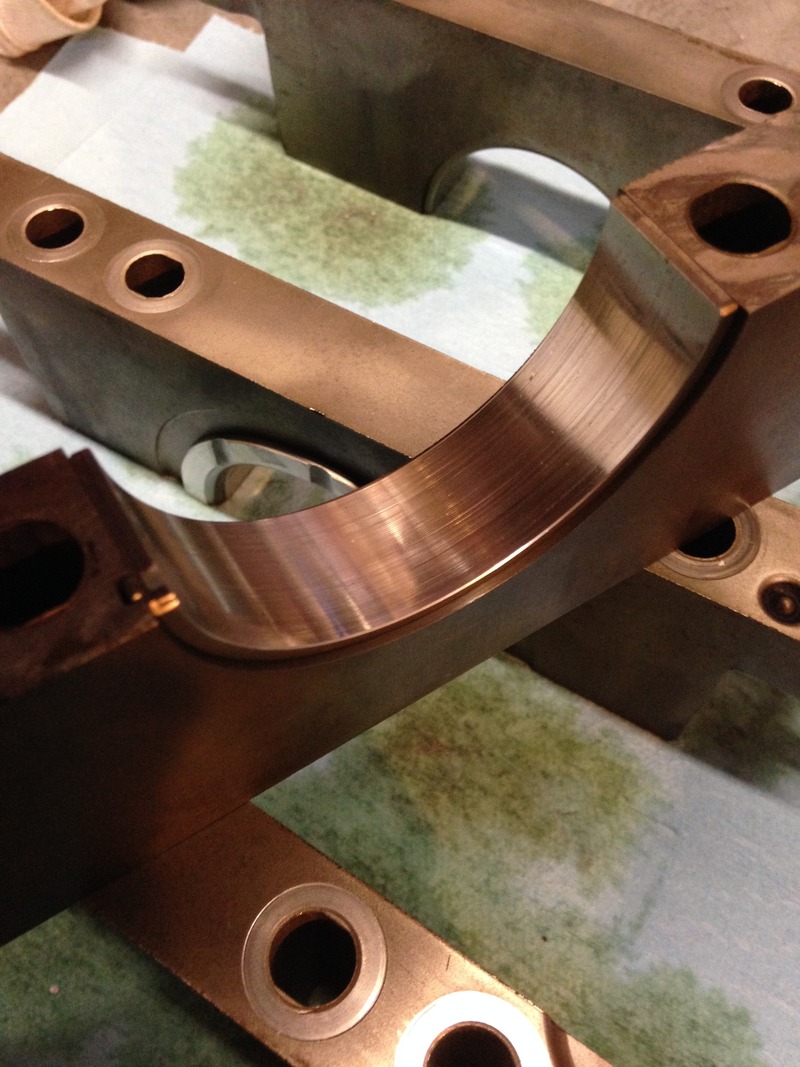

Bearings (these are the orig) showed slight wear on the rod side. Cap side looked just like I remember when I assembled.

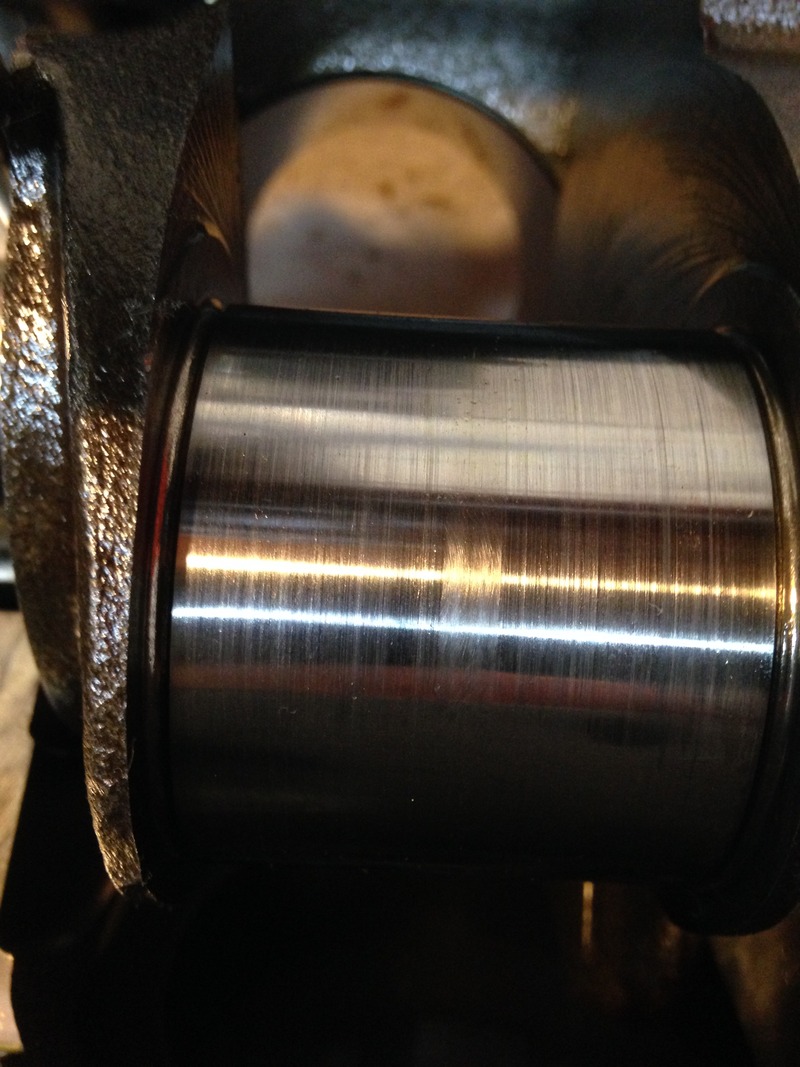

Crank not so hot......a couple of mains were grooved. Not horrible, just catch your finger nail groovy. Bearings are now shiny compared to the dull silver they were when I assembled.

And finally, 7/8 rod journal appears to have a surface crack. I had noted this when I assembled, but it's worse now and will catch your fingernail.

So I need a crank. No sense paying to turn this one and find out it's a real crack.

The thrust however was perfect at .004" the same as when I assembled it.

So maybe I got some dirt in there when assembling. I feel that I was very careful though. #2 and #4 were the worse.

So I need a crank. I do have a nice 5.3 crank from an iron long block I bought.

I have looked into a forged stock stroke unit, but just like everything I research online, there is a failure story about most. So still thinking.

Also considering ARP main studs.......

FWIW, I disassembled, inspected and carefully cleaned this engine before putting it in the car. It was quite gross inside. So at least I'm pleased it stayed together!

Ron

After the season ended last year I decided to add forged rods and pistons to the L33. Basically so I could quit saying "don't blow up" as I approached the finish line every pass.

And I thought I might to really turn it up someday.

I bought the LJMS pistons and Compstar rods.

So thought I'd share what I found on disassembly.

Valvetrain all good. Stock rockers, Comp Trunions BTR springs.

I do have a couple of guides that have become sloppy.

The LS9 heads gaskets showed no signs of even thinking about leaking. Great to see after losing LS1 gaskets and then Felpro gaskets.

Cloyes chain a touch loose as compared to the tight it was when new. Still tighter than an LS2 chain. I am also running the chain damper as this block is drilled for one.

Cam and lifters look good.

Pistons all good. Rings all free.

No bent rods. :-)

Bearings (these are the orig) showed slight wear on the rod side. Cap side looked just like I remember when I assembled.

Crank not so hot......a couple of mains were grooved. Not horrible, just catch your finger nail groovy. Bearings are now shiny compared to the dull silver they were when I assembled.

And finally, 7/8 rod journal appears to have a surface crack. I had noted this when I assembled, but it's worse now and will catch your fingernail.

So I need a crank. No sense paying to turn this one and find out it's a real crack.

The thrust however was perfect at .004" the same as when I assembled it.

So maybe I got some dirt in there when assembling. I feel that I was very careful though. #2 and #4 were the worse.

So I need a crank. I do have a nice 5.3 crank from an iron long block I bought.

I have looked into a forged stock stroke unit, but just like everything I research online, there is a failure story about most. So still thinking.

Also considering ARP main studs.......

FWIW, I disassembled, inspected and carefully cleaned this engine before putting it in the car. It was quite gross inside. So at least I'm pleased it stayed together!

Ron

#3

TECH Addict

iTrader: (1)

All good to hear aside from the crank. I'd expect the bearings to be a little beat up really. Still can't beat the beatings the factory stuff can take. 15 years ago you'd have $10K or more into an engine to do the same thing! Lookin forward to your updates and progress as always.

#4

TECH Veteran

iTrader: (7)

Except for my thrust bearing, pretty much what I found when I tore down my 6.0-rod side bearings had signs of boost pushing them down, lol, and I had some scratching on the main journals, surprised since like you I cleaned everything, maybe not good enough-I am installing new pistons, but kept the bushed rods, budget you know, lol-i went with flat tops and deep valve reliefs, I fig the comp. was better for street driving

Be interesting to see how much boost you throw at it this year

Be interesting to see how much boost you throw at it this year

Trending Topics

#13

Yes, stock everything.

There was some confusion about the torque angle setting for the rod bolts, 75 or 85 degrees I think?

I split the difference.

Funny, I'm going to let my engine builder of 30 years do my machine work. He doesn't know LS stuff at all and of course told me the rod and main bolts couldn't be re-used.........sigh.

I think he has built two of them.

There was some confusion about the torque angle setting for the rod bolts, 75 or 85 degrees I think?

I split the difference.

Funny, I'm going to let my engine builder of 30 years do my machine work. He doesn't know LS stuff at all and of course told me the rod and main bolts couldn't be re-used.........sigh.

I think he has built two of them.

#15

TECH Addict

iTrader: (1)

Crank doesn't look bad at all. I'd have it tested as I don't see how it would crack in a circle (or in the shape of Texas). You'd think it's crack from the oil journal to somewhere! Can't tell if the color of the bearing is copper or of it's the pic, but the bearing looks fine. Crank journal looks normal for the amount of passes and power the engine was making. Plus, I'm sure the aluminum block doesn't help as far as flexing goes.

#18

#20

These cranks are nodular iron. I don't believe they are nitrided.

My builder says we can get it nitrided though.

That defect is weird. It will catch my fingernail.

I trust my guy. We will get it figured out.

No copper on the bearing. I looked at them with a microscope cause I'm a nerd and have one. 😊 Pretty interesting.

My builder says we can get it nitrided though.

That defect is weird. It will catch my fingernail.

I trust my guy. We will get it figured out.

No copper on the bearing. I looked at them with a microscope cause I'm a nerd and have one. 😊 Pretty interesting.