Oil Pressure Woes...Normalish, now low?

#1

Teching In

Thread Starter

iTrader: (5)

Join Date: Apr 2010

Location: NEArkansas

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

I built a new engine for the Vette back in the first of the year. It's a stock LQ4 block with LS2 rotating assembly, the crank had to be turned 10/10. Has Clevite H series bearings in the rods and mains, and Sealed Power Cam bearings. I went with a Melling High Pressure pump, as I figured a non stroker setup wouldn't need the extra volume. Has right at 4k miles on it.

For reason unknown I used the old barbell out of my LS1, the engine only had 90k on it and the barbell looked to be in excellent condition. I just added a new o ring and put the rear cover on. As far as the pump o ring, I would be almost 98% sure it's not pinched, I tried both o rings that came with the pump to see which one fit best. So the o ring that was installed in the car was actually slid into the pump twice. As it didn't pinch the first time, I would be fairly certain it didn't the second. Cam bearings were all knocked in and verified with a flash light to see that they lined up.

Here's the problem. When I first started the engine up it had pretty decent oil pressure with the 5w30. Around 50 psi at idle 100* oil temp, as it warmed up after driving for 20 or so miles I noticed it start to drop at idle to around 30* with a 200* oil temp. One day when the oil temp reached 235* I noticed it drop to about 20 psi. Also something I noticed was that it would build to about 45 psi under load and wouldn't climb any higher. Figuring all the moly lube and break in was the cause I drove it for about 1500 miles before changing the oil.

I wanted something a little thicker because I know the crank is probably not as close of tolerance after the grind as GM builds these cranks. So I found some Castrol Syntec 10w40 locally and decided to give it a try. Draining the oil out, it had some metallic swirl look to the oil which I expected on the break in, I still have the filter but have not cut it apart. There was an immediate difference in oil pressure with the new oil. At a 100* temp start up on the fresh oil it was 55 psi at idle. And at a 210* idle it would stay right at 40 psi which I was happy with. The pressure under load also improved to upwards of 60 psi. I've ran this oil almost 3k miles since then and have seen no problem with any drop in pressure even after 230* oil temps. Then Saturday I went to a meet and had 40 psi pressure all day long until we went on our run. I noticed the oil temp stay around 250* for quite some time as we were driving harder than I had really ever ran the car. When we came back to Sonic the idle pressure was a measly 18 psi. Since then cold pressure is fine but anything over 180* oil temp I have right at 20 psi idle.

I know the crank is probably fine with the pressure I have but it worries me cause with a HP Melling this thing should have 50 psi all the time, if not more. The drastic change since then is what I really don't get. Oil break down, due to the 250* temps perhaps? I'm not sure really what to do. We have been getting some 100* ambient temps, and changing to 15w50 Mobil for the summer has crossed my mind because I'm not convinced there is anything wrong internally with this motor. Other than checking the first filter for rubber fragments is there anything else I should consider?

Thanks in advance!

For reason unknown I used the old barbell out of my LS1, the engine only had 90k on it and the barbell looked to be in excellent condition. I just added a new o ring and put the rear cover on. As far as the pump o ring, I would be almost 98% sure it's not pinched, I tried both o rings that came with the pump to see which one fit best. So the o ring that was installed in the car was actually slid into the pump twice. As it didn't pinch the first time, I would be fairly certain it didn't the second. Cam bearings were all knocked in and verified with a flash light to see that they lined up.

Here's the problem. When I first started the engine up it had pretty decent oil pressure with the 5w30. Around 50 psi at idle 100* oil temp, as it warmed up after driving for 20 or so miles I noticed it start to drop at idle to around 30* with a 200* oil temp. One day when the oil temp reached 235* I noticed it drop to about 20 psi. Also something I noticed was that it would build to about 45 psi under load and wouldn't climb any higher. Figuring all the moly lube and break in was the cause I drove it for about 1500 miles before changing the oil.

I wanted something a little thicker because I know the crank is probably not as close of tolerance after the grind as GM builds these cranks. So I found some Castrol Syntec 10w40 locally and decided to give it a try. Draining the oil out, it had some metallic swirl look to the oil which I expected on the break in, I still have the filter but have not cut it apart. There was an immediate difference in oil pressure with the new oil. At a 100* temp start up on the fresh oil it was 55 psi at idle. And at a 210* idle it would stay right at 40 psi which I was happy with. The pressure under load also improved to upwards of 60 psi. I've ran this oil almost 3k miles since then and have seen no problem with any drop in pressure even after 230* oil temps. Then Saturday I went to a meet and had 40 psi pressure all day long until we went on our run. I noticed the oil temp stay around 250* for quite some time as we were driving harder than I had really ever ran the car. When we came back to Sonic the idle pressure was a measly 18 psi. Since then cold pressure is fine but anything over 180* oil temp I have right at 20 psi idle.

I know the crank is probably fine with the pressure I have but it worries me cause with a HP Melling this thing should have 50 psi all the time, if not more. The drastic change since then is what I really don't get. Oil break down, due to the 250* temps perhaps? I'm not sure really what to do. We have been getting some 100* ambient temps, and changing to 15w50 Mobil for the summer has crossed my mind because I'm not convinced there is anything wrong internally with this motor. Other than checking the first filter for rubber fragments is there anything else I should consider?

Thanks in advance!

#5

Bo.Benson,

strange enough I have the same symptoms and practically the same build with some minor differences that would not make a difference for discussion. I just finished a hybrid on my 944 turbo that is a dedicated race car. For the first time this past weekend was the maiden voyage for the car. We went to thunderbolt raceway at NJMP for a PCA event. When I first broke in the motor (all internals new with an exception to the crank and rods) I had 50 PSI cold and over 60 PSI under load. I am running Rotella T 15W 40 oil as well. The only main difference I am running the LS6 oil pump. After the 3rd run of the day on Sat. I noticed that the oil temp came up to 185 deg. during the hottest part of the day. At this point at idol the oil psi ranged from 20-25PSI at one point dipping down to 18, but normally in the 20-35 range. AFter each run and cool down the oil PSI was back up to the 35-40 Psi range and then would drop down in the 20-25 mark. The car ran great for the rest of the event and on Sunday as well. Under full WOT the oil PSI held steady at 40 PSI no matter what the oil temp. Water temp for the weekend didn't get over 195 deg. thanks to a big Griffen Rad. One note in the braking zone into the turns when I would lift off the throttle the oil PSI would climb up to approx. 55 psi. I feel I have the same oil pressure issues as Bo.Benson and feel that we could both learn from this. I too feel that internally there is no issues due to the fact that the weekend was a success. I am running at Pocono this weekend and going to change out the oil to V. VR1 which is a 20w 50 oil, plus I will check the oil filters as well to see if there are any hidden issues. I guess I am looking for a possible cause for the oil pressure concerns and felt that since my problem is so closely related to his it was worth talking about... BTW I am using a mechanical pressure gauge.

strange enough I have the same symptoms and practically the same build with some minor differences that would not make a difference for discussion. I just finished a hybrid on my 944 turbo that is a dedicated race car. For the first time this past weekend was the maiden voyage for the car. We went to thunderbolt raceway at NJMP for a PCA event. When I first broke in the motor (all internals new with an exception to the crank and rods) I had 50 PSI cold and over 60 PSI under load. I am running Rotella T 15W 40 oil as well. The only main difference I am running the LS6 oil pump. After the 3rd run of the day on Sat. I noticed that the oil temp came up to 185 deg. during the hottest part of the day. At this point at idol the oil psi ranged from 20-25PSI at one point dipping down to 18, but normally in the 20-35 range. AFter each run and cool down the oil PSI was back up to the 35-40 Psi range and then would drop down in the 20-25 mark. The car ran great for the rest of the event and on Sunday as well. Under full WOT the oil PSI held steady at 40 PSI no matter what the oil temp. Water temp for the weekend didn't get over 195 deg. thanks to a big Griffen Rad. One note in the braking zone into the turns when I would lift off the throttle the oil PSI would climb up to approx. 55 psi. I feel I have the same oil pressure issues as Bo.Benson and feel that we could both learn from this. I too feel that internally there is no issues due to the fact that the weekend was a success. I am running at Pocono this weekend and going to change out the oil to V. VR1 which is a 20w 50 oil, plus I will check the oil filters as well to see if there are any hidden issues. I guess I am looking for a possible cause for the oil pressure concerns and felt that since my problem is so closely related to his it was worth talking about... BTW I am using a mechanical pressure gauge.

#6

TECH Resident

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

Probably not your problem, but I had the first cam bearing walk back and covered the galley, giving me almost identical psi issues. But mine never shot back up after an oil change.

#7

Teching In

Thread Starter

iTrader: (5)

Join Date: Apr 2010

Location: NEArkansas

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

Well I tore into the break in Wix oil filter today. No O Ring material was in there. Did have some metallic looking oil in the bottom though. Very small gold pieces. Keep in mind the crankshaft was turned and I cleaned it well before installation but my machine man said it might not have been well enough. Also the batwing oil pan isn't the easiest to clean, especially after multiple bearing failure. I'm more convinced that is where the material is from. I filled it full of gas, pressure washed it, and wiped it three times but some of the bearing material was still embedded in the aluminum.

I'm pulling the last 3k mile filter off tomorrow and see what it has in it. Had a new low of 15 psi today on the factory gauge with a 230* oil temp at idle, but it still holds 40 psi at 2000 RPM. Going to try to get a mechanical gauge tomorrow and check it out also.

I'm pulling the last 3k mile filter off tomorrow and see what it has in it. Had a new low of 15 psi today on the factory gauge with a 230* oil temp at idle, but it still holds 40 psi at 2000 RPM. Going to try to get a mechanical gauge tomorrow and check it out also.

Trending Topics

#10

Teching In

Thread Starter

iTrader: (5)

Join Date: Apr 2010

Location: NEArkansas

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

After letting the machine shop look at the filter he's still not too convinced it's bearing material because of the color of the flakes. He still thinks it may be the filings from the crank or could be everything still breaking in after that hard run Saturday. He suggested an oil change or two in the next two 1k mile periods to see if the pieces get any larger. I went and bought 6 qts of conventional penz 10/40 and 20/50 and two new filters. Just changed the oil and put three 10/40's and three 20/50's since it is 100* here right now. Had a great startup pressure, but as I figured at 230* oil temp is giving me the same 18psi oil pressure. 40psi at 2000 RPM. Atleast now I know that Castrol is not as bad as what everyone says, it was holding the same pressure this brand new heavier weight is.

I would really rather pull the bottom end than risk having to yank the whole engine after it spins the bearings. I will get a mechanical pressure gauge tomorrow and check it with it.

Anyone have any comments on the material that was in this previous filter?

I would really rather pull the bottom end than risk having to yank the whole engine after it spins the bearings. I will get a mechanical pressure gauge tomorrow and check it with it.

Anyone have any comments on the material that was in this previous filter?

#11

Teching In

Thread Starter

iTrader: (5)

Join Date: Apr 2010

Location: NEArkansas

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

Got the mechanical oil pressure installed. Turns out that I'm still having a low pressure at idle for Melling HP specs. Noticed everything but at idle the factory gauge is over 8 or so psi off. Also the very slow building oil pressure that I've been seeing from the factory gauge upon downshifting a couple gears is completely wrong, the car builds pressure instantly.

Cold Idle 52 psi

Cold Rev 2k 60 psi

Cold Rev 4k 75 psi

Hot Idle 21 psi

Hot Rev 2k 40 psi

Hot Rev 4k 60 psi

Crusing at 1500 rpm 41 psi

Crusing at 2000 rpm 45 psi

One thing I did notice, but was not an issue but 3 out of 5 times. WOT through first, second, and third. In third the pressure builds upwards of 60 psi but at about 5k (RPM still rising) I notice the oil pressure drop about 15 psi and then climb back up slowly. What would cause this drop intermittantly?

So guys, I'm still stuck with this 21 psi oil pressure at a hot idle. Short of waiting for this oil change in a few weeks, any new suggestions?

Cold Idle 52 psi

Cold Rev 2k 60 psi

Cold Rev 4k 75 psi

Hot Idle 21 psi

Hot Rev 2k 40 psi

Hot Rev 4k 60 psi

Crusing at 1500 rpm 41 psi

Crusing at 2000 rpm 45 psi

One thing I did notice, but was not an issue but 3 out of 5 times. WOT through first, second, and third. In third the pressure builds upwards of 60 psi but at about 5k (RPM still rising) I notice the oil pressure drop about 15 psi and then climb back up slowly. What would cause this drop intermittantly?

So guys, I'm still stuck with this 21 psi oil pressure at a hot idle. Short of waiting for this oil change in a few weeks, any new suggestions?

#12

Teching In

Thread Starter

iTrader: (5)

Join Date: Apr 2010

Location: NEArkansas

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

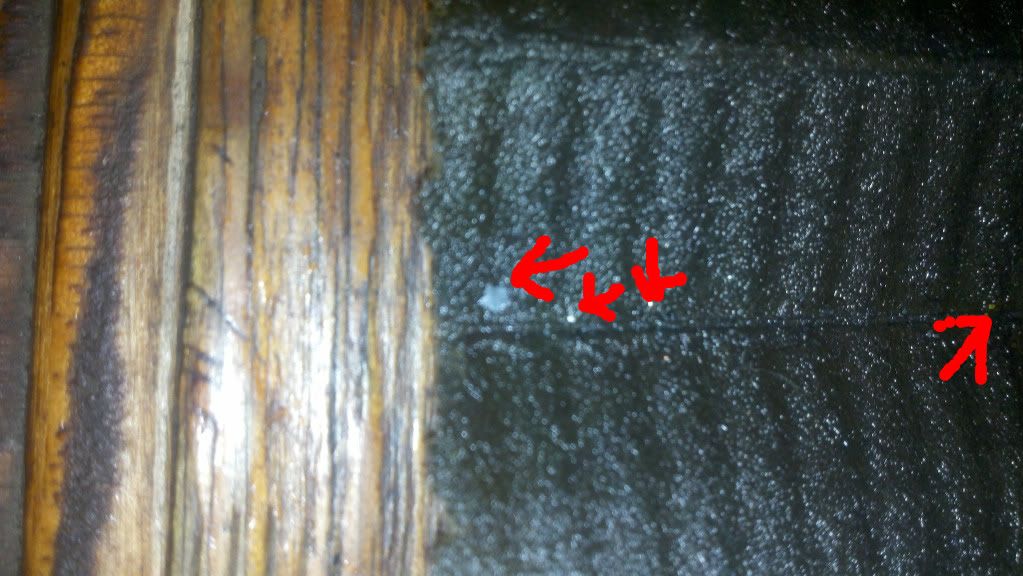

Got sick of the oil pressure and dug in to the oil pan. Here's what I found under the #3 main cap. This was the worst of the three I pulled.

Not what you expect to see at 5k miles, looks like it's time to find a new machine shop because they definitely didn't get the crank right. On the last two pictures you can see little specks where material has came off the bearings, hence all those little flakes in the filter which supposedly was NOT "bearing material". There's about three or four grooves that you can get your fingernail in and can also see bronze in the groove. Thank God I bought H series instead of something cheap, had it been a regular bearing it may not have took the beating so well and I'd been looking for another block.

Anyway, I'm on to pulling the motor tomorrow and get it back on a stand. So much for the summer time and a vette. Maybe it'll be back together before winter.

Not what you expect to see at 5k miles, looks like it's time to find a new machine shop because they definitely didn't get the crank right. On the last two pictures you can see little specks where material has came off the bearings, hence all those little flakes in the filter which supposedly was NOT "bearing material". There's about three or four grooves that you can get your fingernail in and can also see bronze in the groove. Thank God I bought H series instead of something cheap, had it been a regular bearing it may not have took the beating so well and I'd been looking for another block.

Anyway, I'm on to pulling the motor tomorrow and get it back on a stand. So much for the summer time and a vette. Maybe it'll be back together before winter.

#13

9 Second Club

Although didnt actually strip the motor for any specific reason.

#14

TECH Resident

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

Stevie,

MTI (texas, out of business) assembled a junk block out of tolerances and sold it to me as a shortblock. It had spun crank bearings as well. You think your lifter chewed up the bearing? Check this out. Improper installation will also cause it to walk.

MTI (texas, out of business) assembled a junk block out of tolerances and sold it to me as a shortblock. It had spun crank bearings as well. You think your lifter chewed up the bearing? Check this out. Improper installation will also cause it to walk.

Last edited by Steve Gunn; 07-27-2011 at 02:19 PM.

#15

9 Second Club

Same deal, just I caught mine earlier, although by pure chance. I'm assuming they were the original cam bearings in the ( LS2 ) Block.

Uploaded with ImageShack.us

Given the old bearing and new are still an extremely tight fit. There has to be something else causing this.

Block flex or something ?

Uploaded with ImageShack.us

Given the old bearing and new are still an extremely tight fit. There has to be something else causing this.

Block flex or something ?

#16

TECH Resident

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

I'm not an expert, but someone explained to me that LS blocks can distort. I'm not sure if it's from a violent event, heat or just a lot of power. If tolerences aren't checked before reassembly, this can happen to a bearing.

Last edited by Steve Gunn; 07-27-2011 at 04:34 PM.

#17

I'm not gonna point fingers but that looks like bearing damage from not properly cleaning the block and crank during a rebuild. THERE is noway dirt from the oil pan can get past the oil filter SO after a rebuild you pull a few bearing and you see something like this its a safe bet the block and crank were not cleaned well enough. How bad does the crank look? I personally wooooood pull everything down and and clean everything with a pressure washer then start checking clearances and find a someone who knows how to set the crank bearing clearances properly. Good luck finding someone thats not a bser!

#18

9 Second Club

I'm not gonna point fingers but that looks like bearing damage from not properly cleaning the block and crank during a rebuild. THERE is noway dirt from the oil pan can get past the oil filter SO after a rebuild you pull a few bearing and you see something like this its a safe bet the block and crank were not cleaned well enough. How bad does the crank look? I personally wooooood pull everything down and and clean everything with a pressure washer then start checking clearances and find a someone who knows how to set the crank bearing clearances properly. Good luck finding someone thats not a bser!