Inexpensive Opensource Flashing(Read is 100% working)

#621

Not to be pest, but is this the correct setup, https://www.ebay.com/sch/i.html?_fro...nk+SX&_sacat=0

I understand it's low but for the price, I'm ok.

Thanks.

I understand it's low but for the price, I'm ok.

Thanks.

#622

Teching In

Tools working:

AVT - 852

J2343 - Any real J tool will work but OEM tools are much faster then knockoff versions(assuming the knockoff works in the first place)

ALLPRO - NO LONGER IN PRODUCTION! The USB version is the only one we know will work. You may be able to get the Allpro Dev board version to work but its not guaranteed. The BT Allpro WILL NOT WORK.

ObdLink SX - The SX is the only officially supported device but the Lx and Mx have been tested and work as well. You will need to check your firmware if you have trouble, older firmware on these are NOT compatible.

Mike

#624

From the first page:

Tools working:

AVT - 852

J2343 - Any real J tool will work but OEM tools are much faster then knockoff versions(assuming the knockoff works in the first place)

ALLPRO - NO LONGER IN PRODUCTION! The USB version is the only one we know will work. You may be able to get the Allpro Dev board version to work but its not guaranteed. The BT Allpro WILL NOT WORK.

ObdLink SX - The SX is the only officially supported device but the Lx and Mx have been tested and work as well. You will need to check your firmware if you have trouble, older firmware on these are NOT compatible.

Mike

Tools working:

AVT - 852

J2343 - Any real J tool will work but OEM tools are much faster then knockoff versions(assuming the knockoff works in the first place)

ALLPRO - NO LONGER IN PRODUCTION! The USB version is the only one we know will work. You may be able to get the Allpro Dev board version to work but its not guaranteed. The BT Allpro WILL NOT WORK.

ObdLink SX - The SX is the only officially supported device but the Lx and Mx have been tested and work as well. You will need to check your firmware if you have trouble, older firmware on these are NOT compatible.

Mike

Yes, I read which cables work, but, there is fake ones that don't work, and the prices of some of the cables are not cost effective. That's why I'm asking about this cable, due to the price and easy availability. I don't know very much about this, and having are hard time trying to make sure this setup will work for me.

Thanks.

#625

Teching In

Hi all,

Ok. I understand now what you were getting at.

I would be leary of buying any that did NOT come directly from Scantool..net

OBDLink SX

The ones THEY sell are only about 30.00 and should work fine.

I bought a BAFX Bluetooth unit that will NOT work; I got it more for using with Torque pro on my Note 8.

I myself am waiting for Pete and Envyous Customs' new interface to be released.

Mike

Ok. I understand now what you were getting at.

I would be leary of buying any that did NOT come directly from Scantool..net

OBDLink SX

The ones THEY sell are only about 30.00 and should work fine.

I bought a BAFX Bluetooth unit that will NOT work; I got it more for using with Torque pro on my Note 8.

I myself am waiting for Pete and Envyous Customs' new interface to be released.

Mike

Last edited by MudDuck514; 10-03-2019 at 10:59 PM.

#626

I do have a couple of rather OT questions if they don't create too much of a distraction. First, what's the best approach to enable my 2 bar MAP sensor for low level boost?

[...] I particularly figured you guys would be on top of the boost situation. I expect it's still pretty murky.

[...] I particularly figured you guys would be on top of the boost situation. I expect it's still pretty murky.

But there may be a not-quite-right way that is good enough, using a factory operating system. Maybe. There is risk.

Imagine using that sensor with a factory OS and doing the following:

1) change the tune to use speed-density at all times

2) change the XDF so that it shows a VE table axis that matches the 2-bar sensor

3) ditto for the open loop fuel table

4) know that the highest-load row of the spark table is going to be used all the way from 1.2 g/cyl to whatever load you get at full boost.

5) cross your fingers...

That might sound like a terrible idea, but I'm told that somebody out was doing it a few weeks ago. I don't know whether he's on this forum. And I don't know whether he's still doing it.

The biggest obvious issue is that if you tune the last row of the spark table properly for 12psi (or whatever your max boost is), your timing will not be as advanced at it should be at, for example 6psi.

And I wonder about the non-obvious issues. What other tables in the ROM are using the MAP sensor signal, and what changes do they need if the MAP starts reading 0-2bar instead of 0-1bar? I don't know.

I'm kinda hoping that someone from the Sloppy Mechanics school of thought gives this a try, makes it work, and documents it extensively. I don't even plan to run any boost, but I still think this would be really cool.

#627

In other news, I've been making some progress on a data logging app.

It's still a bit too primitive for me to actually recommend it, but it's coming along.

It's still a bit too primitive for me to actually recommend it, but it's coming along.

#628

Definitely the sloppy electronics school here, so we'll see where it goes once I get it wired. My wiring is first rate, it's the programming where I fall short. But here's what I'm thinking at this point anyways. The MAP puts out a 0-5v signal regardless so the input from a 1 bar, 2 bar, or 3 bar MAP is the same, just scaled differently internally. So far so good. In the VE table the fuel continues to go up with boost, so I see no real issues there. That leaves the ignition table, and yes I am running speed/density as there is no place for a MAF to be mounted.

Anyway, I don't see a problem with scaling the ign map so that advance is pulled out under boost. This is actually something you would normally do anyway, but to a lesser degree. Advance reaches maximum under cruise and low manifold pressure, after which it decreases towards WOT. I don't think the controller cares if WOT is at atmo or atmo+1.

Where the confusion sets in, is the reference numbers. With a 2 bar sensor it's all at half scale. That's workable but has to be remembered. There may be other things in the programming I don't know anything about that might also cause trouble, but being a hack and slash kind of guy around computers I probably should stay away from those issues, and if it works, Don't worry/be happy.

At least that's my approach for now.

Jim

Anyway, I don't see a problem with scaling the ign map so that advance is pulled out under boost. This is actually something you would normally do anyway, but to a lesser degree. Advance reaches maximum under cruise and low manifold pressure, after which it decreases towards WOT. I don't think the controller cares if WOT is at atmo or atmo+1.

Where the confusion sets in, is the reference numbers. With a 2 bar sensor it's all at half scale. That's workable but has to be remembered. There may be other things in the programming I don't know anything about that might also cause trouble, but being a hack and slash kind of guy around computers I probably should stay away from those issues, and if it works, Don't worry/be happy.

At least that's my approach for now.

Jim

#629

Not to be pest, but is this the correct setup, https://www.ebay.com/sch/i.html?_fro...nk+SX&_sacat=0

I understand it's low but for the price, I'm ok.

Thanks.

I understand it's low but for the price, I'm ok.

Thanks.

Cost me CAD $56.24 total

#630

#631

Definitely the sloppy electronics school here, so we'll see where it goes once I get it wired. My wiring is first rate, it's the programming where I fall short. But here's what I'm thinking at this point anyways. The MAP puts out a 0-5v signal regardless so the input from a 1 bar, 2 bar, or 3 bar MAP is the same, just scaled differently internally. So far so good. In the VE table the fuel continues to go up with boost, so I see no real issues there. That leaves the ignition table, and yes I am running speed/density as there is no place for a MAF to be mounted.

Anyway, I don't see a problem with scaling the ign map so that advance is pulled out under boost. This is actually something you would normally do anyway, but to a lesser degree. Advance reaches maximum under cruise and low manifold pressure, after which it decreases towards WOT. I don't think the controller cares if WOT is at atmo or atmo+1.

Where the confusion sets in, is the reference numbers. With a 2 bar sensor it's all at half scale. That's workable but has to be remembered. There may be other things in the programming I don't know anything about that might also cause trouble, but being a hack and slash kind of guy around computers I probably should stay away from those issues, and if it works, Don't worry/be happy.

At least that's my approach for now.

Jim

Anyway, I don't see a problem with scaling the ign map so that advance is pulled out under boost. This is actually something you would normally do anyway, but to a lesser degree. Advance reaches maximum under cruise and low manifold pressure, after which it decreases towards WOT. I don't think the controller cares if WOT is at atmo or atmo+1.

Where the confusion sets in, is the reference numbers. With a 2 bar sensor it's all at half scale. That's workable but has to be remembered. There may be other things in the programming I don't know anything about that might also cause trouble, but being a hack and slash kind of guy around computers I probably should stay away from those issues, and if it works, Don't worry/be happy.

At least that's my approach for now.

Jim

The timing table for my car's operating system is in load (g/cyl) so I assume that for anything above 1.2 g/cyl (or whatever the max is) will just get the values from the last row of the timing table. Which basically means you'd have to tune that last row to be right for full boost, which means that at half boost it would be a couple/few degrees less than what would be optimum. So EGT might be high at partial boost, but probably not dangerously so. Probably. Be careful.

I assume the other operating systems work the same way, but if GM has an operating system that uses MAP for the timing table, that would be the way to go. I'm not aware of one though.

#632

TECH Enthusiast

Thread Starter

Rather then quoting several people who all said or had a question regarding the use of a stock OS with a 2 or 3 bar MAP.....

It's already been started that regardless of the BAR rating it will still read a 0-5 volt scale and that is correct.

In a perfect world this would not NEED to be done in Speed Density mode but were already playing with something WELL outside of it's intended use so be smart here and run SD tuning. If you attempt to use a MAF + Map even at low boost you will likely end up with a pile of molten metal.

Your going to give your brain a workout beyond anything you can imagine by doing this unless you alter the XDF values that are displayed. I've spent a "little" bit of time looking into a simple fix for this and unfortunately not only do the displayed XDF map values not correspond to any of the 1/2/3 bar MAP sensor voltage tables a 2 and 3 bar MAP are going to each be slightly different as well.

Here's how this works......

Tuner Pro is listing KPA for a 1 bar MAP as

15 20 25 30 35 40 45 50 60 65 70 75 80 85 90 95 100 105

Lets say your running a 2 bar MAP and your adjusting the table, you need to make your self mentally aware that anything shown above 55kpa in that XDF is now going to be into boost.

So Engine vacuum is going to be show on the XDF as 15-55 KPA and Boost is going to be from 55 KPA to 105 KPA

If you were running a 3 bar MAP you'd have to make your self mentally aware that at 35 KPA your already a little ways into boost

So 15 KPA to 30 KPA is engine vacuum, 35 KPA to 70 KPA is going to be Boost in the 2 bar range and 75 KPA to 105 KPA will be Boost in the 3 bar range.

A simple conversion....

MAP Voltage 1 BAR 2 BAR 3 BAR

0.50V 20 KPA 28 KPA 33 KPA

1.00V 29 KPA 48 KPA 64 KPA

3.00V 67 KPA 128 KPA 190 KPA

As the BAR value of the MAP sensor gets larger and increases in resolution the effective size of the table for each area of the MAP sensor gets smaller since the over all table size is not being changed. So in the case of a 2 bar we have to take the table and split the resolution in half, the bottom half would be every thing up to 105 KPA and the top half would be from 106 KPA to 208 KPA.

Now you may be thinking, but I'm not going to max out a 2 bar sensor, can't I shift the cells around since I'm not using the upper range of the sensor? The short answer is NO, you can NOT....the long answer is it might be possible. The PCM isn't reading KPA, it's reading the voltage value the sensor is supplying and the sensor is designed to output a given value for a given pressure or vacuum level. You can alter how the XDF displays this information so it's not so mentally straining...and TRUST ME.....it WILL become an issue when your reading one thing and it means something totally different eventually you'll make a mistake and put the wrong value in...just hope it's not in a place where its going to have a massive impact as soon as that cell is hit. I have tried to find a conversion that would let me alter the values in the XDF so this wasn't an issue but voltage tables on map sensors do not line up with the scaling in Tuner Pro. I started to map a 3 bar MAP sensors voltage but it became pretty clear right off the bat that no one's going to want to run a 3 bar MAP with a stock OS, the resolution is just cut down so low it would be rather pointless unless it was strictly a race car......and I do not have a 2 bar map sensor I can use to try and remap an XDF for this.

Some other tables/settings that you may also need/want to address.....Not saying that you should as all of this is on the end user to decide what's right for them to do but other places that MAP values can be found/used by the computer.

I've checked a couple of random XDF's and these table numbers seem to be the same across them all but the naming of the tables does change a bit between XDF's.....

C3003 Map Rationality test (Sets DTC P0106)(AKA Predicted MAP MAX )

C3004 Map Rationality test (Sets DTC P0106)(AKA Predicted MAP MIN )

C5501 - MAP Test Maximum RPM

C5502 - MAP Test Maximum RPM

B3810 - MAP Bounderies for LTFT

B3406 - Impact Factor(wall wetting time)

B3401 - Evaporation Time(Intake Port Wetting) **NOT Emissions Evap related

B0120 - RPM Threshold for Airflow Calculations (AKA Dynamic Airflow Calculation)

**B3613 - PE MAP Threshold** It's a PE enabler that's going to be altered by recalling the MAP's range it will need to be looked at

** B3659 - Commanded Fuel in Piston Protection Mode** I would suggest looking into this a bit before writing it off. While you may thinks it's dumb or won't work, I would wager money that if this is was setup correctly it would be able to prevent a piston meltdown if something in your tune if wrong or something in the fuel system gives out.

Don't be afraid to change the O2 sensors switch point so it spends more time rich then it does lean.....

Don't be afraid to drop the target A/F to a much...much lower value then you would expect it to need initially..... your not going to blow up or melt down the engine from running rich....but you will if you go lean even for a very short time.

Make sure lean cruise is disabled, it should be on all US OS's but if you don't check.....you may find out the hard way you had that special one

Make sure DEFO is turned OFF while your getting things worked out, the last thing you want to see is an amazing pull under boost only to have the PCM cut fuel on you.

Check the Rev limiter settings ! ! ! I'm not sure if this comes down to who made the XDF and how they did it or if this is something that's determined by the OS it self but I've seen it both ways but typically the Rev limiter is done by cutting fuel. DO NOT LET THAT HAPPEN ! ! ! You will be better off with no Rev limiter then you are cutting fuel while in boost especially consider your already going to be working with limited table resolution.

I would also STRONGLY suggest ONLY running with Open Loop setting if your going to try out any of this... and don't even think about trying to go into closed loop until your sure you've got a decent handle on things and the engine appeasers to be running in a safe manner AS SHOWN WITH YOUR WIDE BAND O2.

If your not using a wide band with a display you can see at all times then pretend you didn't read any of this and just move along.....

I hope someone finds this information useful and is able to try out what I am unable to myself

It's already been started that regardless of the BAR rating it will still read a 0-5 volt scale and that is correct.

In a perfect world this would not NEED to be done in Speed Density mode but were already playing with something WELL outside of it's intended use so be smart here and run SD tuning. If you attempt to use a MAF + Map even at low boost you will likely end up with a pile of molten metal.

Your going to give your brain a workout beyond anything you can imagine by doing this unless you alter the XDF values that are displayed. I've spent a "little" bit of time looking into a simple fix for this and unfortunately not only do the displayed XDF map values not correspond to any of the 1/2/3 bar MAP sensor voltage tables a 2 and 3 bar MAP are going to each be slightly different as well.

Here's how this works......

Tuner Pro is listing KPA for a 1 bar MAP as

15 20 25 30 35 40 45 50 60 65 70 75 80 85 90 95 100 105

Lets say your running a 2 bar MAP and your adjusting the table, you need to make your self mentally aware that anything shown above 55kpa in that XDF is now going to be into boost.

So Engine vacuum is going to be show on the XDF as 15-55 KPA and Boost is going to be from 55 KPA to 105 KPA

If you were running a 3 bar MAP you'd have to make your self mentally aware that at 35 KPA your already a little ways into boost

So 15 KPA to 30 KPA is engine vacuum, 35 KPA to 70 KPA is going to be Boost in the 2 bar range and 75 KPA to 105 KPA will be Boost in the 3 bar range.

A simple conversion....

MAP Voltage 1 BAR 2 BAR 3 BAR

0.50V 20 KPA 28 KPA 33 KPA

1.00V 29 KPA 48 KPA 64 KPA

3.00V 67 KPA 128 KPA 190 KPA

As the BAR value of the MAP sensor gets larger and increases in resolution the effective size of the table for each area of the MAP sensor gets smaller since the over all table size is not being changed. So in the case of a 2 bar we have to take the table and split the resolution in half, the bottom half would be every thing up to 105 KPA and the top half would be from 106 KPA to 208 KPA.

Now you may be thinking, but I'm not going to max out a 2 bar sensor, can't I shift the cells around since I'm not using the upper range of the sensor? The short answer is NO, you can NOT....the long answer is it might be possible. The PCM isn't reading KPA, it's reading the voltage value the sensor is supplying and the sensor is designed to output a given value for a given pressure or vacuum level. You can alter how the XDF displays this information so it's not so mentally straining...and TRUST ME.....it WILL become an issue when your reading one thing and it means something totally different eventually you'll make a mistake and put the wrong value in...just hope it's not in a place where its going to have a massive impact as soon as that cell is hit. I have tried to find a conversion that would let me alter the values in the XDF so this wasn't an issue but voltage tables on map sensors do not line up with the scaling in Tuner Pro. I started to map a 3 bar MAP sensors voltage but it became pretty clear right off the bat that no one's going to want to run a 3 bar MAP with a stock OS, the resolution is just cut down so low it would be rather pointless unless it was strictly a race car......and I do not have a 2 bar map sensor I can use to try and remap an XDF for this.

Some other tables/settings that you may also need/want to address.....Not saying that you should as all of this is on the end user to decide what's right for them to do but other places that MAP values can be found/used by the computer.

I've checked a couple of random XDF's and these table numbers seem to be the same across them all but the naming of the tables does change a bit between XDF's.....

C3003 Map Rationality test (Sets DTC P0106)(AKA Predicted MAP MAX )

C3004 Map Rationality test (Sets DTC P0106)(AKA Predicted MAP MIN )

C5501 - MAP Test Maximum RPM

C5502 - MAP Test Maximum RPM

B3810 - MAP Bounderies for LTFT

B3406 - Impact Factor(wall wetting time)

B3401 - Evaporation Time(Intake Port Wetting) **NOT Emissions Evap related

B0120 - RPM Threshold for Airflow Calculations (AKA Dynamic Airflow Calculation)

**B3613 - PE MAP Threshold** It's a PE enabler that's going to be altered by recalling the MAP's range it will need to be looked at

** B3659 - Commanded Fuel in Piston Protection Mode** I would suggest looking into this a bit before writing it off. While you may thinks it's dumb or won't work, I would wager money that if this is was setup correctly it would be able to prevent a piston meltdown if something in your tune if wrong or something in the fuel system gives out.

Don't be afraid to change the O2 sensors switch point so it spends more time rich then it does lean.....

Don't be afraid to drop the target A/F to a much...much lower value then you would expect it to need initially..... your not going to blow up or melt down the engine from running rich....but you will if you go lean even for a very short time.

Make sure lean cruise is disabled, it should be on all US OS's but if you don't check.....you may find out the hard way you had that special one

Make sure DEFO is turned OFF while your getting things worked out, the last thing you want to see is an amazing pull under boost only to have the PCM cut fuel on you.

Check the Rev limiter settings ! ! ! I'm not sure if this comes down to who made the XDF and how they did it or if this is something that's determined by the OS it self but I've seen it both ways but typically the Rev limiter is done by cutting fuel. DO NOT LET THAT HAPPEN ! ! ! You will be better off with no Rev limiter then you are cutting fuel while in boost especially consider your already going to be working with limited table resolution.

I would also STRONGLY suggest ONLY running with Open Loop setting if your going to try out any of this... and don't even think about trying to go into closed loop until your sure you've got a decent handle on things and the engine appeasers to be running in a safe manner AS SHOWN WITH YOUR WIDE BAND O2.

If your not using a wide band with a display you can see at all times then pretend you didn't read any of this and just move along.....

I hope someone finds this information useful and is able to try out what I am unable to myself

Last edited by PeteS160; 10-05-2019 at 10:22 PM.

The following users liked this post:

kpeters59 (10-06-2019)

#633

TECH Enthusiast

Thread Starter

To continue with my last post and elaborate a bit on one point I made....there is a longer answer to the one point that I didn't want to try and include as it may have misconstrue what i was saying.

There are 2 tables of *special* interest that relate to the MAP sensor and are outside the scope that would be used for anything "Normal" you might do. However.....they present the possibility to alter the window I guess you could say that the MAP sensor operates with in as far as the PCM's ADC(Analog to Digital Converter) is concerted. The ADC reads the voltage level supplied by the map sensor and then calculates what the "value" that's been read is using a formula that's a part of the OS. While altering the actual formula in the OS would be possible it would also be very difficult(well beyond what 99.99% of people could do) and it would not offer a one size fits all solution so that would be of no real value to anyone but the person who's altered it for their own use.

Now altering how the PCM interrupts the data that's read by the ADC is very much possible. I would like to direct your attention to Scaler C6301 - MAP Sensor A/D Counts per KPA. I do not have any of my notes on this in front of me and this was something I did a while ago so don't quote me on this for an exact value.....but it should give you the idea how this works. The PCM has a value assigned for change in voltage that works out something along the lines of 9.5 KPA for every .5 volt increase.

There is also a table C6302 Map Sensor Offset that can be used to to change the rate that the ADC will increase the KPA based on Map sensor voltage. The Pcm has a preset "curve" if you will that will follow the map sensors voltage, when you alter this table you are changing what I guess you could call "the rate" that the KPA curve grows at.

When you alter these tables together you can effectively remap the range that the MAP sensor will be read by the PCM. You can not make a 1 bar MAP sensor read Boost.....that's a limit of the sensor. You CAN however alter the the range that the map sensor will be read by the PCM so that the MAP sensor is able to max out the PCM long before the Map sensor it self has reached it's limits. To keep the possible use of any of this realistic lets say you have a 2 BAR Map and your running lower boost and you know you'll NEVER get near the top end of the MAP sensor....meaning you have a LOT of VE table cells at the top end your never going to be able to use. Rather then letting those cells just sit there taking up the valuable resolution your lacking you can fudge the Map Offset and Scaler so that as far as the PCM's concerned you are able to max out the values. You make the PCM think that it's seeing the Map sensor at 4.5 volts when really it's only at 2.9 volts. You have altered the ramp on the 0-5 volt ADC now to suit your needs when in fact your map sensor will never get above 3 volts.

Now I know you might be thinking I can't do that....or it won't work.....or that's crazy. You can't make the PCM read a bogus value when it's actually something else and expect things to work right....... But actually you can. Your the one in control of what the PCM will do at any given value and your the one that will be altering what the value will be VS what it actually is. This is something that will mess with your mind in the same way looking at a 1 bar map table and trying to tell your self 80 kpa isn't 80 kpa it;s really 158 kpa. What you see and know by sight are going to be the biggest draw back to doing this. Letting your mind open up and ignore what your eyes are telling you is whats going to be the hardest thing and even after a great deal of though on this for a number of weeks....it might have been months...the point is I wasn't able come up with easy way to make this "display" or even formattable in a manner that isn't going to be confusing.....at least with the tools we have to work with in Tuner Pro. The first person that's able to actually do this in a vehicle and get it working smoothly and in a usable manner is going to be a BEAST and likely it won't be done by a tuner. This will take some amazing mental skills to be able to make sense of what's being done as what's being show it's going to make any sense.

And to make this sound even worse.....the only way to get the actual MAP voltage value is by reading the sensor with a volt meter and comparing that with what's shown by a scan tool from the PCM. Of course once it was rescaled to the desired range none of this matters and you could just reply on readings from the PCM again since your going to leave your self a little overhead anyways you'd never actually have the PCM reading for the MAP maxed out.

I really don't feel like typing out a full explanation so use some imagination here but this also works on the bottom end of the table as well, unless your running a cam that generates a TON of low end vacuum your never going to use the very low end of the map sensor so removing the bottom end of the maps range by increasing the initial sensor offset works in the same manner as above and lets you free up cells that can then be used to gain back some table resolution in the area where you actually need it.

your never going to use the very low end of the map sensor so removing the bottom end of the maps range by increasing the initial sensor offset works in the same manner as above and lets you free up cells that can then be used to gain back some table resolution in the area where you actually need it.

So Yes.....the long version of the answer is that you can squeeze a bit more range back into the table by clipping off the upper and lower ends of the MAP reading using some rather unconventional.......but I guess if your using a stock OS for boost in the first place that already makes it pretty unconventional....this just takes things to the next level I guess lol.

There are 2 tables of *special* interest that relate to the MAP sensor and are outside the scope that would be used for anything "Normal" you might do. However.....they present the possibility to alter the window I guess you could say that the MAP sensor operates with in as far as the PCM's ADC(Analog to Digital Converter) is concerted. The ADC reads the voltage level supplied by the map sensor and then calculates what the "value" that's been read is using a formula that's a part of the OS. While altering the actual formula in the OS would be possible it would also be very difficult(well beyond what 99.99% of people could do) and it would not offer a one size fits all solution so that would be of no real value to anyone but the person who's altered it for their own use.

Now altering how the PCM interrupts the data that's read by the ADC is very much possible. I would like to direct your attention to Scaler C6301 - MAP Sensor A/D Counts per KPA. I do not have any of my notes on this in front of me and this was something I did a while ago so don't quote me on this for an exact value.....but it should give you the idea how this works. The PCM has a value assigned for change in voltage that works out something along the lines of 9.5 KPA for every .5 volt increase.

There is also a table C6302 Map Sensor Offset that can be used to to change the rate that the ADC will increase the KPA based on Map sensor voltage. The Pcm has a preset "curve" if you will that will follow the map sensors voltage, when you alter this table you are changing what I guess you could call "the rate" that the KPA curve grows at.

When you alter these tables together you can effectively remap the range that the MAP sensor will be read by the PCM. You can not make a 1 bar MAP sensor read Boost.....that's a limit of the sensor. You CAN however alter the the range that the map sensor will be read by the PCM so that the MAP sensor is able to max out the PCM long before the Map sensor it self has reached it's limits. To keep the possible use of any of this realistic lets say you have a 2 BAR Map and your running lower boost and you know you'll NEVER get near the top end of the MAP sensor....meaning you have a LOT of VE table cells at the top end your never going to be able to use. Rather then letting those cells just sit there taking up the valuable resolution your lacking you can fudge the Map Offset and Scaler so that as far as the PCM's concerned you are able to max out the values. You make the PCM think that it's seeing the Map sensor at 4.5 volts when really it's only at 2.9 volts. You have altered the ramp on the 0-5 volt ADC now to suit your needs when in fact your map sensor will never get above 3 volts.

Now I know you might be thinking I can't do that....or it won't work.....or that's crazy. You can't make the PCM read a bogus value when it's actually something else and expect things to work right....... But actually you can. Your the one in control of what the PCM will do at any given value and your the one that will be altering what the value will be VS what it actually is. This is something that will mess with your mind in the same way looking at a 1 bar map table and trying to tell your self 80 kpa isn't 80 kpa it;s really 158 kpa. What you see and know by sight are going to be the biggest draw back to doing this. Letting your mind open up and ignore what your eyes are telling you is whats going to be the hardest thing and even after a great deal of though on this for a number of weeks....it might have been months...the point is I wasn't able come up with easy way to make this "display" or even formattable in a manner that isn't going to be confusing.....at least with the tools we have to work with in Tuner Pro. The first person that's able to actually do this in a vehicle and get it working smoothly and in a usable manner is going to be a BEAST and likely it won't be done by a tuner. This will take some amazing mental skills to be able to make sense of what's being done as what's being show it's going to make any sense.

And to make this sound even worse.....the only way to get the actual MAP voltage value is by reading the sensor with a volt meter and comparing that with what's shown by a scan tool from the PCM. Of course once it was rescaled to the desired range none of this matters and you could just reply on readings from the PCM again since your going to leave your self a little overhead anyways you'd never actually have the PCM reading for the MAP maxed out.

I really don't feel like typing out a full explanation so use some imagination here but this also works on the bottom end of the table as well, unless your running a cam that generates a TON of low end vacuum

your never going to use the very low end of the map sensor so removing the bottom end of the maps range by increasing the initial sensor offset works in the same manner as above and lets you free up cells that can then be used to gain back some table resolution in the area where you actually need it.

your never going to use the very low end of the map sensor so removing the bottom end of the maps range by increasing the initial sensor offset works in the same manner as above and lets you free up cells that can then be used to gain back some table resolution in the area where you actually need it.So Yes.....the long version of the answer is that you can squeeze a bit more range back into the table by clipping off the upper and lower ends of the MAP reading using some rather unconventional.......but I guess if your using a stock OS for boost in the first place that already makes it pretty unconventional....this just takes things to the next level I guess lol.

Last edited by PeteS160; 10-05-2019 at 11:44 PM.

#634

You guys rock.

I'm not used to g/cyl but if that's what the '411 uses I can adapt. I still have to connect the injectors, coils and sensors to the harness so it'll be maybe 2-3 weeks before I'm ready for 1st start but this week I'll set the bench back up. Also waiting on some wire for the alternator that I've had trouble getting.

Pete, this engine is much like you described. Boost is not likely to ever go over 7psi and like you mentioned I generally set the lowest cell to 20. So my working range is 20-150. Cutting that in half with the 2-bar means using actual numbers from 10 to 75. I'm not sure I follow why those values can't just be entered into the cells though. Apparently I'm missing something. I do follow the part about expected values but the 2 bar makes it an easy mental exercise to just double the value. It's going to be a fairly serious transition to GM after years with MS so I'm not expecting to completely digest this all overnight. I greatly appreciate your patience and I'm doing my best to follow your discussions. For the most part I think I understand.

Just a stupid question, is there any practical way to enter two numbers into one cell? Like with a diagonal or color coding or large and small fonts for instance? I was just thinking that if you could then maybe you could enter the MAP voltage as a shadow value and the calculated value as the prominent number. Maybe not practical, just trying to come up with an idea.

Jim

I'm not used to g/cyl but if that's what the '411 uses I can adapt. I still have to connect the injectors, coils and sensors to the harness so it'll be maybe 2-3 weeks before I'm ready for 1st start but this week I'll set the bench back up. Also waiting on some wire for the alternator that I've had trouble getting.

Pete, this engine is much like you described. Boost is not likely to ever go over 7psi and like you mentioned I generally set the lowest cell to 20. So my working range is 20-150. Cutting that in half with the 2-bar means using actual numbers from 10 to 75. I'm not sure I follow why those values can't just be entered into the cells though. Apparently I'm missing something. I do follow the part about expected values but the 2 bar makes it an easy mental exercise to just double the value. It's going to be a fairly serious transition to GM after years with MS so I'm not expecting to completely digest this all overnight. I greatly appreciate your patience and I'm doing my best to follow your discussions. For the most part I think I understand.

Just a stupid question, is there any practical way to enter two numbers into one cell? Like with a diagonal or color coding or large and small fonts for instance? I was just thinking that if you could then maybe you could enter the MAP voltage as a shadow value and the calculated value as the prominent number. Maybe not practical, just trying to come up with an idea.

Jim

#635

TECH Enthusiast

Thread Starter

You guys rock.

Pete, this engine is much like you described. Boost is not likely to ever go over 7psi and like you mentioned I generally set the lowest cell to 20. So my working range is 20-150. Cutting that in half with the 2-bar means using actual numbers from 10 to 75. I'm not sure I follow why those values can't just be entered into the cells though. Apparently I'm missing something. I do follow the part about expected values but the 2 bar makes it an easy mental exercise to just double the value. It's going to be a fairly serious transition to GM after years with MS so I'm not expecting to completely digest this all overnight. I greatly appreciate your patience and I'm doing my best to follow your discussions. For the most part I think I understand.

Just a stupid question, is there any practical way to enter two numbers into one cell? Like with a diagonal or color coding or large and small fonts for instance? I was just thinking that if you could then maybe you could enter the MAP voltage as a shadow value and the calculated value as the prominent number. Maybe not practical, just trying to come up with an idea.

Jim

Pete, this engine is much like you described. Boost is not likely to ever go over 7psi and like you mentioned I generally set the lowest cell to 20. So my working range is 20-150. Cutting that in half with the 2-bar means using actual numbers from 10 to 75. I'm not sure I follow why those values can't just be entered into the cells though. Apparently I'm missing something. I do follow the part about expected values but the 2 bar makes it an easy mental exercise to just double the value. It's going to be a fairly serious transition to GM after years with MS so I'm not expecting to completely digest this all overnight. I greatly appreciate your patience and I'm doing my best to follow your discussions. For the most part I think I understand.

Just a stupid question, is there any practical way to enter two numbers into one cell? Like with a diagonal or color coding or large and small fonts for instance? I was just thinking that if you could then maybe you could enter the MAP voltage as a shadow value and the calculated value as the prominent number. Maybe not practical, just trying to come up with an idea.

Jim

The size of the VE table is a fixed number of cells, it doesn't matter if you have a 1 bar, 2 bar or 3 bar map. Every time you increase the resolution of the MAP sensor(Bar rating) you lower the number of cells that are going to be usable for a given range. Now the value's that have to bit fit in that range don't change. With a 1 bar MAP the range is 0-5 volts where 0 volts represents 14.7 inch pounds of vacuum and 5 volts represents a reading equal to atmospheric pressure or 0 inch pounds of vacuum in the intake. With a 2 Bar Map the previous range is now squished into the 0-2.5 volt range. Going back to the XDF, the size of the VE table has not changed and neither have the values they are mapped to based on actual voltage. What has changed is that now the XDF is showing values that are meaning less; it should be showing KPA values that reflect a 2 BAR map sensor rather then 1 bar values. Unfortunately there is no simple way to directly convert the XDF's 1 bar values into 2 bar values. They could be made close(ish) but they would not be accurate by any means.

So I have no idea what you mean when you say you set your working range as 20-150, but you can NOT actually change the scaling in the VE table. You can choose to only alter cells with in a given range but your going to have cells outside of the range you want to work with that you can not do anything about. Your VE tables is going to display in Tuner Pro as 10KPA to 105 KPA but in reality it's going to be 8.8 KPA to 208 KPA. Until someone sits down and crunches the numbers on the conversion between a 1 bar and 2 bar that matches the headers Tuner Pro works with it's going to be extremely challenging to make this work effectively.

The following users liked this post:

kpeters59 (10-07-2019)

#636

Ah, so you are saying that to change the resolution of the cells in the map you have to do that in the XDF file then? OK. Using MS as a frame of reference doesn't seem to work here then, as in MS you can directly change the cell rpm and MAP value on the table axis, then your advance or fueling value goes in the cell.

How difficult is it to edit the XDF? Clearly I need to become more familiar with how this all works, but then I already knew that. This is one area I will have to concentrate on.

But for short term, keeping in mind that all of these maps can be thought of somewhat as floating values, does it really matter if a cell is at 100 kPa or 108? A good estimate is always better than a bad calculation so for rough tuning the values can be thought of as half that of a 1-bar which is enough to get reasonably close in an initial tune. After that it's mostly a matter of making adjustments to get it to run better. Not sure that would be close enough for an AFR table but it should be good enough on the VE and advance to get the engine running and driveable I think. The values at the high end aren't far from being halved with the 2-bar so it's easy to estimate. At and just off idle they are not, so a fudge factor needs to be added but with those values at hand that's also fairly easy to estimate or calculate.

Of course, cutting the table's usable range down to half makes for cruder tuning (but still a bit better than a carb's idle, midrange, and WOT circuits I would think) so changing the cell resolution looks to me like the proper solution. But maybe not. What works one place may not work in another.

Jim

How difficult is it to edit the XDF? Clearly I need to become more familiar with how this all works, but then I already knew that. This is one area I will have to concentrate on.

But for short term, keeping in mind that all of these maps can be thought of somewhat as floating values, does it really matter if a cell is at 100 kPa or 108? A good estimate is always better than a bad calculation so for rough tuning the values can be thought of as half that of a 1-bar which is enough to get reasonably close in an initial tune. After that it's mostly a matter of making adjustments to get it to run better. Not sure that would be close enough for an AFR table but it should be good enough on the VE and advance to get the engine running and driveable I think. The values at the high end aren't far from being halved with the 2-bar so it's easy to estimate. At and just off idle they are not, so a fudge factor needs to be added but with those values at hand that's also fairly easy to estimate or calculate.

Of course, cutting the table's usable range down to half makes for cruder tuning (but still a bit better than a carb's idle, midrange, and WOT circuits I would think) so changing the cell resolution looks to me like the proper solution. But maybe not. What works one place may not work in another.

Jim

#637

TECH Enthusiast

Thread Starter

Ah, so you are saying that to change the resolution of the cells in the map you have to do that in the XDF file then? OK. Using MS as a frame of reference doesn't seem to work here then, as in MS you can directly change the cell rpm and MAP value on the table axis, then your advance or fueling value goes in the cell.

Of course, cutting the table's usable range down to half makes for cruder tuning

The closest thing you can do is play with the 2 scalars for the MAP, I wrote a small bit about this before my initial post on how to alter the XDF for use with a 2 BAR map. I'm not going to suggest anyone attempt to change the scalars and if they do there won't be any one able to assist you with what your doing. It's all going to have to be done trial and error while keeping notes and testing the entire kpa range every time you make a change.(I am of course saying this needs to be done on a bench with a very accurate pump capable of vacuum and pressure not on a running engine)

I've attached a screen shot of what an altered header would look like if it was rescaled for a 2 bar MAP. Keep in mind.....THIS WILL NOT BE ACCURATE. It would be reasonably close(ish) but could be off by 5-8 KPA in places. I would not advise ANYONE to share/distribute an altered XDF unless they were to make sure table conversions from 1 bar to 2 bar were very accurate and that EVERY place there was any reference to map sensor KPA the scaling in the XDF was altered to reflect the overall change in the KPA range. It would also go with out saying to use such an XDF yourself and verify that everything does in fact work and things scale correctly.....and the engine can be made to run safely in boost. Only at that time would I even consider sharing or making such an XDF public and you would want to do so also including a copy of the base tune you have created with it for your own engine so that the next guy that tries to use it isn't starting from scratch with no idea what needs to be done with it.

This is one of the few times where sharing something that's incomplete, untested or very complicated (with no base to start from) will end up causing more trouble in the end then it's worth. A LOT of people are looking for a way to tune an OS with boost, masses will jump on the first bit of information they think will work regardless if its incomplete or not and then do nothing but bad mouth something that was made for free when it doesn't work for them....even if they didn't take the time to read some instruction.

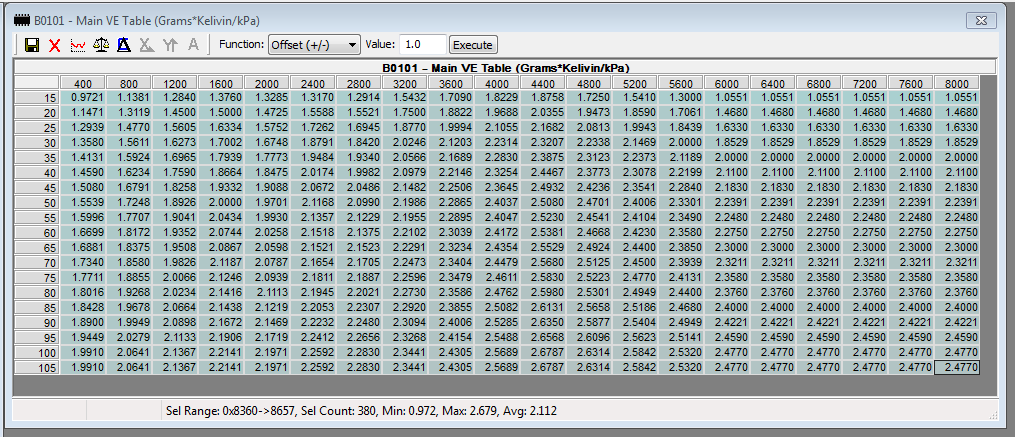

Now just to clear up what a VE table would look like for a 1 bar VS a 2 bar here are 2 pics of the same OS/XDF with the headers changed.

1 BAR MAP

2 BAR MAP. Gray upper part would be where engine is in vacuum, the white lower part is where the engine would be in boost.

#638

Seems like you've lost me Pete. I don't want to make assumptions but, looking at the 2 examples above, the 2nd one which is for a 2 bar map, then looking at the MAP values down the left hand side of the table, those sure look like 2-bar values and there must be some way to enter them if they are there. Maybe I'm just missing the point, but 9 rows in the N/A section seems to me to be enough to work with, and 10 rows in the boosted section is more than enough. I was working with 12x12 tables for both and was able to do OK with that. Now the values in the cells obviously can't be right for both tables but that's where the tuning comes in, right? It all looks pretty straightforward to me, am I missing something here that makes this not work? Didn't GM sell boosted engines in '02?

Jim

Jim

#639

TECH Enthusiast

Thread Starter

Seems like you've lost me Pete. I don't want to make assumptions but, looking at the 2 examples above, the 2nd one which is for a 2 bar map, then looking at the MAP values down the left hand side of the table, those sure look like 2-bar values and there must be some way to enter them if they are there. Maybe I'm just missing the point, but 9 rows in the N/A section seems to me to be enough to work with, and 10 rows in the boosted section is more than enough. I was working with 12x12 tables for both and was able to do OK with that. Now the values in the cells obviously can't be right for both tables but that's where the tuning comes in, right? It all looks pretty straightforward to me, am I missing something here that makes this not work? Didn't GM sell boosted engines in '02?

Jim

Jim

And GM did not make a boosted engine with a PCM...or OS that is usable on the 24X LS engine regardless of the year. If you jump up a few years the CTSV was offered super charged but it's a 4th gen engine with the 58X crank sensor and the Pcm's are not even close to being the same from a flashing standpoint or hardware standpoint.

#640

OK, thanks Pete. That's good to know.

There's no doubt that a double 19x19 table will give exceptional resolution. To me that would represent an embarrassment of riches as a single table that size is 3 more per axis than ANY MS controller can do regardless of boost level. I'd hardly know what to do with all the extra cells with twice that much. So if I understand you correctly, for once the "bad news" makes me very very happy! If I can use a table very similar to that second one and the controller is happy with it, I could ask for no more. It's better than anything I ever had to work with before.

Jim

There's no doubt that a double 19x19 table will give exceptional resolution. To me that would represent an embarrassment of riches as a single table that size is 3 more per axis than ANY MS controller can do regardless of boost level. I'd hardly know what to do with all the extra cells with twice that much. So if I understand you correctly, for once the "bad news" makes me very very happy! If I can use a table very similar to that second one and the controller is happy with it, I could ask for no more. It's better than anything I ever had to work with before.

Jim