New PB: 8.629 @ 158.56

#81

My nightmare continues!!!

Been struggling with what I believe is a converter issue and everyone who has looked at this is baffled. It is a 9.5" PTC that was originally 14-45*-0 SBP it seemed to be working fine, cutting low-high 1.20s with a best of 1.196. One night I made a pass and all was normal then the next pass, the RPM drop on the shifts came down and the next pass I was just blowing through the converter. Sent it back to PTC and they said the bearing saw a lot of heat, enough to blacken it. They freshened it up and I asked them to put a 13-0 stator in, same as the one Mark Frederich was running. Buddy and I tore down the tranny (FTI level 4) and everything looked brand new. Decided to spend some more coin and swapped out the OEM steel direct drum with a 4-element sprag for an alum drum with a 36-element sprag. That sprag uses different intermediate clutches and even though the direct clutches/steels were like new, I put a fresh set in. What's baffling about what I just wrote is this. If the converter got so hot as to burn the bearing and burn the fluid, why didn't I see that high temp on the guage which has the sender in the pan and why didn't clutches and steels show any evidence of heat? Every scenario we come up that would cause the converter to do what it's doing is contradicted by the fact that there is no evidence of it in the tranny.

After I put everything back together, I checked all the line pressures and checked the cooler line pressure at idle and on the t-brake and all was as it should be. Did a 8psi 2nd gear pull on the street and the RPMs ramp and drop on the 2-3 looked normal. Don't have enough ***** to test with track boost on the street.

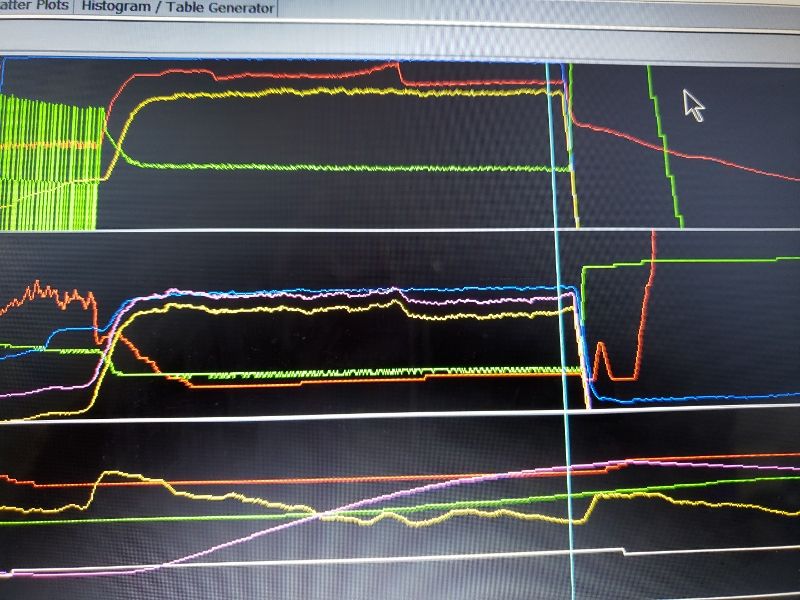

Fast forward to last night. 1st pass and the problem is not fixed!!! All you have to do is look at the datalog and you see what I am talking about. In the first frame, blue is TPS, red is RPM, yellow is boost and green is timing. Launched with 3825 and 7.25psi. After the 2-step, RPMs shot straight up on the launch, shift light came on in .55 secs!!, that first little blip is the 1-2 shift,

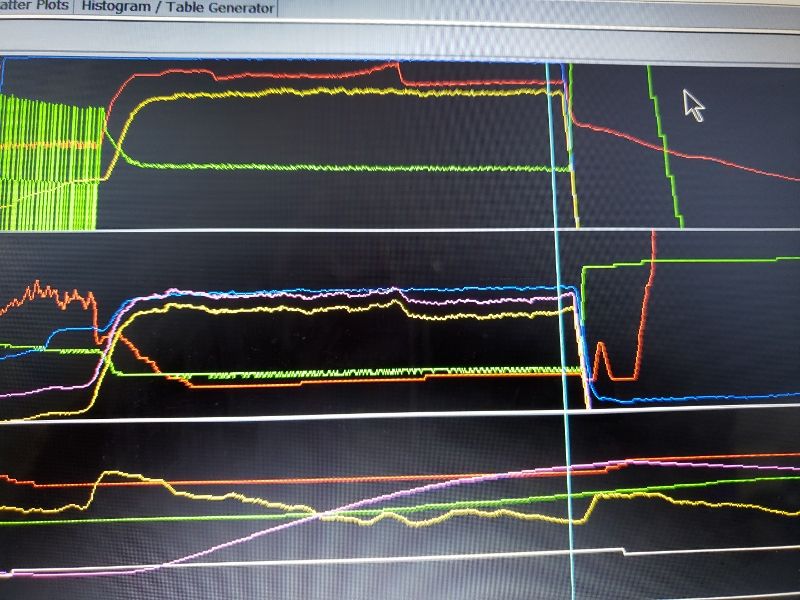

and the RPMs dropped about 200!! and about 800 on the 2-3. Basically, the RPMs flatlined and the shift light stayed on the whole pass. On the return road the tranny temp gauge showed 168*. Ambient was about 55*.In the 2nd frame, blue is FP, purple is fuel flow, yellow is Inj DC%, green is AFR Target and red is Actual AFR. FP is nice and flat matching boost, AFR is a little fat when the alky comes on but right where I want it to be. Fuel flow is about 672lbs/hr which factors out to about 950rwhp + about another 65-70 from the alky. Should be running low 8.30s if those numbers are accurate. I rule out any tuning issues.

and the RPMs dropped about 200!! and about 800 on the 2-3. Basically, the RPMs flatlined and the shift light stayed on the whole pass. On the return road the tranny temp gauge showed 168*. Ambient was about 55*.In the 2nd frame, blue is FP, purple is fuel flow, yellow is Inj DC%, green is AFR Target and red is Actual AFR. FP is nice and flat matching boost, AFR is a little fat when the alky comes on but right where I want it to be. Fuel flow is about 672lbs/hr which factors out to about 950rwhp + about another 65-70 from the alky. Should be running low 8.30s if those numbers are accurate. I rule out any tuning issues.

Sorry for the long diatribe, guys, just frustrated and venting and who knows, maybe someone will come up with something everyone else is missing. Whatever the problem is, it's common to all 3 gears and it tested fine with a 8psi 2nd gear pull and shift on the street but fails on the track.

Been struggling with what I believe is a converter issue and everyone who has looked at this is baffled. It is a 9.5" PTC that was originally 14-45*-0 SBP it seemed to be working fine, cutting low-high 1.20s with a best of 1.196. One night I made a pass and all was normal then the next pass, the RPM drop on the shifts came down and the next pass I was just blowing through the converter. Sent it back to PTC and they said the bearing saw a lot of heat, enough to blacken it. They freshened it up and I asked them to put a 13-0 stator in, same as the one Mark Frederich was running. Buddy and I tore down the tranny (FTI level 4) and everything looked brand new. Decided to spend some more coin and swapped out the OEM steel direct drum with a 4-element sprag for an alum drum with a 36-element sprag. That sprag uses different intermediate clutches and even though the direct clutches/steels were like new, I put a fresh set in. What's baffling about what I just wrote is this. If the converter got so hot as to burn the bearing and burn the fluid, why didn't I see that high temp on the guage which has the sender in the pan and why didn't clutches and steels show any evidence of heat? Every scenario we come up that would cause the converter to do what it's doing is contradicted by the fact that there is no evidence of it in the tranny.

After I put everything back together, I checked all the line pressures and checked the cooler line pressure at idle and on the t-brake and all was as it should be. Did a 8psi 2nd gear pull on the street and the RPMs ramp and drop on the 2-3 looked normal. Don't have enough ***** to test with track boost on the street.

Fast forward to last night. 1st pass and the problem is not fixed!!! All you have to do is look at the datalog and you see what I am talking about. In the first frame, blue is TPS, red is RPM, yellow is boost and green is timing. Launched with 3825 and 7.25psi. After the 2-step, RPMs shot straight up on the launch, shift light came on in .55 secs!!, that first little blip is the 1-2 shift,

and the RPMs dropped about 200!! and about 800 on the 2-3. Basically, the RPMs flatlined and the shift light stayed on the whole pass. On the return road the tranny temp gauge showed 168*. Ambient was about 55*.In the 2nd frame, blue is FP, purple is fuel flow, yellow is Inj DC%, green is AFR Target and red is Actual AFR. FP is nice and flat matching boost, AFR is a little fat when the alky comes on but right where I want it to be. Fuel flow is about 672lbs/hr which factors out to about 950rwhp + about another 65-70 from the alky. Should be running low 8.30s if those numbers are accurate. I rule out any tuning issues.

and the RPMs dropped about 200!! and about 800 on the 2-3. Basically, the RPMs flatlined and the shift light stayed on the whole pass. On the return road the tranny temp gauge showed 168*. Ambient was about 55*.In the 2nd frame, blue is FP, purple is fuel flow, yellow is Inj DC%, green is AFR Target and red is Actual AFR. FP is nice and flat matching boost, AFR is a little fat when the alky comes on but right where I want it to be. Fuel flow is about 672lbs/hr which factors out to about 950rwhp + about another 65-70 from the alky. Should be running low 8.30s if those numbers are accurate. I rule out any tuning issues.Sorry for the long diatribe, guys, just frustrated and venting and who knows, maybe someone will come up with something everyone else is missing. Whatever the problem is, it's common to all 3 gears and it tested fine with a 8psi 2nd gear pull and shift on the street but fails on the track.

#82

TECH Junkie

iTrader: (9)

Your not getting enough dwell time to soak the trans into a heat harm situation if its isolated in the converter which it looks like to me as well. Seeing as this happened suddenly my guess is something in the converter let go, maybe a bent blade/s or tweaked something in there ( im no internal converter expert ) but I can say if possible rather than working the same unit over I would try another unit altogether to rule it out 100%. Funny, I watched Carlyle go through this same issue at the track once. Swapped out converters between rounds for another and the car started working well again.

#83

Sounds like a charge or exhaust issue for the converter on the trans

Baking converter but not seeing it at the sump.... Not coupling correctly

Even with low charge pressure on a 13-0, the stall (where it falls on the 2-3) should not break much above 6k if at all on 900-1kwhp

I run moderate charge on a 14-0 and barely push the stall to 6200 at that 1100-1200 area.

Baking converter but not seeing it at the sump.... Not coupling correctly

Even with low charge pressure on a 13-0, the stall (where it falls on the 2-3) should not break much above 6k if at all on 900-1kwhp

I run moderate charge on a 14-0 and barely push the stall to 6200 at that 1100-1200 area.

#85

Zach, could you be more specific on the converter charge pressure. Its a TH400 and I have a T in the outlet line about 24" from the tranny and measured 34 at idle and 82 on the brake. I had an issue a while back tearing up thrust bearings until I discovered the charge pressure was over 130. I fixed that with a restrictor in the pump by tapping that port and using a 3/16 set screw drilled to .110. I can certainly understand the issue being incorrect charge pressure but not sure what the correct pressures should be and why it just suddenly started happening. Sounds like you're saying the pressure might be low.

Prior to this happening, a 2-3 shift at 7000 would drop to about 5900.

Appreciate any feedback. School me, please.

Prior to this happening, a 2-3 shift at 7000 would drop to about 5900.

Appreciate any feedback. School me, please.

#86

8 Second Club

iTrader: (3)

What Iíve noted in my setup, also has the pump mod you described, is that the more I turn up the boost, the less rpm drop after the shifts. Seems normal as more boost equals more torque equals more converter slip.

I also run a PTC but I have a 17 stator. I donít know anything else about the converter specs.....

I had mine loosened after the first season and PTC didnít really write down what they did.....I suppose I could send them the new serial they stamped on it and ask whatís actually inside it now.

Your measured charge pressure is about what I measured.

I also run a PTC but I have a 17 stator. I donít know anything else about the converter specs.....

I had mine loosened after the first season and PTC didnít really write down what they did.....I suppose I could send them the new serial they stamped on it and ask whatís actually inside it now.

Your measured charge pressure is about what I measured.

#87

Rpm drop on the shift doesn't really mean jack.

It is always going to fall to the same point on shift regardless of what rpm you shift at. It is falling to the true stall point of the given power input

Higer boost and more TQ the stall rpm rises

A 17-0 is ~1000rpm looser than a 13-0

A 14-0 let alone a 13-0 isn't going to stall at almost 7k at 1k HP if everything is happy.

He used to be right where it should.of been when he said it used to be 5900

It really only can be the converter or the converter hydraulics, if the trans itself was slipping you would see that in the pan instantly

Sadly Scotty I don't have much experience with a 400s fluid circuits, I only know a glide inside and out

Let's just expand on this a bit

You say you have checked converter pressure at the cooler line at idle and on the brake. Did or can you monitor the pressure on a track pass so you can see what happens out the back?

Do you have the front bushing in the stator tube?

What input shaft is in it? Do you know how big the exhaust hole/holes are that move it past that forward journal?

And have you confirmed how much flow you have out the cooler port?

On a glide you can have pressure at those ports but zero flow

When checking pressures was oil full temp or cold.

It is always going to fall to the same point on shift regardless of what rpm you shift at. It is falling to the true stall point of the given power input

Higer boost and more TQ the stall rpm rises

A 17-0 is ~1000rpm looser than a 13-0

A 14-0 let alone a 13-0 isn't going to stall at almost 7k at 1k HP if everything is happy.

He used to be right where it should.of been when he said it used to be 5900

It really only can be the converter or the converter hydraulics, if the trans itself was slipping you would see that in the pan instantly

Sadly Scotty I don't have much experience with a 400s fluid circuits, I only know a glide inside and out

Let's just expand on this a bit

You say you have checked converter pressure at the cooler line at idle and on the brake. Did or can you monitor the pressure on a track pass so you can see what happens out the back?

Do you have the front bushing in the stator tube?

What input shaft is in it? Do you know how big the exhaust hole/holes are that move it past that forward journal?

And have you confirmed how much flow you have out the cooler port?

On a glide you can have pressure at those ports but zero flow

When checking pressures was oil full temp or cold.

#88

It really only can be the converter or the converter hydraulics, if the trans itself was slipping you would see that in the pan instantly

Do you have the front bushing in the stator tube?

What input shaft is in it? Do you know how big the exhaust hole/holes are that move it past that forward journal?

And have you confirmed how much flow you have out the cooler port?

On a glide you can have pressure at those ports but zero flow

When checking pressures was oil full temp or cold.

Do you have the front bushing in the stator tube?

What input shaft is in it? Do you know how big the exhaust hole/holes are that move it past that forward journal?

And have you confirmed how much flow you have out the cooler port?

On a glide you can have pressure at those ports but zero flow

When checking pressures was oil full temp or cold.

The front bushing was the first thing we checked when we pulled the pump.

It is a standard TH400 input shaft and don't know the size of the exhaust holes. Since FTI is supposed to dyno every built tranny they sell, you would assume they matched the exhaust hole with the restrictor in the pump to get the correct pressure/flow. Keep in mind it was working fine and then suddenly got bad after a good pass, then worse the next. Next time I take it down I'll check the input shaft closer for a crack causing a hemorrhage we might have missed. I assume the TH400 shaft is same design as a glide since it is an upgrade for some glides.

Only confirmed pressure at the cooler port, not flow and since it was checked on the lift, fluid temp was not at racing temps.

A buddy has offered up to loan me his 9.5PTC to help isolate the problem, but since I have to pull it, I'll see if I can have FTI put it on their dyno with my converter and see if they can find something.

#90

After a lot of head scratching and pulling the tranny apart twice, I think I finally found the problem. The stator support tube, even though it's knurled, spun in the pump cover and the hole in the tube was about 150* off from the converter feed port causing total blockage of fluid getting to the converter. New 895 pump that came in the FTI tranny. Have to assume the pump was defective. Hopefully I can swap it out and test again before the Christmas break.

#93

Decided not to put it on the dyno as I was sure it wouldn't show the problem. I've tested on the backroads several times doing 8+psi 2nd gear pulls from 4500 and the RPMs ramp and then drop on the 2-3 are always normal. The dyno is driven by a n/a 350ci SBC that w/o a doubt, makes way less power than my engine at 8psi under load so I was sure everything would have looked normal. I found the problem after a lot of research and discovering this is not uncommon in high HP glides and rarely seen in the TH400 unless the pump was defective. Everyone sells glide pumps with the stator tube pinned or bolted in, but no one does for the TH400. If there's a 1 in a million chance it will happen, it will happen to me.

#95

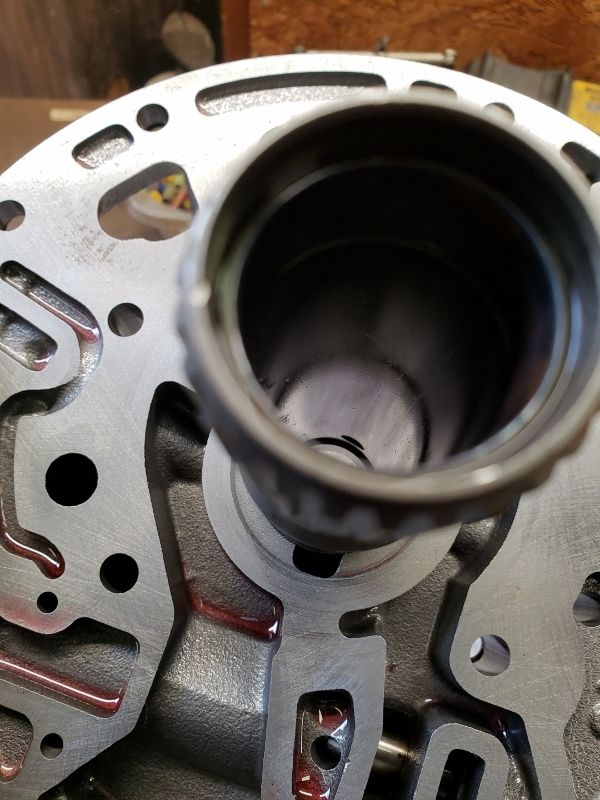

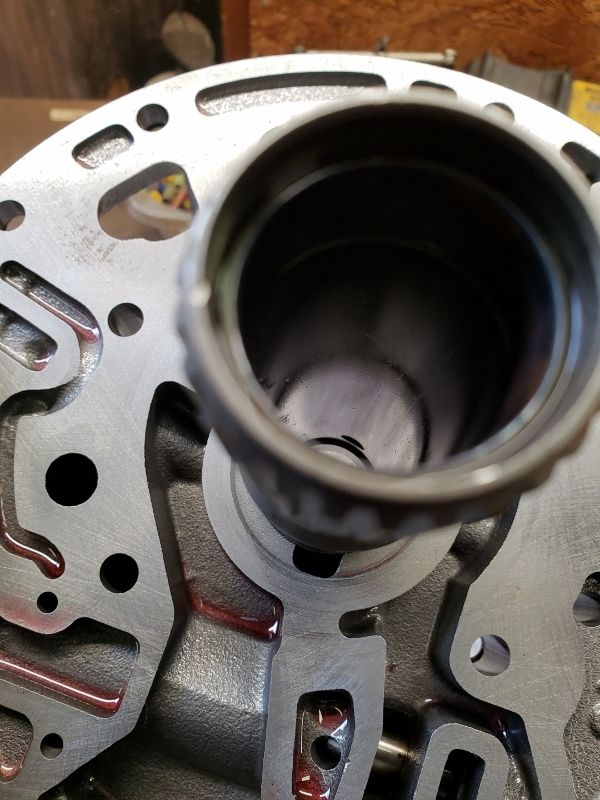

Here is the TH400 pump front cover. The converter feed port is at 6:00 (the top hole angled towards the tube), the tube has a hole that is supposed to be lined up with that port hole and feeds the input shaft between the 2 bushings. If you look down the tube you can see the hole at 1:00. If you look closely where the tube goes through the pump body you can see the knurls.

#99

Well, looks like I won't be having a merry Christmas, car wise, as I had hoped.

Turns out I was wrong on the stator tube position in the pump and that is how it is supposed to be. Took the tranny to FTI see if they could find anything. They disassembled, inspected, reassembled and put it on the dyno to check pressures and the t-brake and said they see nothing wrong. Only thing they couldn't check was releasing the t-brake and monitoring the RPM ramp. I feel confident the cooler is not blocked as I've put 100psi open ended, through it, so back to the converter. Only way I feel I can confidently find the problem now is to use a different converter and foot-braking it to take the t-brake out of the equation. Working with PTC to see if they'll send another one to try and help solve this. This one might be cursed or is that 1 in 1000 that fails.

Cam, retired Lockheed, giving a hint of how my mind works. If I tell you more, I'll have to use my "flashy-thingy" on you

Adam, leaning towards going back to the 14. It was very tight up top but worked well out of hole and why mess with low-1.20s. I used to do a 50/50 type-F/J.D. Hygard mix and dropping the Hygard should loosen it up a tad.

Andrew, you calling me an Old Geezer?

Turns out I was wrong on the stator tube position in the pump and that is how it is supposed to be. Took the tranny to FTI see if they could find anything. They disassembled, inspected, reassembled and put it on the dyno to check pressures and the t-brake and said they see nothing wrong. Only thing they couldn't check was releasing the t-brake and monitoring the RPM ramp. I feel confident the cooler is not blocked as I've put 100psi open ended, through it, so back to the converter. Only way I feel I can confidently find the problem now is to use a different converter and foot-braking it to take the t-brake out of the equation. Working with PTC to see if they'll send another one to try and help solve this. This one might be cursed or is that 1 in 1000 that fails.

Cam, retired Lockheed, giving a hint of how my mind works. If I tell you more, I'll have to use my "flashy-thingy" on you

Adam, leaning towards going back to the 14. It was very tight up top but worked well out of hole and why mess with low-1.20s. I used to do a 50/50 type-F/J.D. Hygard mix and dropping the Hygard should loosen it up a tad.

Andrew, you calling me an Old Geezer?