Can someone help me make sense of my driveline angles?

#1

Staging Lane

Thread Starter

Join Date: Aug 2011

Location: rapid city, sd

Posts: 96

Likes: 0

Received 0 Likes

on

0 Posts

I have the rear end supported on the axle, so having the car like this will affect all angles, but it's the relation of the angles to each other that I'm trying to make sense of. The car is lowered on BMR springs.

Measuring at the yoke on the differential, facing the engine, is pointing down at 1.2*

Measuring on the driveshaft, facing the engine, is pointing down at 1.3*

Measuring at the crankshaft pulley, the tailshaft of the transmission is pointing down at 2.5*

I've been chasing down a highway vibration for a while. I'm 100% it's drivetrain vibration because the frequency of the vibration is very fast, not a shaking like a tire issue would be. It wouldn't be an issue if I had a lower rear gear ratio, but at 4.10, I'm getting pretty bad vibrations around 77mph.

I already shimmed the transmission mount at close to 1/2", I have extended bolts in it to make sure they dig into the transmission enough and don't strip, but I'm kind of uncomfortable adding any more spacing. Shimming the transmission made a huge difference, I used to get vibrations starting at 60mph, and bad enough at 70 that I didn't want to go any faster.

As it is right now, I get no vibrations until 75mph, and they quickly get much worse as I approach 80mph. I feel like shimming created another problem: now the angle relation between my driveshaft and rear diff are too similar, and the needle bearings don't rotate enough for proper lubrication.

I've verified that:

-It isn't caused by 5th/6th gear

-Letting off the gas at speed letting the engine slow the car, and giving throttle to accelerate or maintain speed makes it vibrate, but reducing the throttle to a "sweet spot" where the vehicle is just barely slowing down eliminates all vibration.

Are these healthy angles? Should I be looking driveshaft balancing? Why did my transmission require so much shimming?

EDIT: Mods, I think I should have posted this in gears and axles. Please move if that is a more appropriate sub forum.

Measuring at the yoke on the differential, facing the engine, is pointing down at 1.2*

Measuring on the driveshaft, facing the engine, is pointing down at 1.3*

Measuring at the crankshaft pulley, the tailshaft of the transmission is pointing down at 2.5*

I've been chasing down a highway vibration for a while. I'm 100% it's drivetrain vibration because the frequency of the vibration is very fast, not a shaking like a tire issue would be. It wouldn't be an issue if I had a lower rear gear ratio, but at 4.10, I'm getting pretty bad vibrations around 77mph.

I already shimmed the transmission mount at close to 1/2", I have extended bolts in it to make sure they dig into the transmission enough and don't strip, but I'm kind of uncomfortable adding any more spacing. Shimming the transmission made a huge difference, I used to get vibrations starting at 60mph, and bad enough at 70 that I didn't want to go any faster.

As it is right now, I get no vibrations until 75mph, and they quickly get much worse as I approach 80mph. I feel like shimming created another problem: now the angle relation between my driveshaft and rear diff are too similar, and the needle bearings don't rotate enough for proper lubrication.

I've verified that:

-It isn't caused by 5th/6th gear

-Letting off the gas at speed letting the engine slow the car, and giving throttle to accelerate or maintain speed makes it vibrate, but reducing the throttle to a "sweet spot" where the vehicle is just barely slowing down eliminates all vibration.

Are these healthy angles? Should I be looking driveshaft balancing? Why did my transmission require so much shimming?

EDIT: Mods, I think I should have posted this in gears and axles. Please move if that is a more appropriate sub forum.

Last edited by lt16spd1; 03-06-2018 at 04:58 PM.

#2

11 Second Club

I guess the first thing is do you have an adjustable tq arm? I see your car is lowered. From what they say it's good to have a -2 degree difference between your engine/trans angle & the rear end yoke on a M6 car. Yours is -1.3 if I got that right. Seems when you shimmed the trans., getting better, you got somewhere.

#3

Staging Lane

Thread Starter

Join Date: Aug 2011

Location: rapid city, sd

Posts: 96

Likes: 0

Received 0 Likes

on

0 Posts

HOLY ****. I think I might have figured it out. I've been chasing this down for YEARS and just deal with it because it's not a daily driver and I don't go to the track. It's just a fun car to tear up the streets at low speed.

Anyways...

I found this on another post here

This quote by ******: "...Also if the dust cover for the pinion yoke on the rear end has a small weight tac welded to it..that was for the stock DS assembly and you would need to remove that for the Aluminum one if you do experience any vibes with it."

I don't know how I never noticed it before, but I do have that weight on my dust cover. I replaced my driveshaft with an aluminum one and never removed it. Out to do some grinding and I'll report back.

EDIT: Ugh. Took a quick drive on the highway. About 2 miles each way; first way seemed really smooth up to about 85mph, and the way back seemed even worse than before grinding away that piece.

Anyways...

I found this on another post here

This quote by ******: "...Also if the dust cover for the pinion yoke on the rear end has a small weight tac welded to it..that was for the stock DS assembly and you would need to remove that for the Aluminum one if you do experience any vibes with it."

I don't know how I never noticed it before, but I do have that weight on my dust cover. I replaced my driveshaft with an aluminum one and never removed it. Out to do some grinding and I'll report back.

EDIT: Ugh. Took a quick drive on the highway. About 2 miles each way; first way seemed really smooth up to about 85mph, and the way back seemed even worse than before grinding away that piece.

Last edited by lt16spd1; 03-06-2018 at 06:56 PM.

#5

Staging Lane

Thread Starter

Join Date: Aug 2011

Location: rapid city, sd

Posts: 96

Likes: 0

Received 0 Likes

on

0 Posts

The way I understand it, is driveline angles are a measurement of the relationship of the angles to each other, not relative to the ground. As long as the vehicle weight is correctly resting on the suspension, it would be accurate. Is this not true?

#7

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 79 Likes

on

70 Posts

Trending Topics

#8

Staging Lane

Thread Starter

Join Date: Aug 2011

Location: rapid city, sd

Posts: 96

Likes: 0

Received 0 Likes

on

0 Posts

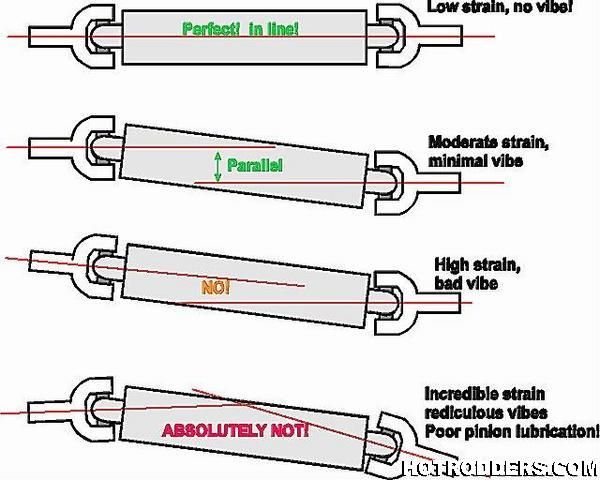

I found this picture posted on here before, and that's why I'm wondering about my driveline angles, because I believe I have the opposite of the bottom picture, with both angles pointing down. Actually, looking again, I believe I have the 3rd one. And even after shimming the transmission half an inch, I'm still nowhere near getting the two angles parallel.

I'm confused how it gets to that point where I can only correct it with an adjustable torque arm. I feel like if lowering a vehicle is what causes this, maybe BMR and UMI should mention that when buying lowering springs, it destroys your pinion angles. It's only a $400 added expense for an adjustable torque arm

Last edited by lt16spd1; 03-07-2018 at 01:01 PM.

#13

TECH Fanatic

iTrader: (1)

The geometry of a bent UV joint makes it so that the forks for the drive vs driven side have a different radius from center and that causes them the driven side to pulse during a constant drive speed. This condition is worse the more the joint is bent. They have to be mounted with a 90 degree offset from front to back of the drive shaft to cancel this out with the reverse effect on the second one. It slows the fast spot and speeds the slow to produce the same constant output as the transmission or transfer case outputs. This video below is one of the best examples of it in action.

The posts about offsetting it from parallel come from flex and movement that happens in certain suspensions as more power is applied. Leaf springs pretty much go where the torque twists the axle to as power is applied.

The car only needs to be flat to make sure the springs are loaded like the normally are while driving. The angle to the ground really has no effect. Measure transmission output angle (often the engine balancer is easiest) and make the axle match. If you have a lot of power over stock and still have loose stock arms and bushings then you may need more, but most build suspension up when they double the horse power.

The posts about offsetting it from parallel come from flex and movement that happens in certain suspensions as more power is applied. Leaf springs pretty much go where the torque twists the axle to as power is applied.

The car only needs to be flat to make sure the springs are loaded like the normally are while driving. The angle to the ground really has no effect. Measure transmission output angle (often the engine balancer is easiest) and make the axle match. If you have a lot of power over stock and still have loose stock arms and bushings then you may need more, but most build suspension up when they double the horse power.

Last edited by Crf450r420; 03-07-2018 at 10:30 PM.

#14

Staging Lane

Thread Starter

Join Date: Aug 2011

Location: rapid city, sd

Posts: 96

Likes: 0

Received 0 Likes

on

0 Posts

I've read through probably 100 threads about this and it seems like the best way to "diagnose" it is to just throw parts at the car which is something I hate to do. I'm hesitant to get an adjustable torque arm because I've run across plenty of threads where people do have one, adjust the angles so they cancel other out (ex: -1 driff, +1 trans) and they still get vibrations.

The more I think about it, if the suspension works how I think it does, lowering it wouldn't cause these crazy angles either because when the rear suspension compresses, the rear angle will change in sync with the front angle. Otherwise cars from the factory would get crazy driveshaft vibrations every time they hit a dip in the road.

#17

12 Second Club

i am currently dealing with the same issue. Both my pinion and transmission were pointing down, and did not have equal but opposite angles. I had a terrible vibration at highway speeds. I jacked up the rear of the trans with a spacer and the vibrations are almost completely gone. Problem is that it's backwards. Trans should slope down and pinion up. The only way I have found to fix it is an adjustable torque arm.

Here goes another $300...

I'd just leave it as is, but my exhaust banging the floor is going to drive me crazy.

#19

12 Second Club

I debated going with the trans crossmember with the torque arm relocation, but the adjustable torque arm won out. If you adjust the pinion angle at the front of the torque arm you are changing instant center and the way the car hooks, and the pinion angle is changing a little. If you use the adjustable torque arm to set pinion angle, you get much more adjustment and your not changing your IC.

#20

LS1Tech Premium Sponsor

iTrader: (40)

There have been some good diagrams and information posted so far. Hopefully this will help answer any questions you may still have!

__________________

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!

Glenn ***

Sales Tech

www.bmrsuspension.com

813.986.9302

Find a Quality alignment shop near you!