Bank to bank .50 afr difference open loop ????

#1

TECH Fanatic

Thread Starter

iTrader: (21)

Join Date: Jan 2008

Location: morristown/newport,tn

Posts: 1,054

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys so I am currently working on my VE table and 2k-4K I have it dialed in waiting to get on the dyno to finish it up. But here is what I am having issues with.

While in forced open loop failed maf mode

Bank 1 will be spot on for commanded or close to but bank 2 seems to have a mind of its own

1500-2k bank 2 .50 afr leaner

2k-2500 bank 2 and 1 the same

2500-3500 bank 2 .50 afr leaner

3500-6000 bank 2 .50 afr richer

Also the difference can be seen in narrowband voltage.

Vehicle:

2006 Chevy silverado manual trans

Mods:

Lq9 Bottom end

243s

.030 head gaskets

Ls7 lifters

228/232 .600 .600 112 lsa cam

Yella terra roller rockers

Meiling high pressure oil pump

Fic 42lb injectors

Holley 255lph drop in fuel pump module

Returnless rails

No evap

Air raid intake tube

Stock air box

K&n filter

87mm tb

Trailblazer ss/nbss intake

Xlink tb adapter

Msd pro 8287 ls2/ls7 style coils

Msd 6014 ingnition controller(yes I know the stock ignition system is fine lol)

Ngk bre7 plugs gapped at .035

Msd plug wires----accept ceramic boots now

(2) innovate lc2 wideband controllers

New denso oxygen sensors

Diag done:

Smoked intake found no leaks

Recalibrated wideband sensors

Moved widebands and controllers side to side

Retightened all exhaust connections even used rtv on the band clamps (that was a mess)

Swapped injectors from bank to bank

Swapped coil packs bank to bank

New plugs

New plug wires

Monitored fuel pressure with a pressure transducer and labscope throughout runs noticed no dropouts or low pressure

Compression test all cylinders show within a few psi of each other

Used a lab scope to verify actually bank 1 and 2 pulse widths were correct

Swapped PCM

Verified torque on all rockers

Verified torque on headers

New AC delco injector plugs

New improved style intake gaskets

Removed msd system and used PCM for ignition control

Removed all vacuum hose from intake except brake booster hose

Any help is appreciated I've fired the parts cannon at this truck I'm really beginning to become frustrated and hate seeing this thing lol

I've read multiple threads and tried everything I know to do at this point I'm lost.

While in forced open loop failed maf mode

Bank 1 will be spot on for commanded or close to but bank 2 seems to have a mind of its own

1500-2k bank 2 .50 afr leaner

2k-2500 bank 2 and 1 the same

2500-3500 bank 2 .50 afr leaner

3500-6000 bank 2 .50 afr richer

Also the difference can be seen in narrowband voltage.

Vehicle:

2006 Chevy silverado manual trans

Mods:

Lq9 Bottom end

243s

.030 head gaskets

Ls7 lifters

228/232 .600 .600 112 lsa cam

Yella terra roller rockers

Meiling high pressure oil pump

Fic 42lb injectors

Holley 255lph drop in fuel pump module

Returnless rails

No evap

Air raid intake tube

Stock air box

K&n filter

87mm tb

Trailblazer ss/nbss intake

Xlink tb adapter

Msd pro 8287 ls2/ls7 style coils

Msd 6014 ingnition controller(yes I know the stock ignition system is fine lol)

Ngk bre7 plugs gapped at .035

Msd plug wires----accept ceramic boots now

(2) innovate lc2 wideband controllers

New denso oxygen sensors

Diag done:

Smoked intake found no leaks

Recalibrated wideband sensors

Moved widebands and controllers side to side

Retightened all exhaust connections even used rtv on the band clamps (that was a mess)

Swapped injectors from bank to bank

Swapped coil packs bank to bank

New plugs

New plug wires

Monitored fuel pressure with a pressure transducer and labscope throughout runs noticed no dropouts or low pressure

Compression test all cylinders show within a few psi of each other

Used a lab scope to verify actually bank 1 and 2 pulse widths were correct

Swapped PCM

Verified torque on all rockers

Verified torque on headers

New AC delco injector plugs

New improved style intake gaskets

Removed msd system and used PCM for ignition control

Removed all vacuum hose from intake except brake booster hose

Any help is appreciated I've fired the parts cannon at this truck I'm really beginning to become frustrated and hate seeing this thing lol

I've read multiple threads and tried everything I know to do at this point I'm lost.

#3

TECH Fanatic

iTrader: (1)

That isn't really that far off. One full point is in the realm of normal. This is why you race teams get 8 O2s and 8 EGT to tune each cylinder and gain sometimes 8% more power. Your crankshaft, your timing chain, and your camshaft are all flexing while it runs and this means your valves close at a slightly different time with each revolution. Then your intake and injectors don't flow the same. Well, maybe closer if you pay 4 times as much for injectors and have your heads and intake cnc to match perfect. Ever thought about why the factory divides the motor into banks and uses two (well 4) O2 sensors to tune each side independently?

Idle is usually the worst and try it with a cam that has over 30 degrees of overlap.

Idle is usually the worst and try it with a cam that has over 30 degrees of overlap.

#5

TECH Fanatic

Just average the two and run with it. Like what was already said, .5 off is hardly something to get bent out of shape over, especially considering in open loop it's not going to be perfect, unless you address transient fuel and charge temp bias too. And you'll have to get those perfect too, to have a "perfect" VE table in all conditions.

Besides, it sounds like you're planning on going back to MAF, or so if seems, maybe not, but if so don't worry about it. It's really not going to make a difference in the long run.

Besides, it sounds like you're planning on going back to MAF, or so if seems, maybe not, but if so don't worry about it. It's really not going to make a difference in the long run.

#6

Given that you've swapped injectors from side to side, and swapped the O2 sensors from side to side, I'm guessing that leaves three possibilities:

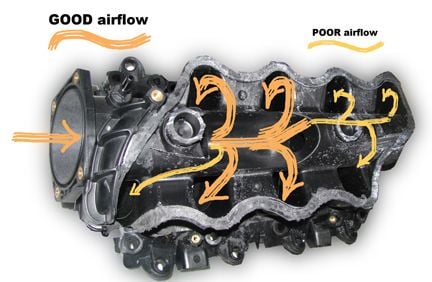

1) Your intake manifold doesn't flow the same side-to-side.

2) Your heads don't flow the same side-to-side.

3) Your fuel lines don't flow the same side-to-side.

None of them sound easy to fix, but fuel line routing sounds like the least painful thing to experiment with.

If you give up on finding the root cause and are still determined to fix it... consider getting O2 bungs added for each cylinder. Run with (for example) the left O2 sensor downstream of the merge collector and more the right O2 sensor from cylinder to cylinder and see how much they vary from the left-bank average (also check those RPM ranges at light-throttle, half-throttle, full-throttle, depending on how thorough you want to be). Then do the opposite, to see how much each left cylinder varies from the right-bank average. Then tweak the per-cylinder fueling accordingly. (I'm guessing your ECU/PCM has tables for that, but being new to GM I might be wrong...)

1) Your intake manifold doesn't flow the same side-to-side.

2) Your heads don't flow the same side-to-side.

3) Your fuel lines don't flow the same side-to-side.

None of them sound easy to fix, but fuel line routing sounds like the least painful thing to experiment with.

If you give up on finding the root cause and are still determined to fix it... consider getting O2 bungs added for each cylinder. Run with (for example) the left O2 sensor downstream of the merge collector and more the right O2 sensor from cylinder to cylinder and see how much they vary from the left-bank average (also check those RPM ranges at light-throttle, half-throttle, full-throttle, depending on how thorough you want to be). Then do the opposite, to see how much each left cylinder varies from the right-bank average. Then tweak the per-cylinder fueling accordingly. (I'm guessing your ECU/PCM has tables for that, but being new to GM I might be wrong...)

#7

TECH Fanatic

Thread Starter

iTrader: (21)

Join Date: Jan 2008

Location: morristown/newport,tn

Posts: 1,054

Likes: 0

Received 0 Likes

on

0 Posts

Given that you've swapped injectors from side to side, and swapped the O2 sensors from side to side, I'm guessing that leaves three possibilities:

1) Your intake manifold doesn't flow the same side-to-side.

2) Your heads don't flow the same side-to-side.

3) Your fuel lines don't flow the same side-to-side.

None of them sound easy to fix, but fuel line routing sounds like the least painful thing to experiment with.

If you give up on finding the root cause and are still determined to fix it... consider getting O2 bungs added for each cylinder. Run with (for example) the left O2 sensor downstream of the merge collector and more the right O2 sensor from cylinder to cylinder and see how much they vary from the left-bank average (also check those RPM ranges at light-throttle, half-throttle, full-throttle, depending on how thorough you want to be). Then do the opposite, to see how much each left cylinder varies from the right-bank average. Then tweak the per-cylinder fueling accordingly. (I'm guessing your ECU/PCM has tables for that, but being new to GM I might be wrong...)

1) Your intake manifold doesn't flow the same side-to-side.

2) Your heads don't flow the same side-to-side.

3) Your fuel lines don't flow the same side-to-side.

None of them sound easy to fix, but fuel line routing sounds like the least painful thing to experiment with.

If you give up on finding the root cause and are still determined to fix it... consider getting O2 bungs added for each cylinder. Run with (for example) the left O2 sensor downstream of the merge collector and more the right O2 sensor from cylinder to cylinder and see how much they vary from the left-bank average (also check those RPM ranges at light-throttle, half-throttle, full-throttle, depending on how thorough you want to be). Then do the opposite, to see how much each left cylinder varies from the right-bank average. Then tweak the per-cylinder fueling accordingly. (I'm guessing your ECU/PCM has tables for that, but being new to GM I might be wrong...)

I would hope both heads flow the same as they are both stock castings. But who knows.

As far as the fuel is concerned I'm running the returnless metal truck rails maybe I could swap the feed to the front of the engine on bank 2 and see if the problem swaps. Never thought there could be a difference in pressure on the feed side and the deadhead side as I'm always measuring pressure on the deadhead side there really no way to measure on the feed side of the rail.

Trending Topics

#9

TECH Apprentice

I'm in the middle of tuning my turbo car with a huron speed v3 kit, I ran my car with out charge pipe on intake to check for leaks etc...(same N.A. tune) the first thing I noticed was my fuel trims was way off from bank to bank when in closed loop. they was almost near the same for years. I'm guessing it's because of the hot side header lengths? I've been trying to dial in the v.e. tables with auto v.e. but I have very lean spikes. going to try and use o2's and see what happens. in theory I will need more fuel on one bank do to header length which should not be a problem as long as it is dialed in?

#10

As far as the fuel is concerned I'm running the returnless metal truck rails maybe I could swap the feed to the front of the engine on bank 2 and see if the problem swaps. Never thought there could be a difference in pressure on the feed side and the deadhead side as I'm always measuring pressure on the deadhead side there really no way to measure on the feed side of the rail.

If that is indeed the culprit, it would be interesting to see if switching to a return system fixes it. Or maybe with aftermarket rails and creative fuel lines you could evenly pressurize each end of each rail. (Warning: I've never tried it. I'm just making this **** up as I go along.)

Which bank is on the feed side? If it's the deadhead side that's going leaner at high flow, this seems like a promising theory.