So i Finally bought an 8.8!

#1

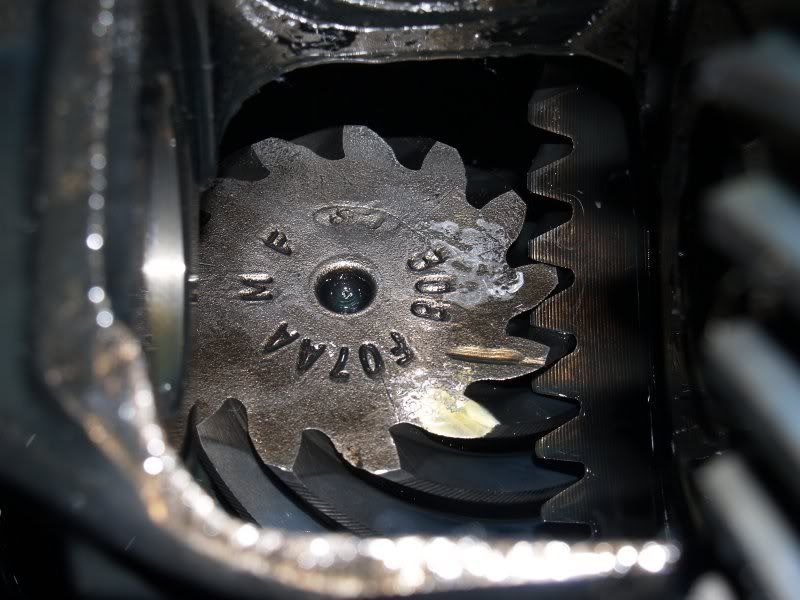

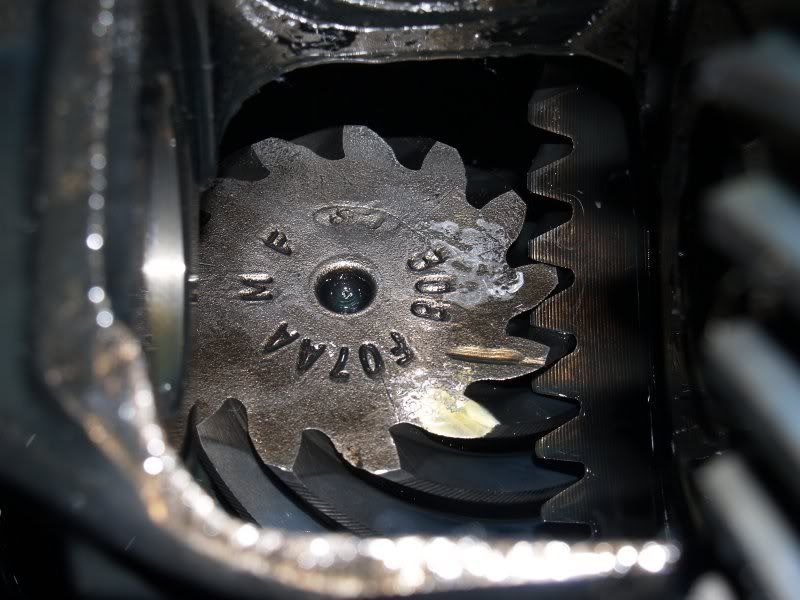

its not much. but its a start! and for $75 i couldnt pass it up, even if i am going to replace everything. Its an 8.8 out of an 80's ranger the guy told me. it has drum brakes and 5 lug axles.when i tore it down after i picked it up i found that it has 3.08 gears, 28 spline axles and an abs reluctor ring. im def going to change the gears to a 3.90 or 4.11 and i might change the spider gears to for 31 spline ones that are alittle newer. just thought you guys would like to hear my new project. thisll be done over the course of afew months so updates will be scarce... and for the best part. pictures!

Trending Topics

#8

to answer all of your questions as best as possible. Yes, I do dare to be different. being a machinist, a fabricator, and a welder. Im fairly confident that i can make this work. Im not one to brag and say "im the best there is i can do anything!" but i can sure as hell try my best. i dont plan on reusing the stock tubes, or spider gears, or axles, nor gears themselves lol. i only bought the rear for whats effectively the pumpkin (center) for $75 it was worth it to me to mess around with.

On other threads about building 8.8's people have quotes from moser with 8.8 splines and 10 bolt ends for around $310. so with that im almost at $400. New 31 spline spider gears are $126 on summit, and gears are around $150. whatever the install kits cost ontop of all that. so im around $700 with all of that right there. the collars to mate the 8.8 tubes to the 10 bolt tubes are free for me considering im making them, along with all of the welding. i do plan on making a torque arm provision for this rear aswell to make it much more install friendly. I will be limited with cash and time, so dont hope to have this thread updated oftenly. but whenever i do something i will update it.

I plan to have the diff out sometime this week aslong as cutting the tubes off. im big into pictures if you cant tell so expect everything to be well documented

on a side note. if anyone has a spare 10 bolt for sale please let me know what you want for it! i could really use one right about now. i only need the housing. nothing else. thanks guys

On other threads about building 8.8's people have quotes from moser with 8.8 splines and 10 bolt ends for around $310. so with that im almost at $400. New 31 spline spider gears are $126 on summit, and gears are around $150. whatever the install kits cost ontop of all that. so im around $700 with all of that right there. the collars to mate the 8.8 tubes to the 10 bolt tubes are free for me considering im making them, along with all of the welding. i do plan on making a torque arm provision for this rear aswell to make it much more install friendly. I will be limited with cash and time, so dont hope to have this thread updated oftenly. but whenever i do something i will update it.

I plan to have the diff out sometime this week aslong as cutting the tubes off. im big into pictures if you cant tell so expect everything to be well documented

on a side note. if anyone has a spare 10 bolt for sale please let me know what you want for it! i could really use one right about now. i only need the housing. nothing else. thanks guys

#13

TECH Senior Member

iTrader: (8)

I'm going to use something line the quick performance mount. That will make the pinion angle adjustable without needing an adjustable tq arm.

Have you seen tgr threads in the gears and axles forum? There ate pics there of a fabbed tq arm mount welded to the side of the 8.8 made of tubing and plate.

Have you seen tgr threads in the gears and axles forum? There ate pics there of a fabbed tq arm mount welded to the side of the 8.8 made of tubing and plate.

#14

I'm going to use something line the quick performance mount. That will make the pinion angle adjustable without needing an adjustable tq arm.

Have you seen tgr threads in the gears and axles forum? There ate pics there of a fabbed tq arm mount welded to the side of the 8.8 made of tubing and plate.

Have you seen tgr threads in the gears and axles forum? There ate pics there of a fabbed tq arm mount welded to the side of the 8.8 made of tubing and plate.

#17

Stock 10 bolt axles will slide right in the 28 spline posi. I was running this for a while till the posi took a dump.

I have a 31 spline posi and custom moser axles to swap in now.

#20

On The Tree

iTrader: (3)

Join Date: Jul 2009

Location: Summerville, SC

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

I put the 8.8 in my blazer too and just got the axles and rotors drilled to the gm pattern. I used an Explorer rear since it comes with the 31 spline axles. My particular setup also came with 4.10's and disk brakes. All I needed was and adapter piece for the brake hose to connect. I used the explorer aluminum driveshaft and installed a adapter u-joint for the yoke. I had to get the driveshaft shortened for my application. I have about $200 in my 8.8 setup.

The diff is offset around 2-9/16" from center towards the passenger side. TheRangerStation has excellent info on the rears. http://www.therangerstation.com/tech_library/Axles.html

The diff is offset around 2-9/16" from center towards the passenger side. TheRangerStation has excellent info on the rears. http://www.therangerstation.com/tech_library/Axles.html