408 teardown, need expert opinions

#1

I usually post over on PT, but I know there are a lot of experts over here.

Backstory:

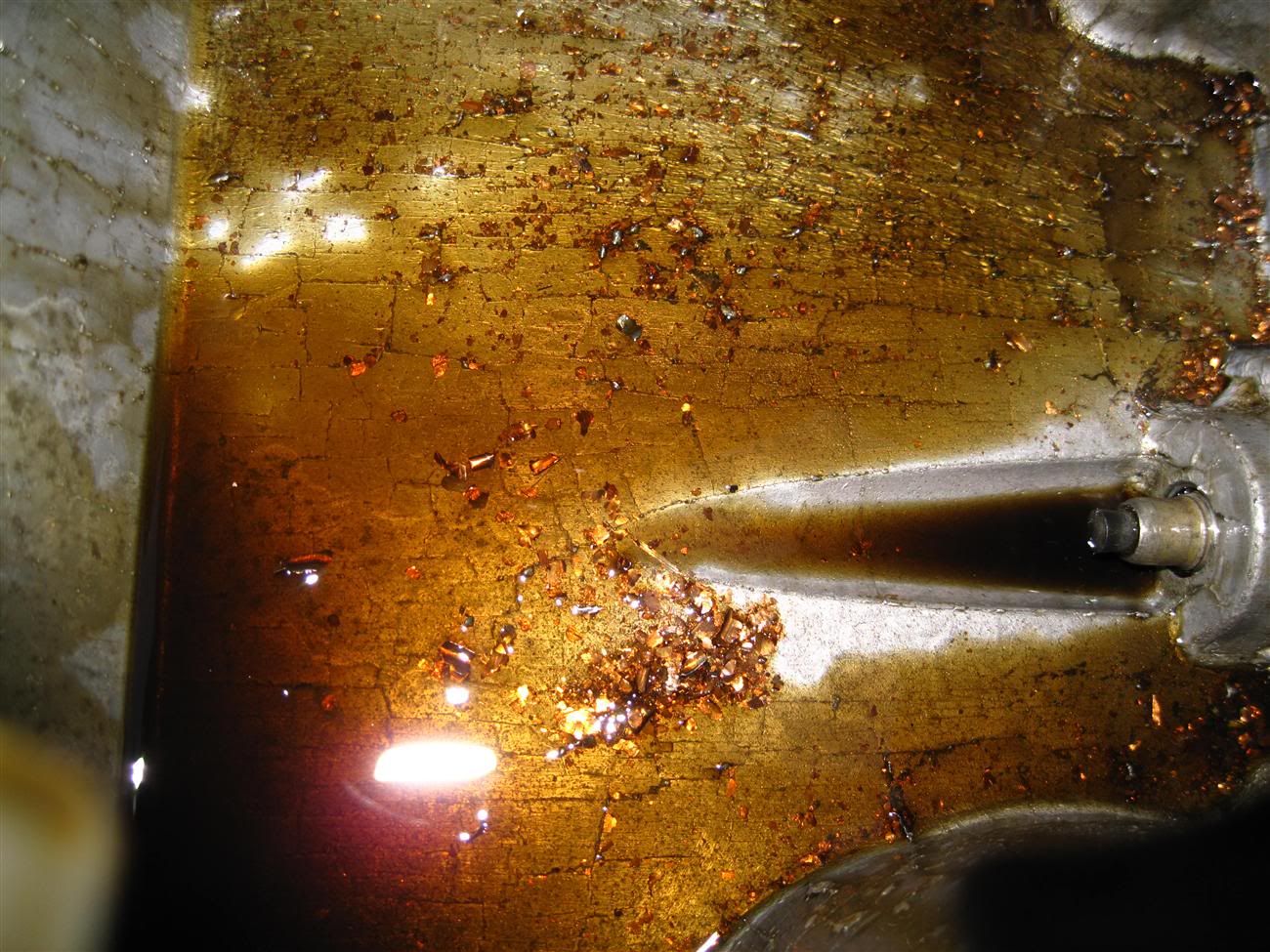

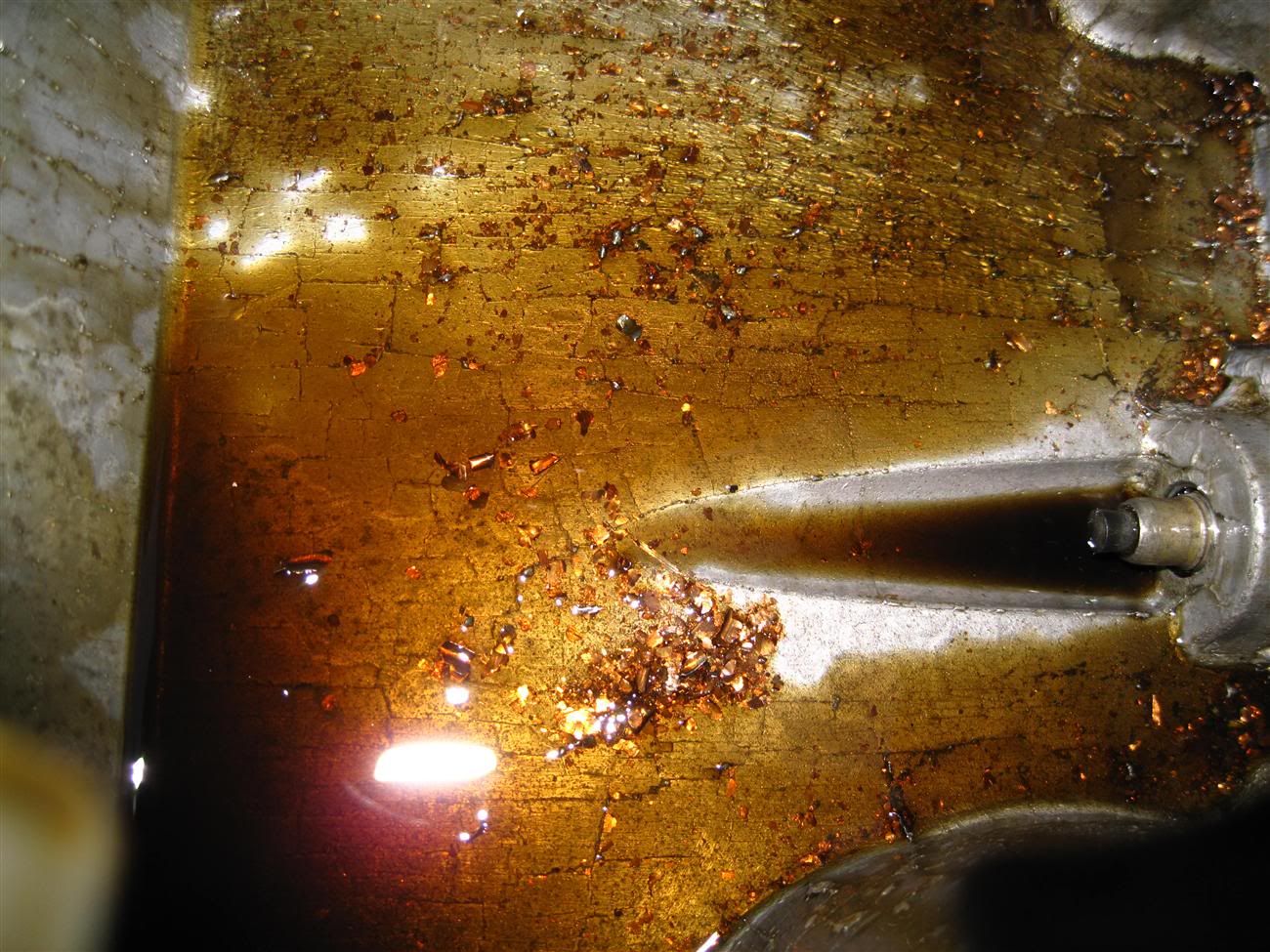

I bought an assemebled 408 shortblock in april, and spent april through august collecting parts to throw it in my truck. I installed it in the middle of August and have been driving it since. Last weekend I noticed I was having low oil pressure so I cut open the oil filter and found a lot of little copper colored shavings. Damn. Soooooo I pulled it out this weekend and put my 5.3 back in, and now I have to decide what to do...

Parts list:

LQ9 iron block

K1 4.00" stroker crank

Diamond flat top pistons 4.03"

Callies compstar 6.125" rods

11:1 compression

All ARP hardware

LS6 oil pump

Pat gold dual springs

REV 2.02/1.6 valves

317 heads

LS9 headgaskets

Pat G custom cam

rollmaster double timing chain

LS7 lifters

Hardened comp pushrods

In total I had 1700 miles and 1.5 months of use from this engine. I put my tvs1900 on it and damn it was fun while it lasted. I bought the shortblock fresh from the machine shop from a guy that was getting deployed and changed his mind or something. I spoke with the shop before hand and they seemed competent enough...

party in the pan,

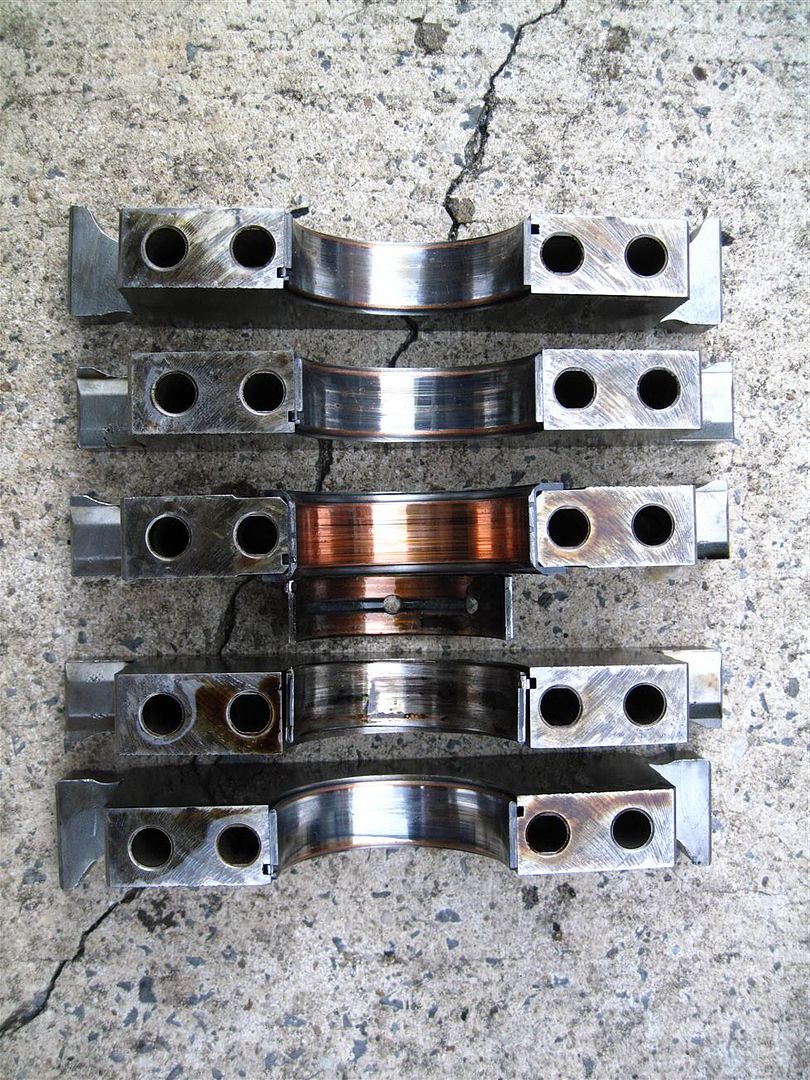

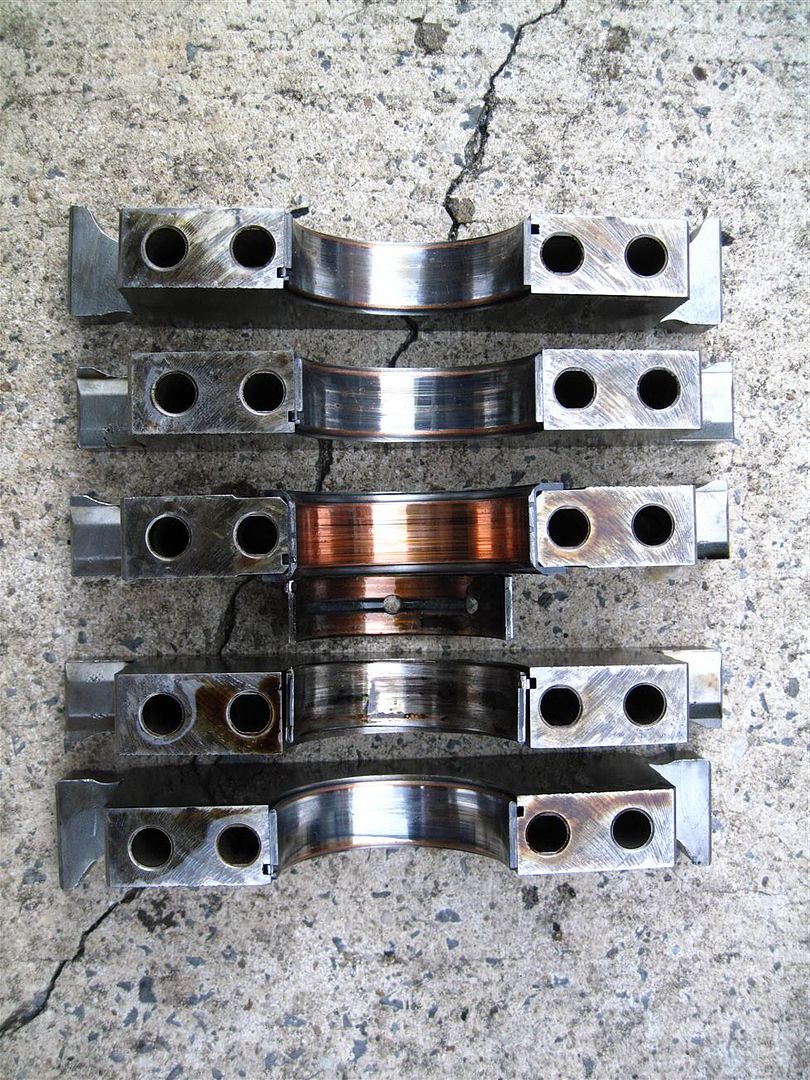

main caps, front on the right,

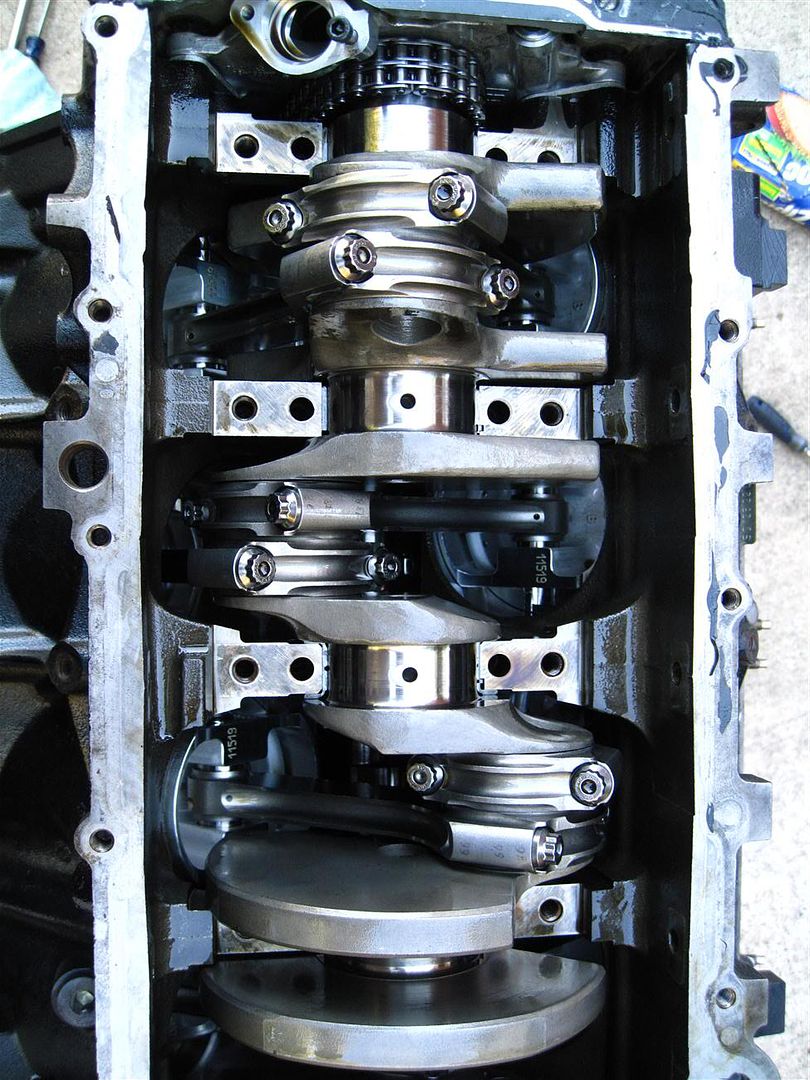

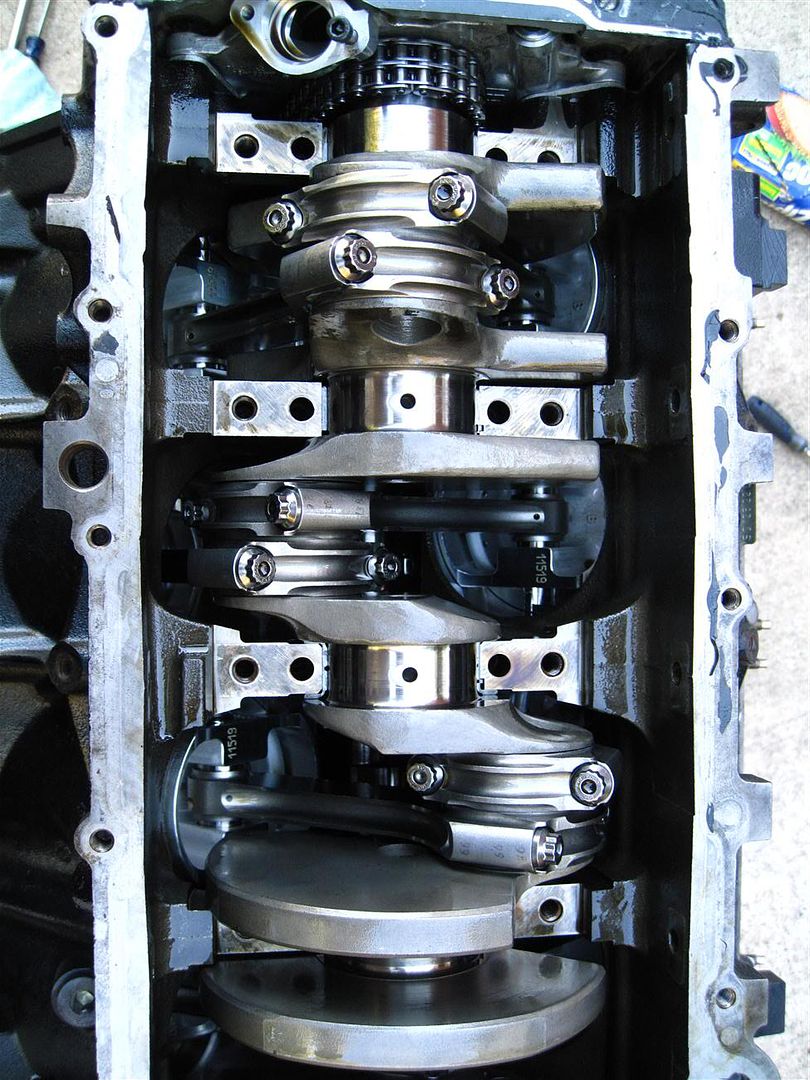

crank,

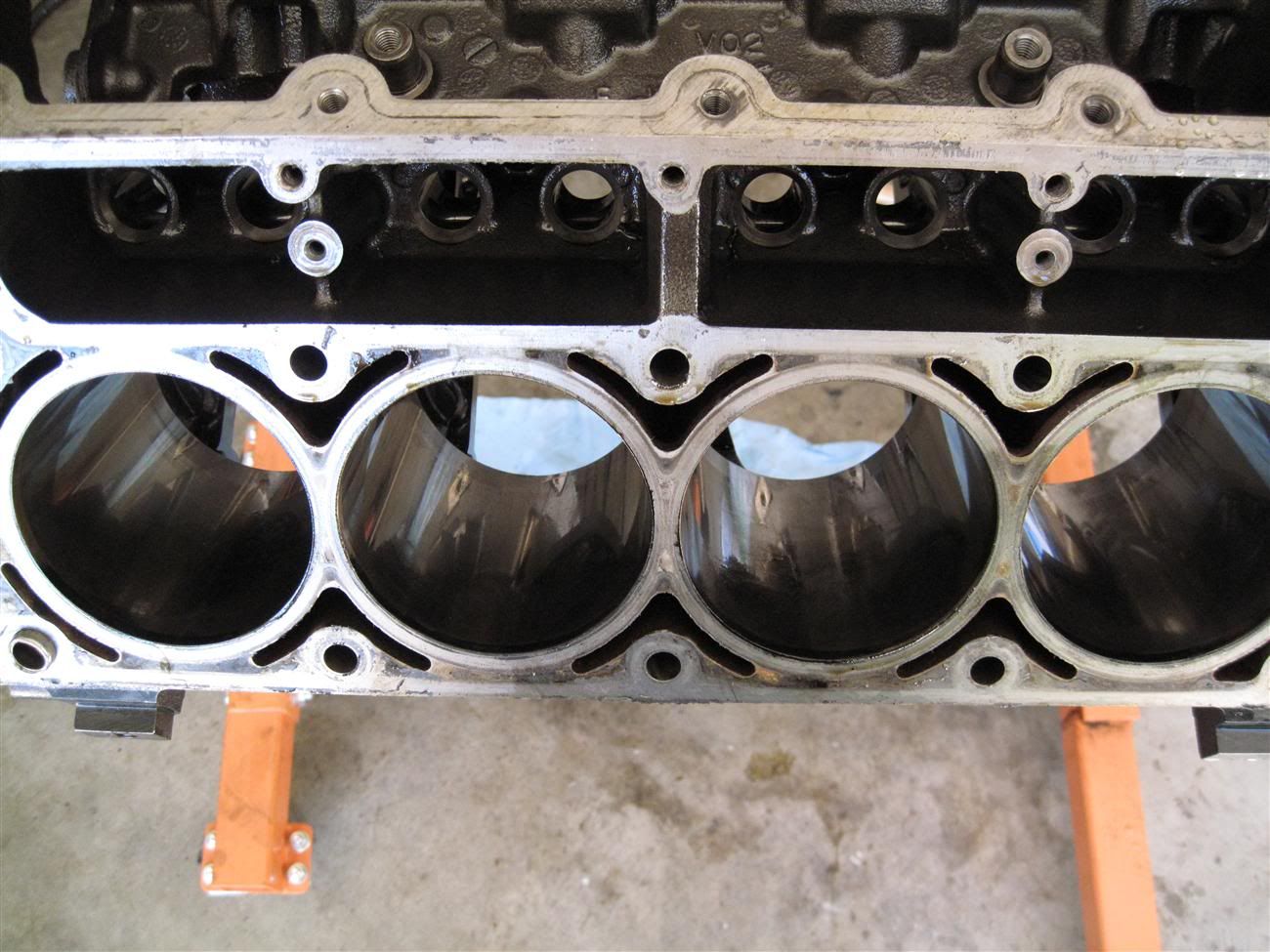

pistons,

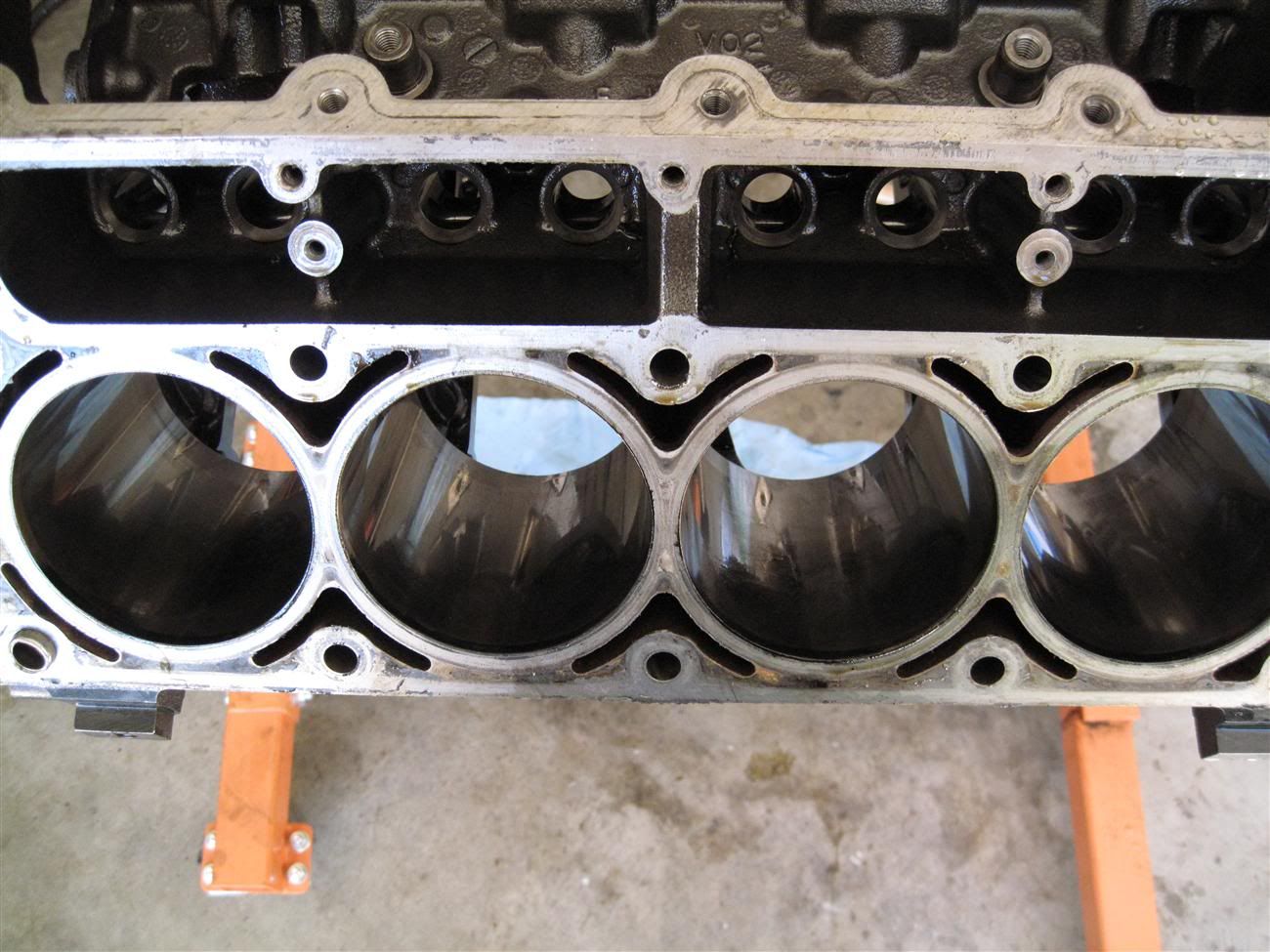

combustion chamber,

Comments

-The cam is in good shape; no wear on the journals, although obviously im going to replace those bearings as well.

-The pistons are not nearly as clean as I was expecting for so few miles...

-The cylinder walls are smooth as glass.

Plans

Even though I didnt have the 408/tvs1900 combo for very long, I maxed out the blower with a 2.8" pulley and got around 7lbs of boost and while it was fun, it was also kind of boring. Based on the time I ran at the track, never got a chance on the dyno, and the weight of my truck it put down right around 600rwhp. So I am going to sell the blower and go with an 88mm turbo setup at some point, but more pressingly I need to get this engine working again since I have too much cash in it for it to be a garage ornament.

I am hoping the crank is fine and just needs a little polishing (cant feel any score marks with my fingernail), and I can use it along with the rods. I am thinking I want to go with dished pistons to put the compression ratio at around 9.5 for 12+ pounds of boost.

Are there any engine builders near Alabama that anyone recommends? I would prefer someone within driving distance so I wouldnt have to worry about shipping this thing via freight. If there arent, does a performance shop like HKE redo failed builds or what? I want the block align honed and all bearings replaced and clearances checked as well as runout on the crank checked; basically I dont want this to happen again for at least 100k miles.

I know this is long winded but I like being thorough.

Thanks for any input

Backstory:

I bought an assemebled 408 shortblock in april, and spent april through august collecting parts to throw it in my truck. I installed it in the middle of August and have been driving it since. Last weekend I noticed I was having low oil pressure so I cut open the oil filter and found a lot of little copper colored shavings. Damn. Soooooo I pulled it out this weekend and put my 5.3 back in, and now I have to decide what to do...

Parts list:

LQ9 iron block

K1 4.00" stroker crank

Diamond flat top pistons 4.03"

Callies compstar 6.125" rods

11:1 compression

All ARP hardware

LS6 oil pump

Pat gold dual springs

REV 2.02/1.6 valves

317 heads

LS9 headgaskets

Pat G custom cam

rollmaster double timing chain

LS7 lifters

Hardened comp pushrods

In total I had 1700 miles and 1.5 months of use from this engine. I put my tvs1900 on it and damn it was fun while it lasted. I bought the shortblock fresh from the machine shop from a guy that was getting deployed and changed his mind or something. I spoke with the shop before hand and they seemed competent enough...

party in the pan,

main caps, front on the right,

crank,

pistons,

combustion chamber,

Comments

-The cam is in good shape; no wear on the journals, although obviously im going to replace those bearings as well.

-The pistons are not nearly as clean as I was expecting for so few miles...

-The cylinder walls are smooth as glass.

Plans

Even though I didnt have the 408/tvs1900 combo for very long, I maxed out the blower with a 2.8" pulley and got around 7lbs of boost and while it was fun, it was also kind of boring. Based on the time I ran at the track, never got a chance on the dyno, and the weight of my truck it put down right around 600rwhp. So I am going to sell the blower and go with an 88mm turbo setup at some point, but more pressingly I need to get this engine working again since I have too much cash in it for it to be a garage ornament.

I am hoping the crank is fine and just needs a little polishing (cant feel any score marks with my fingernail), and I can use it along with the rods. I am thinking I want to go with dished pistons to put the compression ratio at around 9.5 for 12+ pounds of boost.

Are there any engine builders near Alabama that anyone recommends? I would prefer someone within driving distance so I wouldnt have to worry about shipping this thing via freight. If there arent, does a performance shop like HKE redo failed builds or what? I want the block align honed and all bearings replaced and clearances checked as well as runout on the crank checked; basically I dont want this to happen again for at least 100k miles.

I know this is long winded but I like being thorough.

Thanks for any input

#2

10 Second Club

iTrader: (11)

Tear everything down. Send block the machine shop and have the heads decked, crank polished, mains line honed, bores honed, and new cam bearings installed. Clean up the pistons and install a new set of rings.

From the looks of it, the mains weren't line honed before assembly.

From the looks of it, the mains weren't line honed before assembly.

#6

Moderator

iTrader: (20)

I'm guessing those are Clevite bearings? It looks a lot like #3 bearing clearance was too tight (typical of Clevites) and judging by the wear on both outer edges of the other bearings, there may have been some serious taper in the journals.

As for the rods, there is a dowel in the cap that has a press fit with the rod end which makes it difficult to pry the two apart. All you have to do is loosen the bolts out a few turns and tap them with a rubber mallet. That will seperate the rod.

With Compstars, the 7/16" rod bolt torque should be closer to 75-80ft-lbs as well. 40-45ft-lbs is typical of the smaller 9mm or 3/8" diameter bolts.

HKE has basically built a reputation for fixing builds from other shops that didn't live up to the customers' expectations (i.e. last more than 800 miles, etc). Erik and his gang can certainly get you lined out with a nice trouble free engine, so long as it's well maintained and well tuned.

As for the rods, there is a dowel in the cap that has a press fit with the rod end which makes it difficult to pry the two apart. All you have to do is loosen the bolts out a few turns and tap them with a rubber mallet. That will seperate the rod.

With Compstars, the 7/16" rod bolt torque should be closer to 75-80ft-lbs as well. 40-45ft-lbs is typical of the smaller 9mm or 3/8" diameter bolts.

HKE has basically built a reputation for fixing builds from other shops that didn't live up to the customers' expectations (i.e. last more than 800 miles, etc). Erik and his gang can certainly get you lined out with a nice trouble free engine, so long as it's well maintained and well tuned.

#7

Got them out with a rubber mallet, not too bad. Bottoms of the pistons look brand new, and the rod bearings on the crank dont look bad.

Cylinder walls are good,

The dark spot on the center journal is oil.

HKE was the first shop that came to mind, but has any one ever used Hinson performance in Hunstville, AL? I would like to avoid shipping if possible, and Hinson specializes in LSx engines.

Cylinder walls are good,

The dark spot on the center journal is oil.

HKE was the first shop that came to mind, but has any one ever used Hinson performance in Hunstville, AL? I would like to avoid shipping if possible, and Hinson specializes in LSx engines.

Trending Topics

#14

FormerVendor

iTrader: (3)

I'm guessing those are Clevite bearings? It looks a lot like #3 bearing clearance was too tight (typical of Clevites) and judging by the wear on both outer edges of the other bearings, there may have been some serious taper in the journals.

As for the rods, there is a dowel in the cap that has a press fit with the rod end which makes it difficult to pry the two apart. All you have to do is loosen the bolts out a few turns and tap them with a rubber mallet. That will seperate the rod.

With Compstars, the 7/16" rod bolt torque should be closer to 75-80ft-lbs as well. 40-45ft-lbs is typical of the smaller 9mm or 3/8" diameter bolts.

HKE has basically built a reputation for fixing builds from other shops that didn't live up to the customers' expectations (i.e. last more than 800 miles, etc). Erik and his gang can certainly get you lined out with a nice trouble free engine, so long as it's well maintained and well tuned.

As for the rods, there is a dowel in the cap that has a press fit with the rod end which makes it difficult to pry the two apart. All you have to do is loosen the bolts out a few turns and tap them with a rubber mallet. That will seperate the rod.

With Compstars, the 7/16" rod bolt torque should be closer to 75-80ft-lbs as well. 40-45ft-lbs is typical of the smaller 9mm or 3/8" diameter bolts.

HKE has basically built a reputation for fixing builds from other shops that didn't live up to the customers' expectations (i.e. last more than 800 miles, etc). Erik and his gang can certainly get you lined out with a nice trouble free engine, so long as it's well maintained and well tuned.

Always tight on the thrust...

Wow I just saw this was from 10'!!! lol