5.7 rebuild, turning over tight

#1

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys I just rebuilt my first ls engine, long story short the rotating assembly moves freely without the rings in, ring gap measures .018-.021 they went in tight so I took them back out to see nothing wrong with the piston/cylinder the short block is together now and it turns over very rough almost like the rings are chaffing the cylinders. The rings aren't leaving any score Mark's on the cylinder walls, I checked all of the clearances for the bearings and the crank and rod both checked around the .0015 range the crank and rods turn free without rings installed, the rings fit in the lands of the pistons no problem when installing it takes quite the persuasion from the rubber mallet to move the piston nothing absurd but possibly concerning, dont wanna mess this thing up but I've taken everything apart and checked and cleaned for the last 3 days. Can turn it over with a 2 ft breaker bar but "stutters" or chafes will this be ok? I'm soaking it in oil as we speak

#3

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

I have uploaded a photo I'm not quite sure why Its not appearing just yet but yes the #5 cap is opposite of 1-4 the clearances seem fine the and the crank spun freely on it's own I'm re using my ls1 crank and pistons in a iron block 5.3 bored to 5.7 has a slight hone on it and the gaps are .018-.022 it seems piston related but I dont wanna open the gap on the ring too wide the piston moves freely without rings installing rings were a pain but I didnt have to slam on the pistons but it seemed a little more than necessary

#4

TECH Senior Member

iTrader: (16)

I have uploaded a photo I'm not quite sure why Its not appearing just yet but yes the #5 cap is opposite of 1-4 the clearances seem fine the and the crank spun freely on it's own I'm re using my ls1 crank and pistons in a iron block 5.3 bored to 5.7 has a slight hone on it and the gaps are .018-.022 it seems piston related but I dont wanna open the gap on the ring too wide the piston moves freely without rings installing rings was a pain but I didnt have to slam on the pistons but it seemed a little more than necessary

https://ls1tech.com/forums/showthrea...1#post20099501

Depending on the ring pack and the fresh hone job, this could cause resistance.

Can you move a piston with no ring pack freely in the bore or does it drag?

#5

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Can you move a piston with no ring pack freely in the bore or does it drag?

#6

TECH Senior Member

iTrader: (16)

That would make sense !!

Yes with just the piston in the cylinder it will move all the way up and down the bore smoothly. Once I put rings on it is hard from cylinder 1 and only gets slightly harder when all the piston and rod assembly's are installed, maybe around 100ft lbs to rotate the assembly and it stutters but dosent hang, and the faster I turn it the smoother it becomes, a starter will forsure turn the short block over.

Yes with just the piston in the cylinder it will move all the way up and down the bore smoothly. Once I put rings on it is hard from cylinder 1 and only gets slightly harder when all the piston and rod assembly's are installed, maybe around 100ft lbs to rotate the assembly and it stutters but dosent hang, and the faster I turn it the smoother it becomes, a starter will forsure turn the short block over.

Are you lubricating with assembly lube?

Did you or your machine shop check and verify the proper clearances?

#7

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Assembly lube was used and no I didnt have the block checked before assembly but i checked as much as i could I plastigauged everything I know that's not the best but I worked with what I have, the rotating assembly turns over perfect with out rings installed I pulled it apart took the rings out the whole assembly turns over fine as soon as I put the rings on I have a problem, i triple checked my ring gap and and they are consistent with what I have set them to .018-.022 that's why I'm confused

Trending Topics

#8

TECH Addict

I oil the hell out of the pistons and rings as I'm putting them in, I just use a brush to paint oil on the rings..

make sure they are all lubed well. how tight are the rings in the grooves? if they are too tight they don't move like they should..

FWIW,, I pay the 50 bucks to have a machine shop fully check it then I do it.. I've found wild bores, out of alignment mains all kinds of silly crap..

Once had 1 main bearing that had been machined +.010 bigger than the rest,, the shop said "well,, just use a tighter bearing in that one.. "

Like I'm gonna buy a whole set of bearings.. for 1 spot..

make sure they are all lubed well. how tight are the rings in the grooves? if they are too tight they don't move like they should..

FWIW,, I pay the 50 bucks to have a machine shop fully check it then I do it.. I've found wild bores, out of alignment mains all kinds of silly crap..

Once had 1 main bearing that had been machined +.010 bigger than the rest,, the shop said "well,, just use a tighter bearing in that one.. "

Like I'm gonna buy a whole set of bearings.. for 1 spot..

#9

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Yeah I'm gonna pull it back apart and check the bores the rings move freely in the lands maybe one of the cylinders a little small, thanks for the .02 guys hopefully I can find something

#10

You're checking your ring gaps in their respective bores, with a squaring tool of some sort, right? Also, check the ring land depth in the pistons and the section width of the rings. Wouldn't be the first time the wrong set of rings were put in the right (for the application) box. 50-75 lbs is what I shoot for as far as rotational force of a short block (discounting break-away force).

#11

TECH Apprentice

I would suggest that you start over. Pull everything off the short block and then take your time to install bearings, crank, pistons and rods facing the correct way, and so on. It should not take much to turn the crank with new bearings. I don't think it's your piston rings, I think it's something else. And use a lot of WD-40 as you install parts.

#12

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

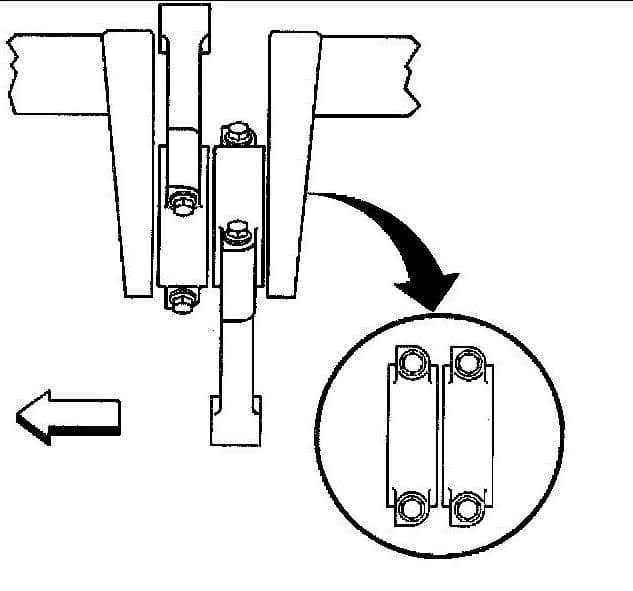

I re assembled everything and did some reading but I'm a bit confused because I've read the the dot on the piston goes forward toward the timing cover, but worh the pistons installed in that orientation the "flat side" of the rods do not face eachother on the crank shaft, as in one "flat side" of the rod is facing the outer edge of the crank journal, clearances for the bearings are a little tight but read around .0015/.002 on the crank and rod bearings, I re set the ring gaps to .020-.022 and installed the pistons on the passenger side with the dot facing the rear main cover to allow both of the "flat side" of the rods to face eachother with the machined chamfered side being outward toward the outside of the crank journal, still turning over tight tough, better at about 85 ft lbs not including breakaway force, pistons no longer chatter in the cylinders

#13

TECH Apprentice

I re assembled everything and did some reading but I'm a bit confused because I've read the the dot on the piston goes forward toward the timing cover, but worh the pistons installed in that orientation the "flat side" of the rods do not face eachother on the crank shaft, as in one "flat side" of the rod is facing the outer edge of the crank journal, clearances for the bearings are a little tight but read around .0015/.002 on the crank and rod bearings, I re set the ring gaps to .020-.022 and installed the pistons on the passenger side with the dot facing the rear main cover to allow both of the "flat side" of the rods to face eachother with the machined chamfered side being outward toward the outside of the crank journal, still turning over tight tough, better at about 85 ft lbs not including breakaway force, pistons no longer chatter in the cylinders

Do you have a Chilton's or other service manual? I rebuilt my SBC 350 in my '73 Nova in December and I viewed a few videos on assembling the parts. For the SBC the dots on the pistons should face the front of the engine/front of the car. Is the LS motor the same or different? You may have just found the problem you are having. My SBC ring gaps from .016 to .021, all within specs and it turned with 25 ftbs on the torque wrench. I'm sure you'll get it.

#16

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

I will swap the passenger side pistons around tomorrow so the dots face forward as they should, as I wasnt sure of rod orientation, the caps/rods look symmetrical to me other than the machined side of the journal and have also read that the ls1 uses floating rods and the orientation of the rod dosent so much matter as long as the dot on the piston faces front?

Last edited by Joshua Weisenborn; 06-05-2019 at 01:05 PM.

#17

11 Second Club

iTrader: (3)

All piston dots should be facing towards the front of the engine. Did you remove the pistons from the connecting rods? Did you have the the rods re-honed for the ARP bolts?

#18

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

I did not remove the pistons from the rods and do you have to get the rods honed for arp bolts ? Am I suppose to take some kind of sleeve out of the end cap? They threaded in with no problem, just as well as the stock bolts, if I have to I'll use the stock bolts. Didnt mention that in the installation instructions for the arp bolts. I'm placing the pistons in the correct orientation tonight, will see if anything changes.

Last edited by Joshua Weisenborn; 06-05-2019 at 07:41 PM.

#19

11 Second Club

iTrader: (3)

Its been my understanding that the clamping forces changes when you use ARP hardware and its recommended that you re-hone the rods and mains when using them.

#20

Teching In

Thread Starter

Join Date: May 2019

Location: Flint township, MI

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hmm, should I just buy a stock set ? I'd hate to waste 80 bucks but it's better than destroying a entire engine I read their is some kind of sleeve in the end cap but I would think removing that would cause the bolt to walk I torqued them 15 ft lbs and 75* 3 times now because I've pulled this engine apart and put it back together trying to get it to rotate easier I'm trying to take my time and do this right