Does YOUR Clutch Setup need a Shim?

#61

TECH Enthusiast

iTrader: (22)

Join Date: Oct 2003

Location: Slinger WI

Posts: 648

Likes: 0

Received 0 Likes

on

0 Posts

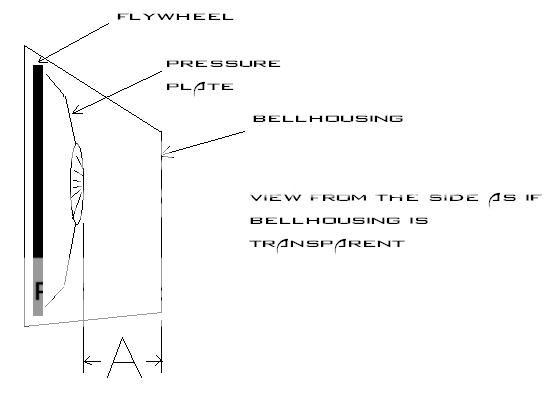

Ok here is my dilema... Spec twin disc setup... Im gettin 2" on the head for measurement "A" and 2" for measurement "B" as well. That leaves me no gap at all.

This is with a stock slave and the throwout that came with the spec twin disc kit, no spacer at all under the slave. I also have a Mcleod adj master too. No the spacer is not stuck in the slave too, i triple checked that.

My main gripe is that the clutch engagment point is too high in the pedal travel and i have to adjust the pedal way down to get it more in the middle where i want it.

Anyone ran into this no gap at all issue before?

This is with a stock slave and the throwout that came with the spec twin disc kit, no spacer at all under the slave. I also have a Mcleod adj master too. No the spacer is not stuck in the slave too, i triple checked that.

My main gripe is that the clutch engagment point is too high in the pedal travel and i have to adjust the pedal way down to get it more in the middle where i want it.

Anyone ran into this no gap at all issue before?

#62

Ok here is my dilema... Spec twin disc setup... Im gettin 2" on the head for measurement "A" and 2" for measurement "B" as well. That leaves me no gap at all.

This is with a stock slave and the throwout that came with the spec twin disc kit, no spacer at all under the slave. I also have a Mcleod adj master too. No the spacer is not stuck in the slave too, i triple checked that.

My main gripe is that the clutch engagment point is too high in the pedal travel and i have to adjust the pedal way down to get it more in the middle where i want it.

Anyone ran into this no gap at all issue before?

This is with a stock slave and the throwout that came with the spec twin disc kit, no spacer at all under the slave. I also have a Mcleod adj master too. No the spacer is not stuck in the slave too, i triple checked that.

My main gripe is that the clutch engagment point is too high in the pedal travel and i have to adjust the pedal way down to get it more in the middle where i want it.

Anyone ran into this no gap at all issue before?

I think you need a drink Tom...

I thought about this all night, I dont understand why it would be like that unless somthing mechanically MOVED forward or backward in the trans or on the engine but we both know that odds of that are about as good as $10,000,000 showing up in my bank account. Did you call spec and ask them how much space there was when they R&D'ed these things? If you need somthing machined out, let me know, ill see if i can do it.

#63

Launching!

iTrader: (2)

Join Date: Nov 2005

Location: Arnold, MO

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

I don't understand this statement. I just put the motor/transmission into my car. After I had measured, "B" was ~1/16 less than "A". I called it good and continued with the install. I figured once the clutch was broke in, the gap would grow due to the fact that the disc becomes thinner and the fingers would pull in towards (away from the TOB). If the pressure plate fingers move in, "A" becomes larger and the gap grows (to 3/16-1/4 of an inch). Am I thinking incorrectly?

#65

Launching!

iTrader: (2)

Join Date: Nov 2005

Location: Arnold, MO

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

I don't understand this statement. I just put the motor/transmission into my car. After I had measured, "B" was ~1/16 less than "A". I called it good and continued with the install. I figured once the clutch was broke in, the gap would grow due to the fact that the disc becomes thinner and the fingers would pull in towards (away from the TOB). If the pressure plate fingers move in, "A" becomes larger and the gap grows (to 3/16-1/4 of an inch). Am I thinking incorrectly?

#67

Launching!

iTrader: (4)

Join Date: Jun 2004

Location: College Station, TX

Posts: 221

Likes: 0

Received 0 Likes

on

0 Posts

To shim or not -

New slave, new Mcleod Single disc, turned Spec flywheel (not some sort of super secret setup, stuff laying around). Measured distance of 0.29in, assembled and bled some. Soft pedal, slight pressure at floor. bled it a bit and it didn't get better. Replaced the master with a new one, bled some more - still feels the same.

So, do i need to bleed some more - or am i to far for the throw out bearing? On paper it seems that everything should be fine?

Thanks,

James

New slave, new Mcleod Single disc, turned Spec flywheel (not some sort of super secret setup, stuff laying around). Measured distance of 0.29in, assembled and bled some. Soft pedal, slight pressure at floor. bled it a bit and it didn't get better. Replaced the master with a new one, bled some more - still feels the same.

So, do i need to bleed some more - or am i to far for the throw out bearing? On paper it seems that everything should be fine?

Thanks,

James

#68

i am in the process of installing a mcleod twin disc i got used. when i went to measure the gap i got .27 then i realized the bearing is supposed to be seated against the slave. now its like 2 inches?!

is that how the bearing is supposed to be when i measure it?

is that how the bearing is supposed to be when i measure it?

#69

how do i measure this?

and is there a way to measure a few more things? like faceplate of trany to polit bearing is X length minus cluctch and that gets me "A" length?

thanks

oh i have a mcleaod twin disk and was going to use stock gm slave with tick adjustmaster. so if anyone has done this please let me know if i need a shim. thanks

and is there a way to measure a few more things? like faceplate of trany to polit bearing is X length minus cluctch and that gets me "A" length?

thanks

oh i have a mcleaod twin disk and was going to use stock gm slave with tick adjustmaster. so if anyone has done this please let me know if i need a shim. thanks

#71

TECH Fanatic

iTrader: (41)

Join Date: Jul 2007

Location: Lancaster California

Posts: 1,431

Likes: 0

Received 0 Likes

on

0 Posts

I found this easier. I actually printed it up and took it with me.

I came out at about 3/16" or .187

http://www.ramclutches.com/Tech/Tech...%20Bearing.jpg

.

I came out at about 3/16" or .187

http://www.ramclutches.com/Tech/Tech...%20Bearing.jpg

.

#72

Launching!

iTrader: (4)

Join Date: Jun 2004

Location: College Station, TX

Posts: 221

Likes: 0

Received 0 Likes

on

0 Posts

I still don't understand why a shim is needed in most of these cases. I can understand the measuring, etc. but since the seal in the slave floats and the stroke of the pedal is such that you should not be over extending the slave even if the gap is up to 0.4 in or possibly more.

Why is a shim needed?

from another post i made -

I spoke with a person at 2 different clutch related companies, only to have them stumped when i got to specifics.

Why is a shim needed?

from another post i made -

OEM Master (3/4 in) - Un-installed, full stroke

Stroke 1.06 in *un-installed full range of travel

O.D. 0.75 in

Wet area 0.44 in2

Volume 0.47 in3

OEM Master (3/4 in) - installed stroke (doesn't bottom out in my car)

Stroke 0.75 in

O.D. 0.75 in

Wet area 0.44 in2

Volume 0.33 in3

OEM Slave

Range 0.96 in

O.D 1.86 in

I.D. 1.43 in

Wet area 1.11 in2

Volume 1.07 in3

Factory Master / Slave ratio 3.2 (3 strokes in car to fully move slave through travel.

So, why would a shim be needed?

Stroke 1.06 in *un-installed full range of travel

O.D. 0.75 in

Wet area 0.44 in2

Volume 0.47 in3

OEM Master (3/4 in) - installed stroke (doesn't bottom out in my car)

Stroke 0.75 in

O.D. 0.75 in

Wet area 0.44 in2

Volume 0.33 in3

OEM Slave

Range 0.96 in

O.D 1.86 in

I.D. 1.43 in

Wet area 1.11 in2

Volume 1.07 in3

Factory Master / Slave ratio 3.2 (3 strokes in car to fully move slave through travel.

So, why would a shim be needed?

#73

TECH Fanatic

iTrader: (41)

Join Date: Jul 2007

Location: Lancaster California

Posts: 1,431

Likes: 0

Received 0 Likes

on

0 Posts

It appears that shims are needed for some aftermarket clutches.

The geometry and dimensions are sometimes different.

There really is no reason for a stock clutch to need a shim because the stack height should usually be more consistant. With that said the slave was designed around the stock Luk clutches. So was the master for that matter.

Even with the correct stack height... anything other than the stock LS1 or LS6 clutch usually has disengagement and peddle issues. This isn't because of dimensions, it's because the stock master cylinder is to weak to disengage most clutches with higher pressure.

The Tick m/c is a breath of fresh air. Thier billet bracket fitted to a Tilton cylinder is just what we needed.

After being plagued with clutch issues for years it seems Tick was aware of the inherent hydraulic weakness and came up with a solution.

.

The geometry and dimensions are sometimes different.

There really is no reason for a stock clutch to need a shim because the stack height should usually be more consistant. With that said the slave was designed around the stock Luk clutches. So was the master for that matter.

Even with the correct stack height... anything other than the stock LS1 or LS6 clutch usually has disengagement and peddle issues. This isn't because of dimensions, it's because the stock master cylinder is to weak to disengage most clutches with higher pressure.

The Tick m/c is a breath of fresh air. Thier billet bracket fitted to a Tilton cylinder is just what we needed.

After being plagued with clutch issues for years it seems Tick was aware of the inherent hydraulic weakness and came up with a solution.

.

#74

Staging Lane

iTrader: (14)

Join Date: Jun 2007

Location: Sierra Vista, Arizona

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

I took my measurements according to everything i have read. and i am at 3/16s air gap. meaning i am 1/16 too much. What should i do. this has a monster clutch btw and a tick rebuild in it. any help would be appreciated. thank you.

#80

Teching In

Join Date: May 2008

Location: Reynoldsburg, Ohio

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

I am stumped at this point. I have a 00 Trans Am, stock clutch with 93K miles that started losing it's pedal at the end of the 1/4 and would be extremely weak but the pedal would come back. I was told that it was the clutch so I got a used Ram twin disk, aluminum flywheel, new ram master cylinder and new slave cylinder. I installed in all with out taking a measurement for the gap because I never heard of shimming the slave before.

After installing everything the car is hard to shift into any gear upon start up and impossible to go into reverse. If I key it up without starting it goes into each gear and reverse fine. If I drive it I have to force it into each gear harder than normal but after driving it a little ways I can shift into reverse. I though that it could be the fluid so I re-bled the system and put in DOT 4. Still have the issue and then came across this thread and I figured that it may need shimmed because when the car is stopped and in the process of putting it into 1st gear, the car will start to roll forward, start to put it into reverse and the car will roll backwards. It seems like the slave is not not fully disengaging the clutch.

I took the trans back out to measure for a shim and I get a negative number. the clutch measures 1.85 and the slave/trans measures 1.98. The clutch disks were thick and seemed to have plenty of life left so what could be causing the issue, any ideas?

After installing everything the car is hard to shift into any gear upon start up and impossible to go into reverse. If I key it up without starting it goes into each gear and reverse fine. If I drive it I have to force it into each gear harder than normal but after driving it a little ways I can shift into reverse. I though that it could be the fluid so I re-bled the system and put in DOT 4. Still have the issue and then came across this thread and I figured that it may need shimmed because when the car is stopped and in the process of putting it into 1st gear, the car will start to roll forward, start to put it into reverse and the car will roll backwards. It seems like the slave is not not fully disengaging the clutch.

I took the trans back out to measure for a shim and I get a negative number. the clutch measures 1.85 and the slave/trans measures 1.98. The clutch disks were thick and seemed to have plenty of life left so what could be causing the issue, any ideas?