Clutch dragging on flywheel and pressure plate

#1

Teching In

Thread Starter

iTrader: (5)

Join Date: Feb 2011

Location: San Diego, CA

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

This is on a LS1 swapped Porsche 944 Turbo, but the basic components are all from a C5 Vette.

LS1

C5 2-pc bell housing

C5 throwout bearing

Spec Stage 2 clutch package (disc and pressure plate)

Spec aluminum flywheel

Wilwood master cylinder; i have tried multiple sizes, currently i have the largest made (.8125" bore / displaces .71cu in).

Now the issue is i am having alot of trouble getting the car into gear at a stop, 1st is extremely difficult to engage and reverse nearly impossible. I pulled the bell housing inspection cover and noticed the disc will drag on either the flywheel or pressure plate depending on some variables, mostly if the car is nose up or nose down on an incline. With the disc dragging, it causes the torque tube to spin continuously even with the clutch pedal depressed, this is the cause of my shifting issues.

I pressed the disc up against the pressure plate and measured the air gap between the disc and flywheel with feeler gauges. I got around .049" or about 1.25mm gap between the two. Now mind you, that would leave just .025" or .625mm gap between the disc, pressure plate and flywheel assuming the disc stays perfectly centered.

Now the shop that installed the engine for me also did the clutch; they measured everything as per Spec's instructions and said it did not require the shim. Now i reckon the shim should have been installed and even questioned them on this as i took my own measurements previously which said it required the shim. I trusted what they had said though...

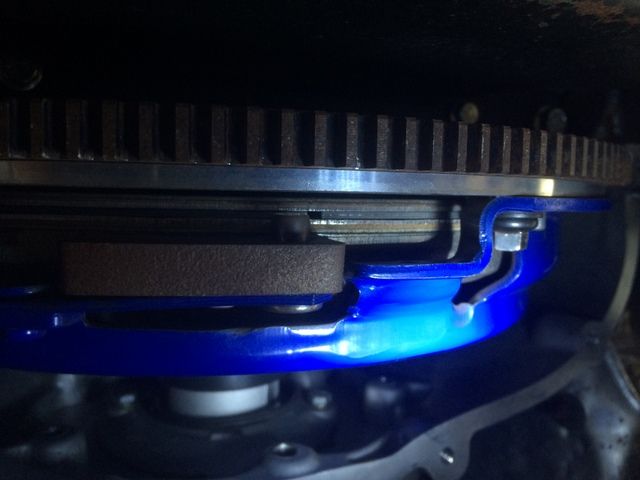

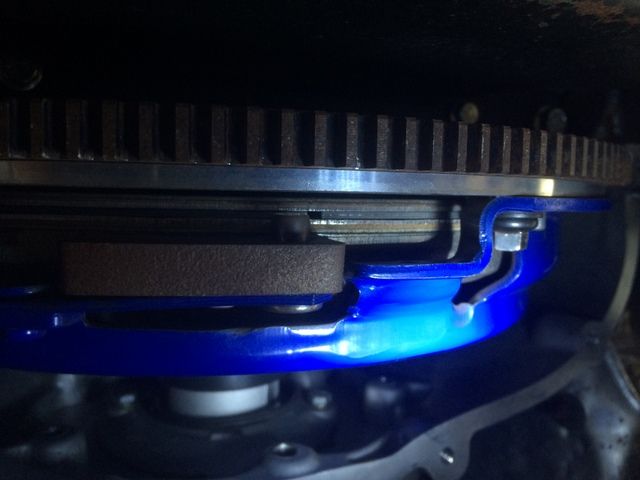

Here you can see the disc dragging on the pressure plate..

The Spec shim provided is .115" thick, so with that installed i should see around .164" of total gap with the disc resting on the pressure plate, that is over 3x the gap i get now which i would guess would cure the issues i am having.

Now i guess my question is how much of a gap should i see between the disc and flywheel / pressure plate assuming everything is setup correctly?

Also is their any risk of over extending the pressure plate?

LS1

C5 2-pc bell housing

C5 throwout bearing

Spec Stage 2 clutch package (disc and pressure plate)

Spec aluminum flywheel

Wilwood master cylinder; i have tried multiple sizes, currently i have the largest made (.8125" bore / displaces .71cu in).

Now the issue is i am having alot of trouble getting the car into gear at a stop, 1st is extremely difficult to engage and reverse nearly impossible. I pulled the bell housing inspection cover and noticed the disc will drag on either the flywheel or pressure plate depending on some variables, mostly if the car is nose up or nose down on an incline. With the disc dragging, it causes the torque tube to spin continuously even with the clutch pedal depressed, this is the cause of my shifting issues.

I pressed the disc up against the pressure plate and measured the air gap between the disc and flywheel with feeler gauges. I got around .049" or about 1.25mm gap between the two. Now mind you, that would leave just .025" or .625mm gap between the disc, pressure plate and flywheel assuming the disc stays perfectly centered.

Now the shop that installed the engine for me also did the clutch; they measured everything as per Spec's instructions and said it did not require the shim. Now i reckon the shim should have been installed and even questioned them on this as i took my own measurements previously which said it required the shim. I trusted what they had said though...

Here you can see the disc dragging on the pressure plate..

The Spec shim provided is .115" thick, so with that installed i should see around .164" of total gap with the disc resting on the pressure plate, that is over 3x the gap i get now which i would guess would cure the issues i am having.

Now i guess my question is how much of a gap should i see between the disc and flywheel / pressure plate assuming everything is setup correctly?

Also is their any risk of over extending the pressure plate?

#2

TECH Addict

iTrader: (14)

I'm not familiar with the c5 trans but they should have installed the supplied shim. I highly doubt they measured anything and just had a technician who has done clutches "a million times". Toss everything in.

The shim places the slave closer to the pressure plate so it can apply full pressure to it and release the clutch. Call your shop, they need to re do the job on their dollar for being reckless

The shim places the slave closer to the pressure plate so it can apply full pressure to it and release the clutch. Call your shop, they need to re do the job on their dollar for being reckless

#4

Teching In

Thread Starter

iTrader: (5)

Join Date: Feb 2011

Location: San Diego, CA

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

To follow up with this;

Shop remeasured for the shim and again looks like it was not really needed. They installed the shim anyhow and the problem still persists.

Basically with the engine running, the driveshaft will continue to spin even with the clutch depressed. We are sort of at a loss right now. The last things we can think of are a bent / damaged clutch disc or perhaps an issue with the pilot bearing or pilot bearing adapter required for my application in the crank.

Shop remeasured for the shim and again looks like it was not really needed. They installed the shim anyhow and the problem still persists.

Basically with the engine running, the driveshaft will continue to spin even with the clutch depressed. We are sort of at a loss right now. The last things we can think of are a bent / damaged clutch disc or perhaps an issue with the pilot bearing or pilot bearing adapter required for my application in the crank.

#5

FormerVendor

iTrader: (15)

To follow up with this;

Shop remeasured for the shim and again looks like it was not really needed. They installed the shim anyhow and the problem still persists.

Basically with the engine running, the driveshaft will continue to spin even with the clutch depressed. We are sort of at a loss right now. The last things we can think of are a bent / damaged clutch disc or perhaps an issue with the pilot bearing or pilot bearing adapter required for my application in the crank.

Shop remeasured for the shim and again looks like it was not really needed. They installed the shim anyhow and the problem still persists.

Basically with the engine running, the driveshaft will continue to spin even with the clutch depressed. We are sort of at a loss right now. The last things we can think of are a bent / damaged clutch disc or perhaps an issue with the pilot bearing or pilot bearing adapter required for my application in the crank.

That said, give us a call and ask for Steve (817-750-2000). As long as you have a shop press I can walk you through diagnosing, measuring, and setting up the clutch to release properly on your application.

#6

Teching In

Thread Starter

iTrader: (5)

Join Date: Feb 2011

Location: San Diego, CA

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

Steve, appreciate your offer.

I am going to stop down at the shop on monday morning to discuss options. I am trying to make a track day on thursday but its not looking likely the car will be ready.

We are aware of the issues with adding a shim when its not needed, but we were basically out of ideas on what could be causing this. So it was done just to see what would happen.

I think this is going to be our plan of attack;

-Inspect pilot bearing and adapter

-Inspect input shaft splines

-Inspect clutch disc hub; perhaps spines are damaged

-Check clutch disc is true

-Check pressure plate for damage

I am currently using a Spec stage 2 disc (kevlar friction material). I have a brand new stage 1 disc i might try and swap in instead also.

I am going to stop down at the shop on monday morning to discuss options. I am trying to make a track day on thursday but its not looking likely the car will be ready.

We are aware of the issues with adding a shim when its not needed, but we were basically out of ideas on what could be causing this. So it was done just to see what would happen.

I think this is going to be our plan of attack;

-Inspect pilot bearing and adapter

-Inspect input shaft splines

-Inspect clutch disc hub; perhaps spines are damaged

-Check clutch disc is true

-Check pressure plate for damage

I am currently using a Spec stage 2 disc (kevlar friction material). I have a brand new stage 1 disc i might try and swap in instead also.