Anyone ported 243?

#2

FormerVendor

iTrader: (18)

Other than hand porting? Are you talking about CNC porting? If so, we can CNC port those heads for you. You would be looking $750 for CNC porting and 5-angle valvejob. Here's some specs on what you would be looking at. Pricing is obviously higher on these with them being new cores but you can definitely send those in for porting. I don't know if this is what you were looking for but hopefully it helps.

PRC Stg.1 LS6 Heads

PRC Stg.1 LS6 Heads

#3

TECH Enthusiast

iTrader: (4)

Ethan, every CNC program out there is a digitized copy of a port job done by hand. But many many different done-by-hand results get tested, both on the flow bench and at the drag strip, before choosing which results get digitized.

CNC has the advantage of getting the exact same result, every time. Doing porting by hand, this isn't possible. Even the best guys, with unlimited flow bench access, can't quite get there.

And with CNC, there's no risk of your slipping, hurting the seat or the guide, or hitting water ( unless there's casting / core shift, which isn't an issue with modern heads )

CNC has the advantage of getting the exact same result, every time. Doing porting by hand, this isn't possible. Even the best guys, with unlimited flow bench access, can't quite get there.

And with CNC, there's no risk of your slipping, hurting the seat or the guide, or hitting water ( unless there's casting / core shift, which isn't an issue with modern heads )

#4

Yes, I am talking about CNC porting. And as I said, I will be taking a class within the next month at my college over engine machine. I will have access to a CNC machine. I guess I was just looking for info on port sizes and air flow. Just curious to see what people are doing with these heads.

#5

TECH Enthusiast

iTrader: (4)

So you want to use their CNC machine to improve your heads?

You have almost no options that are legal, and the few you have, either the school won't be set up for, or you won't have the resources.

If they are set up to do heads, then you need a program for an improved 243 head. You could, illegally, order one from TEA or PRC or AI, digitize that, then return that, and then do yours.

You'd need a good porter, with a good flow bench, to create you a new port design you could legally use, but that'd cost even more than buying CNC heads.

Plus your design wouldn't be track tested or dyno tested.

And your school probably isn't set up to digitize port designs, anyway.

You have almost no options that are legal, and the few you have, either the school won't be set up for, or you won't have the resources.

If they are set up to do heads, then you need a program for an improved 243 head. You could, illegally, order one from TEA or PRC or AI, digitize that, then return that, and then do yours.

You'd need a good porter, with a good flow bench, to create you a new port design you could legally use, but that'd cost even more than buying CNC heads.

Plus your design wouldn't be track tested or dyno tested.

And your school probably isn't set up to digitize port designs, anyway.

#7

what do you mean no options that are legal? The class is specifically designed on "high performance engine machining"(that's the name of the class haha). How would you know if the school has the resources or not? I would hope that the engine machining class taken under the "high performance motorsports technology" degree would be able to accommodate those needs. I wasn't going to do the 243's as my first run lol. I have 3 sets of LS heads sitting at the house now and was planning on playing around with some old sbc heads I have here as well. I don't care about getting the full potential of these heads, I'm aware that i will not be skilled enough to do so. I just want them to be better than stock and was curious to see if anyone else had ported them themselves instead of purchasing them from someone else.

Trending Topics

#9

TECH Fanatic

iTrader: (14)

Join Date: Mar 2007

Location: Phoenix/Tempe, AZ

Posts: 1,969

Likes: 0

Received 0 Likes

on

0 Posts

Ethan, some people consider them to be the 'best' GM ls head in the gen 3 variety. If you learn how to port properly in class, theres huge room for potential (and of course, if someone like me were to take a hand at it, they'd probably suffer compared to stock.. hence the learning curve)

I think everyone was too confused by the simplicity of the question to say "do a search", but there are a bajillion threads

Here are my numbers, since im already here:

Valve Lift / Intake cfm / Exhaust cfm

0.200 144 112

0.300 205 170

0.400 264 203

0.500 294 224

0.550 310 228

0.600 318 233

There's some more info and pics in my mustang thread in my sig

I think everyone was too confused by the simplicity of the question to say "do a search", but there are a bajillion threads

Here are my numbers, since im already here:

Valve Lift / Intake cfm / Exhaust cfm

0.200 144 112

0.300 205 170

0.400 264 203

0.500 294 224

0.550 310 228

0.600 318 233

There's some more info and pics in my mustang thread in my sig

#10

TECH Fanatic

iTrader: (1)

Are you going to port one intake and one exhaust, then digitize the results to make it repeatable? The operation of CNC porting a head is essentially running a program to ensure that human error doesn't stand in the way of consistant results. You have to have something to work from in order to port your head.

Who developed the CNC program for the 243 heads there?

Who developed the CNC program for the 243 heads there?

#11

TECH Enthusiast

iTrader: (4)

There are different kinds of CNC machines for doing heads. Not all of them do porting, and of the ones that do, not all of them are loaded with the software to digitize, you would have to upload a program instead.

I thought the Serdi was a miracle when it first appeared, it really was a revolution in cutting valve seats. But these days, they've even added CNC to those.

Maybe faster, with repeatability, but can't improve the flow of 243 heads by any significant amount.

Machining and porting are 2 barely related things. I know, I mastered both, and have only been out of the game for not about 2 years now.

The Serdi can do great things for the exhaust flow of 062 and 906 SBC heads, the Vortec 350 heads. But you didn't specify what your other 4 heads are.

A good school should have a flow bench. Spend as much time with it as you can. When you can't be on it, spend as much time as you can trying different port shapes in spare heads. Do that at home after school closes, too.

If you do that, and they can digitize, you might graduate with something worth far more than what you're paying for those classes.

I thought the Serdi was a miracle when it first appeared, it really was a revolution in cutting valve seats. But these days, they've even added CNC to those.

Maybe faster, with repeatability, but can't improve the flow of 243 heads by any significant amount.

Machining and porting are 2 barely related things. I know, I mastered both, and have only been out of the game for not about 2 years now.

The Serdi can do great things for the exhaust flow of 062 and 906 SBC heads, the Vortec 350 heads. But you didn't specify what your other 4 heads are.

A good school should have a flow bench. Spend as much time with it as you can. When you can't be on it, spend as much time as you can trying different port shapes in spare heads. Do that at home after school closes, too.

If you do that, and they can digitize, you might graduate with something worth far more than what you're paying for those classes.

#12

Univeristy of Northwestern Ohio. I'm receiving an associates degree in "high performance motorsports technology"

There are different kinds of CNC machines for doing heads. Not all of them do porting, and of the ones that do, not all of them are loaded with the software to digitize, you would have to upload a program instead.

I thought the Serdi was a miracle when it first appeared, it really was a revolution in cutting valve seats. But these days, they've even added CNC to those.

Maybe faster, with repeatability, but can't improve the flow of 243 heads by any significant amount.

Machining and porting are 2 barely related things. I know, I mastered both, and have only been out of the game for not about 2 years now.

The Serdi can do great things for the exhaust flow of 062 and 906 SBC heads, the Vortec 350 heads. But you didn't specify what your other 4 heads are.

A good school should have a flow bench. Spend as much time with it as you can. When you can't be on it, spend as much time as you can trying different port shapes in spare heads. Do that at home after school closes, too.

If you do that, and they can digitize, you might graduate with something worth far more than what you're paying for those classes.

I thought the Serdi was a miracle when it first appeared, it really was a revolution in cutting valve seats. But these days, they've even added CNC to those.

Maybe faster, with repeatability, but can't improve the flow of 243 heads by any significant amount.

Machining and porting are 2 barely related things. I know, I mastered both, and have only been out of the game for not about 2 years now.

The Serdi can do great things for the exhaust flow of 062 and 906 SBC heads, the Vortec 350 heads. But you didn't specify what your other 4 heads are.

A good school should have a flow bench. Spend as much time with it as you can. When you can't be on it, spend as much time as you can trying different port shapes in spare heads. Do that at home after school closes, too.

If you do that, and they can digitize, you might graduate with something worth far more than what you're paying for those classes.

#14

TECH Enthusiast

iTrader: (4)

First clean the heads, then flow them to get a baseline. If they don't have a radius entry plate, at least clay around whichever intake port you're testing, otherwise it's useless.

The length of header tube is not necessary, but if they have it, use it.

The exhaust ports are relatively easy to improve, I suggest you start there. Blend away anything showing the exhaust spring seat location, though 243s may not have these. 241s and 706s do.

Then taper the guide bosses.

On the intakes, just remove the boss, if it's there, for the rocker studs, then taper the guide 3/4 of the way around. If 243s have the swirl shelf, leave that alone for now.

Then polish the exhaust ports.

Stop, and go back to the flow bench.

Then you've completed an entry level "stage 1".

At that point, post up your results on here.

The length of header tube is not necessary, but if they have it, use it.

The exhaust ports are relatively easy to improve, I suggest you start there. Blend away anything showing the exhaust spring seat location, though 243s may not have these. 241s and 706s do.

Then taper the guide bosses.

On the intakes, just remove the boss, if it's there, for the rocker studs, then taper the guide 3/4 of the way around. If 243s have the swirl shelf, leave that alone for now.

Then polish the exhaust ports.

Stop, and go back to the flow bench.

Then you've completed an entry level "stage 1".

At that point, post up your results on here.

#16

TECH Senior Member

iTrader: (28)

I would not do anything Isolde said other then clean them 1st, and deburr them. Its sucks handing dirty sharp casting.

whats are you looking to do? just mess around a little for a set to put on your car in your free time, and get a credit for a class? Or learn how a engine moves air, and how to size a port and control air speed for the motor under the head? I'd get to the class and see what the teacher says 1st, before you get to far ahead of yourself and what you think you know or you read on the internet about this.

There is a ton to gain in the valvejob. And the shape and size the port blends to it and after. If you want to start anywhere testing, work on the stock VJ and see what happens blending it, keep track of what your doing. Your see some sizes and %s that work for getting air around the valve head. You have 8 ports to do this on. Then you can see about making improvements cutting different VJs. When you get into that and setting up CSA you see how different engines are, they all do the same thing alike.

what a flow bench models is not how a engine moves air, its not all about getting a bigger number on a flowbench. And at what valve lifts, and times to what the piston is doing. A bench has no piston moving, and engine to not run on steady state flow.

polishing is not always a improvement, sometimes and is some areas of a port a rougher finish works better.

a 243 will move over 310cfm without touching the rocker boss.

Get the swirl dam out, and put a big bowl in for a good VJ and it will run good.

Short turn is really important too setting that up, that casting is better then other LS1 that choke at higher valve lifts.

whats are you looking to do? just mess around a little for a set to put on your car in your free time, and get a credit for a class? Or learn how a engine moves air, and how to size a port and control air speed for the motor under the head? I'd get to the class and see what the teacher says 1st, before you get to far ahead of yourself and what you think you know or you read on the internet about this.

There is a ton to gain in the valvejob. And the shape and size the port blends to it and after. If you want to start anywhere testing, work on the stock VJ and see what happens blending it, keep track of what your doing. Your see some sizes and %s that work for getting air around the valve head. You have 8 ports to do this on. Then you can see about making improvements cutting different VJs. When you get into that and setting up CSA you see how different engines are, they all do the same thing alike.

what a flow bench models is not how a engine moves air, its not all about getting a bigger number on a flowbench. And at what valve lifts, and times to what the piston is doing. A bench has no piston moving, and engine to not run on steady state flow.

polishing is not always a improvement, sometimes and is some areas of a port a rougher finish works better.

a 243 will move over 310cfm without touching the rocker boss.

Get the swirl dam out, and put a big bowl in for a good VJ and it will run good.

Short turn is really important too setting that up, that casting is better then other LS1 that choke at higher valve lifts.

#17

TECH Senior Member

iTrader: (28)

to give you a idea on a stock unported head, with just a VJ and a blend will run. I did this last year for a friend, quick a 2-3 hours. While changing spings had a head that was leaking air bad, tunred out it had some bent valves, form a missed shift over rev with stock interalns. Took a 853 casting set sitting around, people say is the worst casting. These is how they were put on the car and ran, dose not look bling, and kinds embarrassed to show pics of the work. it was kinds a inside joke with him how its gona make close to the same power of a buget CNC ported head, and look so bad. I had to do it quick at night right then, the car had to be running again the next day, to get tuned and off the dyno. The port is 95% stock cast still, just set the throat size and blended the VJ. Wasn't even that great of a cutter used.

http://i2.photobucket.com/albums/y11...3/DSC03337.jpg

http://i2.photobucket.com/albums/y11...3/DSC03345.jpg

http://i2.photobucket.com/albums/y11...3/DSC03361.jpg

http://i2.photobucket.com/albums/y11...3/DSC03365.jpg

http://i2.photobucket.com/albums/y11...3/DSC03373.jpg

http://i2.photobucket.com/albums/y11...3/DSC03360.jpg

http://i2.photobucket.com/albums/y11...3/DSC03354.jpg

http://i2.photobucket.com/albums/y11...3/DSC03355.jpg

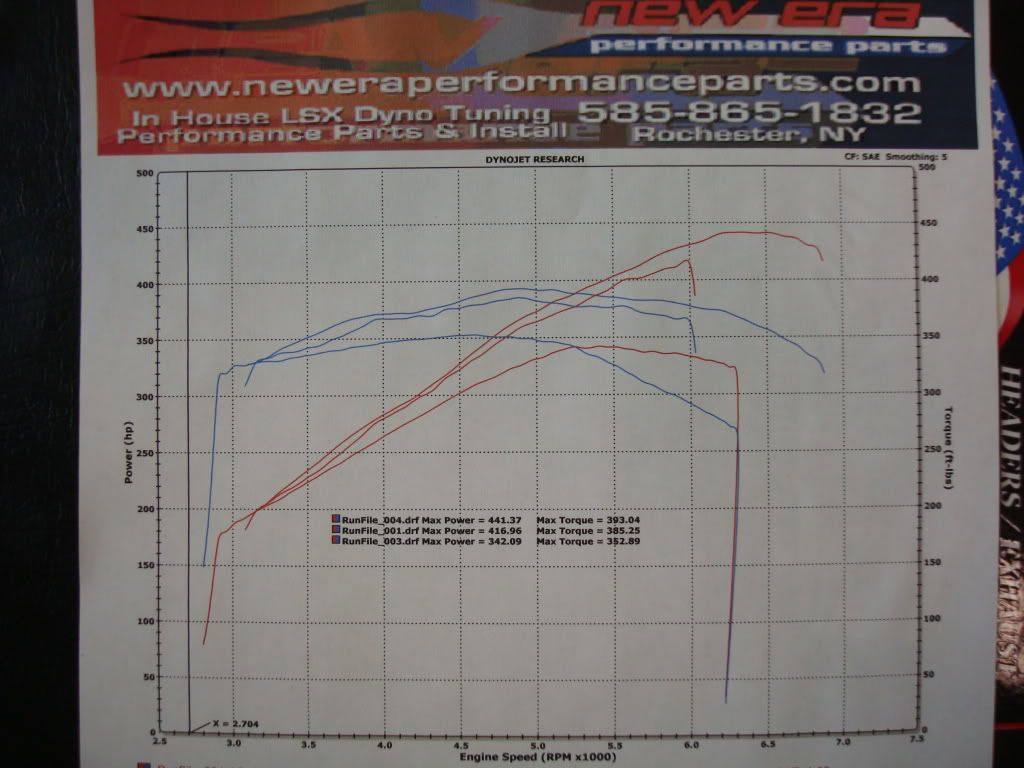

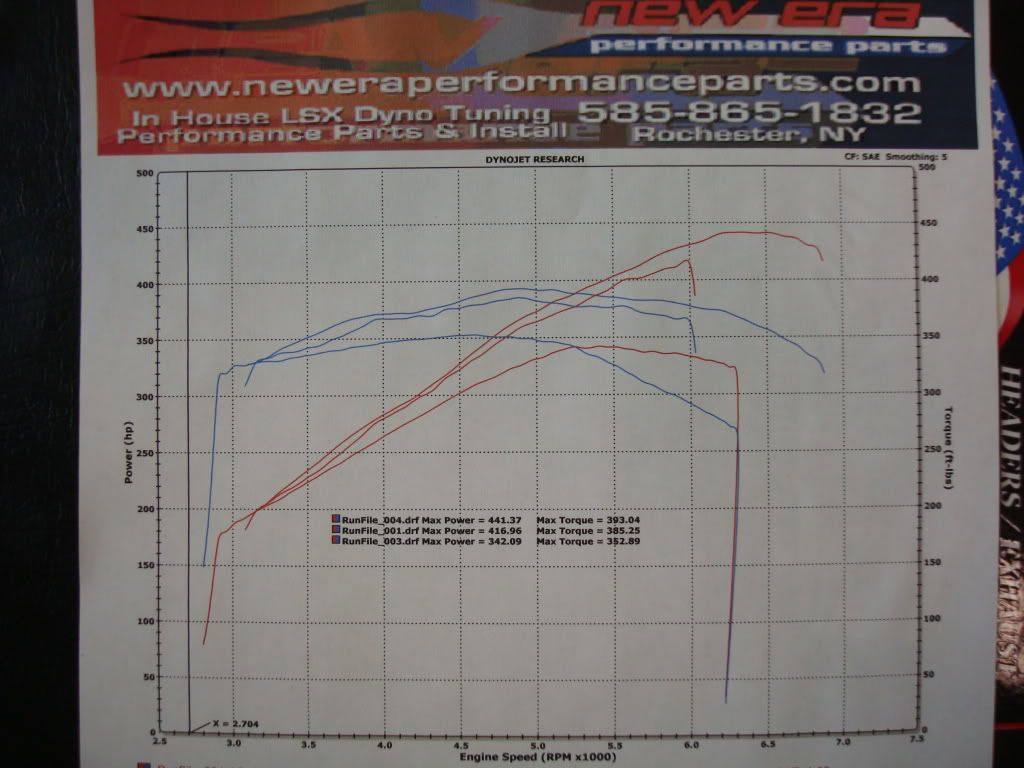

I only got a pic of these pulls printed out. 99 Z28, m6, stock 10bolt, LS6intake, ported TB, pacsetters ORY, powerbond UDP, lid, We made some air ducts SUX2BU style to go under the airbox with the AC still. This setup makes 410-425 on stock heads lots of times on this dyno. 60-80K stock LS1, heads were not milled, GM head gaskets and bolts.

I only got a pic of these pulls printed out. 99 Z28, m6, stock 10bolt, LS6intake, ported TB, pacsetters ORY, powerbond UDP, lid, We made some air ducts SUX2BU style to go under the airbox with the AC still. This setup makes 410-425 on stock heads lots of times on this dyno. 60-80K stock LS1, heads were not milled, GM head gaskets and bolts.

342 was last year, stock heads/cam, bolt ons

416 1st pull, adding streetsweeper cam, and these VJ blended heads above

441 After Mike@NewEra tuned the car.

http://i2.photobucket.com/albums/y11...3/DSC03337.jpg

http://i2.photobucket.com/albums/y11...3/DSC03345.jpg

http://i2.photobucket.com/albums/y11...3/DSC03361.jpg

http://i2.photobucket.com/albums/y11...3/DSC03365.jpg

http://i2.photobucket.com/albums/y11...3/DSC03373.jpg

http://i2.photobucket.com/albums/y11...3/DSC03360.jpg

http://i2.photobucket.com/albums/y11...3/DSC03354.jpg

http://i2.photobucket.com/albums/y11...3/DSC03355.jpg

I only got a pic of these pulls printed out. 99 Z28, m6, stock 10bolt, LS6intake, ported TB, pacsetters ORY, powerbond UDP, lid, We made some air ducts SUX2BU style to go under the airbox with the AC still. This setup makes 410-425 on stock heads lots of times on this dyno. 60-80K stock LS1, heads were not milled, GM head gaskets and bolts.

I only got a pic of these pulls printed out. 99 Z28, m6, stock 10bolt, LS6intake, ported TB, pacsetters ORY, powerbond UDP, lid, We made some air ducts SUX2BU style to go under the airbox with the AC still. This setup makes 410-425 on stock heads lots of times on this dyno. 60-80K stock LS1, heads were not milled, GM head gaskets and bolts.342 was last year, stock heads/cam, bolt ons

416 1st pull, adding streetsweeper cam, and these VJ blended heads above

441 After Mike@NewEra tuned the car.

Last edited by studderin; 01-14-2011 at 03:26 PM.

#18

I dunno if you have ever seen this series But Here you go

http://racingsecrets.com/speedtalk_head_porting.shtml

http://racingsecrets.com/speedtalk_head_porting.shtml

#20

Yeah, I'm not looking to become a pro before I even take the class lol. Just looking for a little better understanding so I'm not going into it completely blind. I'm going to use these heads for something to play with and put on my car. They don't have to be max potential when I'm done with them, but since I'm able to do free work in class with my instructor guiding me I figured it would be a good chance to turn these heads into anything better than stock casting haha.