One more time BUILD THREAD I must be stupid

#1

So I guess im gonna try this one more time. I recently blew up my 418 LS3 build. Nothing but the heads are salvageable.

If anyone has any insight to help me not waste my money on the wrong parts I would greatly appreciate it.

My new motor will probably be as follows

Dart SHP block

4.125 bore 4.1 stroke.

cam motion solid roller

trick flow 255 heads.

my issues are :

cam selection

compression ratio

what is the limit of airflow of the trickflow heads.

what is the limit of the intake i have

based on my few runs i had before it blew. The other motors power was falling off sooner then i expected based on the big cam i had. was the cam just wrong? or are the heads maxed out?

Specs from the old engine

trick flow 255 heads with hollow intake valves

4.08 bore

4 inch stroke

2 inch headers

sheet metal intake and 102 tb

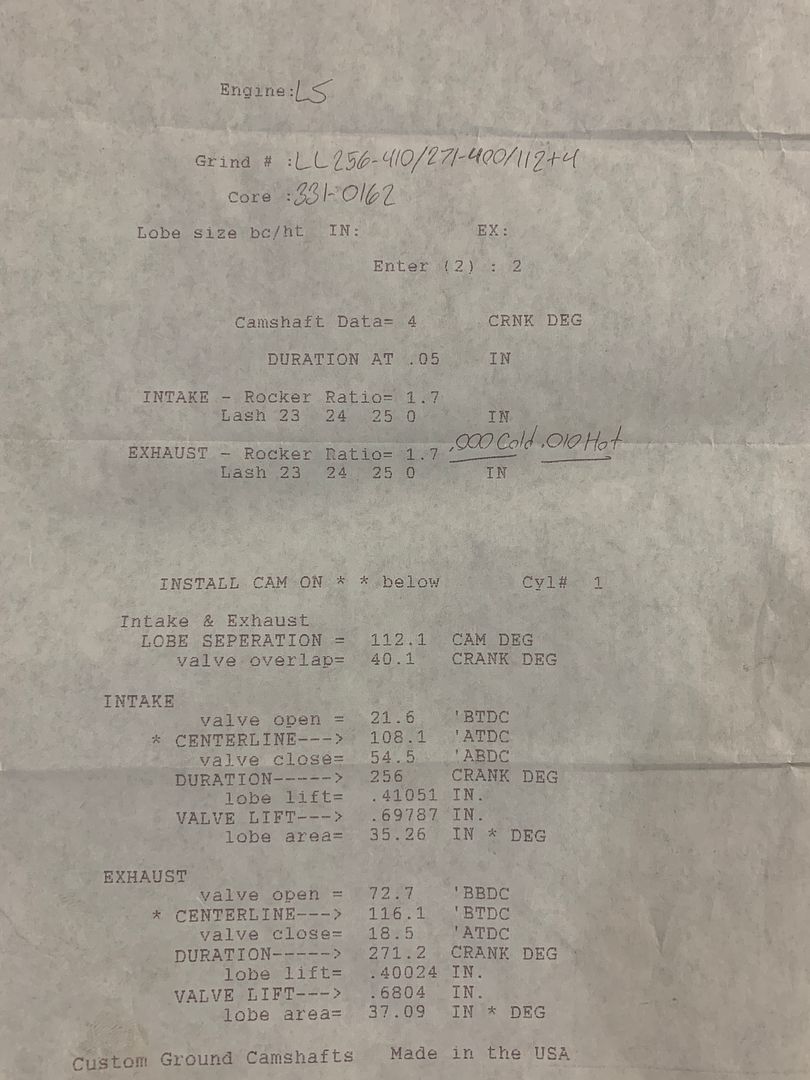

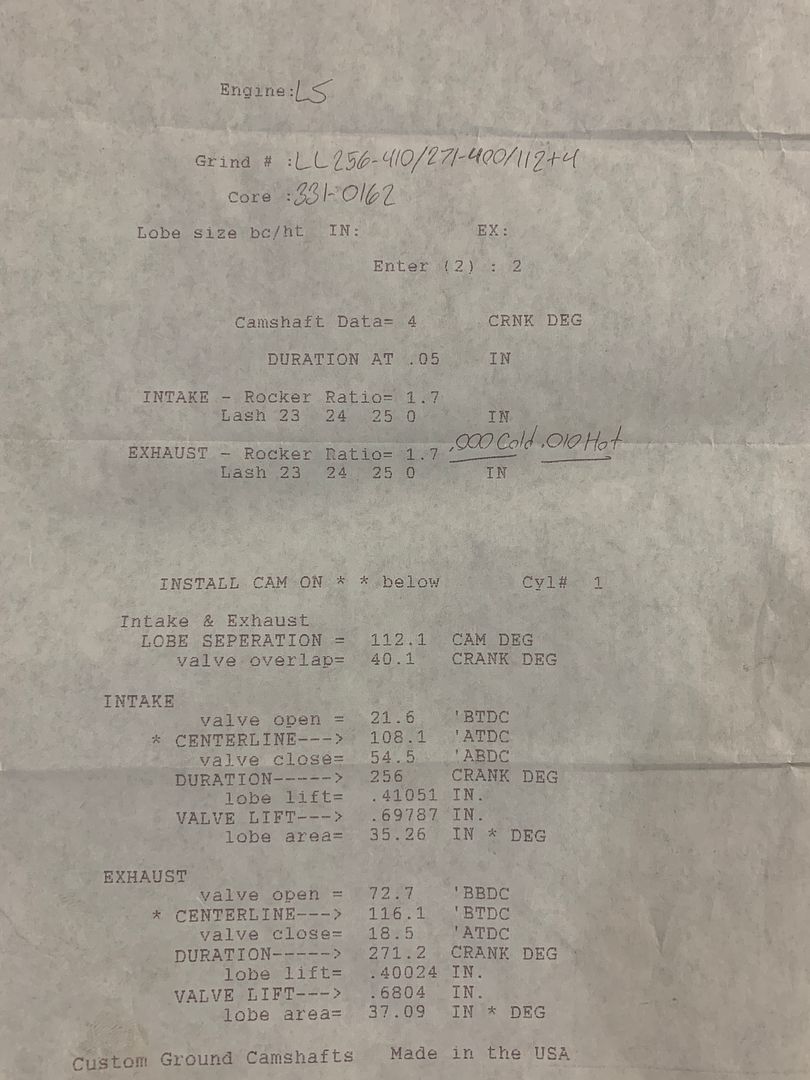

cam motion llsr

around 13.5 compression

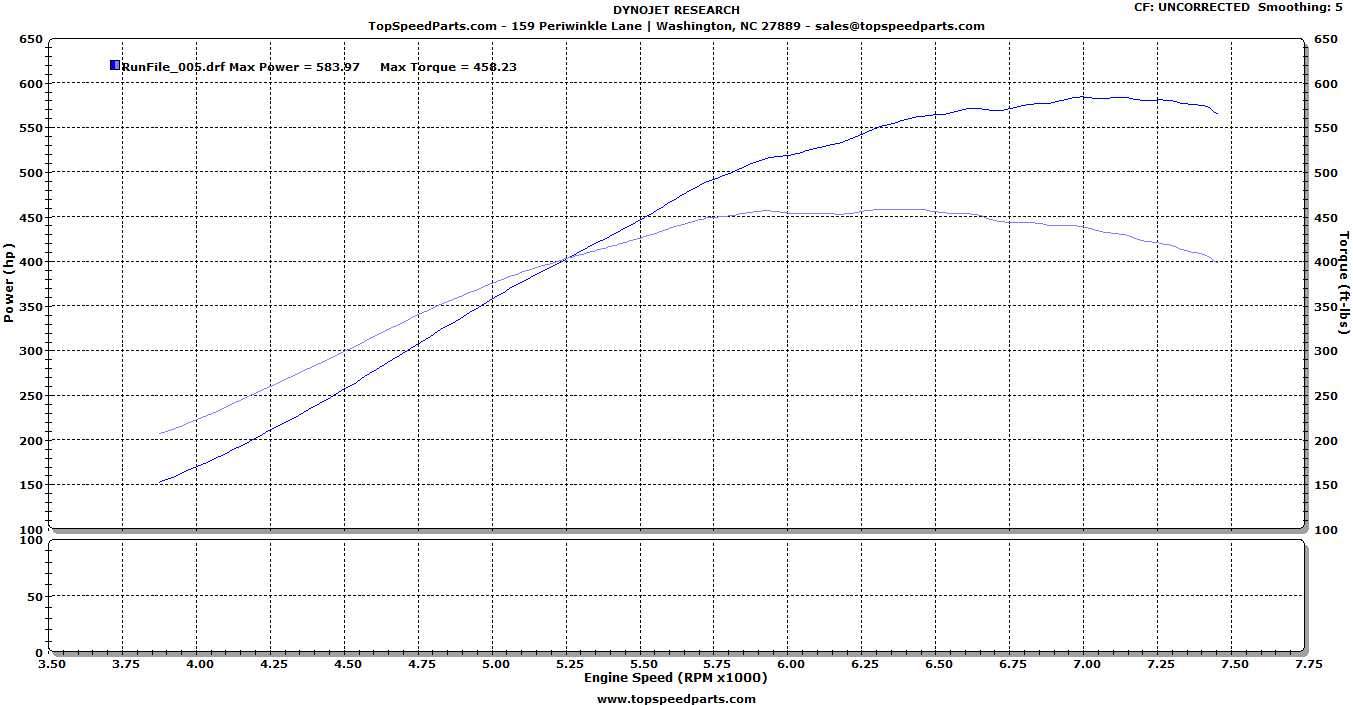

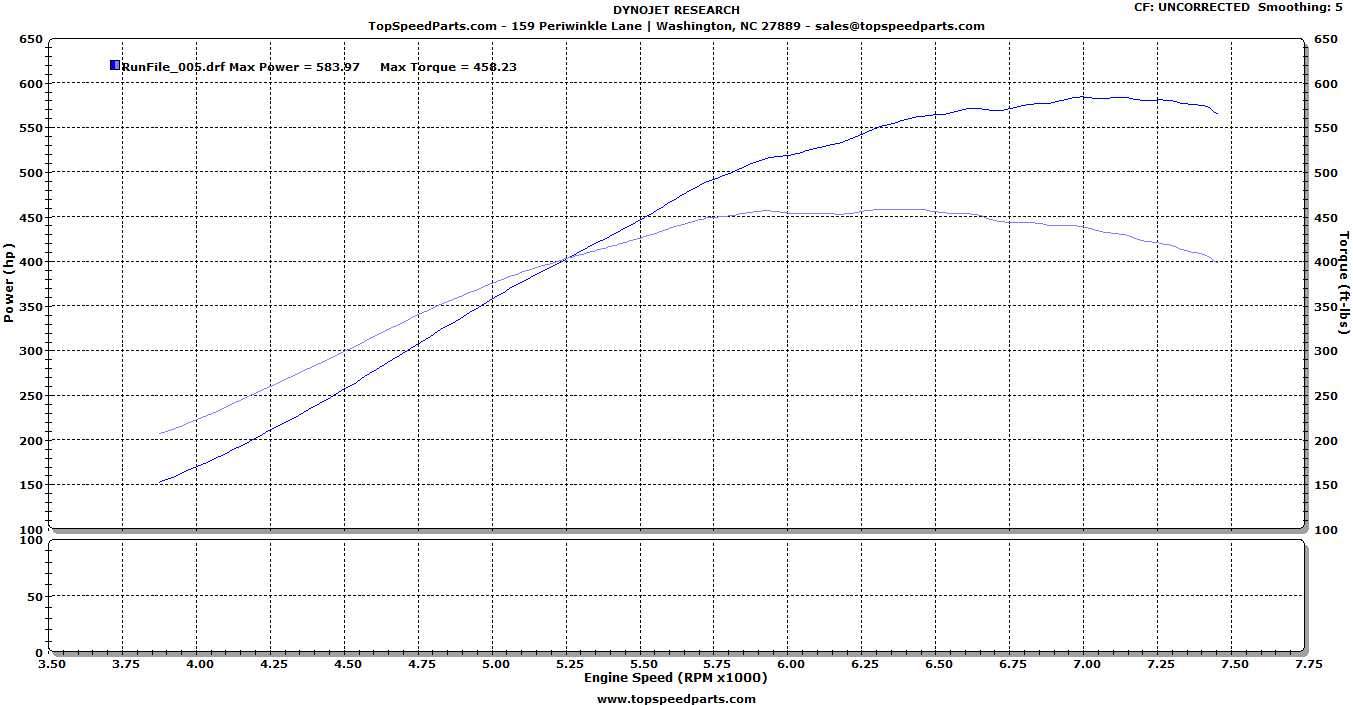

here is the cam specs and dyno chart

any help would be appreciated.

If anyone has any insight to help me not waste my money on the wrong parts I would greatly appreciate it.

My new motor will probably be as follows

Dart SHP block

4.125 bore 4.1 stroke.

cam motion solid roller

trick flow 255 heads.

my issues are :

cam selection

compression ratio

what is the limit of airflow of the trickflow heads.

what is the limit of the intake i have

based on my few runs i had before it blew. The other motors power was falling off sooner then i expected based on the big cam i had. was the cam just wrong? or are the heads maxed out?

Specs from the old engine

trick flow 255 heads with hollow intake valves

4.08 bore

4 inch stroke

2 inch headers

sheet metal intake and 102 tb

cam motion llsr

around 13.5 compression

here is the cam specs and dyno chart

any help would be appreciated.

#2

Someone like Darthv8r could definitely help you out with most of this.

But firstly, did you find the root cause of your first motor exploding? What happened? Knowing what caused the first try to fail, is probably our best learning experience.

Was it tuned at the Dyno? (Or just ran on the rollers for numbers?)

How was the AFR?

Was PTV checked?

Did the motor give any symptoms before its' demise?

But firstly, did you find the root cause of your first motor exploding? What happened? Knowing what caused the first try to fail, is probably our best learning experience.

Was it tuned at the Dyno? (Or just ran on the rollers for numbers?)

How was the AFR?

Was PTV checked?

Did the motor give any symptoms before its' demise?

#3

Someone like Darthv8r could definitely help you out with most of this.

But firstly, did you find the root cause of your first motor exploding? What happened? Knowing what caused the first try to fail, is probably our best learning experience.

Was it tuned at the Dyno? (Or just ran on the rollers for numbers?)

How was the AFR?

Was PTV checked?

Did the motor give any symptoms before its' demise?

But firstly, did you find the root cause of your first motor exploding? What happened? Knowing what caused the first try to fail, is probably our best learning experience.

Was it tuned at the Dyno? (Or just ran on the rollers for numbers?)

How was the AFR?

Was PTV checked?

Did the motor give any symptoms before its' demise?

i dropped the heads off at the machine shop this morning and i showed him the carnage in the block. It appears the number one main bearing was starved for oil. which would starve the number one rod bearing. all other bearings in the motor look good.

to answer other questions.

it was dyno tuned

the ptv was check and there was plenty of room

afr's were perfect.

so im thinking there must have been something wrong with the block casting. When i bought the block it was used and the number one cylinder was scored which is why i had to bore it out to 4.08.

then last year i spun the number one rod bearing with no warning.

then last week i chunked the number one rod with no warning.

no oil pressure changes, no noises, nothing

#6

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,835 Likes

on

1,145 Posts

@AndyTA, thank you for the kind words

Short answer, on your heads carrying power into higher RPM, for the new, larger engine, tfs255 won't be enough. Even with someone like TEA touching them up, they are flowing around 375 at 700 lift. I'm basing this on you seem unhappy it did not carry out to 8000? Although, I do wonder how much of that was mechanical drag from the bearing dying. There are two cylinder heads that I think will meet your needs nicely. First is tony's 265 based off the tfs265. He's hitting 410 cfm with a 265 runner. Only one other head I'm aware of in that flow territory, and that's brodix BR7 273, which hits 415 cfm. Either way, those are both LS7 castings and ~40 cfm better flow from a very modest bump in port volume. Probably not what you wanted to hear, and I'm really sorry. But with both of these over 400 CFM, you should have a foundation for 800+ FWHP.

As to cam, when i was looking at a 454, I was at 12.5:1 and a 270/290 cam. I think that's about where you'll be on the cam specs. I think your current cam is enough cam for the 418. I think it will be small on a 440+. Depending on RPM, you may even end up in the 280/300 range. Would depend on planned compression, which of course is fuel-dependent. Cam that big should be OK, but idle like ****.

On intake, i wonder if you will need more throttle area than a 102 can provide. Your intake options may need to get more "exotic".

Something else to throw out there... consider porting the oil filter opening through the pan. to allow more flow through there.

Short answer, on your heads carrying power into higher RPM, for the new, larger engine, tfs255 won't be enough. Even with someone like TEA touching them up, they are flowing around 375 at 700 lift. I'm basing this on you seem unhappy it did not carry out to 8000? Although, I do wonder how much of that was mechanical drag from the bearing dying. There are two cylinder heads that I think will meet your needs nicely. First is tony's 265 based off the tfs265. He's hitting 410 cfm with a 265 runner. Only one other head I'm aware of in that flow territory, and that's brodix BR7 273, which hits 415 cfm. Either way, those are both LS7 castings and ~40 cfm better flow from a very modest bump in port volume. Probably not what you wanted to hear, and I'm really sorry. But with both of these over 400 CFM, you should have a foundation for 800+ FWHP.

As to cam, when i was looking at a 454, I was at 12.5:1 and a 270/290 cam. I think that's about where you'll be on the cam specs. I think your current cam is enough cam for the 418. I think it will be small on a 440+. Depending on RPM, you may even end up in the 280/300 range. Would depend on planned compression, which of course is fuel-dependent. Cam that big should be OK, but idle like ****.

On intake, i wonder if you will need more throttle area than a 102 can provide. Your intake options may need to get more "exotic".

Something else to throw out there... consider porting the oil filter opening through the pan. to allow more flow through there.

#7

ModSquad

iTrader: (6)

@AndyTA, thank you for the kind words

Short answer, on your heads carrying power into higher RPM, for the new, larger engine, tfs255 won't be enough. Even with someone like TEA touching them up, they are flowing around 375 at 700 lift. I'm basing this on you seem unhappy it did not carry out to 8000? Although, I do wonder how much of that was mechanical drag from the bearing dying. There are two cylinder heads that I think will meet your needs nicely. First is tony's 265 based off the tfs265. He's hitting 410 cfm with a 265 runner. Only one other head I'm aware of in that flow territory, and that's brodix BR7 273, which hits 415 cfm. Either way, those are both LS7 castings and ~40 cfm better flow from a very modest bump in port volume. Probably not what you wanted to hear, and I'm really sorry. But with both of these over 400 CFM, you should have a foundation for 800+ FWHP.

As to cam, when i was looking at a 454, I was at 12.5:1 and a 270/290 cam. I think that's about where you'll be on the cam specs. I think your current cam is enough cam for the 418. I think it will be small on a 440+. Depending on RPM, you may even end up in the 280/300 range. Would depend on planned compression, which of course is fuel-dependent. Cam that big should be OK, but idle like ****.

On intake, i wonder if you will need more throttle area than a 102 can provide. Your intake options may need to get more "exotic".

Something else to throw out there... consider porting the oil filter opening through the pan. to allow more flow through there.

Short answer, on your heads carrying power into higher RPM, for the new, larger engine, tfs255 won't be enough. Even with someone like TEA touching them up, they are flowing around 375 at 700 lift. I'm basing this on you seem unhappy it did not carry out to 8000? Although, I do wonder how much of that was mechanical drag from the bearing dying. There are two cylinder heads that I think will meet your needs nicely. First is tony's 265 based off the tfs265. He's hitting 410 cfm with a 265 runner. Only one other head I'm aware of in that flow territory, and that's brodix BR7 273, which hits 415 cfm. Either way, those are both LS7 castings and ~40 cfm better flow from a very modest bump in port volume. Probably not what you wanted to hear, and I'm really sorry. But with both of these over 400 CFM, you should have a foundation for 800+ FWHP.

As to cam, when i was looking at a 454, I was at 12.5:1 and a 270/290 cam. I think that's about where you'll be on the cam specs. I think your current cam is enough cam for the 418. I think it will be small on a 440+. Depending on RPM, you may even end up in the 280/300 range. Would depend on planned compression, which of course is fuel-dependent. Cam that big should be OK, but idle like ****.

On intake, i wonder if you will need more throttle area than a 102 can provide. Your intake options may need to get more "exotic".

Something else to throw out there... consider porting the oil filter opening through the pan. to allow more flow through there.

Ive spent some time thinking about your recent dyno mess, and until you mentioned today that your number one main was hurt, Iíve been scratching my head on that. You previously said all your main bearings were fine, which didnít make sense. The Dart block has priority main oiling, so youíll not have to worry about this anymore.

Trending Topics

The following users liked this post:

anotherTodd (12-11-2020)

#9

TECH Fanatic

Join Date: Aug 2009

Location: Coast of San Mateo County Between Pacifica & HMB

Posts: 1,815

Received 215 Likes

on

128 Posts

I agree with both Darth & Chevelle re Tony's MMS 265 LS7 Heads, An alternative is Tony working your existing TFS LS3 Heads. He did a set for me that flowed 387 CFM @ .650". My Builder Dustin Lee Racing said they were capable of 800 HP at the crank shaft in the right build.

My 4.175" Bore 396" with 243/249 LLR made 690 Crank @ 7100-7300 Peak with 11.7:1 Comp and FAST LS3 Intake with Mid Length Runners. I would suggest the New Comp Hi-Ram Intake which is supposed to available shortly for both LS7 & 3 Heads.

That Intake will allow either type Head to reach its full potential with 440" & 8000 RPM.

I used a GM LSX Block for priority main Oiling which was a requirement for my build, along with a Dailey 3 Stage Dry Sump. There is horsepower (better ring seal etc, with a well planned Dry Sump Build) as well as longevity/reliability.

So just depends on horsepower goal and application up, to 800 horsepower I would have Tony work your Heads and put the savings into a better Intake. 820+ New Heads & Intake.

I am truly sorry for your Engine loss and wish you Good Luck with your current Build.

My 4.175" Bore 396" with 243/249 LLR made 690 Crank @ 7100-7300 Peak with 11.7:1 Comp and FAST LS3 Intake with Mid Length Runners. I would suggest the New Comp Hi-Ram Intake which is supposed to available shortly for both LS7 & 3 Heads.

That Intake will allow either type Head to reach its full potential with 440" & 8000 RPM.

I used a GM LSX Block for priority main Oiling which was a requirement for my build, along with a Dailey 3 Stage Dry Sump. There is horsepower (better ring seal etc, with a well planned Dry Sump Build) as well as longevity/reliability.

So just depends on horsepower goal and application up, to 800 horsepower I would have Tony work your Heads and put the savings into a better Intake. 820+ New Heads & Intake.

I am truly sorry for your Engine loss and wish you Good Luck with your current Build.

#11

Thanks for the info. Got good news from machine shop. Heads are good! gonna replace the valves from number one cylinder and go through everything else.

Probably gonna run those heads until i can buy something else.

Trying to decide between strokes? 4.1 or 4.125

Also 4.125 bore or go bigger?

Regardless of what heads i end up using it pretty apparent the intake manifold is a problem.

I may get a holley high ram and modify it for a bigger throttle body? Or i may weld a larger plenum on my current manifold and use a bigger tb?

Probably gonna run those heads until i can buy something else.

Trying to decide between strokes? 4.1 or 4.125

Also 4.125 bore or go bigger?

Regardless of what heads i end up using it pretty apparent the intake manifold is a problem.

I may get a holley high ram and modify it for a bigger throttle body? Or i may weld a larger plenum on my current manifold and use a bigger tb?

#13

I agree with both Darth & Chevelle re Tony's MMS 265 LS7 Heads, An alternative is Tony working your existing TFS LS3 Heads. He did a set for me that flowed 387 CFM @ .650". My Builder Dustin Lee Racing said they were capable of 800 HP at the crank shaft in the right build.

My 4.175" Bore 396" with 243/249 LLR made 690 Crank @ 7100-7300 Peak with 11.7:1 Comp and FAST LS3 Intake with Mid Length Runners. I would suggest the New Comp Hi-Ram Intake which is supposed to available shortly for both LS7 & 3 Heads.

That Intake will allow either type Head to reach its full potential with 440" & 8000 RPM.

I used a GM LSX Block for priority main Oiling which was a requirement for my build, along with a Dailey 3 Stage Dry Sump. There is horsepower (better ring seal etc, with a well planned Dry Sump Build) as well as longevity/reliability.

So just depends on horsepower goal and application up, to 800 horsepower I would have Tony work your Heads and put the savings into a better Intake. 820+ New Heads & Intake.

I am truly sorry for your Engine loss and wish you Good Luck with your current Build.

My 4.175" Bore 396" with 243/249 LLR made 690 Crank @ 7100-7300 Peak with 11.7:1 Comp and FAST LS3 Intake with Mid Length Runners. I would suggest the New Comp Hi-Ram Intake which is supposed to available shortly for both LS7 & 3 Heads.

That Intake will allow either type Head to reach its full potential with 440" & 8000 RPM.

I used a GM LSX Block for priority main Oiling which was a requirement for my build, along with a Dailey 3 Stage Dry Sump. There is horsepower (better ring seal etc, with a well planned Dry Sump Build) as well as longevity/reliability.

So just depends on horsepower goal and application up, to 800 horsepower I would have Tony work your Heads and put the savings into a better Intake. 820+ New Heads & Intake.

I am truly sorry for your Engine loss and wish you Good Luck with your current Build.

Last edited by topspeed1; 01-30-2019 at 09:32 PM.

#15

TECH Senior Member

#16

I think for now im gonna use my current heads to get it running. I really don't have the money to upgrade right now. Then im probably gonna get mamo 265s v2s

Darth is helping me with my cam. Thanks!

Next question i have is, Should I do 4.125 or bump it up to 4.155ish?

Probably gonna stick with 4.1 stroke maybe back it down to 4 inch?

Block is gonna take almost a month to get here, that sucks

but that give me a little more time to figure everything out.

Thanks again for the help.

Darth is helping me with my cam. Thanks!

Next question i have is, Should I do 4.125 or bump it up to 4.155ish?

Probably gonna stick with 4.1 stroke maybe back it down to 4 inch?

Block is gonna take almost a month to get here, that sucks

but that give me a little more time to figure everything out.

Thanks again for the help.

#17

Super Hulk Smash

iTrader: (7)

4.185" bore and 4.125" stroke if NA. Block will handle it.

LS3 heads will perform much better on bigger bores. The LS7 will still out run it, but the bigger the bore, the better for LS3.

Look at this data for LS3 heads. The TFS 255 fixes some of it by rolling the valve over to 12 degree. But here's what a stock LS3 head shows:

4.090" chamber diameter

.107" between a 2.165" valve @ .400" lift and the chamber edge, that gives:

.062" clearance from the bore wall on a 4.000" bore

.077" clearance from the bore wall on a 4.030" bore

.095" clearance from the bore wall on a 4.065" bore

Most would say you need DOUBLE that. More bore helps a lot with the valve shrouding. A 4.185" bore gets the valve out .155" on a stock LS3... .200" is still ideal. The larger valve in the TFS head and the rolled valve angle sort of negate each other.

That'll help with power production.

LS3 heads will perform much better on bigger bores. The LS7 will still out run it, but the bigger the bore, the better for LS3.

Look at this data for LS3 heads. The TFS 255 fixes some of it by rolling the valve over to 12 degree. But here's what a stock LS3 head shows:

4.090" chamber diameter

.107" between a 2.165" valve @ .400" lift and the chamber edge, that gives:

.062" clearance from the bore wall on a 4.000" bore

.077" clearance from the bore wall on a 4.030" bore

.095" clearance from the bore wall on a 4.065" bore

Most would say you need DOUBLE that. More bore helps a lot with the valve shrouding. A 4.185" bore gets the valve out .155" on a stock LS3... .200" is still ideal. The larger valve in the TFS head and the rolled valve angle sort of negate each other.

That'll help with power production.

#18

ModSquad

iTrader: (6)

4.185" bore and 4.125" stroke if NA. Block will handle it.

LS3 heads will perform much better on bigger bores. The LS7 will still out run it, but the bigger the bore, the better for LS3.

Look at this data for LS3 heads. The TFS 255 fixes some of it by rolling the valve over to 12 degree. But here's what a stock LS3 head shows:

4.090" chamber diameter

.107" between a 2.165" valve @ .400" lift and the chamber edge, that gives:

.062" clearance from the bore wall on a 4.000" bore

.077" clearance from the bore wall on a 4.030" bore

.095" clearance from the bore wall on a 4.065" bore

Most would say you need DOUBLE that. More bore helps a lot with the valve shrouding. A 4.185" bore gets the valve out .155" on a stock LS3... .200" is still ideal. The larger valve in the TFS head and the rolled valve angle sort of negate each other.

That'll help with power production.

LS3 heads will perform much better on bigger bores. The LS7 will still out run it, but the bigger the bore, the better for LS3.

Look at this data for LS3 heads. The TFS 255 fixes some of it by rolling the valve over to 12 degree. But here's what a stock LS3 head shows:

4.090" chamber diameter

.107" between a 2.165" valve @ .400" lift and the chamber edge, that gives:

.062" clearance from the bore wall on a 4.000" bore

.077" clearance from the bore wall on a 4.030" bore

.095" clearance from the bore wall on a 4.065" bore

Most would say you need DOUBLE that. More bore helps a lot with the valve shrouding. A 4.185" bore gets the valve out .155" on a stock LS3... .200" is still ideal. The larger valve in the TFS head and the rolled valve angle sort of negate each other.

That'll help with power production.

#20

ModSquad

iTrader: (6)

Agreed. For either his current heads, or Tonyís new V2.0 MMS 265ís, Iíd go 4.155Ē bore. Help the heads help you.