OEM Crankshaft Main Bolts are TTY (just a little)

#1

TECH Fanatic

Thread Starter

I was messing around with my current project block (2000 LQ4) the other day and I wanted to share my findings. This site has been a tremendous resource, hopefully I can give back

Potak’s book says “Time and retorqueing seem to take their toll on the factory main bolts” (page 104) and that got me curious.

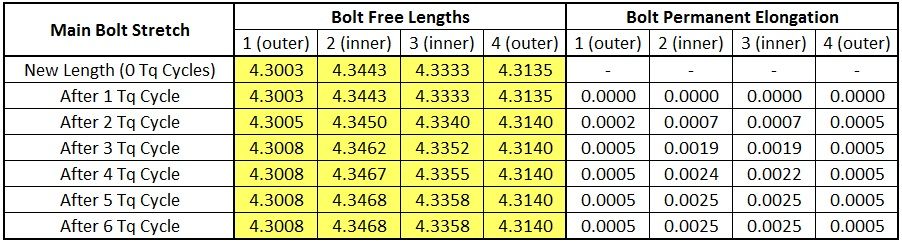

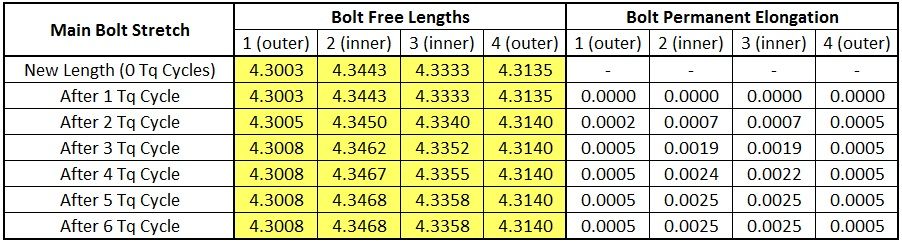

Of course there are many engine builders who re-use the OEM crankshaft main bolts with success, so I’m not saying this is not possible. However, I have found that after repeat torque cycles, the OEM main bolts will in fact experience permanent elongation (yield). The inner bolts stretch 0.0025-in and the outer bolts stretch 0.0005-in. This results in a roughly 10% reduction in clamping force for the inner bolts.

Setup

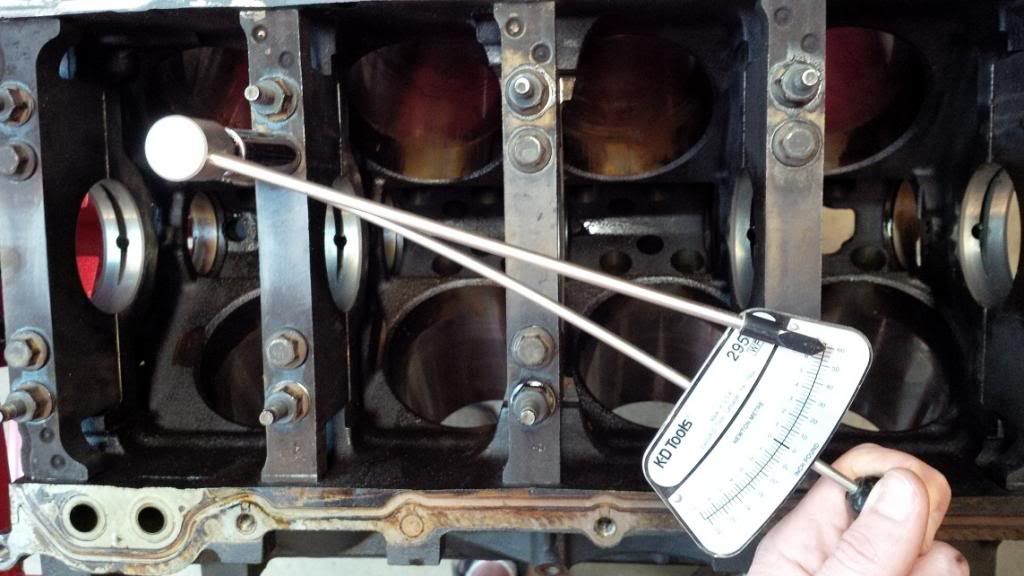

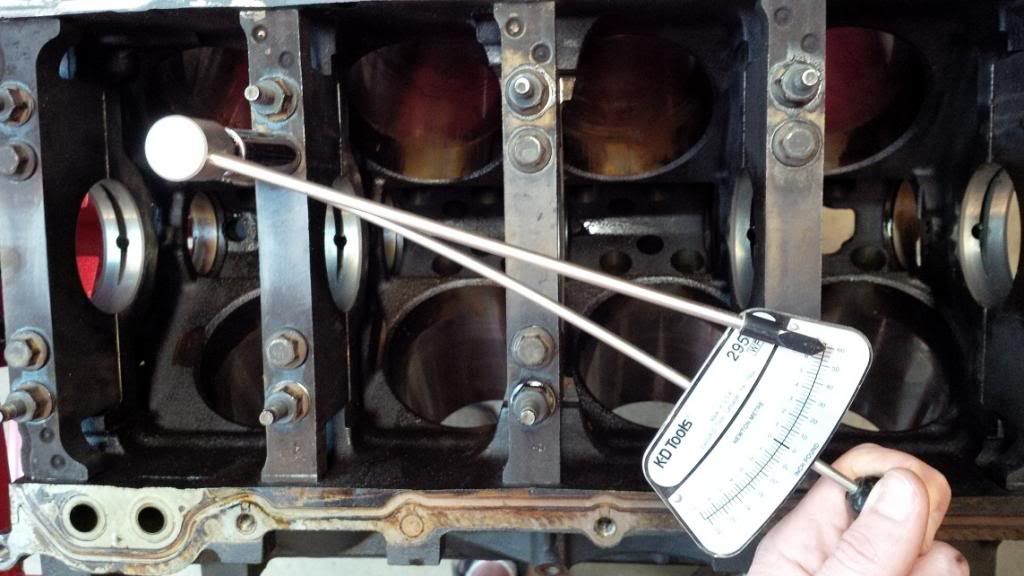

2000 LQ4 block

Number 2 main cap

lubricant used = clean engine oil

Methodology

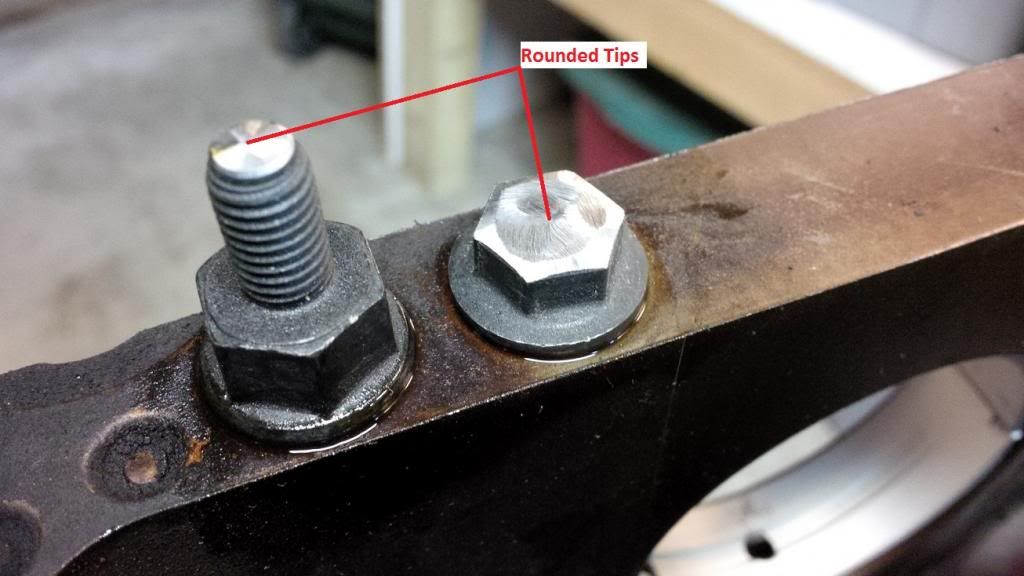

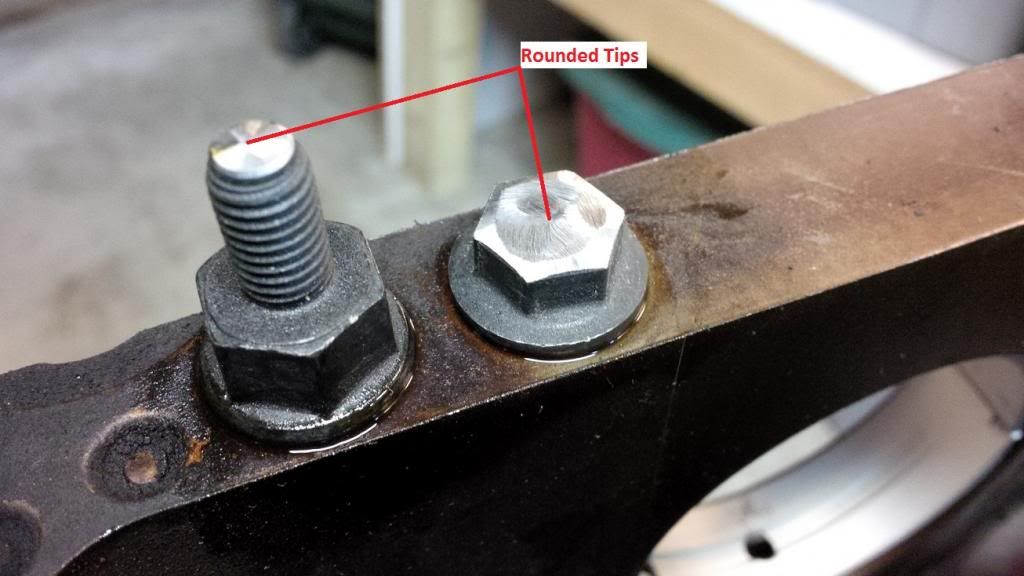

1. Measure free length of new bolts, before any torque cycles. In order to measure the free length accurately with a micrometer, it was required to grind down the tips of the bolt to achieve a “peak” that is able to be measured as a single point

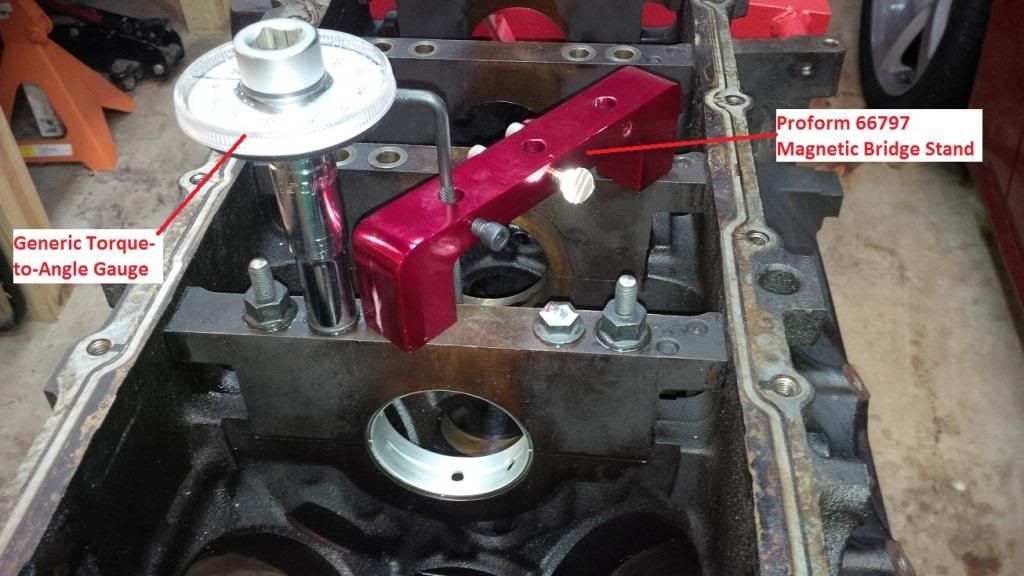

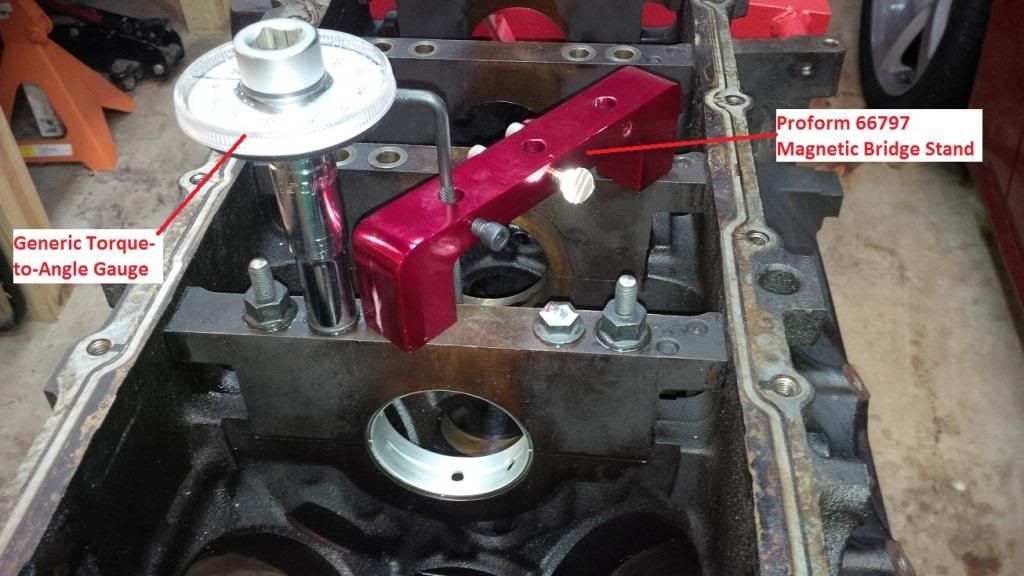

2. Install main cap and torque to the procedure in the Potak book, including the initial 40 lb-ft to set the cap, and the 48 in-lb to snug the bolts.

3. Inner bolts were 16 lb-ft plus 80-deg rotation, outer bolts were 16 lb-ft plus 53-deg rotation.

4. Remove bolts and measure free length. Record values.

5. Repeat steps 1-4 until permanent elongation is observed.

Results

As can be seen, the observed bolt stretch was the same across both inside and outside bolts respectively. It took 6 torque cycles to “level out”.

My calculations also indicate roughly 200ksi stress is applied to the inner bolts when fully torqued. That is asking a lot for a bolt with a specified minimum yield strength of 136ksi.

Conclusion

OEM bolts have been shown to be re-usable, and these results don’t discredit that. Especially if they are only re-torqued one time, there are likely no adverse effects. However, if you are going to be torqueing the bolts repeatedly, checking different bearing clearances, etc., then it is best to replace with new bolts. You can do all the bearing clearance measurements with the old bolts, then replace with new OEM bolts (roughly $75 per set) for the final installation.

Inner Bolts GM P/N: 12560272

Outer Bolts GM P/N: 12560273

Potak’s book says “Time and retorqueing seem to take their toll on the factory main bolts” (page 104) and that got me curious.

Of course there are many engine builders who re-use the OEM crankshaft main bolts with success, so I’m not saying this is not possible. However, I have found that after repeat torque cycles, the OEM main bolts will in fact experience permanent elongation (yield). The inner bolts stretch 0.0025-in and the outer bolts stretch 0.0005-in. This results in a roughly 10% reduction in clamping force for the inner bolts.

Setup

2000 LQ4 block

Number 2 main cap

lubricant used = clean engine oil

Methodology

1. Measure free length of new bolts, before any torque cycles. In order to measure the free length accurately with a micrometer, it was required to grind down the tips of the bolt to achieve a “peak” that is able to be measured as a single point

2. Install main cap and torque to the procedure in the Potak book, including the initial 40 lb-ft to set the cap, and the 48 in-lb to snug the bolts.

3. Inner bolts were 16 lb-ft plus 80-deg rotation, outer bolts were 16 lb-ft plus 53-deg rotation.

4. Remove bolts and measure free length. Record values.

5. Repeat steps 1-4 until permanent elongation is observed.

Results

As can be seen, the observed bolt stretch was the same across both inside and outside bolts respectively. It took 6 torque cycles to “level out”.

My calculations also indicate roughly 200ksi stress is applied to the inner bolts when fully torqued. That is asking a lot for a bolt with a specified minimum yield strength of 136ksi.

Conclusion

OEM bolts have been shown to be re-usable, and these results don’t discredit that. Especially if they are only re-torqued one time, there are likely no adverse effects. However, if you are going to be torqueing the bolts repeatedly, checking different bearing clearances, etc., then it is best to replace with new bolts. You can do all the bearing clearance measurements with the old bolts, then replace with new OEM bolts (roughly $75 per set) for the final installation.

Inner Bolts GM P/N: 12560272

Outer Bolts GM P/N: 12560273

Last edited by RezinTexas; 04-26-2014 at 06:38 AM.

#4

I'm sure this is a stupid question but is there a method to get the correct clamping force from stretched bolts? I'm working on building my first ls motor so don't jump my *** too hard. lol

Could you over torque the bolts to some degree? Idk why I'm even asking, $75 bolts are a lot cheaper than ruining an engine haha

Could you over torque the bolts to some degree? Idk why I'm even asking, $75 bolts are a lot cheaper than ruining an engine haha

#6

Thats great info right there.

I wonder what you would find if you did the same test on ARP bolts.

In reality, most people reusing these bolts would probably have torqued them down 3 or more times finding clearances. Which would bring them into the range where the elongation "levels out".

I read this thread several days ago, and thought "funny how useful information gets no attention on this board, while the crap threads are 4 pages long".

I wonder what you would find if you did the same test on ARP bolts.

In reality, most people reusing these bolts would probably have torqued them down 3 or more times finding clearances. Which would bring them into the range where the elongation "levels out".

I read this thread several days ago, and thought "funny how useful information gets no attention on this board, while the crap threads are 4 pages long".

#7

TECH Fanatic

Thread Starter

I'm sure this is a stupid question but is there a method to get the correct clamping force from stretched bolts? I'm working on building my first ls motor so don't jump my *** too hard. lol

Could you over torque the bolts to some degree? Idk why I'm even asking, $75 bolts are a lot cheaper than ruining an engine haha

Could you over torque the bolts to some degree? Idk why I'm even asking, $75 bolts are a lot cheaper than ruining an engine haha

Trending Topics

#11

TECH Fanatic

Thread Starter

I'm curious to know what you think the term "yield" means. The degree to which the fastener yields is what determines if it can be re-used or not. I clearly stated the bolts can be reused.

#13

TECH Enthusiast

iTrader: (19)

I know what the term yield means in respects to metals. Once a metal has reached the point of yield it has permanent elongation and is no longer reusable. If you've ever done destructive testing on metals you would see this. A little before the test coupon breaks it reaches the yield point and you can see it happen. People often confuse tty= torque to yield and tta= torque to angle. TTA is the process of installation and works very well. It's more accurate than torque alone. TTY is in the fastener design. The fastener is stretched to the point it yields and creates a lot of clamp force for a given grade of material.

#14

TECH Fanatic

Thread Starter

I know what the term yield means in respects to metals. Once a metal has reached the point of yield it has permanent elongation and is no longer reusable. If you've ever done destructive testing on metals you would see this. A little before the test coupon breaks it reaches the yield point and you can see it happen. People often confuse tty= torque to yield and tta= torque to angle. TTA is the process of installation and works very well. It's more accurate than torque alone. TTY is in the fastener design. The fastener is stretched to the point it yields and creates a lot of clamp force for a given grade of material.

#15

TECH Enthusiast

iTrader: (19)

There isn't a degree of yield. Once the material has reached that point it is scrap. Your test shows nothing. The ends of the fasteners are not parallel. You can not achieve accurate measurements with hand ground ends because you can not measure with any repeatability. This has been gone over so many times it's stupid. Conducting an uncontrolled test to provide data as factual does nothing to help the users of this forum. If we're going to provide information to the community we need to ensure that it's factual. These are principles of metallurgy and should not be overlooked.

#16

TECH Fanatic

Thread Starter

I stand by my results. I was very careful to ensure I had a repeatable measurement before I recorded the value. The measurements were also reinforced by the fact that I got the same results from 2 of each inner and outer bolts. Time and patience, with steady hands will give repeatable measurements.

How do you explain the text from Joseph Potak's book?

How do you explain the text from Joseph Potak's book?

#17

TECH Enthusiast

iTrader: (19)

I stand by my results. I was very careful to ensure I had a repeatable measurement before I recorded the value. The measurements were also reinforced by the fact that I got the same results from 2 of each inner and outer bolts. Time and patience, with steady hands will give repeatable measurements.

How do you explain the text from Joseph Potak's book?

How do you explain the text from Joseph Potak's book?

#20

TECH Fanatic

Thread Starter

Don't think that this an attack at you. I spend a lot of my day measuring and evaluating metal. Things are rarely what they seem. Once a person has become involved in evaluating products they begin to see the error in commonly utilized methods. A lot has to be accounted for in order to accurately assess the properties of the fastener. OEM main bolts are pretty strong and I have yet to see a failure caused by the fastener. If you were to pin the factory main caps and use the factory bolts, you would see many other areas fail long before.

Great question, I am planning to find out soon