Mamo ported 102 vs Veng. Racing ported 102?

#41

You guys would all do yourself a big favor if you would take a 102 apart and measure the inside of the ports. The ports get progessively larger after the first 2 inches. ie much larger cross section than the heads. I call bs to anyone claiming gains from porting more than the first 2 to 3 inches of these intakes. After all is it not all about "small runners and high velocity" It is marketing hype to intimate that only (fill in a name) understands the mysteries of porting these intakes. I wonder if (fill in a name) believes all of their own marketing hype. Hopefully I have not made the numerous hero worshipers that populate this forum too angry.

#46

12 Second Club

iTrader: (20)

You guys would all do yourself a big favor if you would take a 102 apart and measure the inside of the ports. The ports get progessively larger after the first 2 inches. ie much larger cross section than the heads. I call bs to anyone claiming gains from porting more than the first 2 to 3 inches of these intakes. After all is it not all about "small runners and high velocity" It is marketing hype to intimate that only (fill in a name) understands the mysteries of porting these intakes. I wonder if (fill in a name) believes all of their own marketing hype. Hopefully I have not made the numerous hero worshipers that populate this forum too angry.

#47

You guys would all do yourself a big favor if you would take a 102 apart and measure the inside of the ports. The ports get progessively larger after the first 2 inches. ie much larger cross section than the heads. I call bs to anyone claiming gains from porting more than the first 2 to 3 inches of these intakes. After all is it not all about "small runners and high velocity" It is marketing hype to intimate that only (fill in a name) understands the mysteries of porting these intakes. I wonder if (fill in a name) believes all of their own marketing hype. Hopefully I have not made the numerous hero worshipers that populate this forum too angry.

#48

What a bunch of ****** haters, i wasnt going for the whole bling factor , i wanted something more settle with the look of a stock style intake.....His port work has proven to pick up time and time again, He has a little more experience and time invested into getting the most out of the Fast intakes and does a little more than ******* cleaning up edges with a file.

#50

Staging Lane

Join Date: Mar 2011

Location: Newark, CA

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

I can understand how some might feel that way....but there is much more invested than meets the casual observer's eye I assure you.

No one has the level of R&D I have invested in these manifolds....no one. I pioneered this exercise back in 2004, have spent countless hours since then improving my craft....searching and finding "more", and recently spent an additional 60-80 hours of heavy development work on the flowbench that unlocked some new gains I now include on all my customer ported intakes.

Truth be told, this latest round of testing was primarily driven for personal reasons wanting to push my own 454 LS combo even further with the next round of dyno testing I have planned in February (the engine pictured in my avatar), but in the end, everyone benefits from the additional work I invested and trust me when I tell you this type of work can be frustrating, exhausting, and it takes an enormous amount of dedication and patience. Learning what I did recently it takes me even longer to port a manifold but I didn't raise my pricing....just added more value to the customers that opt to deal with me.

This thread is old but it shows how much plastic used to come out of a 102 intake.....if you've purchased a manifold from me since last September or so you have my latest port designs which have considerably more material removed in key areas.

https://ls1tech.com/forums/generatio...-102-fast.html

Bottom line, having a choice of vendors is always a good thing (no matter what your shopping for) but if you want the most from your FAST and your willing to pay for the extra R&D time invested, proven results, and an incredibly neat and detailed execution of the work I'm your man.....

I would also like to add that at any point in time I could decide to do half the work, charge half the price, and quite honestly 99% of the customers would still be thrilled when they removed that manifold from the box but it's just not what I'm about....it's not what I represent or what am trying to build....for me its utmost quality over quantity in spite of the sales I may lose from that business model.

Whether I'm porting a set of heads.....porting a manifold, or building a detailed optimized engine combination....I take the same approach to everything I do as it relates to this hobby (and most other things in life I'm passionate about). At the risk of stating the obvious, I design cylinder heads and intake manifolds for a living....my background offers me a bit of an "edge" shall we say, and when I'm not doing that I'm usually building an engine or doing something related directly to this industry.

Anyway, sorry for the novel. The last thing I would like to add is I really appreciate all the folks that truly understand what I'm about and have done business with me in the past....hopefully we can continue to work together in the future as well.

Cheers,

Tony

No one has the level of R&D I have invested in these manifolds....no one. I pioneered this exercise back in 2004, have spent countless hours since then improving my craft....searching and finding "more", and recently spent an additional 60-80 hours of heavy development work on the flowbench that unlocked some new gains I now include on all my customer ported intakes.

Truth be told, this latest round of testing was primarily driven for personal reasons wanting to push my own 454 LS combo even further with the next round of dyno testing I have planned in February (the engine pictured in my avatar), but in the end, everyone benefits from the additional work I invested and trust me when I tell you this type of work can be frustrating, exhausting, and it takes an enormous amount of dedication and patience. Learning what I did recently it takes me even longer to port a manifold but I didn't raise my pricing....just added more value to the customers that opt to deal with me.

This thread is old but it shows how much plastic used to come out of a 102 intake.....if you've purchased a manifold from me since last September or so you have my latest port designs which have considerably more material removed in key areas.

https://ls1tech.com/forums/generatio...-102-fast.html

Bottom line, having a choice of vendors is always a good thing (no matter what your shopping for) but if you want the most from your FAST and your willing to pay for the extra R&D time invested, proven results, and an incredibly neat and detailed execution of the work I'm your man.....

I would also like to add that at any point in time I could decide to do half the work, charge half the price, and quite honestly 99% of the customers would still be thrilled when they removed that manifold from the box but it's just not what I'm about....it's not what I represent or what am trying to build....for me its utmost quality over quantity in spite of the sales I may lose from that business model.

Whether I'm porting a set of heads.....porting a manifold, or building a detailed optimized engine combination....I take the same approach to everything I do as it relates to this hobby (and most other things in life I'm passionate about). At the risk of stating the obvious, I design cylinder heads and intake manifolds for a living....my background offers me a bit of an "edge" shall we say, and when I'm not doing that I'm usually building an engine or doing something related directly to this industry.

Anyway, sorry for the novel. The last thing I would like to add is I really appreciate all the folks that truly understand what I'm about and have done business with me in the past....hopefully we can continue to work together in the future as well.

Cheers,

Tony

Porting the intake manifold itself, that is without port matching, may not help much, if at all.

example: A fast 102 ported for a AFR 215 head will not match the intake ports on a PRC or a TFS 215 head. This must mean you would need all the parts at your hand to make the most out of a combo since that is what you represent.

#51

FormerVendor

iTrader: (13)

The tooling that makes heads and the Fast intakes are made with "shrink" included, meaning that the part in the tooling is made longer than the desired final part, and depending on how hot the material is injected or poured will depend on the total amount of shrink factored into the tooling.

If you port a Fast intake to where every intake port looks symmetrical compared to the o-ring gasket, then it's not going to perfectly match every port in any CNC heads made.

If the intake is taken apart and bolted to the heads, and then the intake is ground to perfectly match the existing ports in the heads, every port will look different in relation to the o-ring gaskets.

I was going to make a video of a Fast port matched to some TFS heads, but to avoid the TFS bashing that might ensue I instead used some new AFR 230 V2 heads. The point is the Fast intake doesn't have the perfect shrink factor, so every port is oriented different in relation to the o-rings. I hope this make sense! http://youtu.be/x0LVddVYfNI

#52

Does your price include port matching to the heads and the throttle body?

Porting the intake manifold itself, that is without port matching, may not help much, if at all.

example: A fast 102 ported for a AFR 215 head will not match the intake ports on a PRC or a TFS 215 head. This must mean you would need all the parts at your hand to make the most out of a combo since that is what you represent.

Porting the intake manifold itself, that is without port matching, may not help much, if at all.

example: A fast 102 ported for a AFR 215 head will not match the intake ports on a PRC or a TFS 215 head. This must mean you would need all the parts at your hand to make the most out of a combo since that is what you represent.

Turns out most of the ported aftermarket and factory castings are 1.060 - 1.100 wide (I have seen a tremendous amount of heads over the years).....bone stock the port is closer to 1" or even less. No you might see some of the larger cathedrals coming in at 1.120 or so and I usually check with my customer to see if that is the case. Typically I port my intakes to 1.080.....right in the middle of the "average" cross section of heads (our 210, 215, 230, and our 245 all fall in around 1.080 and so do alot of the other aftermarket CNC castings). If I'm porting a stock or close to stock head and the customer will never swap to an aftermarket head I may leave the port opening a little conservative but it will still be larger than the stock entrance.

Bottom line....a .020 and even an .030 mismatch per side (that means the outlet is off almost .060 total) wouldn't effect performance at all. There is very little air flowing near the outside wall of the ports....only very slow moving air called the "boundary layer" which for the most part provides a cushion for the higher speed charge located further off the wall and closer to the center of the port. When reworking intake manifolds in general (not just related to FAST LS intakes), the port match in and of itself does very little (it really just needs to be close).....its all the work further into the port that changes the flow characteristics of the runner and there are some other tricks to the outlet that my more recent ported FAST manifolds feature (in last 6 months or so), different even than the pics in the thread you linked above but that thread gives you a good idea of the extent of the work involved and how much material is actually removed (there is a good bit more removed in the newer intakes I am working on).

Guys, I've been doing this a looooong time (reworking these FAST intakes, tweaking and honing the process along the way) and I have shipped hundreds of these with very positive results....bad news travels fast on the Internet and if you want to take the time to dig you will be hard pressed to find anyone not satisfied with what they got for the money spent, not to mention what they got for actual results. To try and debate the effectiveness of the work now, for this and that reason, this late in the game is almost silly....there are far too many positive results to do so.

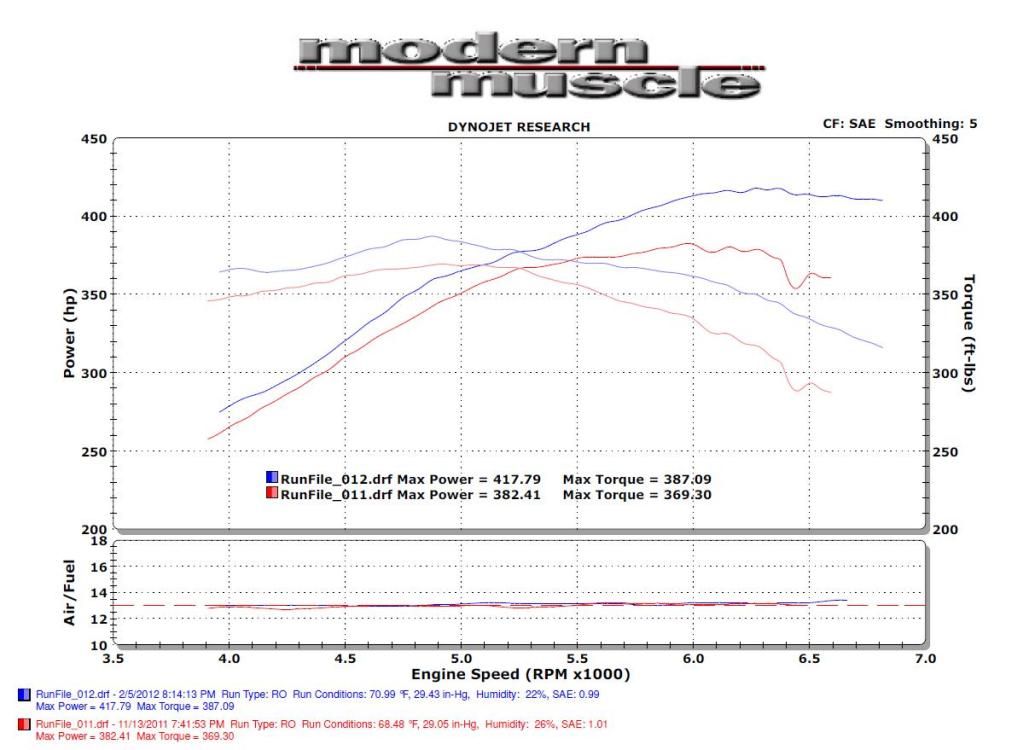

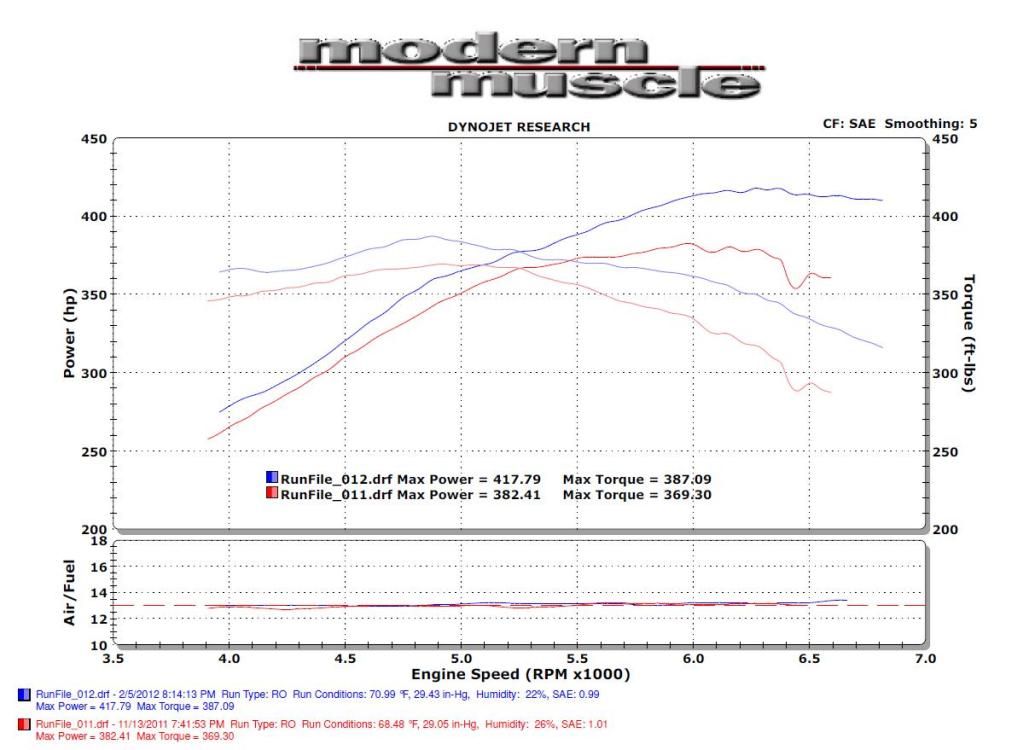

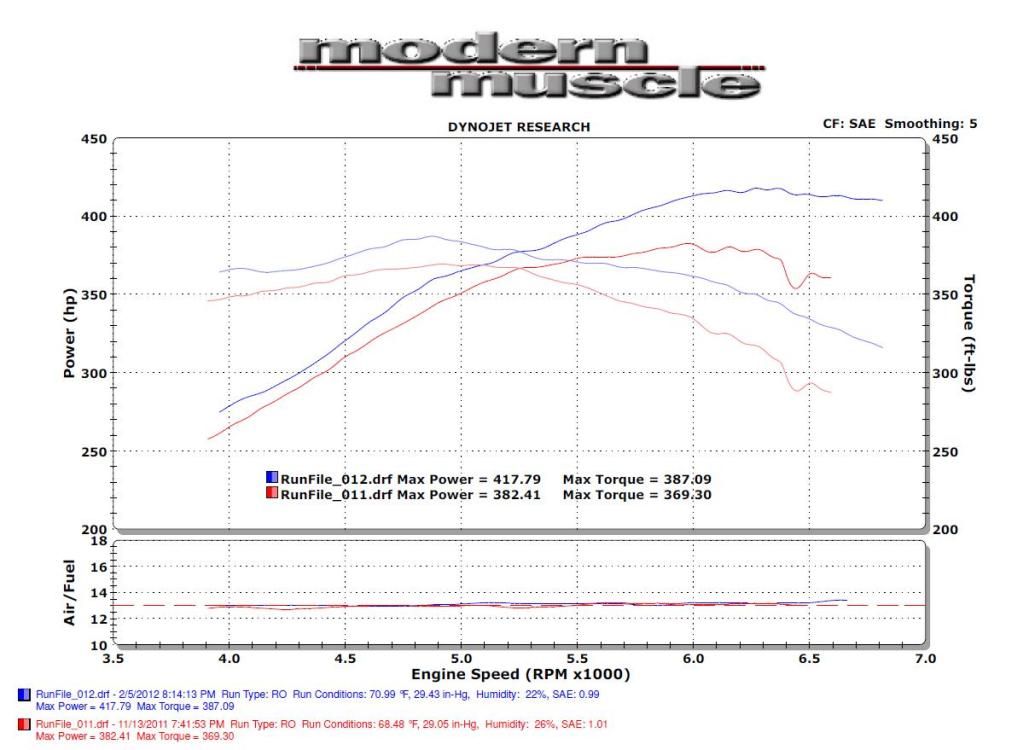

The dyno graph above is proof positive a port match isn't as critical as you might think (not to mention how effective the proper port work can be). It reprsents the back to back results of a cam only 6.0 liter truck. These are the gains seen with STOCK 317 heads (unported....virgin) which always limits the amount of gains from a manifold swap because the large gains are always seen when you have high flow heads and the stock intake cant keep up. I ported this intake to a 1.070 width suspecting this customer was going to install heads at a later date (turns out Im working on a set of Mamofied 230's for him right now). Anyway.....the stock port is about an inch wide....the larger intake leaving a forward step was still extremely effective and if anything exceeded anything we discussed or hoped for prior to the swap. This is a ported LSXRT versus a stock truck intake which actually works pretty well with stock heads....with a notable mismatch at the port opening which I hope I shed some light on here regarding how a "perfect match" isn't really necessary.

Same dyno....no other changes except the intake swap and a larger 102 TB of course.

-Tony

#53

Hey Tony, at what level of head flow rate would you recommend a Fast 102? I plan to get some trickflow 220 heads for my LS2 and have my 90mm TB ported, most likely by you along with the Intake, but Im undecided on whether or not to track down a 92 or just outright purchase a 102. Im leaning towards the 102, reason being is because the 102 is the most refined design, works with my LS2 fuel rails, etc

Last edited by family-man; 02-20-2012 at 03:03 AM.

#54

Hey Tony, at what level of head flow rate would you recommend a Fast 102? I plan to get some trickflow 220 heads for my LS2 and have my 90mm TB ported, most likely by you along with the Intake, but Im undecided on whether or not to track down a 92 or just outright purchase a 102. Im leaning towards the 102, reason being is because the 102 is the most refined design, works with my LS2 fuel rails, etc

The better the heads the larger the gain from the swap as I have mentioned previously but your combination will certainly benefit from the better manifold.

Go 102....its a much better designed intake out of the box and due to its different build/construction design allows me to port it differently (allows me freedoms with the grinder I would have put a hole in the former 78/90/92 series) which compounds the gains even further from the swap. On a really good combination my ported 102 could be worth 10+ more HP over one of my former ported 90/92 intakes (which were no slouches and typically worth a 20-25 RWHP improvement....even more than that if the baseline intake was a LS1/LS2 manifold).

Shoot me a PM if you have an interest in getting something going or have any more questions related to your particular build.

-Tony

#55

Staging Lane

Join Date: Mar 2011

Location: Newark, CA

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

Not necessarily true....as long as the port widths are close (and most are) the effectiveness of the porting is still realized.

Turns out most of the ported aftermarket and factory castings are 1.060 - 1.100 wide (I have seen a tremendous amount of heads over the years).....bone stock the port is closer to 1" or even less. No you might see some of the larger cathedrals coming in at 1.120 or so and I usually check with my customer to see if that is the case. Typically I port my intakes to 1.080.....right in the middle of the "average" cross section of heads (our 210, 215, 230, and our 245 all fall in around 1.080 and so do alot of the other aftermarket CNC castings). If I'm porting a stock or close to stock head and the customer will never swap to an aftermarket head I may leave the port opening a little conservative but it will still be larger than the stock entrance.

Bottom line....a .020 and even an .030 mismatch per side (that means the outlet is off almost .060 total) wouldn't effect performance at all. There is very little air flowing near the outside wall of the ports....only very slow moving air called the "boundary layer" which for the most part provides a cushion for the higher speed charge located further off the wall and closer to the center of the port. When reworking intake manifolds in general (not just related to FAST LS intakes), the port match in and of itself does very little (it really just needs to be close).....its all the work further into the port that changes the flow characteristics of the runner and there are some other tricks to the outlet that my more recent ported FAST manifolds feature (in last 6 months or so), different even than the pics in the thread you linked above but that thread gives you a good idea of the extent of the work involved and how much material is actually removed (there is a good bit more removed in the newer intakes I am working on).

Guys, I've been doing this a looooong time (reworking these FAST intakes, tweaking and honing the process along the way) and I have shipped hundreds of these with very positive results....bad news travels fast on the Internet and if you want to take the time to dig you will be hard pressed to find anyone not satisfied with what they got for the money spent, not to mention what they got for actual results. To try and debate the effectiveness of the work now, for this and that reason, this late in the game is almost silly....there are far too many positive results to do so.

The dyno graph above is proof positive a port match isn't as critical as you might think (not to mention how effective the proper port work can be). It reprsents the back to back results of a cam only 6.0 liter truck. These are the gains seen with STOCK 317 heads (unported....virgin) which always limits the amount of gains from a manifold swap because the large gains are always seen when you have high flow heads and the stock intake cant keep up. I ported this intake to a 1.070 width suspecting this customer was going to install heads at a later date (turns out Im working on a set of Mamofied 230's for him right now). Anyway.....the stock port is about an inch wide....the larger intake leaving a forward step was still extremely effective and if anything exceeded anything we discussed or hoped for prior to the swap. This is a ported LSXRT versus a stock truck intake which actually works pretty well with stock heads....with a notable mismatch at the port opening which I hope I shed some light on here regarding how a "perfect match" isn't really necessary.

Same dyno....no other changes except the intake swap and a larger 102 TB of course.

-Tony

Turns out most of the ported aftermarket and factory castings are 1.060 - 1.100 wide (I have seen a tremendous amount of heads over the years).....bone stock the port is closer to 1" or even less. No you might see some of the larger cathedrals coming in at 1.120 or so and I usually check with my customer to see if that is the case. Typically I port my intakes to 1.080.....right in the middle of the "average" cross section of heads (our 210, 215, 230, and our 245 all fall in around 1.080 and so do alot of the other aftermarket CNC castings). If I'm porting a stock or close to stock head and the customer will never swap to an aftermarket head I may leave the port opening a little conservative but it will still be larger than the stock entrance.

Bottom line....a .020 and even an .030 mismatch per side (that means the outlet is off almost .060 total) wouldn't effect performance at all. There is very little air flowing near the outside wall of the ports....only very slow moving air called the "boundary layer" which for the most part provides a cushion for the higher speed charge located further off the wall and closer to the center of the port. When reworking intake manifolds in general (not just related to FAST LS intakes), the port match in and of itself does very little (it really just needs to be close).....its all the work further into the port that changes the flow characteristics of the runner and there are some other tricks to the outlet that my more recent ported FAST manifolds feature (in last 6 months or so), different even than the pics in the thread you linked above but that thread gives you a good idea of the extent of the work involved and how much material is actually removed (there is a good bit more removed in the newer intakes I am working on).

Guys, I've been doing this a looooong time (reworking these FAST intakes, tweaking and honing the process along the way) and I have shipped hundreds of these with very positive results....bad news travels fast on the Internet and if you want to take the time to dig you will be hard pressed to find anyone not satisfied with what they got for the money spent, not to mention what they got for actual results. To try and debate the effectiveness of the work now, for this and that reason, this late in the game is almost silly....there are far too many positive results to do so.

The dyno graph above is proof positive a port match isn't as critical as you might think (not to mention how effective the proper port work can be). It reprsents the back to back results of a cam only 6.0 liter truck. These are the gains seen with STOCK 317 heads (unported....virgin) which always limits the amount of gains from a manifold swap because the large gains are always seen when you have high flow heads and the stock intake cant keep up. I ported this intake to a 1.070 width suspecting this customer was going to install heads at a later date (turns out Im working on a set of Mamofied 230's for him right now). Anyway.....the stock port is about an inch wide....the larger intake leaving a forward step was still extremely effective and if anything exceeded anything we discussed or hoped for prior to the swap. This is a ported LSXRT versus a stock truck intake which actually works pretty well with stock heads....with a notable mismatch at the port opening which I hope I shed some light on here regarding how a "perfect match" isn't really necessary.

Same dyno....no other changes except the intake swap and a larger 102 TB of course.

-Tony

The dyno chart you have provided compared a "ported LSXRT versus a stock truck intake". This is not a fair comparison Tony.

We want a scientific experiment. Over the long years of porting these, you must have a honest apple to apple comparison. Something that a more experienced tuner can be convinced with and not just an average Joe.

An oversized port on the FAST running into an undersized intake port on your favorite head should hurt performance. Be it .01% or 5%.

If I was paying big bucks, everything needs to be ported and port matched. You will make more power guaranteed. This statement can be proven on your flow bench.

Otherwise, this does not represent the best. Do you agree or disagree?

Is the fast intake on your own car port matched to your heads Tony?

Last edited by revtech101; 02-20-2012 at 08:01 PM.

#56

I have quite a bit of dyno time and hands on real world experience backing what I'm saying about port matching and how not so critical it really is. Some of the information I have access to is from other highly qualified people that work and test parts on a dyno for a living (flywheel and chassis) and share this kind of information with me. I have personally been privied to multiple back to back testing of manifolds....one of which was port matched and the other out of the box, yielding minimal gains (a couple of HP) and some absolutely nothing. And some of these manifold swaps Im referencing had sizable mismatches....cost me lunch a few times betting what it might be worth with the dyno operator (not even kidding). I've even seen a few where the port matched intake made slightly less power but I suspect there may have been a slight difference in other aspects of that manifold not easily seen by eye.

Truthfully I wish it had a larger impact on things because it would be an easy way to extract more power from a combination but the testing I have done has shown me otherwise. Also note that when I reference personal experience I am speaking of intake manifold testing in general including testing BBC and Gen I 23' SBC which I have alot of dyno time and experience with as well. Ask Richard Holdener, a sharp guy and a very respected author (a guy that spends a ton of time on the dyno testing a host of different things) what he feels about intake port matching....I assure you his sentiment would parallel the point I'm trying to make here and few guys have as much real world experience as he does related to what we are discussing.

In a perfect world if your looking for the last 1-2 HP (such as my personal engine) you optimize and match everything including the port match, but alot of this work does more to give you a better nights sleep than actually add measurably to your combinations power output assuming the port match was reasonably close to begin with which is what I have said all along. A customer getting a manifold from myself ported would have a much better looking situation that the one in your pic without me having the heads in hand. In fact there are areas of the port outlet (and inside the runner for that matter) I barely breathe on with the grinder because I know the material needs to stay there. Its a common mistake I see when I have gotten the opportunity to inspect some other manifold porting....some just make the outlet opening (and area's further up the port) bigger everywhere and that is clearly not a wise move as your picture certainly illustrates. Purposely leaving material in key areas helps flow and is just as important as removing material in others.....its the total package that nets you the big results.

-Tony

#57

Staging Lane

Join Date: Mar 2011

Location: Newark, CA

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

The comparison above was never meant to be a port match versus non port match comparison....it was shown clearly to illustrate my point that a perfect port match is not required to get the bulk of the gains available when swapping to a better intake. Also, I clearly stated that I felt a small mismatch is acceptable.....not a really bad mismatch like the over ported FAST in your picture. But you would be surprised how small a difference even that scenario would actually be on the dyno where you to test a perfect match against that mismatched intake you featured (if every other part of the manifold itself was kept the same).

I have quite a bit of dyno time and hands on real world experience backing what I'm saying about port matching and how not so critical it really is. Some of the information I have access to is from other highly qualified people that work and test parts on a dyno for a living (flywheel and chassis) and share this kind of information with me. I have personally been privied to multiple back to back testing of manifolds....one of which was port matched and the other out of the box, yielding minimal gains (a couple of HP) and some absolutely nothing. And some of these manifold swaps Im referencing had sizable mismatches....cost me lunch a few times betting what it might be worth with the dyno operator (not even kidding). I've even seen a few where the port matched intake made slightly less power but I suspect there may have been a slight difference in other aspects of that manifold not easily seen by eye.

Truthfully I wish it had a larger impact on things because it would be an easy way to extract more power from a combination but the testing I have done has shown me otherwise. Also note that when I reference personal experience I am speaking of intake manifold testing in general including testing BBC and Gen I 23' SBC which I have alot of dyno time and experience with as well. Ask Richard Holdener, a sharp guy and a very respected author (a guy that spends a ton of time on the dyno testing a host of different things) what he feels about intake port matching....I assure you his sentiment would parallel the point I'm trying to make here and few guys have as much real world experience as he does related to what we are discussing.

In a perfect world if your looking for the last 1-2 HP (such as my personal engine) you optimize and match everything including the port match, but alot of this work does more to give you a better nights sleep than actually add measurably to your combinations power output assuming the port match was reasonably close to begin with which is what I have said all along. A customer getting a manifold from myself ported would have a much better looking situation that the one in your pic without me having the heads in hand. In fact there are areas of the port outlet (and inside the runner for that matter) I barely breathe on with the grinder because I know the material needs to stay there. Its a common mistake I see when I have gotten the opportunity to inspect some other manifold porting....some just make the outlet opening (and area's further up the port) bigger everywhere and that is clearly not a wise move as your picture certainly illustrates. Purposely leaving material in key areas helps flow and is just as important as removing material in others.....its the total package that nets you the big results.

-Tony

I have quite a bit of dyno time and hands on real world experience backing what I'm saying about port matching and how not so critical it really is. Some of the information I have access to is from other highly qualified people that work and test parts on a dyno for a living (flywheel and chassis) and share this kind of information with me. I have personally been privied to multiple back to back testing of manifolds....one of which was port matched and the other out of the box, yielding minimal gains (a couple of HP) and some absolutely nothing. And some of these manifold swaps Im referencing had sizable mismatches....cost me lunch a few times betting what it might be worth with the dyno operator (not even kidding). I've even seen a few where the port matched intake made slightly less power but I suspect there may have been a slight difference in other aspects of that manifold not easily seen by eye.

Truthfully I wish it had a larger impact on things because it would be an easy way to extract more power from a combination but the testing I have done has shown me otherwise. Also note that when I reference personal experience I am speaking of intake manifold testing in general including testing BBC and Gen I 23' SBC which I have alot of dyno time and experience with as well. Ask Richard Holdener, a sharp guy and a very respected author (a guy that spends a ton of time on the dyno testing a host of different things) what he feels about intake port matching....I assure you his sentiment would parallel the point I'm trying to make here and few guys have as much real world experience as he does related to what we are discussing.

In a perfect world if your looking for the last 1-2 HP (such as my personal engine) you optimize and match everything including the port match, but alot of this work does more to give you a better nights sleep than actually add measurably to your combinations power output assuming the port match was reasonably close to begin with which is what I have said all along. A customer getting a manifold from myself ported would have a much better looking situation that the one in your pic without me having the heads in hand. In fact there are areas of the port outlet (and inside the runner for that matter) I barely breathe on with the grinder because I know the material needs to stay there. Its a common mistake I see when I have gotten the opportunity to inspect some other manifold porting....some just make the outlet opening (and area's further up the port) bigger everywhere and that is clearly not a wise move as your picture certainly illustrates. Purposely leaving material in key areas helps flow and is just as important as removing material in others.....its the total package that nets you the big results.

-Tony

Do you ask your clients to take apart the fast and check the ports in its installed position to avoid situations such as the picture I have posted?

I would not be surprised at what a good ported+port matched combo would do against an individually ported parts slapped together. You know which one represents the best and that is why you have what you have. I would preach exactly just that.

On a FI car, this tiny loss in torque and hp due to mis-matched ports will amplify.

Last edited by revtech101; 02-20-2012 at 05:29 PM.

#59

Agreed this is the problem I saw with both my 92 & 102 intake. The ports on the fast are not exactly the same as the heads and there is a slight shift. My fast 102 looked the same after I ported it...front runners were thin on one side and the back ones were thin on other side...

If you look at the port openings on the TFS 215, 225, 235 and 245 they're all different, and none of them are like an AFR head or a OEM CNC head. If you go with the TFS As Cast heads, they can be different from port to port due to shrink.

The tooling that makes heads and the Fast intakes are made with "shrink" included, meaning that the part in the tooling is made longer than the desired final part, and depending on how hot the material is injected or poured will depend on the total amount of shrink factored into the tooling.

If you port a Fast intake to where every intake port looks symmetrical compared to the o-ring gasket, then it's not going to perfectly match every port in any CNC heads made.

If the intake is taken apart and bolted to the heads, and then the intake is ground to perfectly match the existing ports in the heads, every port will look different in relation to the o-ring gaskets.

I was going to make a video of a Fast port matched to some TFS heads, but to avoid the TFS bashing that might ensue I instead used some new AFR 230 V2 heads. The point is the Fast intake doesn't have the perfect shrink factor, so every port is oriented different in relation to the o-rings. I hope this make sense! http://youtu.be/x0LVddVYfNI

The tooling that makes heads and the Fast intakes are made with "shrink" included, meaning that the part in the tooling is made longer than the desired final part, and depending on how hot the material is injected or poured will depend on the total amount of shrink factored into the tooling.

If you port a Fast intake to where every intake port looks symmetrical compared to the o-ring gasket, then it's not going to perfectly match every port in any CNC heads made.

If the intake is taken apart and bolted to the heads, and then the intake is ground to perfectly match the existing ports in the heads, every port will look different in relation to the o-ring gaskets.

I was going to make a video of a Fast port matched to some TFS heads, but to avoid the TFS bashing that might ensue I instead used some new AFR 230 V2 heads. The point is the Fast intake doesn't have the perfect shrink factor, so every port is oriented different in relation to the o-rings. I hope this make sense! http://youtu.be/x0LVddVYfNI