Making a New Front Shock Mount

#1

Okay, this is on a 99 Trans Am. I want to swap front shocks without unbolting the upper control arm. Technically I can already do that since I cut open the metal above the shock nut. I'm halfway done with the drivers side.

I was going to weld in a 1.5" diameter steel ring right above the shock nut and then weld in some side braces like stock. So I can basically undo the shock nut with an impact gun and drop the shock out the bottom.

That's cool and all, but should I go further?

Should I just bolt the upper control arm to the car with 4 bolts and then make a whole new style shock mount using a rod end or a bushing of some sort?

I'd kinda like to adjust my Koni shocks from under the hood. Any ideas on how I could do that?

Hell, should I just cut out the wheel wells and build new ones from steel tubing?

Here's me with most of the metal cut out.

I think I'll cut away the rest of that upper most brace (number 3). There are 3 layers of steel in all.

I cut the 1.5" diameter pipe about 1.5" tall (blue) and then add the reinforcement (pink).

I even found these cool rubber caps to pop on top to keep the water out.

I was going to weld in a 1.5" diameter steel ring right above the shock nut and then weld in some side braces like stock. So I can basically undo the shock nut with an impact gun and drop the shock out the bottom.

That's cool and all, but should I go further?

Should I just bolt the upper control arm to the car with 4 bolts and then make a whole new style shock mount using a rod end or a bushing of some sort?

I'd kinda like to adjust my Koni shocks from under the hood. Any ideas on how I could do that?

Hell, should I just cut out the wheel wells and build new ones from steel tubing?

Here's me with most of the metal cut out.

I think I'll cut away the rest of that upper most brace (number 3). There are 3 layers of steel in all.

I cut the 1.5" diameter pipe about 1.5" tall (blue) and then add the reinforcement (pink).

I even found these cool rubber caps to pop on top to keep the water out.

Last edited by JasonWW; 01-28-2011 at 03:48 AM.

#3

This is the koni top hat.

I can easily swap to a different style that has a rod end.

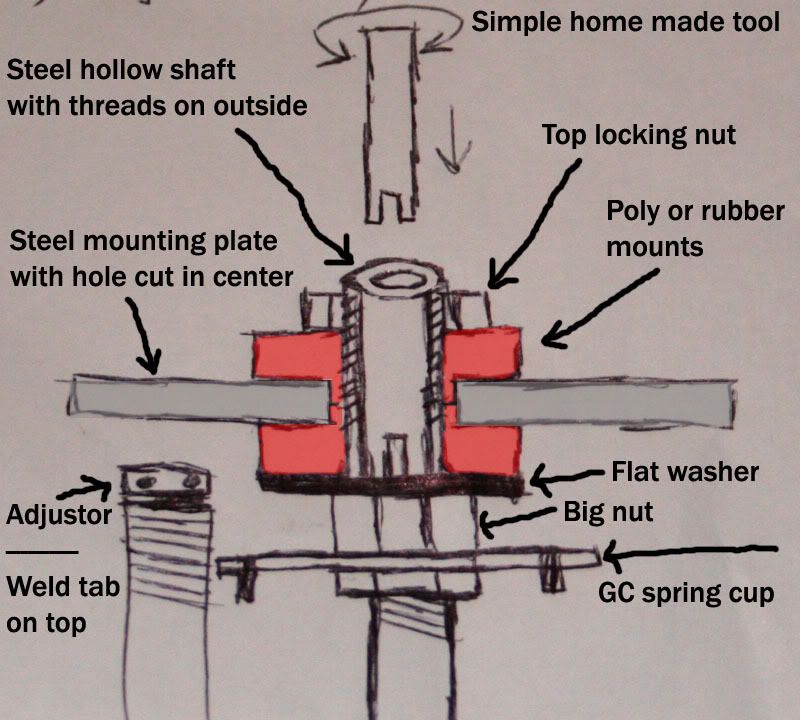

Then it's just a matter of making a simple mount. Maybe like this.

The only issue is that you have to fiddle in the wheel well to remove the shock as well as adjust it. So I'm not really diggin it.

Has anyone seen this done before?

Or have any suggestions?

I can easily swap to a different style that has a rod end.

Then it's just a matter of making a simple mount. Maybe like this.

The only issue is that you have to fiddle in the wheel well to remove the shock as well as adjust it. So I'm not really diggin it.

Has anyone seen this done before?

Or have any suggestions?

#6

Rod-end front shock in Fbody.

https://ls1tech.com/forums/suspensio...zing-ride.html

https://ls1tech.com/forums/suspensio...zing-ride.html

Trending Topics

#8

12 Second Club

iTrader: (21)

Join Date: Jun 2007

Location: Muskegon, MI

Posts: 1,102

Likes: 0

Received 0 Likes

on

0 Posts

Where did you fine that rubber cap? I have Penske 7500SA's that the adjuster is a small allen right in the top of the shock shaft. I want to cut a hole with a holesaw so I can just pop the hood and adjust but I like the idea of have a plug there.

#9

My shocks are already 3/4" higher than stock and the upper control arms are very close to touching the shock tower.

If I move the shock any higher, I will need to tub the wheel wells and redesign the upper control arms. I might do that later on, but not right now.

Remember that for every inch the shock goes up, the tire goes up 1.7" and you lose that same 1.7" on the extension side.

#10

If so, you don't want a rubber cap, a simple rubber plug would work better. Both parts can be found at a hardware store.

#13

12 Second Club

iTrader: (21)

Join Date: Jun 2007

Location: Muskegon, MI

Posts: 1,102

Likes: 0

Received 0 Likes

on

0 Posts

Do you mean for the compression/bump adjuster? I would assume it's facing outward away from the car for easy access through the wheelwell. Are you thinking of turning it inward and then cutting a hole near the headers to stick the allen key in?

If so, you don't want a rubber cap, a simple rubber plug would work better. Both parts can be found at a hardware store.

If so, you don't want a rubber cap, a simple rubber plug would work better. Both parts can be found at a hardware store.

#16

11 Second Club

iTrader: (103)

Join Date: Aug 2005

Location: South of West Point Iowa

Posts: 2,633

Likes: 0

Received 1 Like

on

1 Post

varishocks are sold by chris alston . . . heres an article w/them installed...

http://www.lsxtv.com/forum/chassiswo...over-2017.html

http://www.lsxtv.com/forum/chassiswo...over-2017.html

#17

I know we discussed this in the Penske thread, but I will continue here...

I looked at my edelbrock coilovers today and I don't know how a heim would hold up on the top of the shock. The size of the stud is only about 3/8", I could cut the stud down, rethread it lower and add an adjusting nut to keep it tight and in place, but I don't know how strong the 3/8 bolt would be without the rubber isolator, I would worry about it bending or breaking off on a big bump.

Now I know that you can get heims that thread onto a bolt thats already there and that fabbing a new upper mount would be pretty simple, but the durablilty is my only concern at this point. And that cutting off the stud on top of my coilovers might be a permanent move.

And then replacing the rubber bushing would increase the response of the shock like BRD-PREY mentioned in his post, not having the rubber mount there anymore.

Heres a pic of the heim I'm talking about

I looked at my edelbrock coilovers today and I don't know how a heim would hold up on the top of the shock. The size of the stud is only about 3/8", I could cut the stud down, rethread it lower and add an adjusting nut to keep it tight and in place, but I don't know how strong the 3/8 bolt would be without the rubber isolator, I would worry about it bending or breaking off on a big bump.

Now I know that you can get heims that thread onto a bolt thats already there and that fabbing a new upper mount would be pretty simple, but the durablilty is my only concern at this point. And that cutting off the stud on top of my coilovers might be a permanent move.

And then replacing the rubber bushing would increase the response of the shock like BRD-PREY mentioned in his post, not having the rubber mount there anymore.

Heres a pic of the heim I'm talking about

#18

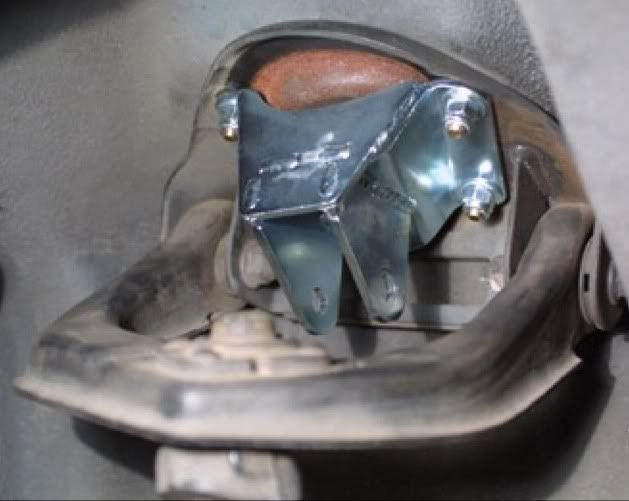

I'm sure it would work fine with an aftermarket coilover. Although it seems easy enough to just weld mounting tabs to the stock a-arm sheetmetal. Like the pic in post 3 and these below.

Unknown.

From Unbalanced Engineering.

These are LG Motorsports units.

LG again.

Last edited by JasonWW; 01-30-2011 at 03:00 AM.

#19

I know we discussed this in the Penske thread, but I will continue here...

I looked at my edelbrock coilovers today and I don't know how a heim would hold up on the top of the shock. The size of the stud is only about 3/8", I could cut the stud down, rethread it lower and add an adjusting nut to keep it tight and in place, but I don't know how strong the 3/8 bolt would be without the rubber isolator, I would worry about it bending or breaking off on a big bump.

Now I know that you can get heims that thread onto a bolt thats already there and that fabbing a new upper mount would be pretty simple, but the durablilty is my only concern at this point. And that cutting off the stud on top of my coilovers might be a permanent move.

And then replacing the rubber bushing would increase the response of the shock like BRD-PREY mentioned in his post, not having the rubber mount there anymore.

I looked at my edelbrock coilovers today and I don't know how a heim would hold up on the top of the shock. The size of the stud is only about 3/8", I could cut the stud down, rethread it lower and add an adjusting nut to keep it tight and in place, but I don't know how strong the 3/8 bolt would be without the rubber isolator, I would worry about it bending or breaking off on a big bump.

Now I know that you can get heims that thread onto a bolt thats already there and that fabbing a new upper mount would be pretty simple, but the durablilty is my only concern at this point. And that cutting off the stud on top of my coilovers might be a permanent move.

And then replacing the rubber bushing would increase the response of the shock like BRD-PREY mentioned in his post, not having the rubber mount there anymore.

I also would not feel good abouting all that compression load on the top 3/8 stud. When you look at the way the load is distributed on the stock mount, the stud only sees part of the load, the rest gets pressed down on the area surrounding the stud. About an 1/8" all around the stud.

The solution is to spread the load over that area around the stud. Doing so will increase the surface area from 3/8" to 5/8". Simply thread the new heim joint (like in your picture) all the way down against the shock body and tighten it to 33 foot pounds. If the heim joint needs to be higher, simply stack some 3/8 flat washers onto the stud and then tighten. Washers look unprofessional? Use a short piece of 3/8" inner diameter heavy wall tubing. Using this method I would feel 100% sure about it.

BTW, by switching to a heim joint your actually reducing the side loads on that top stud, not increasing them. The heim will let the shock pivot easily, while the stock mount forces the stud to compress rubber in order to pivot. So no worries about side load. Focus mainly on the compression load. Then the extension load second. Not a problem.

Last edited by JasonWW; 01-30-2011 at 08:46 AM.

#20

^^^Thats what I was thinking, tighten the heim down tight on top of the coilover or add a spacer like you mentioned. I'm still a little weary of the mount of stress applied there, but it would spread it our over a larger area. I'll check the thread pitch tomorrow and maybe order a couple of heims rather than the new shock mounts. This might solve my decision to buy new shock mounts, and if I dislike how it is I can always get a new set of UCA mounts

I'm subscribed and will post pics of what I come up with.

I'm subscribed and will post pics of what I come up with.