Help with clearances on alum L33 5.3

#1

Posted this on the Bullet as well, but here I can add photos.

This is a turbocharged setup.

This is a turbo engine so I'm asking here.

After 3 years on the stock bottom end with the rings gapped for boost, I decided to upgrade to the LJMS Wiseco piston Compstar rod combo.

My engine builder handled this and delivered an assembled short block.

Mains were set to .002" Rods .0023". Piston to bore .005". Rings .024 and .028.

Stock crank.

With no change in the tune or boost (18psi at the time) the car was 3 mph slower.

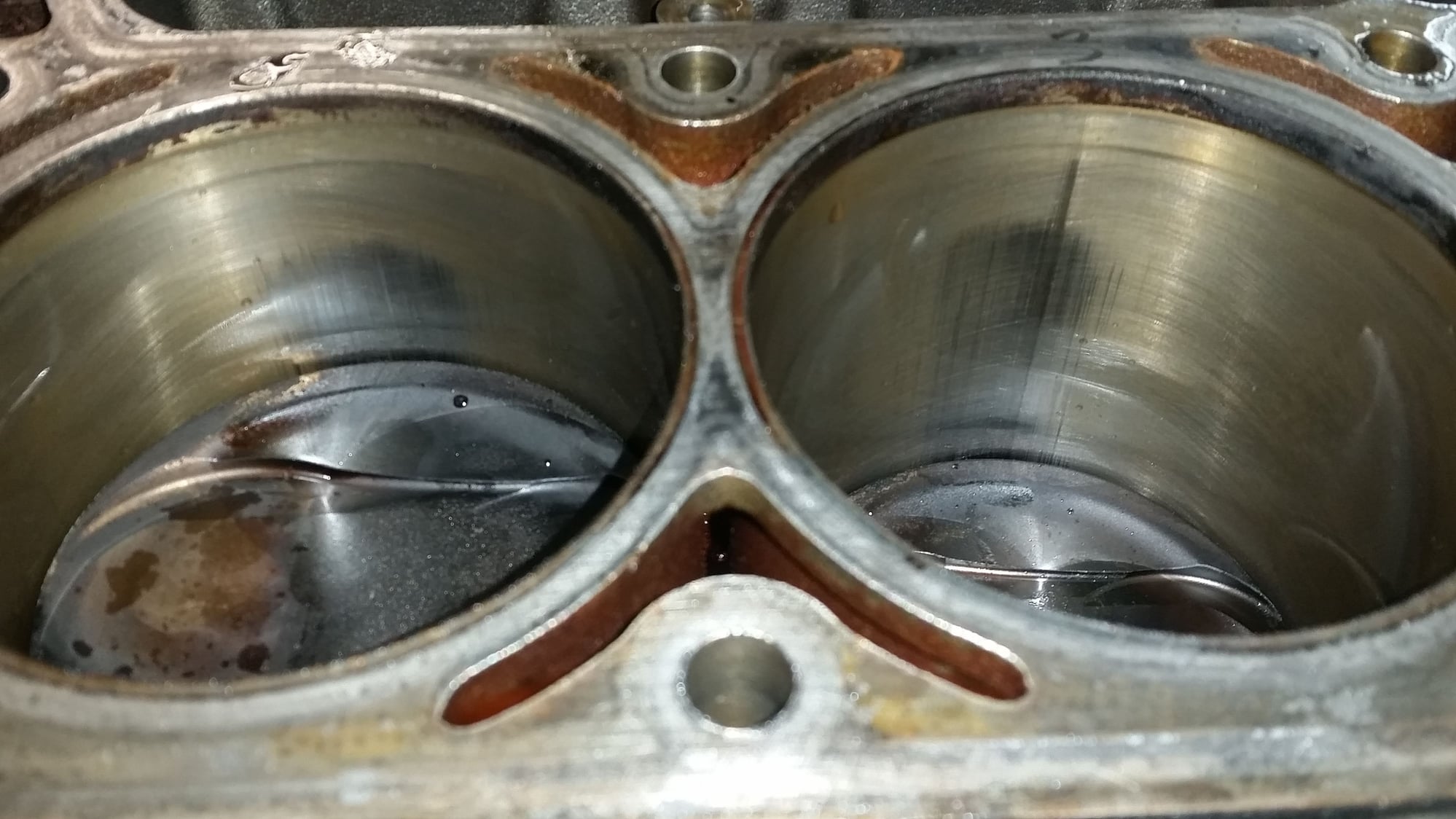

After the season ended and I had about 20 passes and 1000 street miles I peeked in the cylinders with my bore scope and noted mild scuffing.

Max boost was 24 psi for maybe 6 passes.

Out it came and disassembled.

All cylinders show these scuffs, but only one piston showed and sort of skirt contact. The coating on these piston skirts didn't look good. Flaking off on most.

I carefully checked the ring ends and can see that we didn't have them wide enough.

The bearings told a different story. These are Clevite H series and it's aparrent that I have uneven wear across the surfaces and soms shiny spots which indicate metal to metal contact.

Pretty much the same for the mains.

To top that off, the thrust failed and had opened up to .012".

The only things changed were the rods pistons and bearings, so very puzzled why the thrust failed. My TH400 has the converter feed mod and after 3 years on the stock bottom end the end play was .005".

Oil is redline 30wt. Oil pressure 32 hot idle and 50 plus down track.

Anyway, I know **** happens when you push stuff, but this is quite disheartening. And my engine guy is talking $2000 cranks, better rods etc etc. None of which is in my budget.

With stock **** (I should have left it alone) surviving better than my semi fancy stuff, I'm a bit lost.

Ideas on what we did wrong?

A few photos below

Ron

This is a turbocharged setup.

This is a turbo engine so I'm asking here.

After 3 years on the stock bottom end with the rings gapped for boost, I decided to upgrade to the LJMS Wiseco piston Compstar rod combo.

My engine builder handled this and delivered an assembled short block.

Mains were set to .002" Rods .0023". Piston to bore .005". Rings .024 and .028.

Stock crank.

With no change in the tune or boost (18psi at the time) the car was 3 mph slower.

After the season ended and I had about 20 passes and 1000 street miles I peeked in the cylinders with my bore scope and noted mild scuffing.

Max boost was 24 psi for maybe 6 passes.

Out it came and disassembled.

All cylinders show these scuffs, but only one piston showed and sort of skirt contact. The coating on these piston skirts didn't look good. Flaking off on most.

I carefully checked the ring ends and can see that we didn't have them wide enough.

The bearings told a different story. These are Clevite H series and it's aparrent that I have uneven wear across the surfaces and soms shiny spots which indicate metal to metal contact.

Pretty much the same for the mains.

To top that off, the thrust failed and had opened up to .012".

The only things changed were the rods pistons and bearings, so very puzzled why the thrust failed. My TH400 has the converter feed mod and after 3 years on the stock bottom end the end play was .005".

Oil is redline 30wt. Oil pressure 32 hot idle and 50 plus down track.

Anyway, I know **** happens when you push stuff, but this is quite disheartening. And my engine guy is talking $2000 cranks, better rods etc etc. None of which is in my budget.

With stock **** (I should have left it alone) surviving better than my semi fancy stuff, I'm a bit lost.

Ideas on what we did wrong?

A few photos below

Ron

#3

Mains were line honed and he used two sets of Clevites H series, std and X bearings to get to .002".

Rods are new Callies, I assume he checked the big end for roundness before measuring bearing clearances.

Been my guy for 30 plus years, never done me wrong.

But he has very little LS experience......

Rods are new Callies, I assume he checked the big end for roundness before measuring bearing clearances.

Been my guy for 30 plus years, never done me wrong.

But he has very little LS experience......

#4

ModSquad

iTrader: (6)

Piston to bore seems too big. I like .0035 with forged pistons.

Your thrust settings seem tight for an automatic. I like .010 to .012 with race converter. What did you set it up when you built it? Lots of guys go .015 for track use with the ls stuff. Old sbc was much different.

Your thrust settings seem tight for an automatic. I like .010 to .012 with race converter. What did you set it up when you built it? Lots of guys go .015 for track use with the ls stuff. Old sbc was much different.

#5

11 Second Club

iTrader: (2)

IMO. factory pistons having a tight fit are more stable in the bores. Less ring flutter. Less blow by. Less oil contamination. Less rock on directional change. Etc

The factory rings after so many miles of wear are sorta by accident the best choice for boosted applications. They seal and merely opening the gaps and reinstalling seems to do pretty well. The new SBE 5.3 record is 7.16@190 with forty pounds of boost. Old *** original rings.

New rings have moly facing. The moly is designed to wear and seat into the Cross hatching. IMO the dramatic cylinder heat from boost burns and flakes off the moly facing which kills your skirts/coating and the cylinders in the thrust areas

Believe it or not; some of the crappiest old ball hone 350s I’ve built using factory dished pistons and nineteen dollar Hastings cast rings never experienced these issues with nitrous or turbos. Sometimes it’s best to put the cheapest sacrificial lamb in there and laugh at how long it lasts and what actuall fails.

The factory rings after so many miles of wear are sorta by accident the best choice for boosted applications. They seal and merely opening the gaps and reinstalling seems to do pretty well. The new SBE 5.3 record is 7.16@190 with forty pounds of boost. Old *** original rings.

New rings have moly facing. The moly is designed to wear and seat into the Cross hatching. IMO the dramatic cylinder heat from boost burns and flakes off the moly facing which kills your skirts/coating and the cylinders in the thrust areas

Believe it or not; some of the crappiest old ball hone 350s I’ve built using factory dished pistons and nineteen dollar Hastings cast rings never experienced these issues with nitrous or turbos. Sometimes it’s best to put the cheapest sacrificial lamb in there and laugh at how long it lasts and what actuall fails.

#6

Piston to bore seems too big. I like .0035 with forged pistons.

Your thrust settings seem tight for an automatic. I like .010 to .012 with race converter. What did you set it up when you built it? Lots of guys go .015 for track use with the ls stuff. Old sbc was much different.

Your thrust settings seem tight for an automatic. I like .010 to .012 with race converter. What did you set it up when you built it? Lots of guys go .015 for track use with the ls stuff. Old sbc was much different.

And the thrust was .004" all along with the stock **** and never changed.

This was .003 when built and machined itself to .012".

You are an engine builder?

#7

IMO. factory pistons having a tight fit are more stable in the bores. Less ring flutter. Less blow by. Less oil contamination. Less rock on directional change. Etc

The factory rings after so many miles of wear are sorta by accident the best choice for boosted applications. They seal and merely opening the gaps and reinstalling seems to do pretty well. The new SBE 5.3 record is 7.16@190 with forty pounds of boost. Old *** original rings.

New rings have moly facing. The moly is designed to wear and seat into the Cross hatching. IMO the dramatic cylinder heat from boost burns and flakes off the moly facing which kills your skirts/coating and the cylinders in the thrust areas

Believe it or not; some of the crappiest old ball hone 350s I’ve built using factory dished pistons and nineteen dollar Hastings cast rings never experienced these issues with nitrous or turbos. Sometimes it’s best to put the cheapest sacrificial lamb in there and laugh at how long it lasts and what actuall fails.

The factory rings after so many miles of wear are sorta by accident the best choice for boosted applications. They seal and merely opening the gaps and reinstalling seems to do pretty well. The new SBE 5.3 record is 7.16@190 with forty pounds of boost. Old *** original rings.

New rings have moly facing. The moly is designed to wear and seat into the Cross hatching. IMO the dramatic cylinder heat from boost burns and flakes off the moly facing which kills your skirts/coating and the cylinders in the thrust areas

Believe it or not; some of the crappiest old ball hone 350s I’ve built using factory dished pistons and nineteen dollar Hastings cast rings never experienced these issues with nitrous or turbos. Sometimes it’s best to put the cheapest sacrificial lamb in there and laugh at how long it lasts and what actuall fails.

I know a guy who pushed his until it blew the head off.......it wasn't mentioned in the forums......and it wasn't 40 psi.

The rings on these Wiesco pistons do not appear to be moly. If you know different, speak up.

You do have a turbo setup correct?

Trending Topics

#8

ModSquad

iTrader: (6)

#13

11 Second Club

iTrader: (2)

Yeah, wasn't looking for a dissertation on why the stock stuff lives. I get that. I also get that those folks don't bother to mention how much of this stock stuff blows up. It's not in their interest to mention that.

I know a guy who pushed his until it blew the head off.......it wasn't mentioned in the forums......and it wasn't 40 psi.

The rings on these Wiesco pistons do not appear to be moly. If you know different, speak up.

You do have a turbo setup correct?

I know a guy who pushed his until it blew the head off.......it wasn't mentioned in the forums......and it wasn't 40 psi.

The rings on these Wiesco pistons do not appear to be moly. If you know different, speak up.

You do have a turbo setup correct?

If credentials seem needed here in order for you to value my opinion; I’ve assembled well more than twelve hundred engines in 32 years. YES I’ve owned a turbo car and built dozens of turbo engines for friends. I’ve studied failure analysis an awful lot over the years to see trends with parts and combinations

IMO your PTW clearance should be closer to .003” than five; looser allows much more combustion heat to attack that primary ring moly facing

Also keep in mind the temperature of the block when measuring the bore hone. Room temp and/or even a hundred degrees from honing friction is nowhere even close to operating temp when boosted

You simply can’t get a cheap cast ring set for those pistons, Hell Fire would be my suggestion. I highly doubt that skirt coating just flakeD off because Wiseco quality became sketchy

Looser clearance also allows more oil contamination which contributes to detonation in boosted and spray applications. Kicking the slugs backwards drives the skirts into the walls

The thrust not only should be doubled but many shops I know make additional oiling grooves to help with the converter ballooning issue.

I’m assuming you run an AIR pump and the design as well as the health of that system is VERY important for higher boost. I’d say ten pounds down. No biggie but after that it pays exponential dividends HUGE

RING SEAL. RING SEAL. RING SEAL

#14

Moderator

iTrader: (20)

Many of us know your frustration right now. Things like this are hard to diagnose over the internet too, so sometimes these threads only add to the frustration. I rarely post on this type of stuff for that reason. All I can share is what I do differently with similar applications.

With the power you're making, I usually set the clearances for power adder stuff with at least .0025" on the mains (more with iron blocks) and almost .003" on steel rods. Crank thrust endplay would be closer to .010" for an automatic trans. I've found that the stock crank flexes as you approach 1000hp, usually showing the worst on mains #2 and #4, and on the thrust faces when it starts really bad. If an 8 counterweight crank is not in the budget, then adding clearance is the only there thing that seems to keep the bearings looking pretty on teardown at that power level.

The piston to wall clearance seems very loose to me. Not that it won't work, but Wiseco normally specs about .0035", and with the higher horsepower applications, I would go up to .004". I used .004" PTW clearance in an LS7 powered Texas Mile car that made 990whp. The skirts on those Wiseco's looked a lot better than the pistons you pulled out. The scuffs on the cylinder walls, IMO, just seem to be typical of a forged piston and any amount of power worth mentioning.

Best of luck getting it figured out.

#15

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 16 Likes

on

16 Posts

Hi Ron, the piston picture does not show the Top Ring very well.

Take a picture of that RING, look for "flaking" ?

Did you fit a Moly Top Ring ?

YOUR HONE pattern is TERRIBLE.

I would have fit a piston with "Off-Set" pin position.

Lance

Take a picture of that RING, look for "flaking" ?

Did you fit a Moly Top Ring ?

YOUR HONE pattern is TERRIBLE.

I would have fit a piston with "Off-Set" pin position.

Lance

#16

Thanks guys.

I appreciate the credentials. It matters.

Over on the bullet, opinions varied, sometimes polar opposite.

So it gets double confusing. :-)

On the pistons, the paper work said to set them at .004". My guy was concerned that was too tight. So he asked me......like I'mm a machinist? So I said just call Weisco. They said that at the proposed 25-26 lbs of boost I was planning on to set them to .005". IIRC, we compromised and set them to .0045". I'll measure this as soon as I get everything cleaned up.

A little more on the coating. I took the parts to another guy who does mostly LS stuff. He showed me Weiscos with only dyno time and the coating was gone. Same piston in a Mahle (stock in these) coating looked fine. The folks on the bullet said the same, you can wipe it off with carb cleaner.....I might try that.

On the main clearance I did my research regarding the alum blocks which of course grow with heat. I figured the .002" we set them to would grow to near .003" when hot. I never make passes with a cold engine. Anyway, it was clearly too tight. See the photo. #1 at the top.

Those guys said in unison don't run these hard bearings on the stock crank......

As soon as I had the engine on the stand I checked the crank end play. And measured .012". So I measured across the thrust bearing and compared to a new as well as a used stock bearing and it was worn the .009" mentioned. This would leave it at .003" as assembled. Prob too tight, but in spec. When I assembled this the first time all stock it was .005", that was never an issue. it didn't change after 150 or so passes. So a little puzzled what happened there. I will say that it clearanced itself nicely......

Now I know where the fine glitter in the oil came from. Although there was never anything in the filter. Stuff is too fine to see.

BTW, I know about that thrust mod to the bearing shell. I thought my guy was going to do that, I guess he forgot.

So perhaps the metal from the thrust basically got everywhere?

I'll yank the trans and check to make sure my converter feed restrictor remained in place. I'd like to see how the trans fared as well, I built it my own bad self.

A couple more questions.

The guys on the bullet said I need more oil flow and pressure. Actually suggested that I use a pump for the AFM engines. I get that, but with opened main clearance, is my 6qt oil pan going to be an issue? They suggested the COPO Camaro pan if it will fit, they don't give those away. I'm running the MAST pan.

Then finally, the harmonic balancer. I'm running the PowerBond 25% UD SFI spec unit. Certainly not of ATI quality. But is this an issue?

Thanks again

Ron

I appreciate the credentials. It matters.

Over on the bullet, opinions varied, sometimes polar opposite.

So it gets double confusing. :-)

On the pistons, the paper work said to set them at .004". My guy was concerned that was too tight. So he asked me......like I'mm a machinist? So I said just call Weisco. They said that at the proposed 25-26 lbs of boost I was planning on to set them to .005". IIRC, we compromised and set them to .0045". I'll measure this as soon as I get everything cleaned up.

A little more on the coating. I took the parts to another guy who does mostly LS stuff. He showed me Weiscos with only dyno time and the coating was gone. Same piston in a Mahle (stock in these) coating looked fine. The folks on the bullet said the same, you can wipe it off with carb cleaner.....I might try that.

On the main clearance I did my research regarding the alum blocks which of course grow with heat. I figured the .002" we set them to would grow to near .003" when hot. I never make passes with a cold engine. Anyway, it was clearly too tight. See the photo. #1 at the top.

Those guys said in unison don't run these hard bearings on the stock crank......

As soon as I had the engine on the stand I checked the crank end play. And measured .012". So I measured across the thrust bearing and compared to a new as well as a used stock bearing and it was worn the .009" mentioned. This would leave it at .003" as assembled. Prob too tight, but in spec. When I assembled this the first time all stock it was .005", that was never an issue. it didn't change after 150 or so passes. So a little puzzled what happened there. I will say that it clearanced itself nicely......

Now I know where the fine glitter in the oil came from. Although there was never anything in the filter. Stuff is too fine to see.

BTW, I know about that thrust mod to the bearing shell. I thought my guy was going to do that, I guess he forgot.

So perhaps the metal from the thrust basically got everywhere?

I'll yank the trans and check to make sure my converter feed restrictor remained in place. I'd like to see how the trans fared as well, I built it my own bad self.

A couple more questions.

The guys on the bullet said I need more oil flow and pressure. Actually suggested that I use a pump for the AFM engines. I get that, but with opened main clearance, is my 6qt oil pan going to be an issue? They suggested the COPO Camaro pan if it will fit, they don't give those away. I'm running the MAST pan.

Then finally, the harmonic balancer. I'm running the PowerBond 25% UD SFI spec unit. Certainly not of ATI quality. But is this an issue?

Thanks again

Ron

#17

TECH Fanatic

iTrader: (8)

Have you considered posting your concerns on http://speedtalk.com/forum/ as well?

Not that you aren't getting solid advice here now. But there, are far fewer uppity bitches over there slinging conjecture and misinformation than here or Yellowbullet (keeping in mind that every site has it's KingTaloooon).

As for oiling system adjustments I would go for a high pressure pump, and back it up with an Accusump in case you are subject to a pressure/volume loss. Consider adding a pressure transducer too so you can log the goings on. Just a thought.

Good luck.

Not that you aren't getting solid advice here now. But there, are far fewer uppity bitches over there slinging conjecture and misinformation than here or Yellowbullet (keeping in mind that every site has it's KingTaloooon).

As for oiling system adjustments I would go for a high pressure pump, and back it up with an Accusump in case you are subject to a pressure/volume loss. Consider adding a pressure transducer too so you can log the goings on. Just a thought.

Good luck.

Last edited by mOtOrHeAd MiKe; 01-22-2018 at 12:29 PM.

#19

The rings came with the pistons and are 1.0 1.2 and 2.8mm.

Wiesco refers to the top ring as Gas Nitrided.

I know what moly rings look like and these are not.

FWIW, I leaked this think after I noted the scuffs with the bore scope. 7 holes were 3% and one was 5%.

What is wrong with the crosshatch?

I believe these are offset pins. There are left and right pistons.

Ron