How to calculate compound pump volume/pressure

#1

TECH Resident

Thread Starter

iTrader: (36)

Join Date: Dec 2006

Location: Lafayette, CA

Posts: 985

Likes: 0

Received 0 Likes

on

0 Posts

Hey Guys,

How do you calculate the HP support of a in series dual pump setup? I picked up a couple slightly used Bosch 044's and currently am running a Walbro 255lph intank and an Alky twin nozzle Meth system. I'll be using a Aeromotive 13101 FPR with a -6An return line and keeping the factory returnless fuel rail.

I'm considering a few options for a 900 RWHP fuel system and one of them is keeping the 255 intank and adding one of the 044's inline. How do you calculate the lbs per hr (and convert it to supported HP) for a compound in series system?

The other two options I'm contemplating are running the walbro and using two inline (one triggered by a HOBBS switch) instead of just one 044 spliced into the stock fuel line. The 2nd option is running the 255 to a 2l surge tank under the hood feeding two 044's (again one triggered by a HOBBS switch).

Advice?

Rick

How do you calculate the HP support of a in series dual pump setup? I picked up a couple slightly used Bosch 044's and currently am running a Walbro 255lph intank and an Alky twin nozzle Meth system. I'll be using a Aeromotive 13101 FPR with a -6An return line and keeping the factory returnless fuel rail.

I'm considering a few options for a 900 RWHP fuel system and one of them is keeping the 255 intank and adding one of the 044's inline. How do you calculate the lbs per hr (and convert it to supported HP) for a compound in series system?

The other two options I'm contemplating are running the walbro and using two inline (one triggered by a HOBBS switch) instead of just one 044 spliced into the stock fuel line. The 2nd option is running the 255 to a 2l surge tank under the hood feeding two 044's (again one triggered by a HOBBS switch).

Advice?

Rick

#2

TECH Resident

Thread Starter

iTrader: (36)

Join Date: Dec 2006

Location: Lafayette, CA

Posts: 985

Likes: 0

Received 0 Likes

on

0 Posts

Rick

#3

If u put them in line they will only flow as well as smallest in the line. So if your walbro is flowing 235lph, thats all wour system will ever flow. The only way to get more out of it is to put them both in the tank and Y them together. I Wasted 2 days figuring this out on my own. Good luck with the build I hope i saved u some time

#4

9 Second Club

iTrader: (10)

This setup is for a C5 but it will give you an idea of how to set it up properly.I would run the 044s side by side.

Good luck.

http://www.aacorvette.com/pdf/aa_fue...structions.pdf

Good luck.

http://www.aacorvette.com/pdf/aa_fue...structions.pdf

#6

FormerVendor

iTrader: (33)

Join Date: Feb 2002

Location: Lake in the Hills, IL

Posts: 5,052

Likes: 0

Received 0 Likes

on

0 Posts

Our dual intank walbro systems make well over 1000rwhp and they are quiet and 100%reliable internal. give me a call I will help you figure out the system that is right for your application.

#7

TECH Addict

iTrader: (5)

I'm not a calculator, I'm a seemer. And it seems to me that you should be able uprate the intank pump to whatever the manufacturer rates it at 0 psi. So in my scenario the inline would help the intank by eliminating the head of the intank, to put it in pump terms. There has to be some kind of easing of the work load for the inline, but I can't imagine how much. I also can't imagine that a series setup like this won't work, because it made a big difference puting an inline on my truck, although it still was inadequate. I think it added about 10 psi during my fuel starvation where I needed 20 more.

Trending Topics

#8

LS1TECH Sponsor

iTrader: (16)

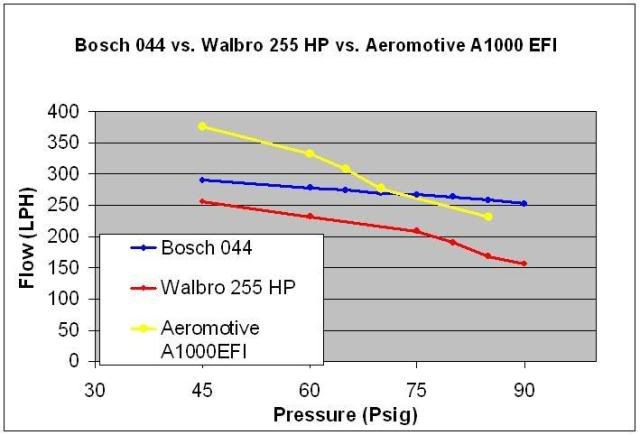

I do not have all the flow charts for the pumps at low pressures (where you ned the data), to give you the flow calcs, but from seeing (& replacing) these inline setups, typically you can pick up about 10% flow over the worst flowing pump.

The series pumps are a good way to boost pressure as in systems using fuel management units to boost pressure under boost, but series pumps are not that good at boosting flow at the pumps rated pressure.

example as stated above, you can flow maybe 10% more at 58psi, but if you are trying to run 75psi, then the series pumps helps more in this situation.

If you are looking for a 900rwhp setup, this is not the way to get there.

If you are interested in a dual intank setup, plase contact me. I offer a proven setup with no experimentation required, that will easily support your performance needs.

The series pumps are a good way to boost pressure as in systems using fuel management units to boost pressure under boost, but series pumps are not that good at boosting flow at the pumps rated pressure.

example as stated above, you can flow maybe 10% more at 58psi, but if you are trying to run 75psi, then the series pumps helps more in this situation.

If you are looking for a 900rwhp setup, this is not the way to get there.

If you are interested in a dual intank setup, plase contact me. I offer a proven setup with no experimentation required, that will easily support your performance needs.