Which ARP rob bolt kit? 08 LH6 5.3

#1

Staging Lane

Thread Starter

Join Date: Jan 2012

Location: Santa Rosa, Ca

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

I see two kit numbers. Both are described as cracked cap rod design.

134-6006 or 234-6301?

134-6006 or 234-6301?

Last edited by Grip; 05-24-2017 at 08:39 PM. Reason: Rod, not rob

#3

Moderator

iTrader: (20)

I've used the ARP 2000 kit in a set with of LS3 rods and it did distort the bore, but it wasn't out of spec. I just used a "race" style bearing and set the clearances accordingly. It ran fine like that, but I'll have the engine out and apart soon due to a broken valve spring, so I can see what it looks like.

#4

Staging Lane

Thread Starter

Join Date: Jan 2012

Location: Santa Rosa, Ca

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

The Pro Series (234-6301) is a stronger alloy, that is the main difference. In my opinion I would go with those. Just remember to have the rods resized with a line bore to prevent uneven clamping force which can lead to a spun bearing or worse.

#5

TECH Enthusiast

iTrader: (1)

As mentioned, the 234 kit is the ARP 2000 alloy which is stronger than the 8740 alloy used in the 134 kit. The ARP 2000 alloy has a higher recommended torque value so there's a better chance that the big end bore will distort more.

I've used the ARP 2000 kit in a set with of LS3 rods and it did distort the bore, but it wasn't out of spec. I just used a "race" style bearing and set the clearances accordingly. It ran fine like that, but I'll have the engine out and apart soon due to a broken valve spring, so I can see what it looks like.

I've used the ARP 2000 kit in a set with of LS3 rods and it did distort the bore, but it wasn't out of spec. I just used a "race" style bearing and set the clearances accordingly. It ran fine like that, but I'll have the engine out and apart soon due to a broken valve spring, so I can see what it looks like.

Trending Topics

#8

Moderator

iTrader: (20)

Even with the bore slightly out of round, 12 and 6 o'clock was still the tightest clearance like it's supposed to be.

#10

TECH Resident

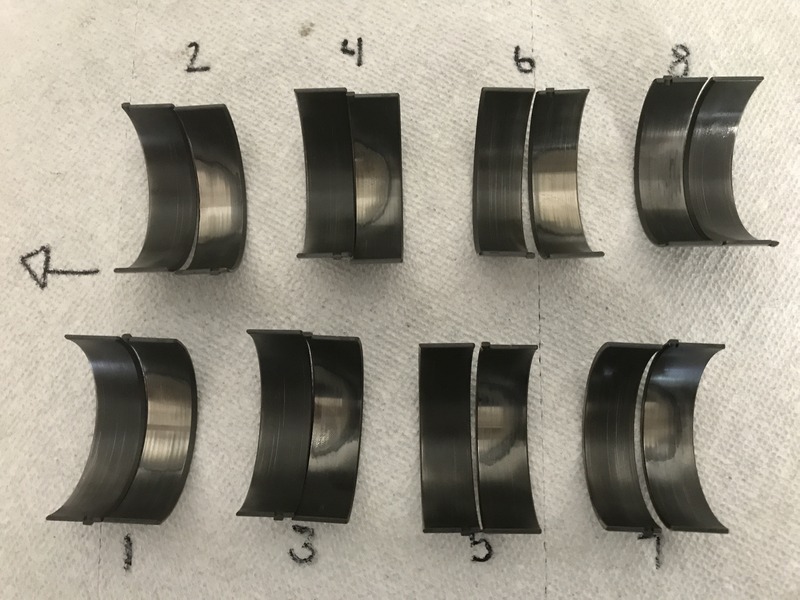

I just had my machine shop install ARP bolts and check the rod ends, one was so distorted I had to get a new rod. I had always thought this was BS but I guess is really is a issue.I also had my mains checked and it only took a touch-up hone job but the crank is in and torqued and it spins easily by hand and the thrust checks out...