Moving T56 in F-body to Rear of Car - Possible?

#1

Hey guys, I have a 99 Trans Am with LS1 and T56, regular stuff, but I'd like to get some info on moving this trans to the back of the car. Something like this:

No, I'm not talking about using a C5/C6 transmission or rearend. I'm talking about using the regular T56 trans. Just so you know, I already have the output side figured out to bolt to a Ford 8.8 IRS diff, so please no questions about that end. I mainly need to figure out how to run either an open driveshaft or a torque tube between the engine and rear mounted transmission.

At first I thought the torque tube setup would be best choice (it may still be) and I would just change the tube length and driveshaft length to what I need. Now the engine side should work out fine, but there's 2 issues with the transmission input side. The torque tube is flared out overly large for my needs and the T56 not having the right plate for it to bolt to. I'd have to fabricate some kind of adaptor to get them together. Even then I'd still have that big empty bulge (for torque converter on auto cars) taking up valuable room, though. Would I need a carrier bearing on that end?

I'm hoping there are some transmission experts in here who are familiar with both the f-body and the vette parts and know whats compatible with what.

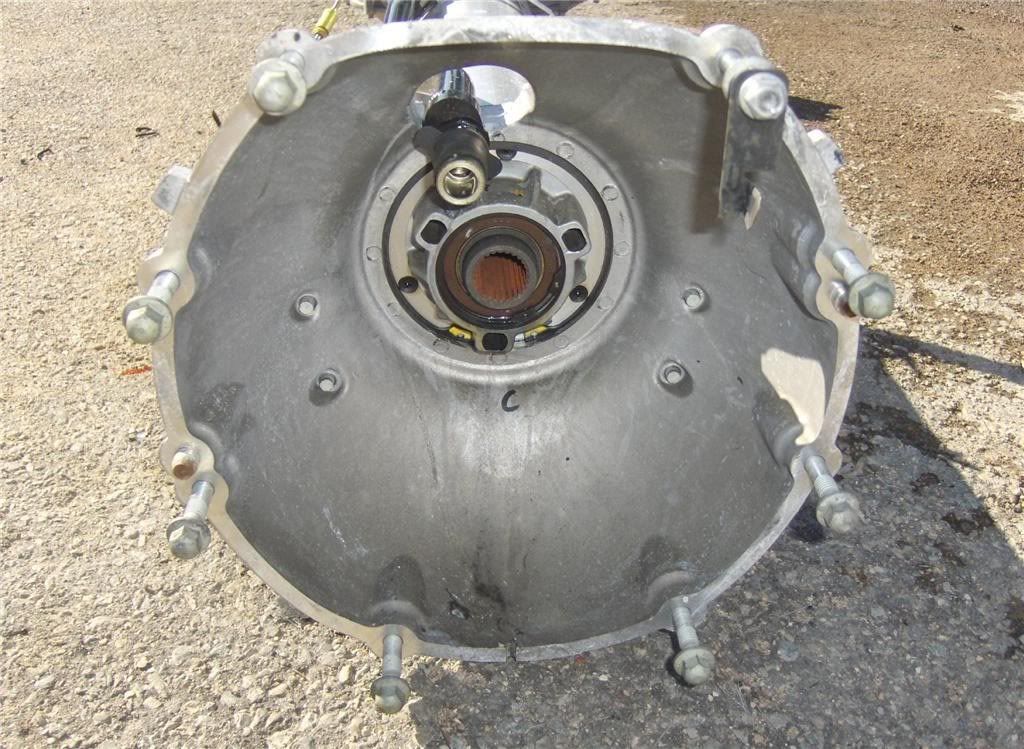

Here are some pics of a custom built open driveshaft setup using a C5 trans and rearend with a Dodge engine using an aftermarket bellhousing and a carrier bearing. He then had a splined shaft made. His stuff is on a high end build, but I hope it can be done on a budget.

What I think is going on is the splined shaft has the pilot bearing on the engine side and the carrier bearing on the back end to keep the clutch and pressure plate lined up. The shaft uses a C clip on either side of the carrier bearing to hold it in position. The hydraulic throwout bearing is bolted to the thick aluminum plate to slide the pressure plate forward on the splines. It pretty much duplicates the trans input shaft and it has a driveshaft yoke spline on the end so a regular driveshaft can slide on.

No, I'm not talking about using a C5/C6 transmission or rearend. I'm talking about using the regular T56 trans. Just so you know, I already have the output side figured out to bolt to a Ford 8.8 IRS diff, so please no questions about that end. I mainly need to figure out how to run either an open driveshaft or a torque tube between the engine and rear mounted transmission.

At first I thought the torque tube setup would be best choice (it may still be) and I would just change the tube length and driveshaft length to what I need. Now the engine side should work out fine, but there's 2 issues with the transmission input side. The torque tube is flared out overly large for my needs and the T56 not having the right plate for it to bolt to. I'd have to fabricate some kind of adaptor to get them together. Even then I'd still have that big empty bulge (for torque converter on auto cars) taking up valuable room, though. Would I need a carrier bearing on that end?

I'm hoping there are some transmission experts in here who are familiar with both the f-body and the vette parts and know whats compatible with what.

Here are some pics of a custom built open driveshaft setup using a C5 trans and rearend with a Dodge engine using an aftermarket bellhousing and a carrier bearing. He then had a splined shaft made. His stuff is on a high end build, but I hope it can be done on a budget.

What I think is going on is the splined shaft has the pilot bearing on the engine side and the carrier bearing on the back end to keep the clutch and pressure plate lined up. The shaft uses a C clip on either side of the carrier bearing to hold it in position. The hydraulic throwout bearing is bolted to the thick aluminum plate to slide the pressure plate forward on the splines. It pretty much duplicates the trans input shaft and it has a driveshaft yoke spline on the end so a regular driveshaft can slide on.

Last edited by JasonWW; 11-12-2008 at 08:09 AM.

#4

I would like to offer advice on this one, but I would have to have all the parts side by side to see what could be used and what would have to be made. Too many variables to figure out by pictures. Clutch, shifter, input shaft for driveshaft or torquetube, input for transmission, etc.. Hell with it Ill give it a shot.

I would think you could use your stock bellhousing. Fabricate a plate that bolts where the transmission bolted up. Use that as a backing plate for the throwout bearing and slave cylinder. I believe you would have to use the carrier bearing deal on that plate too. With the driveshaft not moving up and down I dont see a reason to have a that separate shaft.

To the back. Mount thansmission where it needs to be. Pull input shaft out of transmission and have a very competent welder weld a driveshaft yoke onto the end of it.

Driveshaft. Use a driveshaft with the correct length of tube. On the input end you would have to have a very long shaft with the input splines and bearing end on it. I dont know if this would work, but maybe you could weld another input shaft inside the yoke on the end of the driveshaft?

Those are the best rigging ideas I could get without having the parts infront of me.

I would think you could use your stock bellhousing. Fabricate a plate that bolts where the transmission bolted up. Use that as a backing plate for the throwout bearing and slave cylinder. I believe you would have to use the carrier bearing deal on that plate too. With the driveshaft not moving up and down I dont see a reason to have a that separate shaft.

To the back. Mount thansmission where it needs to be. Pull input shaft out of transmission and have a very competent welder weld a driveshaft yoke onto the end of it.

Driveshaft. Use a driveshaft with the correct length of tube. On the input end you would have to have a very long shaft with the input splines and bearing end on it. I dont know if this would work, but maybe you could weld another input shaft inside the yoke on the end of the driveshaft?

Those are the best rigging ideas I could get without having the parts infront of me.

#7

Jeez, are you one of those guys that thinks every part has to be designed on a computer and cut out of a solid chunk of billet aluminum with a 5 axis CNC machine? Why can't this be done on a small budget?

I've seen complete torque tubes sell for around $300 on eBay. That's not super expensive. Especially if you can get one locally to avoid shipping costs. If there was a transmission rebuilder here they could probably tell me if the T56 input shaft can be seperated. I might can get a used one from a junked T56 and have the back of the shaft splined or else a yoke welded on to it. Cutting the little grooves for the C clips is easy enough to do.

If I really put some thought into it I bet I could keep the cost low.

Getting back to the thread, I bet the trans input shaft needs to have a carrier bearing on it. There's probably one on the end of it inside the case and the front of the shaft is tradionally supported by the pilot bearing. So I bet the C5 torque tube uses a carrier bearing on both ends. It makes sense to me.

I've seen complete torque tubes sell for around $300 on eBay. That's not super expensive. Especially if you can get one locally to avoid shipping costs. If there was a transmission rebuilder here they could probably tell me if the T56 input shaft can be seperated. I might can get a used one from a junked T56 and have the back of the shaft splined or else a yoke welded on to it. Cutting the little grooves for the C clips is easy enough to do.

If I really put some thought into it I bet I could keep the cost low.

Getting back to the thread, I bet the trans input shaft needs to have a carrier bearing on it. There's probably one on the end of it inside the case and the front of the shaft is tradionally supported by the pilot bearing. So I bet the C5 torque tube uses a carrier bearing on both ends. It makes sense to me.

Last edited by JasonWW; 11-12-2008 at 11:36 PM.

Trending Topics

#10

I'm learning as I'm going.

#11

I found a thread here in this forum on altering the length of the torque tube.

https://ls1tech.com/forums/conversio...ml#post8958726

https://ls1tech.com/forums/conversio...ml#post8958726

#14

I did do some research and I'm not disagreeing. Jeez, get some coffee or something grumpy.

The reason I don't think it's promary roll is as a safety device is that GM doesn't use then on all their RWD vehicles. I mean the f-body doesn't have one. Are we all in danger? I don't think so.

Secondly, it looks like it transmits forward loads from the tires all the way up to the engine mounts. So the entire drivetrain is under a compression type stress when accelerating.

Third, it looks like it may resist some of the torsional or twisting loads from being transmitted to the frame.

It may also reduce NVH.

I would guess all these before safety. If it was all about protection, they could have just added a shield or something simple and lighter in weight.

Oh yeah, as far as anyone knows, you think every thread on this forum is useless. I really don't care for your criticism. If you don't like it, why read it and post on it? Wouldn't the smart thing to do be to ignore it or at least unsubscribe? I don't know, maybe that's just me.

The reason I don't think it's promary roll is as a safety device is that GM doesn't use then on all their RWD vehicles. I mean the f-body doesn't have one. Are we all in danger? I don't think so.

Secondly, it looks like it transmits forward loads from the tires all the way up to the engine mounts. So the entire drivetrain is under a compression type stress when accelerating.

Third, it looks like it may resist some of the torsional or twisting loads from being transmitted to the frame.

It may also reduce NVH.

I would guess all these before safety. If it was all about protection, they could have just added a shield or something simple and lighter in weight.

Oh yeah, as far as anyone knows, you think every thread on this forum is useless. I really don't care for your criticism. If you don't like it, why read it and post on it? Wouldn't the smart thing to do be to ignore it or at least unsubscribe? I don't know, maybe that's just me.

Last edited by JasonWW; 11-13-2008 at 01:53 PM.

#15

TECH Fanatic

iTrader: (7)

Join Date: May 2007

Location: Arab, Al

Posts: 1,735

Likes: 0

Received 0 Likes

on

0 Posts

I think you are one of the most clever/open minded person on the site. I love every damn idea you have and every mod you do! I would love to see you pull this one off, I can't help with idea's, but I'll be rooting for you haha.

#16

10 Second Club

iTrader: (26)

How is saying "i dont think thats its main purpose" not disagreeing?And where did i say that "every" thread on this forum is useless?i have more than 1 sticky on ls1tech so get your facts straight son.

I did do some research and I'm not disagreeing. Jeez, get some coffee or something grumpy.

The reason I don't think it's promary roll is as a safety device is that GM doesn't use then on all their RWD vehicles. I mean the f-body doesn't have one. Are we all in danger? I don't think so.

Secondly, it looks like it transmits forward loads from the tires all the way up to the engine mounts. So the entire drivetrain is under a compression type stress when accelerating.

Third, it looks like it may resist some of the torsional or twisting loads from being transmitted to the frame.

It may also reduce NVH.

I would guess all these before safety. If it was all about protection, they could have just added a shield or something simple and lighter in weight.

Oh yeah, as far as anyone knows, you think every thread on this forum is useless. I really don't care for your criticism. If you don't like it, why read it and post on it? Wouldn't the smart thing to do be to ignore it or at least unsubscribe? I don't know, maybe that's just me.

The reason I don't think it's promary roll is as a safety device is that GM doesn't use then on all their RWD vehicles. I mean the f-body doesn't have one. Are we all in danger? I don't think so.

Secondly, it looks like it transmits forward loads from the tires all the way up to the engine mounts. So the entire drivetrain is under a compression type stress when accelerating.

Third, it looks like it may resist some of the torsional or twisting loads from being transmitted to the frame.

It may also reduce NVH.

I would guess all these before safety. If it was all about protection, they could have just added a shield or something simple and lighter in weight.

Oh yeah, as far as anyone knows, you think every thread on this forum is useless. I really don't care for your criticism. If you don't like it, why read it and post on it? Wouldn't the smart thing to do be to ignore it or at least unsubscribe? I don't know, maybe that's just me.

#19

LS1TECH Sponsor

iTrader: (5)

If you use the regular f-body transmission, how are you going to shift it? The vettes shift rail exits the front adapter plate of the transmission. Then it is linked to a long rod that travels up to the shifter itself.

I suppose you could still use the f-body transmission, but switch the shift rail as well as the top plate that mounts the reverse lockout solenoid and the piece inside that contains the detent ball (not sure the proper term for it). Then you could just make a blockoff plate where the f-body shifter was. You'd also have to use the vettes adapter plate which would then allow you to bolt up the torque tube.

This is assuming the f-body and vettes input shafts are the same legnth. They are not the same part due to the different syncro styles. If the f-body shaft was longer you may be able to just space between the torque tube and the tranny.

The torque tube has a pilot bearing in the end where the input shaft goes. Theres also a pilot bearing in the engine for the torque tube as well. Other than the legnth of the tube and shifter location, everything would bolt right up if using a vette bellhousing. I'm not really sure what shortening the torque tube would involve...I've never had one appart myself.

I'd think if this is possible, it would be much easier to just sell the f-body trans you have. Then buy the vette torque tube, transmission, and diff. rather than using an 8.8. It may even be cheaper overall after trying build your t56 as a vette/f-body hybrid.

I suppose you could still use the f-body transmission, but switch the shift rail as well as the top plate that mounts the reverse lockout solenoid and the piece inside that contains the detent ball (not sure the proper term for it). Then you could just make a blockoff plate where the f-body shifter was. You'd also have to use the vettes adapter plate which would then allow you to bolt up the torque tube.

This is assuming the f-body and vettes input shafts are the same legnth. They are not the same part due to the different syncro styles. If the f-body shaft was longer you may be able to just space between the torque tube and the tranny.

The torque tube has a pilot bearing in the end where the input shaft goes. Theres also a pilot bearing in the engine for the torque tube as well. Other than the legnth of the tube and shifter location, everything would bolt right up if using a vette bellhousing. I'm not really sure what shortening the torque tube would involve...I've never had one appart myself.

I'd think if this is possible, it would be much easier to just sell the f-body trans you have. Then buy the vette torque tube, transmission, and diff. rather than using an 8.8. It may even be cheaper overall after trying build your t56 as a vette/f-body hybrid.

Good luck mounting the rear suspension/cradle.

Good luck mounting the rear suspension/cradle.