what's with all the different torque specs for arp head bolts?

#1

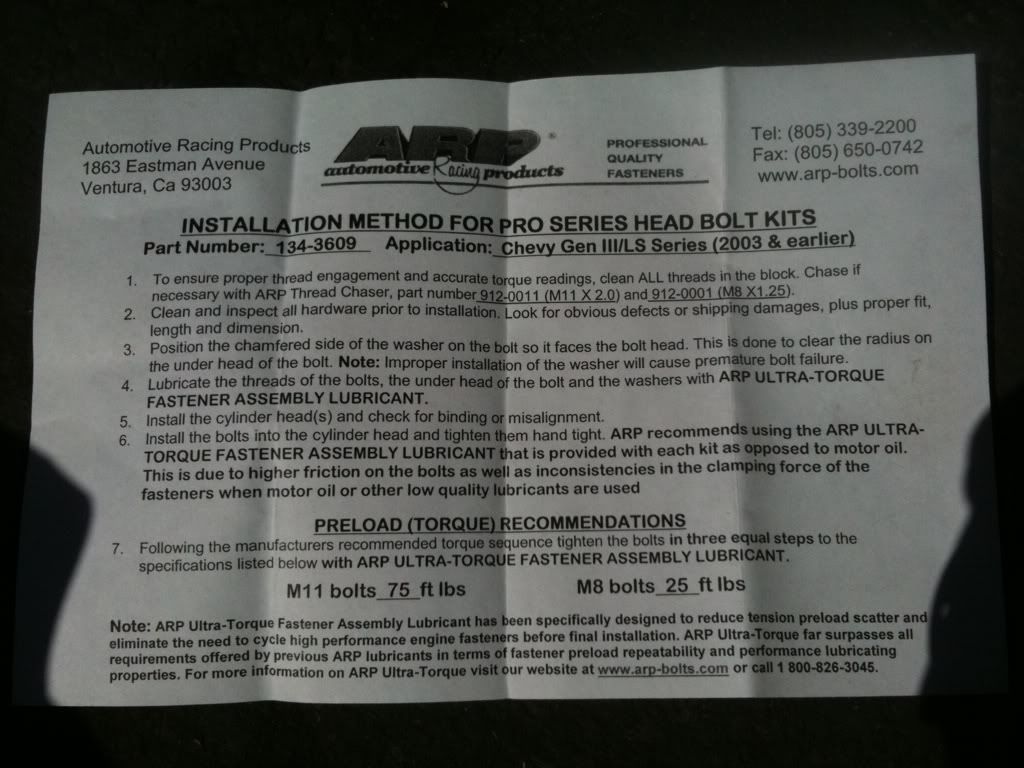

Searching around I have found on this site the following torque specs:

1: 15mm 35/65/85

11mm 10/20/30

2: 15mm 30/60/85

11mm 18/29

3: 15mm 30/50/70

11mm 22

4: 15mm 40/60/70/85

11mm 22/29

They are all with the arp moly lube. So which one is the correct one? Number is the LS1howto specs, the rest i found using the search.

1: 15mm 35/65/85

11mm 10/20/30

2: 15mm 30/60/85

11mm 18/29

3: 15mm 30/50/70

11mm 22

4: 15mm 40/60/70/85

11mm 22/29

They are all with the arp moly lube. So which one is the correct one? Number is the LS1howto specs, the rest i found using the search.

#5

#6

Launching!

iTrader: (9)

Join Date: Sep 2007

Location: Broken Arrow, OK

Posts: 259

Likes: 0

Received 0 Likes

on

0 Posts

Ok so I called a few people and it looks like I will indeed have to remove the bolts to fix this problem. However I have gotten a few different opinions on how to re torque. Should I pull one bolt at a time and just re torque all the way back to final torque? Or should I pull all the bolts and go back over the original torque sequence. Also the motor has been run for like a minute or two. Will any coolant seep into these holes when I pull the bolts? Thanks for all the help. Im so pissed AHHHHHH

#7

Ok so I called a few people and it looks like I will indeed have to remove the bolts to fix this problem. However I have gotten a few different opinions on how to re torque. Should I pull one bolt at a time and just re torque all the way back to final torque? Or should I pull all the bolts and go back over the original torque sequence. Also the motor has been run for like a minute or two. Will any coolant seep into these holes when I pull the bolts? Thanks for all the help. Im so pissed AHHHHHH

I am not sure... there is a torque sequence for a reason if you take everything all the way back off you will probable get coolant into the bolt holes and risk messing with your head gasket. basically this is a big learning experience that may cost you another set of gaskets

Trending Topics

#8

Launching!

iTrader: (9)

Join Date: Sep 2007

Location: Broken Arrow, OK

Posts: 259

Likes: 0

Received 0 Likes

on

0 Posts

I am not sure... there is a torque sequence for a reason if you take everything all the way back off you will probable get coolant into the bolt holes and risk messing with your head gasket. basically this is a big learning experience that may cost you another set of gaskets

#9

Launching!

iTrader: (9)

Join Date: Sep 2007

Location: Broken Arrow, OK

Posts: 259

Likes: 0

Received 0 Likes

on

0 Posts

Ok so here is the final consensus. I talked with two guys from ARP and also to Ron at Vengeance. All three agreed that I can pull one bolt at a time and re-torque to the final torque of 70 ft lbs. I feel that this should work because the head is already clamped to the block. Any ideas or suggestions to this method would be appreciated.

#10

TECH Addict

iTrader: (2)

Ok so here is the final consensus. I talked with two guys from ARP and also to Ron at Vengeance. All three agreed that I can pull one bolt at a time and re-torque to the final torque of 70 ft lbs. I feel that this should work because the head is already clamped to the block. Any ideas or suggestions to this method would be appreciated.

#12

TECH Addict

iTrader: (2)

At one time ARP specified that their bolts should be re-torqued after several heat cycles, and I think the procedure you describe (except for the need in your case to actually remove the bolts during the procedure) is the same. The trick is to not have all the bolts completely loose at the same time, which of course is just common sense.

#13

Launching!

iTrader: (9)

Join Date: Sep 2007

Location: Broken Arrow, OK

Posts: 259

Likes: 0

Received 0 Likes

on

0 Posts

Sounds right to me.

At one time ARP specified that their bolts should be re-torqued after several heat cycles, and I think the procedure you describe (except for the need in your case to actually remove the bolts during the procedure) is the same. The trick is to not have all the bolts completely loose at the same time, which of course is just common sense.

At one time ARP specified that their bolts should be re-torqued after several heat cycles, and I think the procedure you describe (except for the need in your case to actually remove the bolts during the procedure) is the same. The trick is to not have all the bolts completely loose at the same time, which of course is just common sense.

#15

TECH Senior Member

iTrader: (4)

Follow the torque sequence and do one bolt at a time. There should be no coolant issues. Also, if you are concerned, after you get the bolt out check the hole with a flashlight and mirrow to ensure its dry (I don't think you will have an issue).

I re-tightened my studs after running the motor to temperature twice by loosening each nut 1/8 turn and then tightening to the final torque in the proper sequence. Just be thankful you caught it early.

I re-tightened my studs after running the motor to temperature twice by loosening each nut 1/8 turn and then tightening to the final torque in the proper sequence. Just be thankful you caught it early.

#17

TECH Addict

iTrader: (2)

The 30 foot pound and 50 foot pound figures given for the 70 foot pound final pass scenario will work, but if you are just doing one bolt at a time I am not sure what the purpose of a first and second pass would be. The original pupose of the multiple-pass procedure, as I understand it, is to mate the block/head surfaces evenly.

#18

TECH Senior Member

#19

TECH Addict

iTrader: (4)

Ok so here is the final consensus. I talked with two guys from ARP and also to Ron at Vengeance. All three agreed that I can pull one bolt at a time and re-torque to the final torque of 70 ft lbs. I feel that this should work because the head is already clamped to the block. Any ideas or suggestions to this method would be appreciated.