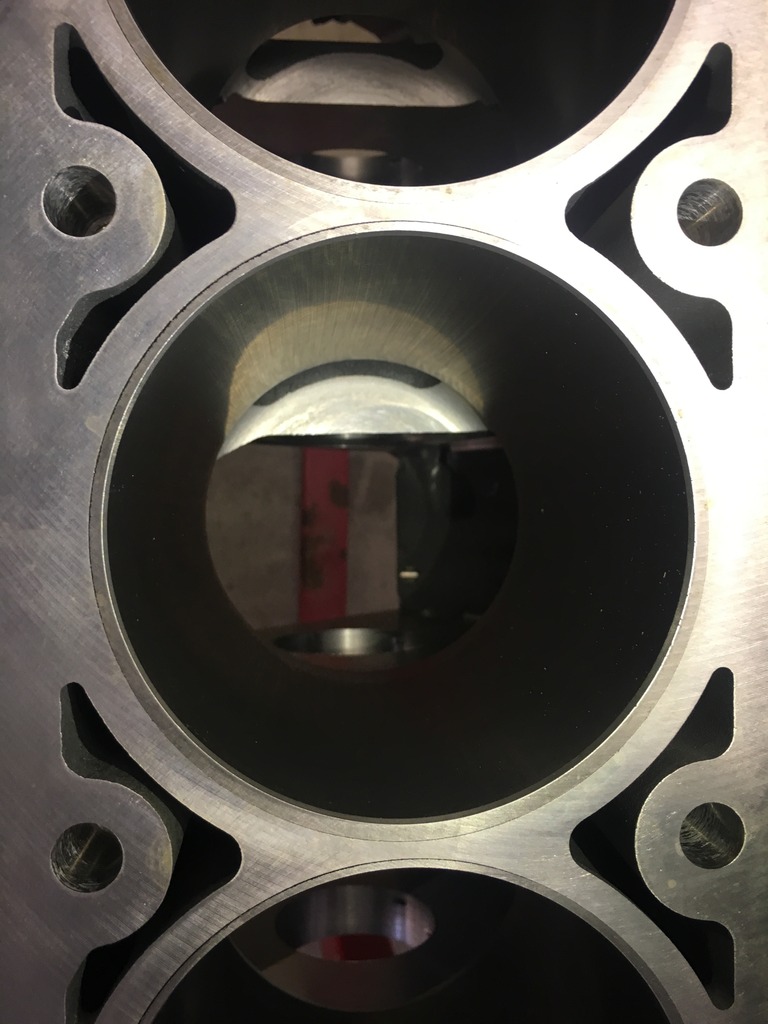

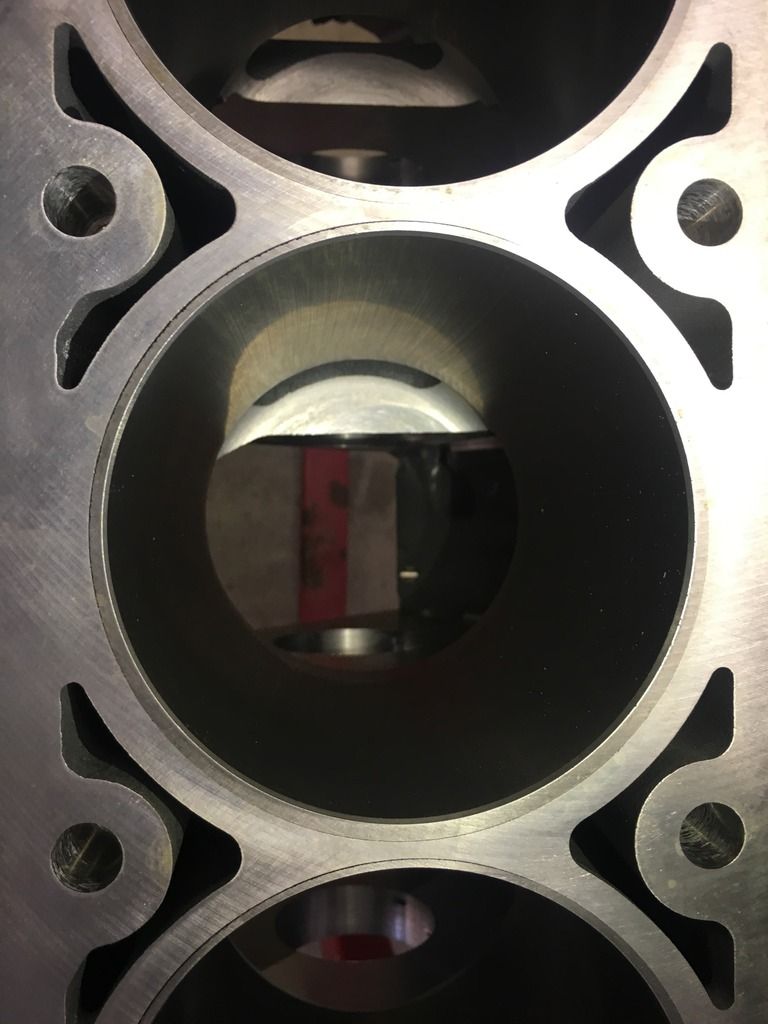

Brand new ls3 block deck flaw need help

#1

hi I recently bought a new ls3 block and the block has a casting flaw on deck. Should I be concerned? Also the steel liner looks like there is a gap between steel liner and aluminum casting. Please see pics.

Thanks

richard

Thanks

richard

#3

its not uncommon for them to be like that around the liner mine was similar although yours is a bit worse than mine was my machine shop told me it would be fine I would ask your machine shop tho to be safe

#4

TECH Resident

iTrader: (4)

My crate LS3 had a bit of a gap between the liners and the block as well. It seems the aluminum casting doesn't quite cover 100% of the liner surface as it flows into the mold. I suspect that structurally, it must not be significant, as they probably all have this to some degree--even below the deck where it is not exposed.

Mine did not have the surface imperfection yours has. I am not sure if that is something to be concerned about.

Mine did not have the surface imperfection yours has. I am not sure if that is something to be concerned about.

Trending Topics

#8

TECH Addict

Ive fixed dings like that with high temp metal epoxy. They make it in aluminum for industrial Air Conditioning applications like repairing ex-changers or pumps. Then just use a small block to smoooth it flush.

But usually its damage not a void, one option might be to have someone ultrasound the block just to make sure there are no serious voids in the casting.

But usually its damage not a void, one option might be to have someone ultrasound the block just to make sure there are no serious voids in the casting.

Last edited by pdxmotorhead; 03-16-2017 at 12:48 AM.

#13

TECH Addict

iTrader: (11)

Join Date: Jan 2003

Location: Minnesota Corn Fields

Posts: 2,451

Likes: 0

Received 9 Likes

on

8 Posts

Ive fixed dings like that with high temp metal epoxy. They make it in aluminum for industrial Air Conditioning applications like repairing ex-changers or pumps. Then just use a small block to smoooth it flush.

But usually its damage not a void, one option might be to have someone ultrasound the block just to make sure there are no serious voids in the casting.

But usually its damage not a void, one option might be to have someone ultrasound the block just to make sure there are no serious voids in the casting.

#15