Updated: THREE trips to TNT with pics + vids

#364

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

I forgot all about the TFS bracket deal.

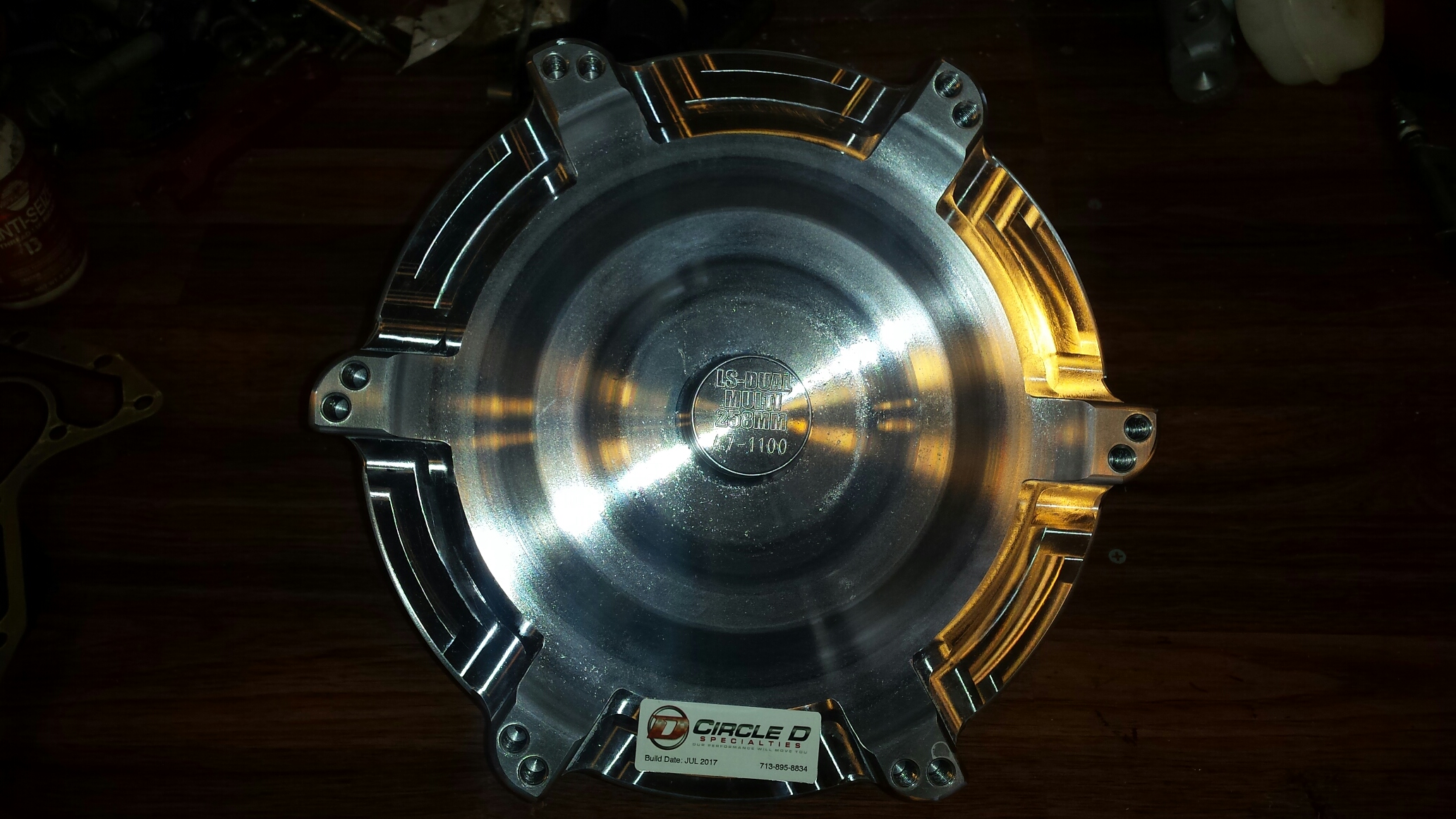

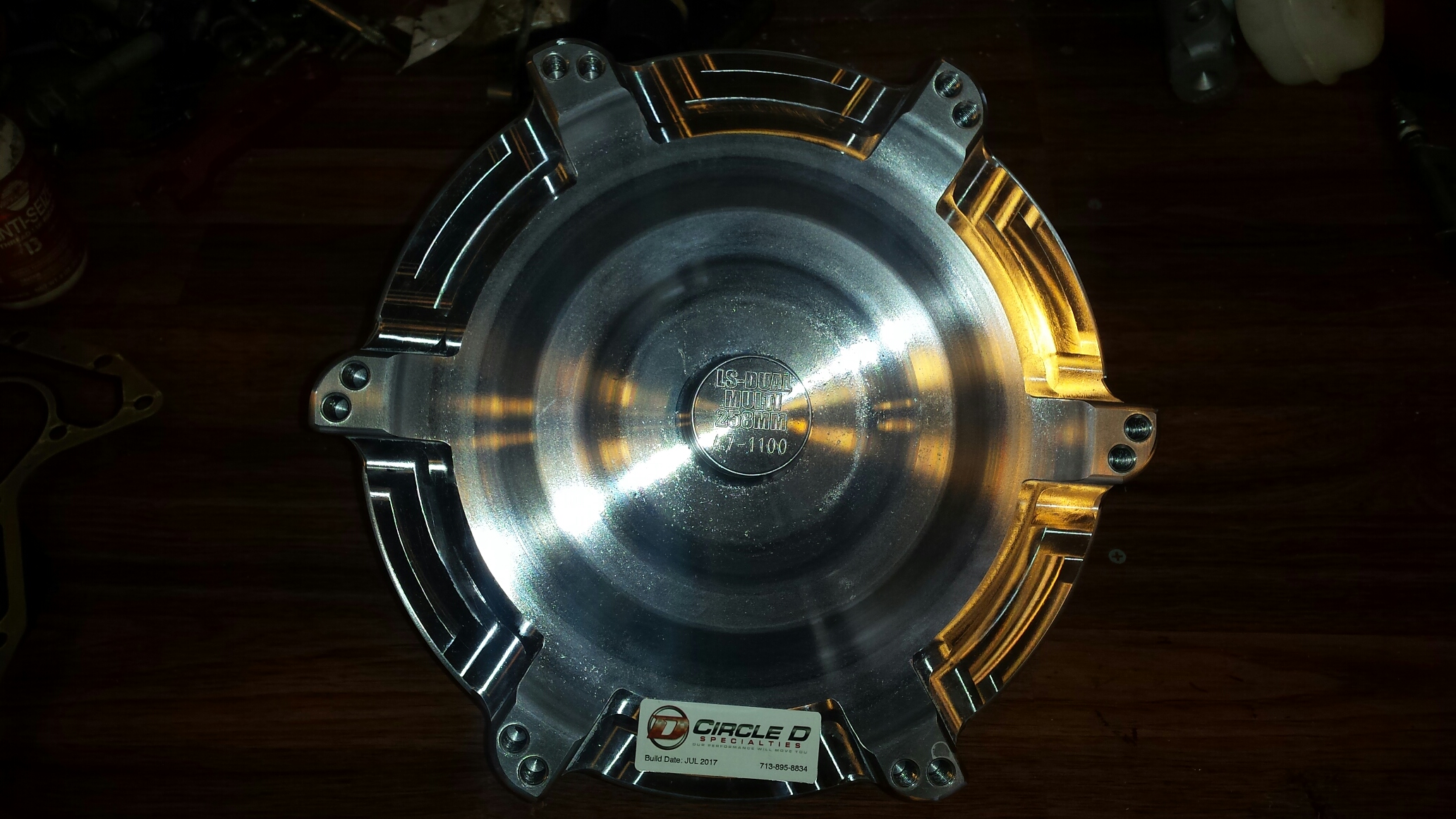

Got a lot done but only a few pics. First, the converter showed up just like circle D promised. I wanna talk about this converter for a second, as its not listed on their website. Here's a link to it:

http://www.circledspecialties.com/p-...converter.aspx

Chris at circle D spec'd this one to foot brake to around 3500 and should give a nice hard launch for use without a transbrake since I dont have one. When ask for more clarity, here was his response:

This converter has the D stator.

It has dual x6 patterns, so it works with virtually any flexplate.

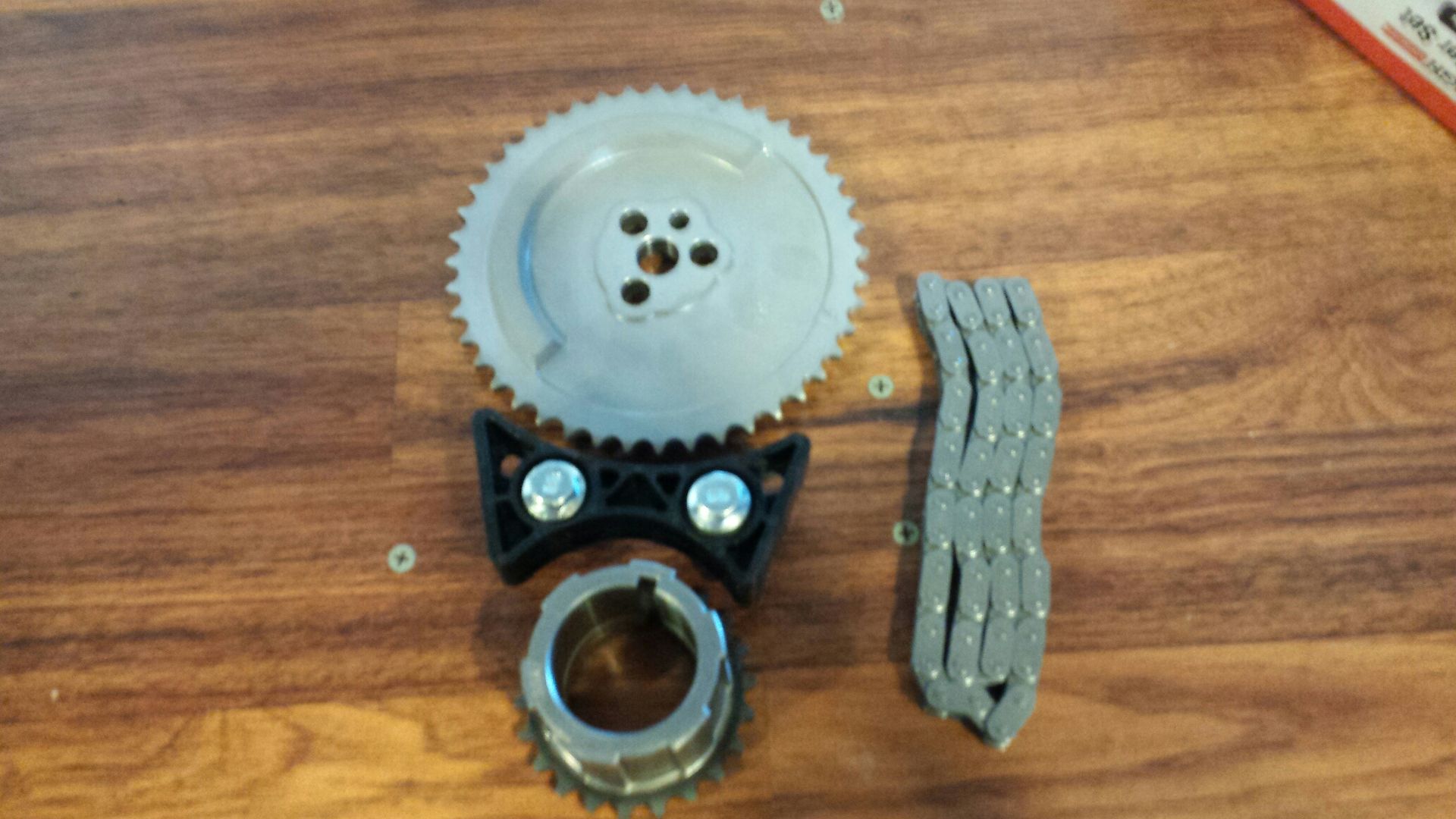

So with the converter here I couldnt wait to get it bolted up. So I started on the motor, I did a front cover seal, then installed the crank pulley. I went ahead and painted the water pump and manifolds black and bolted them on. I also added the motor mounts and plugs (gapped at 22) and wires. Then I lifted the motor up off the engine stand and replaced the rear cover seal and rear main seal. Flexplate bolted up perfect. I mated the trans and motor together and called it a day.

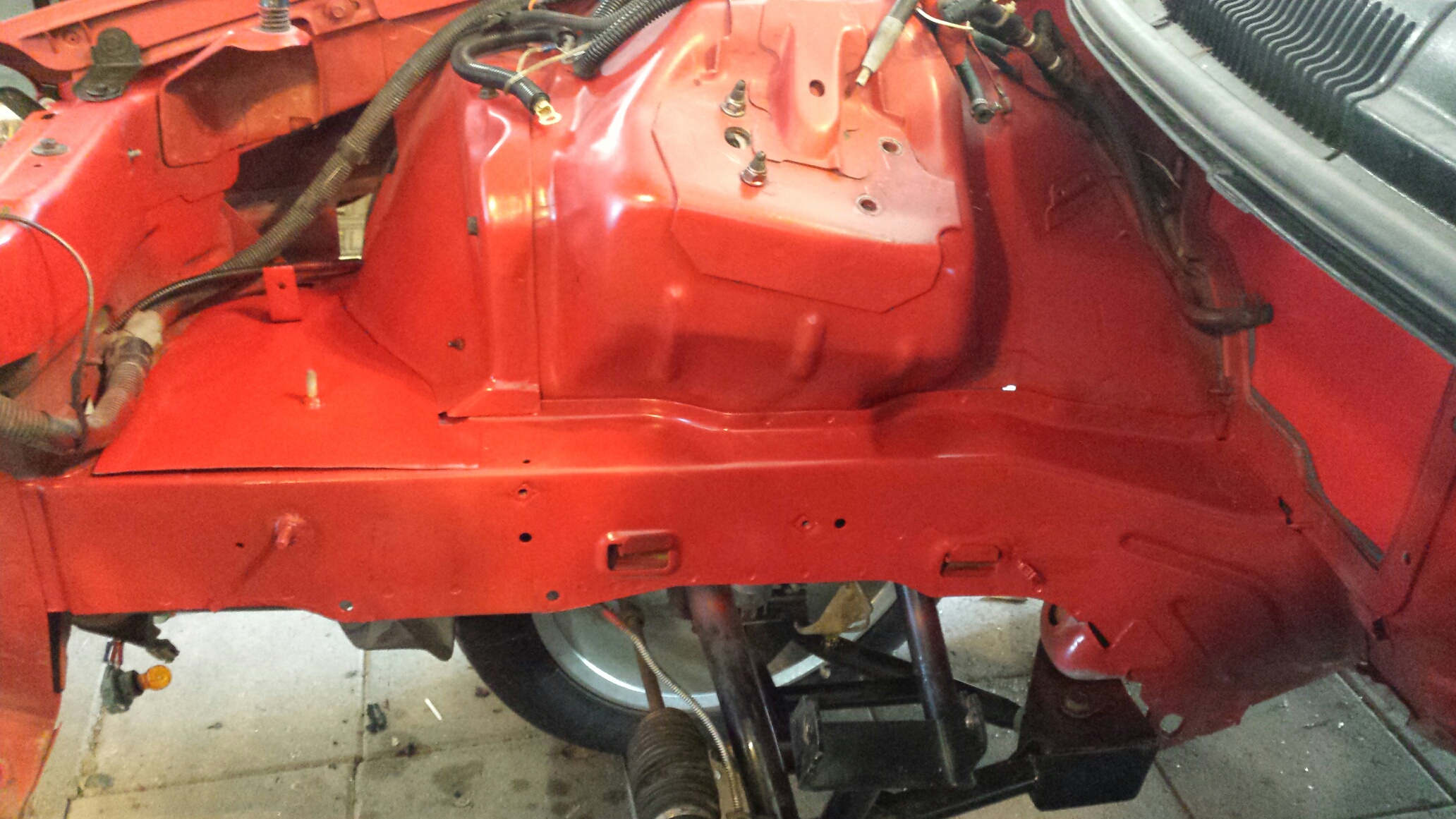

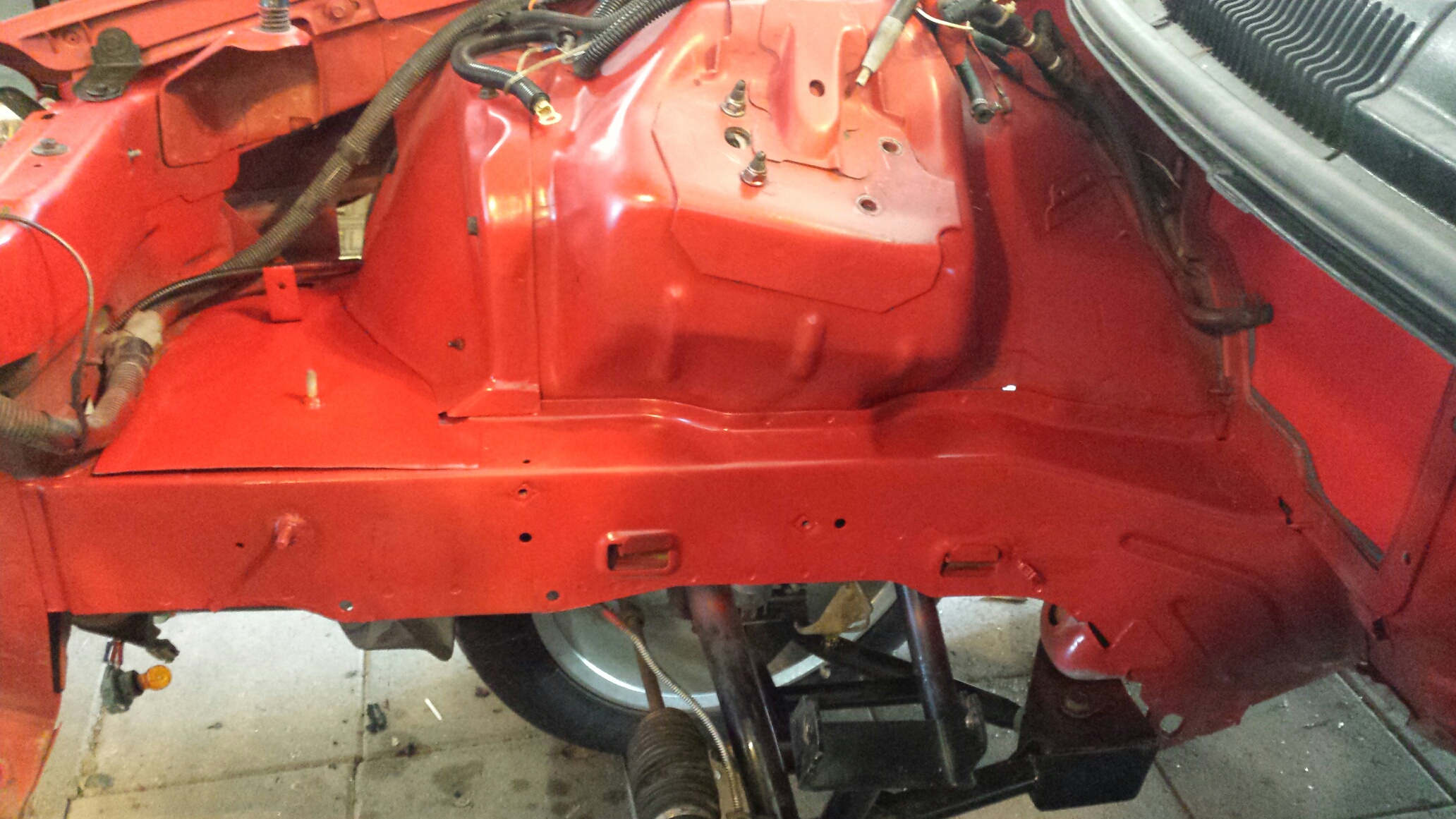

You can refer a few pics up to how dirty under the hood was. Well after some cleaning I realized it wasnt all coming clean and the discoloration that was near the battery tray was pretty bad. I had some Duplicolor engine enamel in red so I took a chance to see if it matched, and it did. Also, I started on a sheet metal tray to go where the battery was to hold the coolant tank and shield the heat that will be coming from the bumper exhaust. You can see a small bracket bolted to the radiator support in this pic that holds the top of the coolant tank. More on that when i finish it. Painted both inner frame rails, battery area, and firewall.

Got a lot done but only a few pics. First, the converter showed up just like circle D promised. I wanna talk about this converter for a second, as its not listed on their website. Here's a link to it:

http://www.circledspecialties.com/p-...converter.aspx

Chris at circle D spec'd this one to foot brake to around 3500 and should give a nice hard launch for use without a transbrake since I dont have one. When ask for more clarity, here was his response:

Originally Posted by Circle-D

There are 3 common stators for the 258mm core. We assign each of them letters. A, B, and C. We generally use the "A" stator in our bigger cube turbo builds or nitrous builds. It's the tightest of the bunch. The "B" stator has been our go-to for most turbo setups as it has a nice footbrake down low for spooling. The "C" stator is one we generally reserve for PD blown applications.

The "D" stator is a modified "C" stator. We throw it in our CNC and machine the fins for max effort footbrake turbo cars. It works great because of it's high fin count (21) and our custom angles made available by the CNC. It's not on our website, but we have been using it for a while now with great results. It's all a bit confusing, but it's kind of meant to be:

The "D" stator is a modified "C" stator. We throw it in our CNC and machine the fins for max effort footbrake turbo cars. It works great because of it's high fin count (21) and our custom angles made available by the CNC. It's not on our website, but we have been using it for a while now with great results. It's all a bit confusing, but it's kind of meant to be:

It has dual x6 patterns, so it works with virtually any flexplate.

So with the converter here I couldnt wait to get it bolted up. So I started on the motor, I did a front cover seal, then installed the crank pulley. I went ahead and painted the water pump and manifolds black and bolted them on. I also added the motor mounts and plugs (gapped at 22) and wires. Then I lifted the motor up off the engine stand and replaced the rear cover seal and rear main seal. Flexplate bolted up perfect. I mated the trans and motor together and called it a day.

You can refer a few pics up to how dirty under the hood was. Well after some cleaning I realized it wasnt all coming clean and the discoloration that was near the battery tray was pretty bad. I had some Duplicolor engine enamel in red so I took a chance to see if it matched, and it did. Also, I started on a sheet metal tray to go where the battery was to hold the coolant tank and shield the heat that will be coming from the bumper exhaust. You can see a small bracket bolted to the radiator support in this pic that holds the top of the coolant tank. More on that when i finish it. Painted both inner frame rails, battery area, and firewall.

#366

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

If you refer back to a pic of the battery area, there is a hole in the lower part, and I talked about wanting to make something to cover it. Well i traced the area out of cardboard and made a little sheet metal piece to cover the hole. I also welded a stud to it and the framerail. Here it is just sitting in place.

Bent an aluminum strap to go over the battery and it attaches to the studs i welded on.

Looking from the front...You see the short bracket i made for the top of the coolant tank, and i went ahead and bolted it to the car so i could swap it easily if my recovery tank changes at any point.

Looking from the passenger side.

Got the manual master mounted, pulled the pedals out and redrilled the hole 1" higher on the pedal bracket for more leverage. Not an enjoyable job at all. Also, not in the pic, I did bend up new brake lines but wont attach them yet due to the k member needing to come out one more time. I originally cut the center cowl out with the motor in the car....and i could only go so far back. I may go ahead and finish it now.

Got some stuff in, hotside wrap, fuel line clamps, copper collector gaskets, and a fitted waterpump heater delete.

And here's how she sits currently. Couple of things, i do still have the horns on the framerail, so i will be removing those, and a mysterious vacuum canister in the same area, no clue how i missed that over all these years, that's going away also. I will have a chance to work on it again mid/late week so my plan is, pull the k member back out and mount the engine on it. Then finish removing exhaust heat shields and stock fuel lines from the body, and make my cut by the transmission connector for clearance. If all that goes well I may go ahead and roll the motor and trans under the car and bolt them up.....

Bent an aluminum strap to go over the battery and it attaches to the studs i welded on.

Looking from the front...You see the short bracket i made for the top of the coolant tank, and i went ahead and bolted it to the car so i could swap it easily if my recovery tank changes at any point.

Looking from the passenger side.

Got the manual master mounted, pulled the pedals out and redrilled the hole 1" higher on the pedal bracket for more leverage. Not an enjoyable job at all. Also, not in the pic, I did bend up new brake lines but wont attach them yet due to the k member needing to come out one more time. I originally cut the center cowl out with the motor in the car....and i could only go so far back. I may go ahead and finish it now.

Got some stuff in, hotside wrap, fuel line clamps, copper collector gaskets, and a fitted waterpump heater delete.

And here's how she sits currently. Couple of things, i do still have the horns on the framerail, so i will be removing those, and a mysterious vacuum canister in the same area, no clue how i missed that over all these years, that's going away also. I will have a chance to work on it again mid/late week so my plan is, pull the k member back out and mount the engine on it. Then finish removing exhaust heat shields and stock fuel lines from the body, and make my cut by the transmission connector for clearance. If all that goes well I may go ahead and roll the motor and trans under the car and bolt them up.....

#367

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

First thing i needed to do was remove the master cylinder (after bending new lines) and bench bleed it for final install. This is the contraption I made to cycle the fluid back into the reservoir. It took about 20 full pumps to remove all air bubbles.

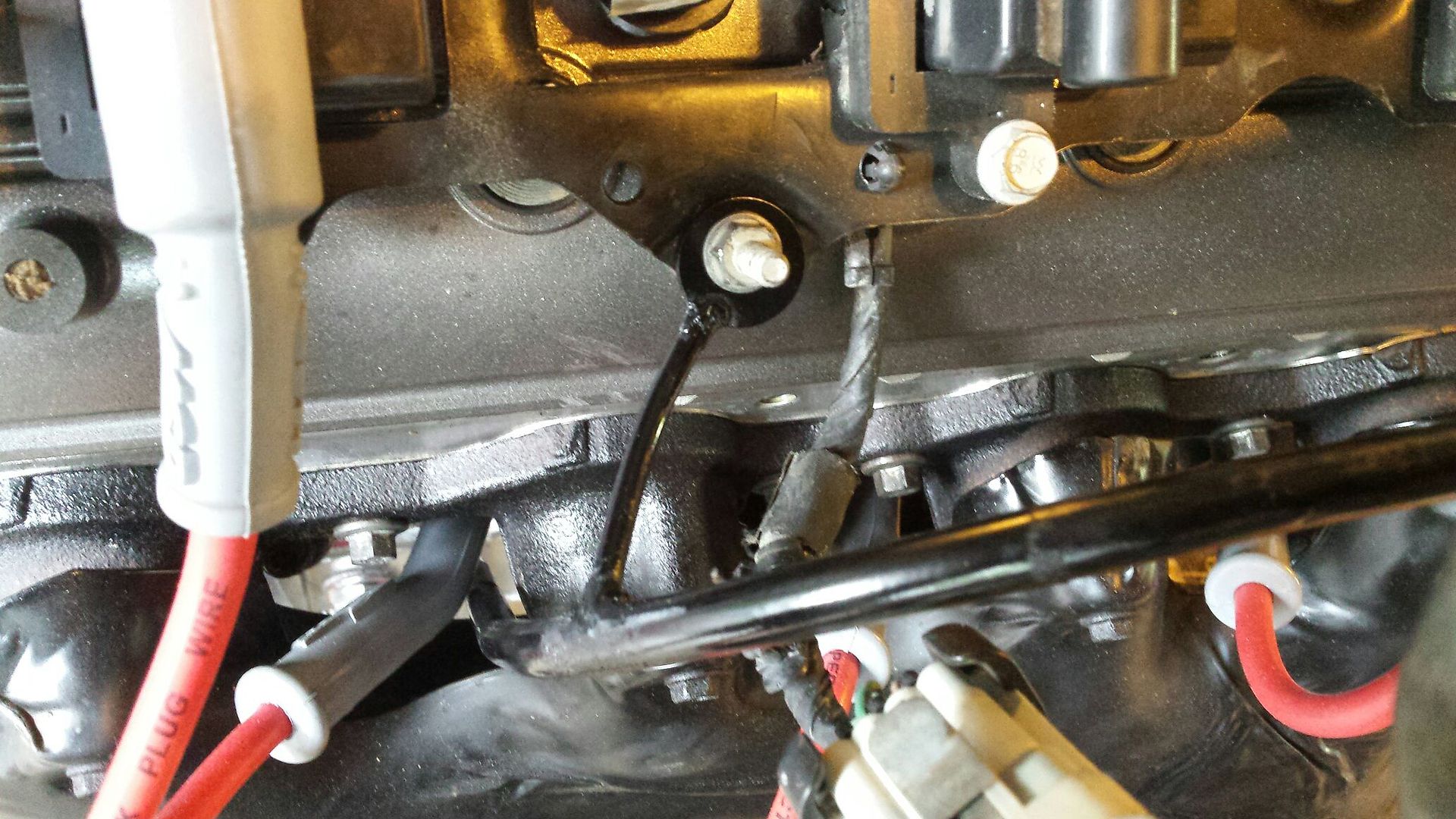

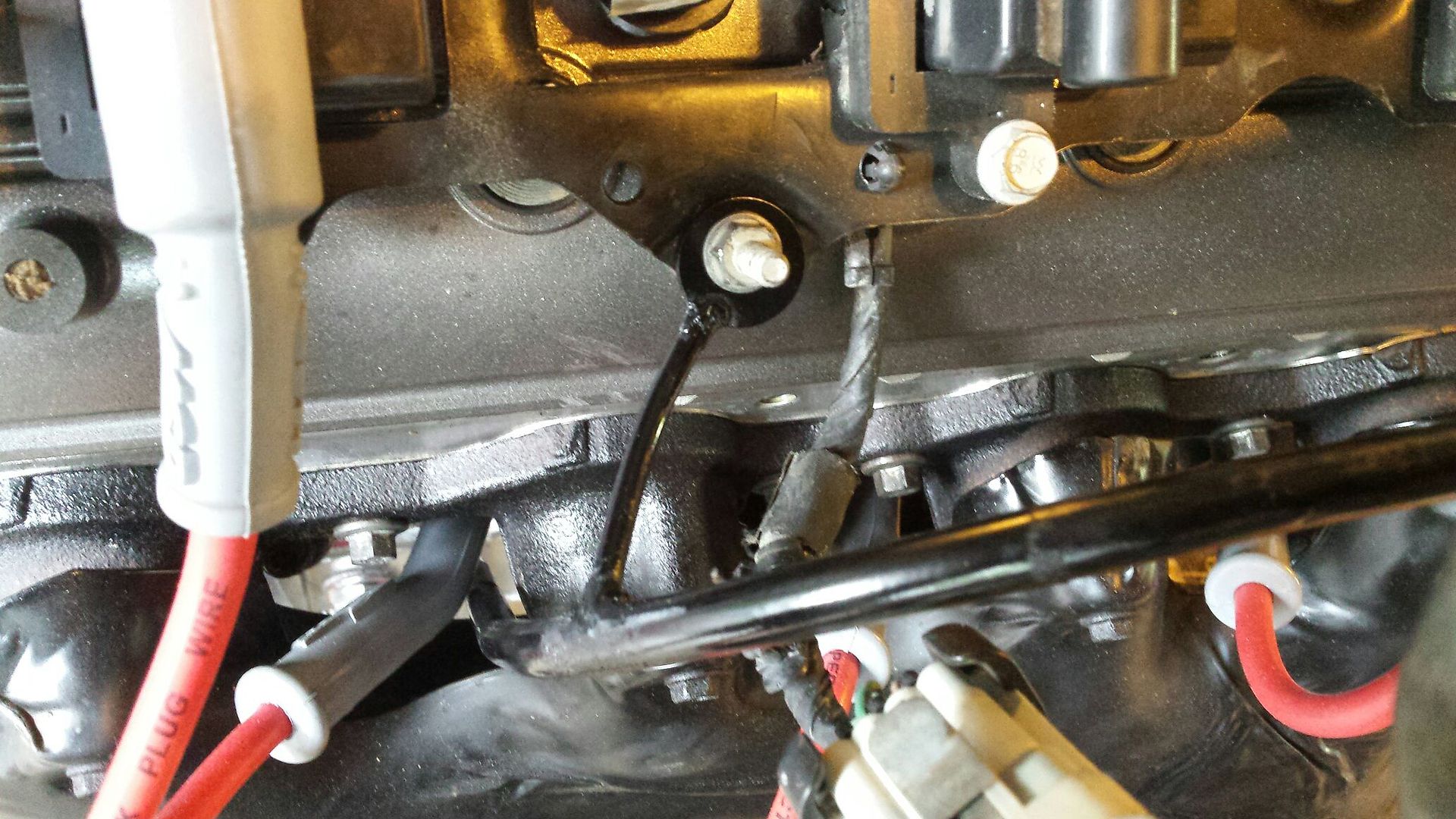

Not sure what happened to the oil dipstick bracket but all i had left was a tube with no way to stabilize it. I took a washer, and a small piece of (probably) 3/16th stainless rod, bent it, and welded them together to make a makeshift bracket that attaches to a coil pack bracket bolt.

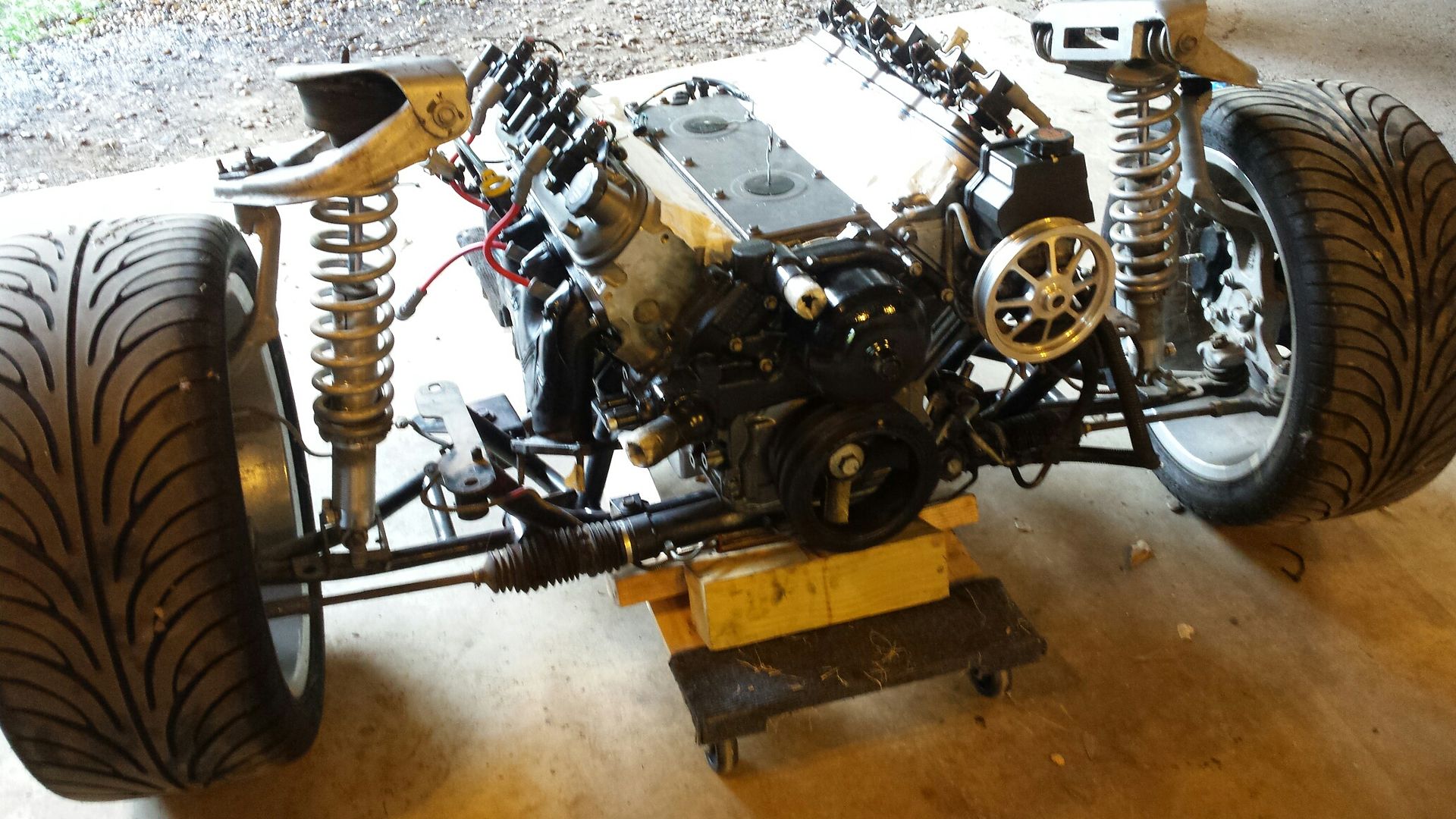

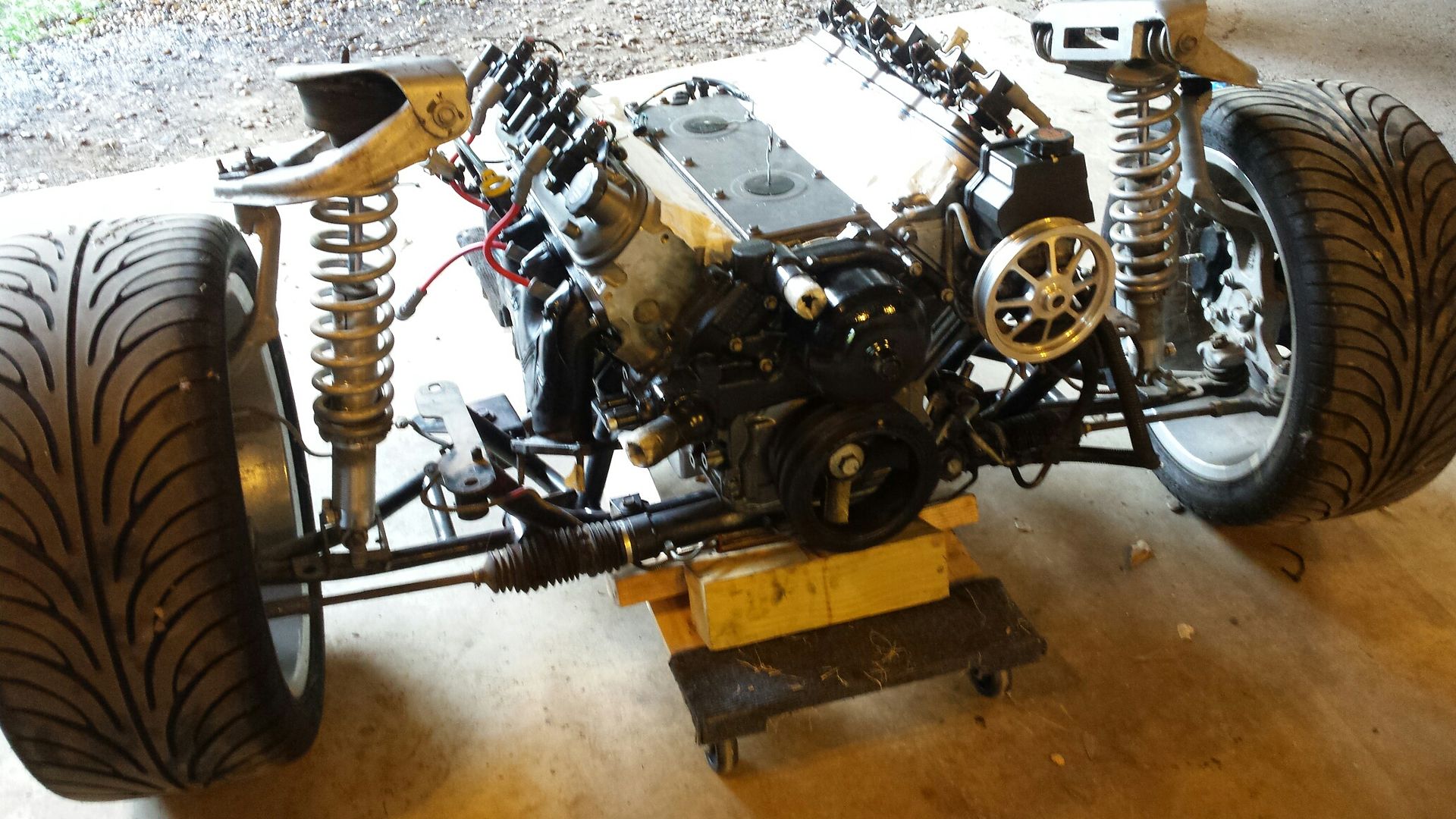

Dropped the motor on the k member

I originally took the wipers out and cut some of the cowl back (under the windshield). I did the best I could with the engine in the car. It was time consuming and I had to make a bunch of small cuts. Now that the engine is out I wasnt gonna waste the opportunity to complete the cut. My focus was the metal over the engine, and since i kept the plastic cowl cover, i have to leave some metal at the ends to support it. Here is what it looks like after we got through. This will make working on the top and rear of the engine so much easier.

Cut the floorboard for the trans plug and put some red paint on the cuts. Red brake lines never hurt nobody. This is required or you wont be able to plug the trans in.

Here is most of the stuff I removed from the car. The red is the cowl, the black brackets are for fog lights, horns on the left, then you have metal fuel line and metal exhaust shields. I threw this whole pile behind my wife's bushes in the back yard.

A few cuss words and a couple hours later.....

Not sure what happened to the oil dipstick bracket but all i had left was a tube with no way to stabilize it. I took a washer, and a small piece of (probably) 3/16th stainless rod, bent it, and welded them together to make a makeshift bracket that attaches to a coil pack bracket bolt.

Dropped the motor on the k member

I originally took the wipers out and cut some of the cowl back (under the windshield). I did the best I could with the engine in the car. It was time consuming and I had to make a bunch of small cuts. Now that the engine is out I wasnt gonna waste the opportunity to complete the cut. My focus was the metal over the engine, and since i kept the plastic cowl cover, i have to leave some metal at the ends to support it. Here is what it looks like after we got through. This will make working on the top and rear of the engine so much easier.

Cut the floorboard for the trans plug and put some red paint on the cuts. Red brake lines never hurt nobody. This is required or you wont be able to plug the trans in.

Here is most of the stuff I removed from the car. The red is the cowl, the black brackets are for fog lights, horns on the left, then you have metal fuel line and metal exhaust shields. I threw this whole pile behind my wife's bushes in the back yard.

A few cuss words and a couple hours later.....

Last edited by 01ssreda4; 07-29-2017 at 07:47 AM.

#371

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

Figured as i STILL dont have the turbo piping i would move to the rear of the car and get a few things done there. I dropped the fuel tank.......you can see in this pic the excess lines and charcoal canister. Yep you guessed it, thats all going away.

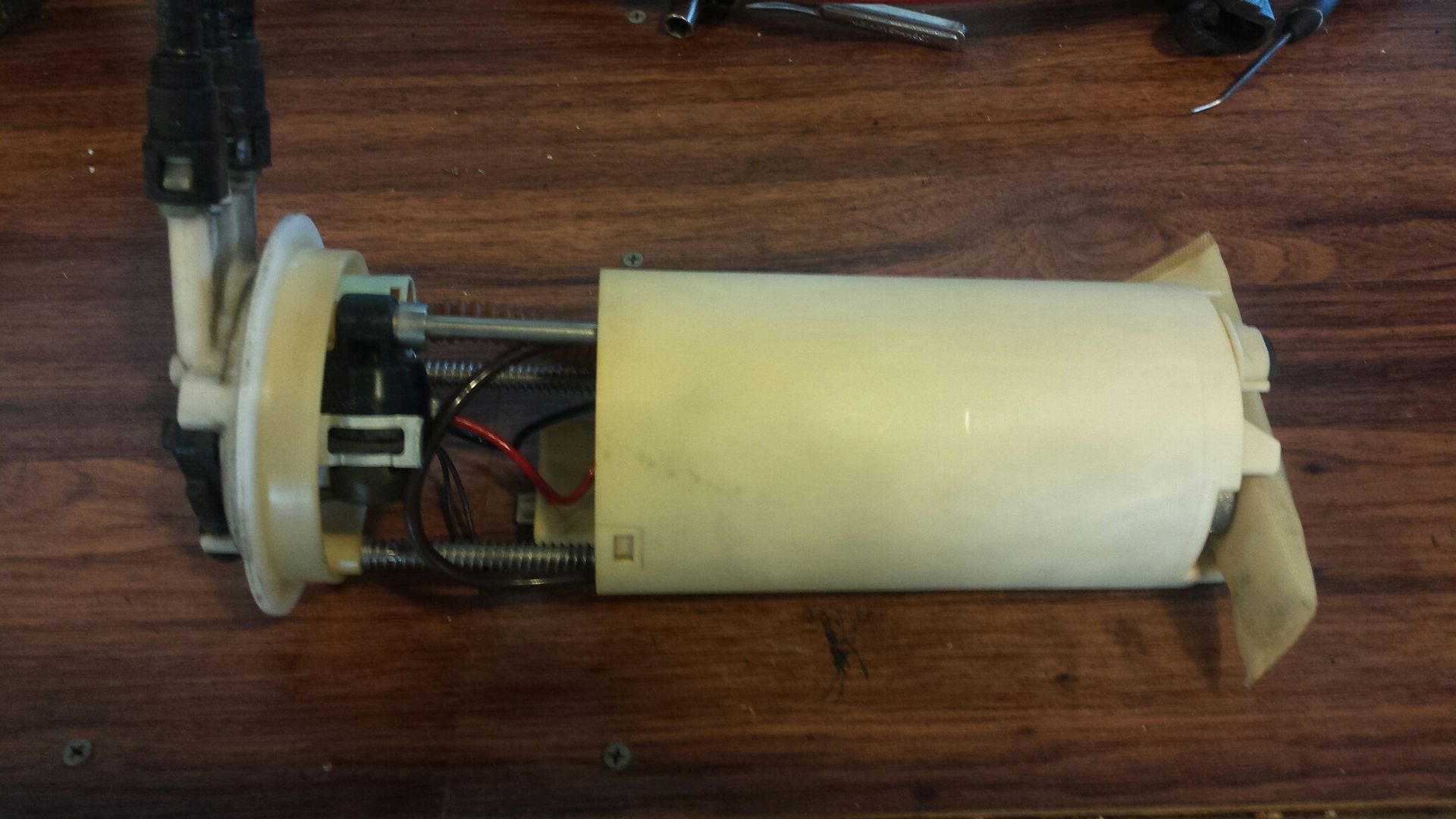

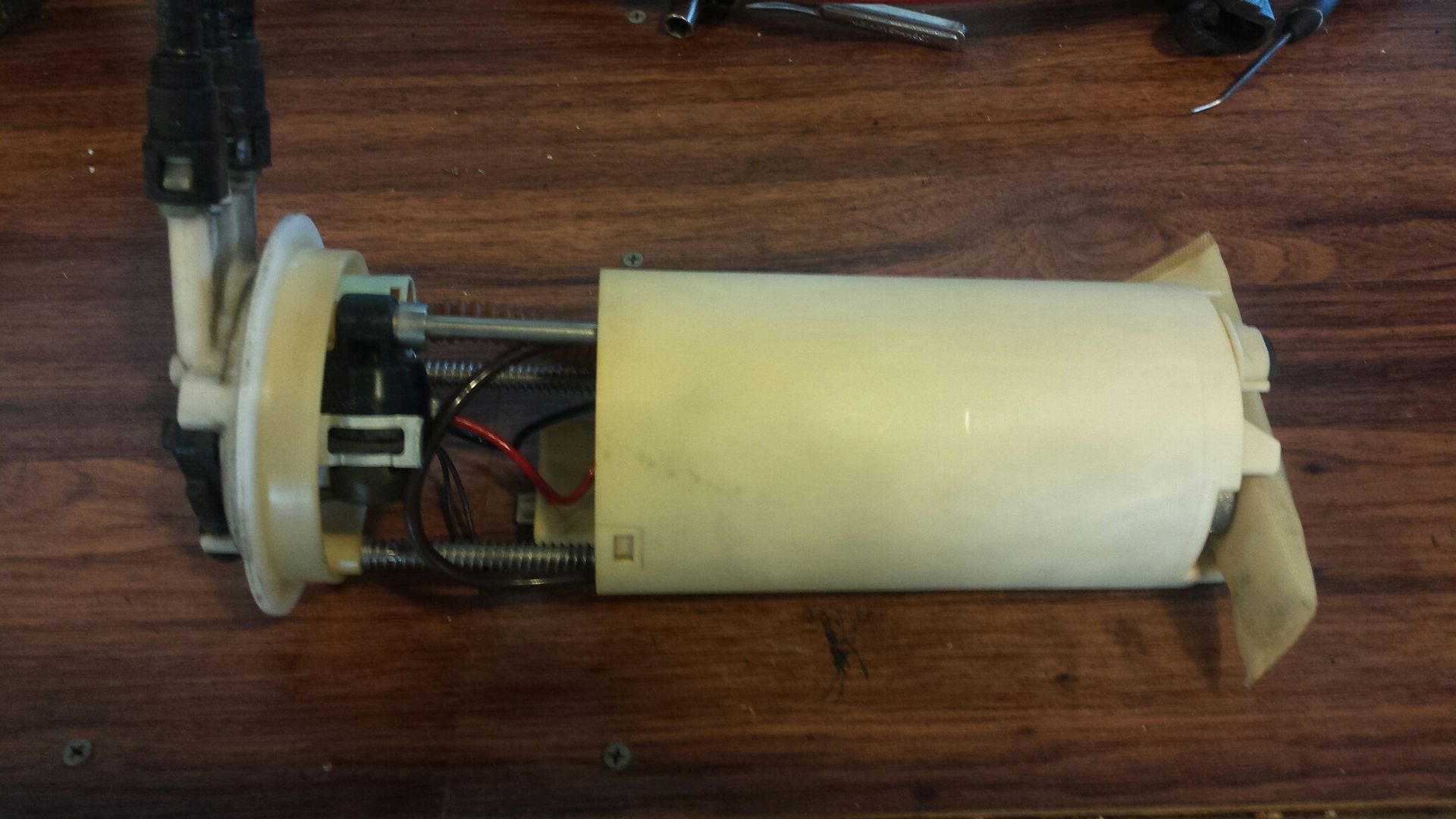

Stock bucket, and it has a Racetronix 255 pump installed. I had to remove the float assembly and transfer it to the dual pump setup. I was able to sell this locally on FB in like 4 hours!

Here's all the extra crap gone and the dual 450s installed. They were actually easier then I figured. This is basically ready to go back in the car.....but ah, not just yet, I've got something up my sleeve.

Here is the new PST forged yoke installed on my old DS, with the 4l60e yoke next to it for reference. Quick little mock up under the car seems its going to fit correctly.

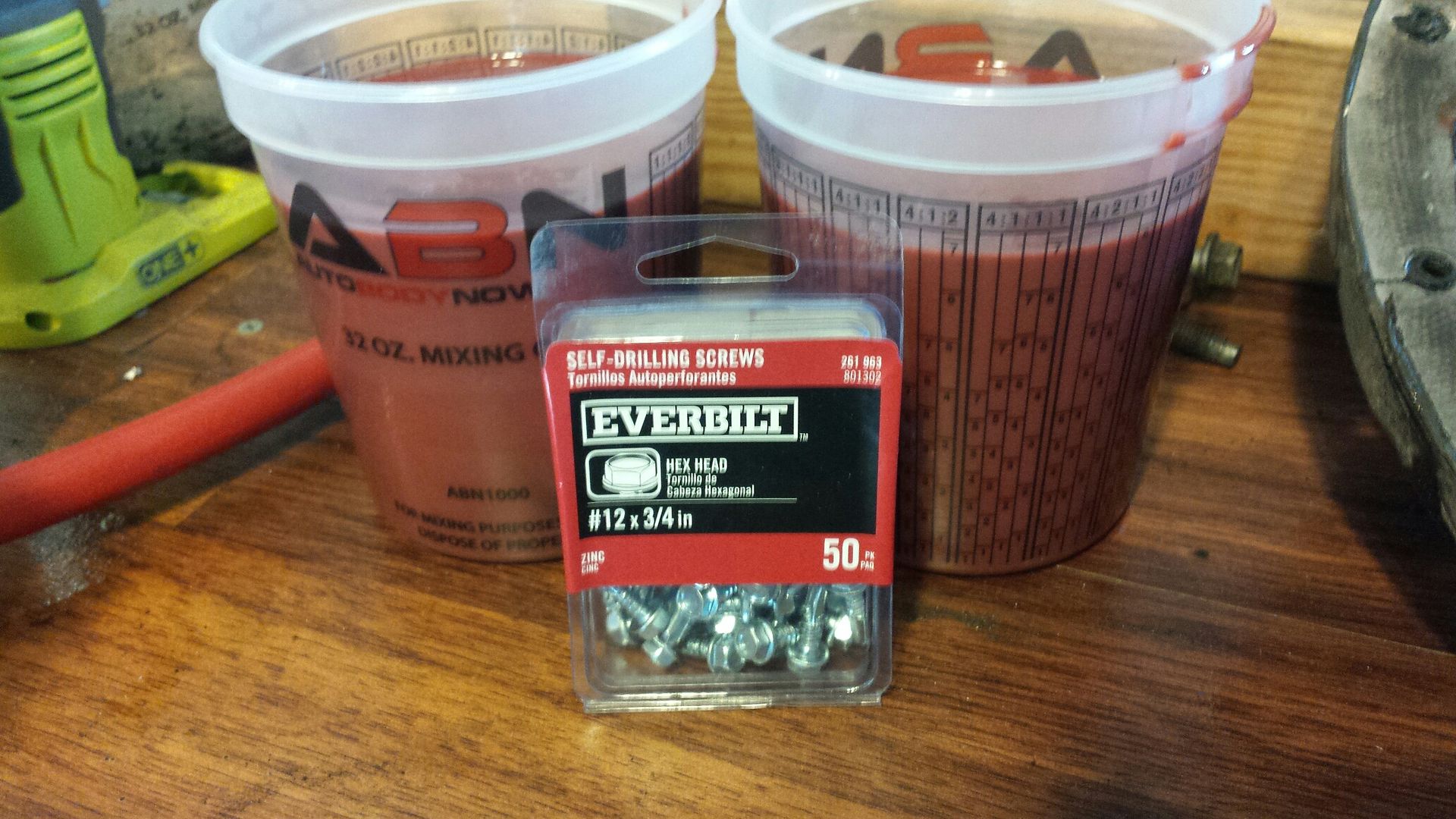

Went to home depot and picked up some screws that I think will work on the fuel line clamps, these should go right through the floor and hold well....but we shall see. Also, I drained the rear diff. That is redline shockproof oil I just put in it so I plan on reusing it since its $$.

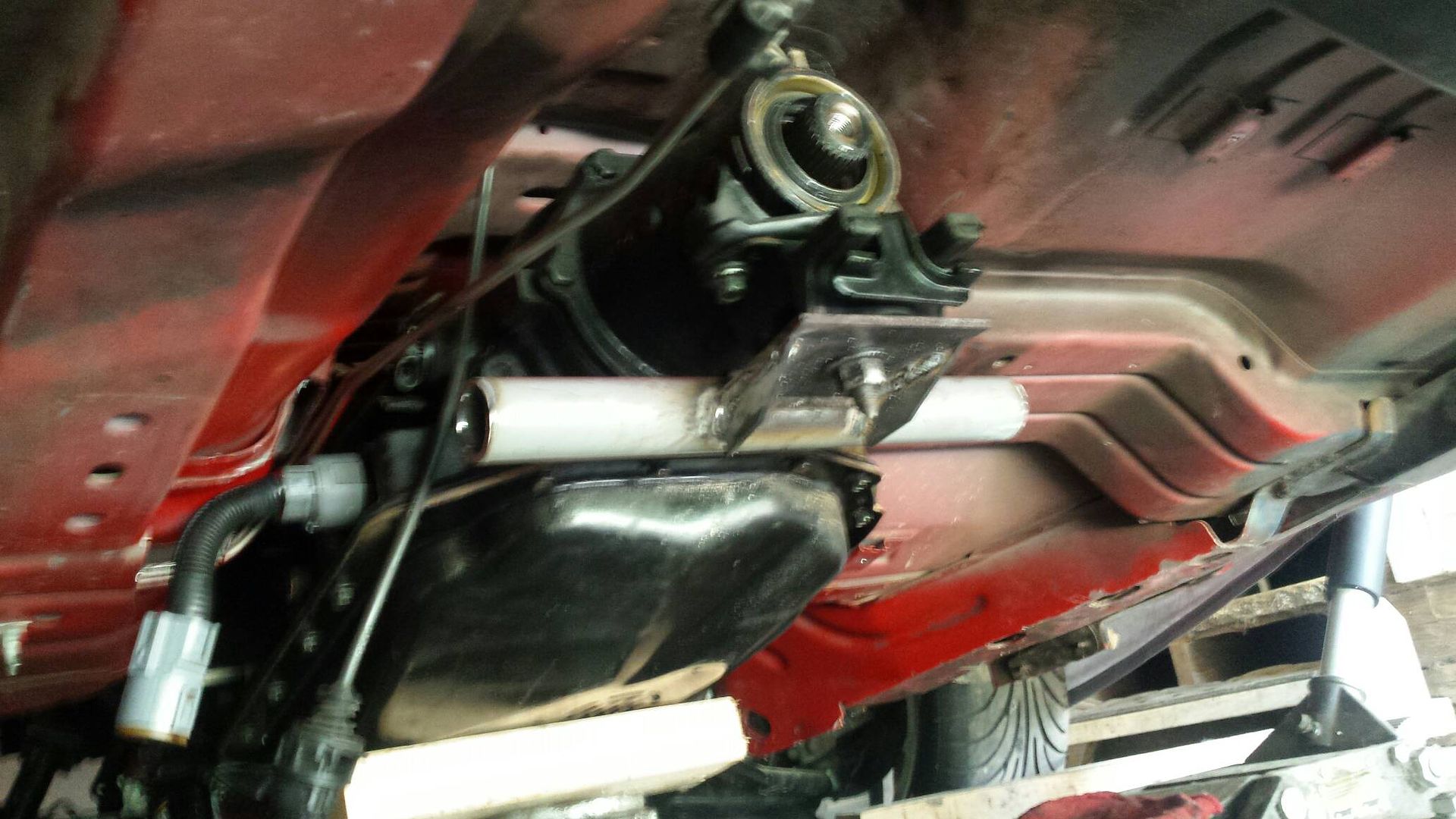

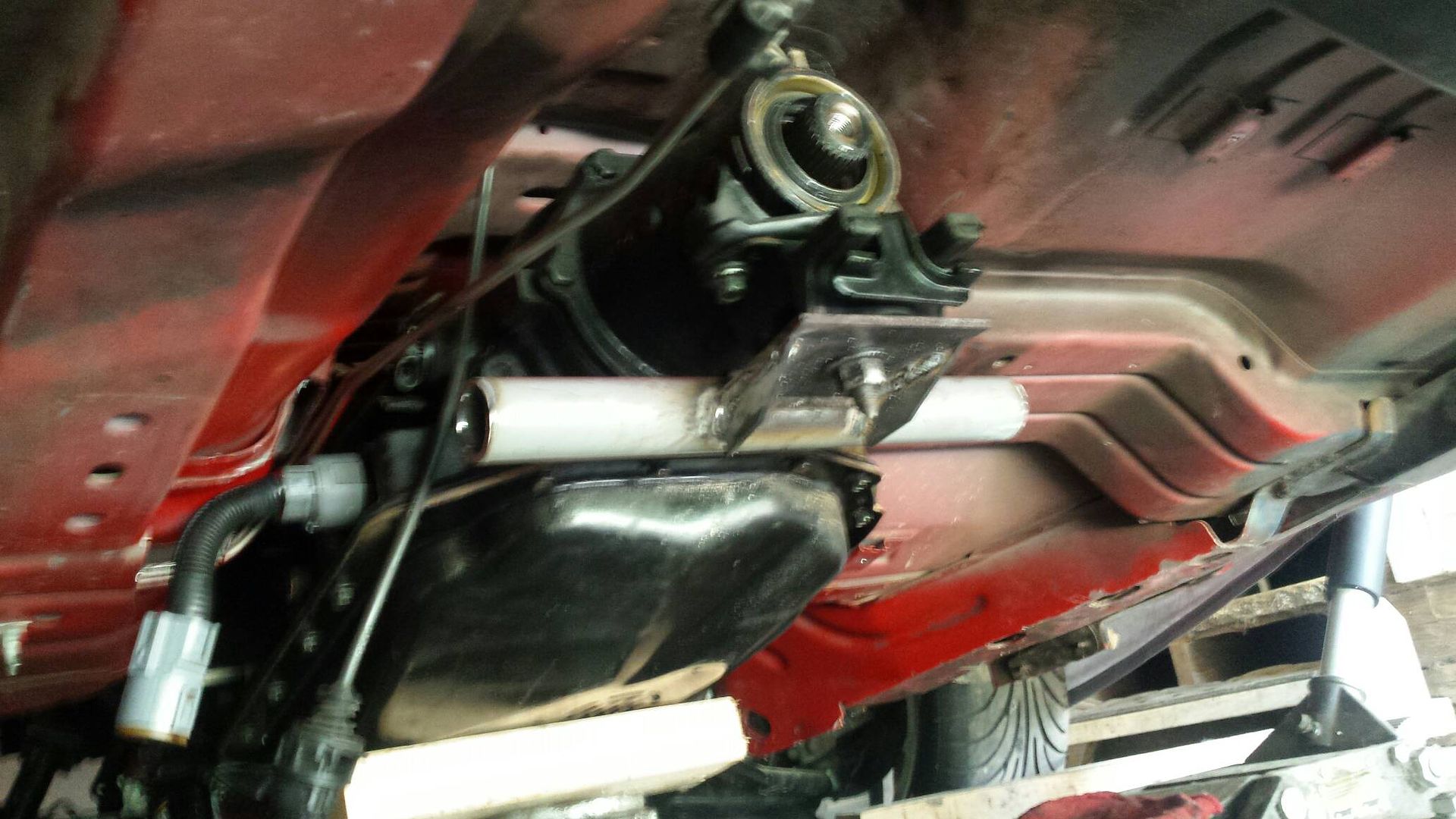

Here's where I stopped for the day. I also got the brake pedal rod installed, and adjusted so that I can go ahead and bleed these back brakes. Basically I am going to do a quick 4.10>3.73 gear swap. I had bought a new pinion seal but figured out yesterday I had no cover gasket and I'd like to replace the ring gear bolts, so I ordered those two things. Also, you can see the jack under the trans, the stock crossmember is nowhere close to working, and the rear oil port is almost against the floorpan in the tunnel. Since my cooler has 45 bends on it i ordered some 90s which will help, but Im still gonna have to alter the floor for the rear one and completely fab a crossmember from scratch. Stay tuned.

Stock bucket, and it has a Racetronix 255 pump installed. I had to remove the float assembly and transfer it to the dual pump setup. I was able to sell this locally on FB in like 4 hours!

Here's all the extra crap gone and the dual 450s installed. They were actually easier then I figured. This is basically ready to go back in the car.....but ah, not just yet, I've got something up my sleeve.

Here is the new PST forged yoke installed on my old DS, with the 4l60e yoke next to it for reference. Quick little mock up under the car seems its going to fit correctly.

Went to home depot and picked up some screws that I think will work on the fuel line clamps, these should go right through the floor and hold well....but we shall see. Also, I drained the rear diff. That is redline shockproof oil I just put in it so I plan on reusing it since its $$.

Here's where I stopped for the day. I also got the brake pedal rod installed, and adjusted so that I can go ahead and bleed these back brakes. Basically I am going to do a quick 4.10>3.73 gear swap. I had bought a new pinion seal but figured out yesterday I had no cover gasket and I'd like to replace the ring gear bolts, so I ordered those two things. Also, you can see the jack under the trans, the stock crossmember is nowhere close to working, and the rear oil port is almost against the floorpan in the tunnel. Since my cooler has 45 bends on it i ordered some 90s which will help, but Im still gonna have to alter the floor for the rear one and completely fab a crossmember from scratch. Stay tuned.

#372

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

Got some parts in, bottom left is the new ring gear bolts and cover gasket for the 12 bolt, bottom right is wideband o2 harness extension, top right is a fuel filter with the stainless washable element, left is the 3.73 gears I'm reinstalling.

Wasn't gonna buy a prefab crossmember to the tune of $180 dollars so I decided I'd make one. As I sat there thinking about material size, type, thickness I spied the driver door bar I pulled out earlier in the year. Its about 1.5" seemless steel tube with a decent wall thickness, that should do the trick and the best part is, it was zero dollars. I made a mount for the trans out of maybe 5/16 plate I had, then cut a 1 foot section of the door bar, welded them together and add small gussets under the plate for extra strength.....also, in this pic you can see the clearance and why i cut for the electrical connector.

Late evening pic (washout), but you get the idea of the finished product. I was going to make new sides plates where this bolts to the car but after looking at the stock crossmember I was like **** it i will just cut the ends off and make it work. In this pic you can see I used a small section to drop down vertically, then I hand notched the tubing to get a decent fit going back to the original 12" piece. Got the trans in place and this thing didnt budge as i set the weight down on it, it should be fine.

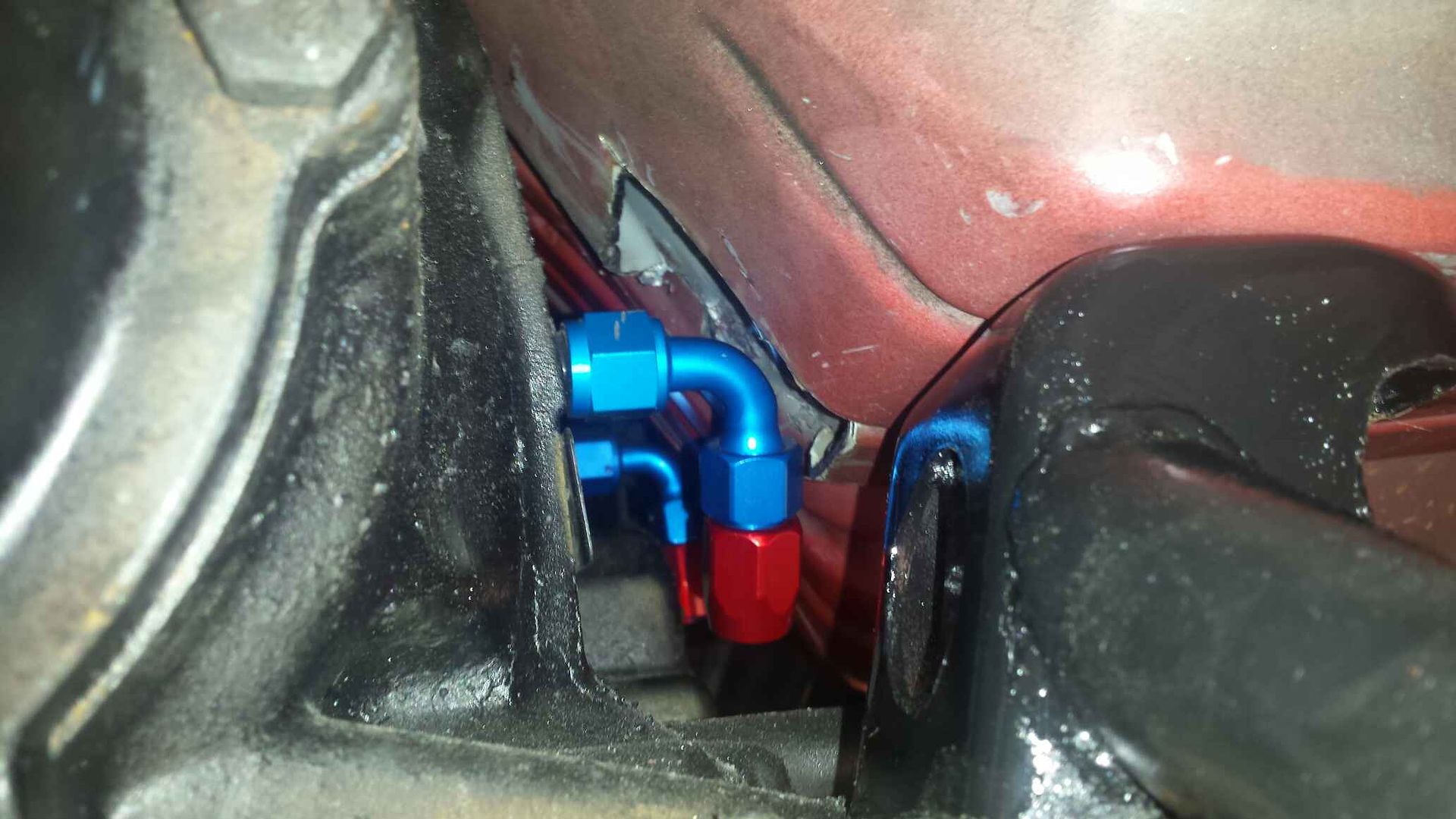

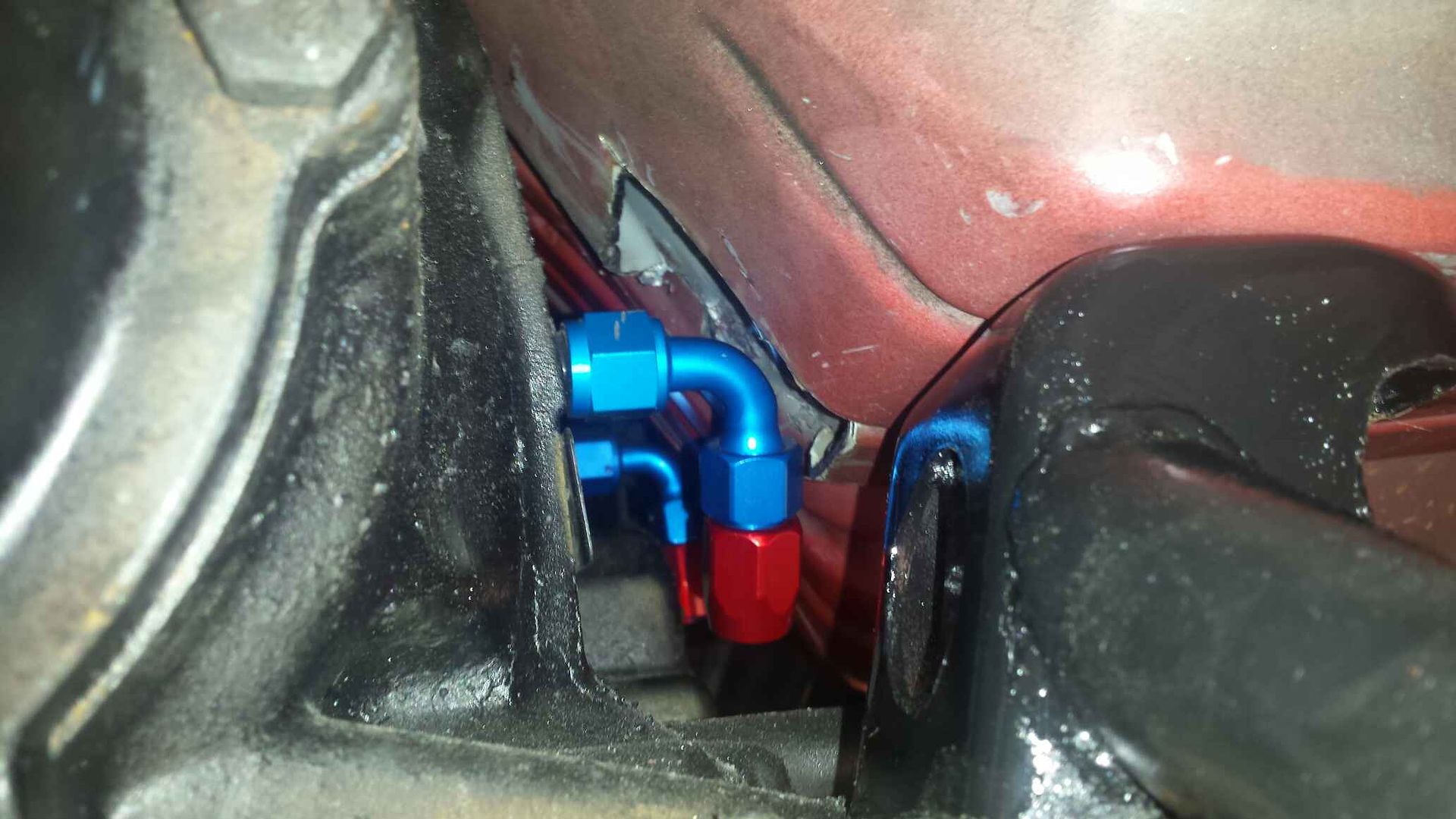

My cooler lines have 45s on them. I knew that wouldn't fit so I ordered 90s. I was wondering if they would clear so I put them on the trans to give me an idea. The front line has about 1/4" clearance from the body, the rear one, no chance in hell getting it on there. I quickly lowered the trans tail and snuck my grinder in there. After some hot sparks it does fit, but I only have about 30 degrees of rotation, looking at the trans and fitting it will swivel from about 2 to 5 oclock.....so the rear line will have to exit towards the front and loop back around. You can see both fittings in this pic.

Wasn't gonna buy a prefab crossmember to the tune of $180 dollars so I decided I'd make one. As I sat there thinking about material size, type, thickness I spied the driver door bar I pulled out earlier in the year. Its about 1.5" seemless steel tube with a decent wall thickness, that should do the trick and the best part is, it was zero dollars. I made a mount for the trans out of maybe 5/16 plate I had, then cut a 1 foot section of the door bar, welded them together and add small gussets under the plate for extra strength.....also, in this pic you can see the clearance and why i cut for the electrical connector.

Late evening pic (washout), but you get the idea of the finished product. I was going to make new sides plates where this bolts to the car but after looking at the stock crossmember I was like **** it i will just cut the ends off and make it work. In this pic you can see I used a small section to drop down vertically, then I hand notched the tubing to get a decent fit going back to the original 12" piece. Got the trans in place and this thing didnt budge as i set the weight down on it, it should be fine.

My cooler lines have 45s on them. I knew that wouldn't fit so I ordered 90s. I was wondering if they would clear so I put them on the trans to give me an idea. The front line has about 1/4" clearance from the body, the rear one, no chance in hell getting it on there. I quickly lowered the trans tail and snuck my grinder in there. After some hot sparks it does fit, but I only have about 30 degrees of rotation, looking at the trans and fitting it will swivel from about 2 to 5 oclock.....so the rear line will have to exit towards the front and loop back around. You can see both fittings in this pic.

#374

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

NP bud.

First thing first I had to finish the 4.10 to 3.73 gear swap. Here is the 3.73 mounted to the Strange lightweight steel spool.

Before final assembly I inspected the axles closely, I also measured engagement just due to curiosity. No damage and everything looked good.

Once the rear end was reassembled I wanted to test fit the driveshaft. Even bottomed out in the trans it wouldn't fit, it was too long. I had pulled the rear end forward to fit (center) the 28" slicks. I made a quick adjustment and moved the rear end back about an inch and had plenty of room to get the DS in. I also reset pinion angle to -2. Im planning on trimming some on the back bumper for the tires (since I moved them back) but this may need a final adjustment later.

Bring on the grinder!!!! Notice on the driver's side that black flapper thingy, that's a cab vent that prevents air lock in the cab when you shut the door. I'm gonna try and reinstall it.

A closer look.

T top well and driver cubbie. I removed he passenger side tub (spare tire well) about a year or two ago.

On the scale, 20.2 pounds

All the cuts will be covered by the bumper. Ive got the main replacement panel rough cut but i ran out of time so I didnt get a chance to get it fitted. I will be relocating the trans cooler to the rear bumper area to make room for the intercooler up front.

First thing first I had to finish the 4.10 to 3.73 gear swap. Here is the 3.73 mounted to the Strange lightweight steel spool.

Before final assembly I inspected the axles closely, I also measured engagement just due to curiosity. No damage and everything looked good.

Once the rear end was reassembled I wanted to test fit the driveshaft. Even bottomed out in the trans it wouldn't fit, it was too long. I had pulled the rear end forward to fit (center) the 28" slicks. I made a quick adjustment and moved the rear end back about an inch and had plenty of room to get the DS in. I also reset pinion angle to -2. Im planning on trimming some on the back bumper for the tires (since I moved them back) but this may need a final adjustment later.

Bring on the grinder!!!! Notice on the driver's side that black flapper thingy, that's a cab vent that prevents air lock in the cab when you shut the door. I'm gonna try and reinstall it.

A closer look.

T top well and driver cubbie. I removed he passenger side tub (spare tire well) about a year or two ago.

On the scale, 20.2 pounds

All the cuts will be covered by the bumper. Ive got the main replacement panel rough cut but i ran out of time so I didnt get a chance to get it fitted. I will be relocating the trans cooler to the rear bumper area to make room for the intercooler up front.

#377

TECH Resident

iTrader: (21)

Join Date: Sep 2009

Location: MD

Posts: 766

Likes: 0

Received 0 Likes

on

0 Posts

Yep your right there is really not a good flat surface in the back to mount the trans cooler. I ended up mounting mine in front of the rear axle. It doesn't get much air tucked up in there but the fan moves the heat out well.

#379

TECH Resident

iTrader: (21)

Join Date: Sep 2009

Location: MD

Posts: 766

Likes: 0

Received 0 Likes

on

0 Posts

Yea definitely couldn't do it without a fan. I had it mounted up front last year but wanted to get it to the back for weight and to clean up the front. My temps stay under 200 but the fan does run more than when it was up front.

#380

TECH Senior Member

Thread Starter

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

Driver bucket I finished off with 22G sheetmetal. I painted the bottom black and sides red to make it appear somewhat factory.

16g center panel, 2.5 tubes of seam sealer, and yes it is strong enough for me to stand on it. Total weight that went back IN the car is about 10. So this saves me 10 pounds however we are killing two birds with one stone...

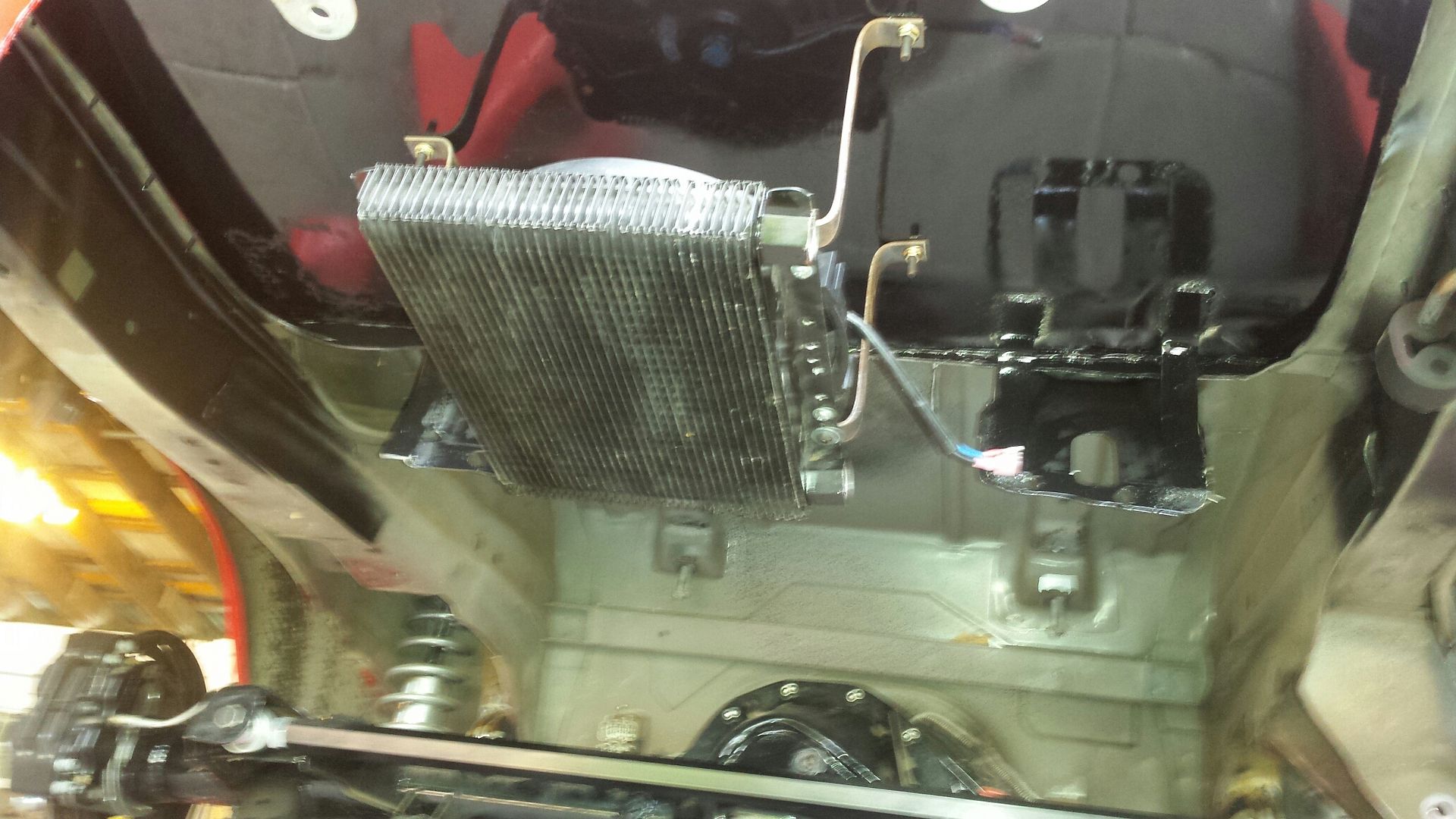

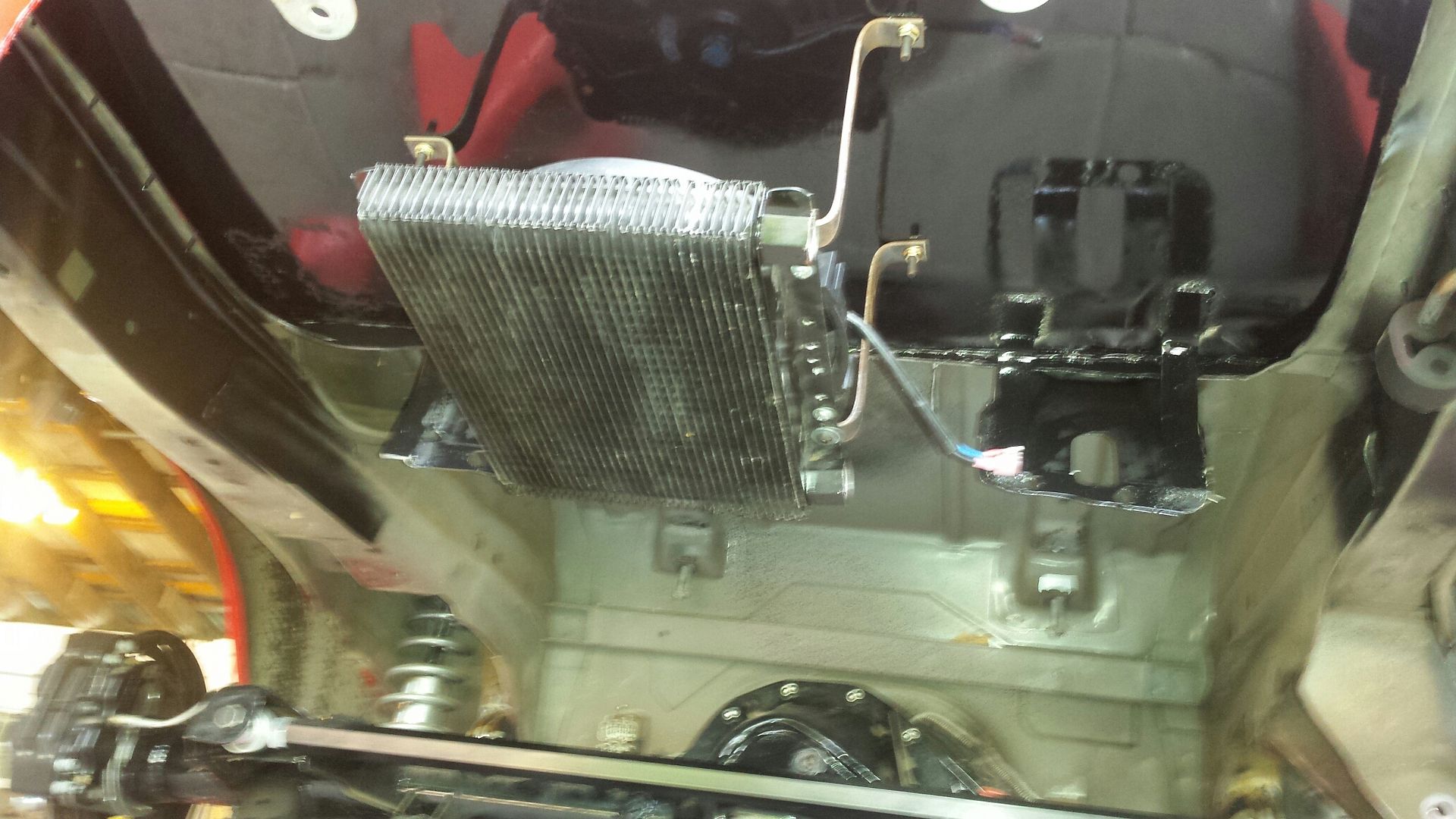

There she is, I left as much of an air gap without leaving it hanging under bumper level. I did not want it to be visible from the rear.

In this pic you can see i made 3 S shaped brackets out of flat bar to attach it to the floor. Its all bolted so if i change coolers at some point i don't have brackets welded to the floor. Also, you can see the L shaped brackets i used to brace the stock gas tank strap holder thingys.

Found this guy wandering around the shop. Old lady asked if she could pick him up, I said sure! Take my welding gloves.

Long two afternoons of work. She is put to bed, time to relax.

So the panels are done, cooler is done except for the lines needing to be run. I reinstalled the fuel tank (boo no pic), got the hot wire relays mounted, and got fuel lines and fuel filter mounted and run up to about the tail of the trans and got the rear bumper/lights reinstalled. I also bled the brakes. First thing next go round is to get the cooler lines done (and fan wiring), then I will be working towards the front of the car where i have a list of things a mile long to do.....but we are making good progress. I still have no piping for the turbo kit so.....should be here soon though.

16g center panel, 2.5 tubes of seam sealer, and yes it is strong enough for me to stand on it. Total weight that went back IN the car is about 10. So this saves me 10 pounds however we are killing two birds with one stone...

There she is, I left as much of an air gap without leaving it hanging under bumper level. I did not want it to be visible from the rear.

In this pic you can see i made 3 S shaped brackets out of flat bar to attach it to the floor. Its all bolted so if i change coolers at some point i don't have brackets welded to the floor. Also, you can see the L shaped brackets i used to brace the stock gas tank strap holder thingys.

Found this guy wandering around the shop. Old lady asked if she could pick him up, I said sure! Take my welding gloves.

Long two afternoons of work. She is put to bed, time to relax.

So the panels are done, cooler is done except for the lines needing to be run. I reinstalled the fuel tank (boo no pic), got the hot wire relays mounted, and got fuel lines and fuel filter mounted and run up to about the tail of the trans and got the rear bumper/lights reinstalled. I also bled the brakes. First thing next go round is to get the cooler lines done (and fan wiring), then I will be working towards the front of the car where i have a list of things a mile long to do.....but we are making good progress. I still have no piping for the turbo kit so.....should be here soon though.