Bolts for the Brake Caliper bracket-Options !

#3

Save the manuals!

iTrader: (5)

I think the reason this idea has spread has been because the GM Factory Service Manual instructs us to replace the bolts after every use. I haven't seen a good reason why. Maybe this is a copy/paste error from an earlier version of the manual from an earlier F-Body? Maybe it is because some of the black oxide coating rubs off with each use? I don't know, but I'm re-using the bolts with confidence and without issue.

You could increase the torque to the bolt to a higher, proper value, but that leads to a question as to if the spindle or mounting plate threads can take the higher strain and match up to the bolt. (They could strip out.)

If you know the exact type of steel the bolts go into, the proper torque can be calculated, but that takes a little bit of engineering to make sure it's going to be safe and make sure the bolts won't vibrate out.

Last edited by wssix99; 05-17-2018 at 10:31 PM.

#5

it does not say in the manual that the bolts are TTY so that may just be a internet rumor....it just says that the bolts should not be reused ...curious why GM would state that too

now that the question is raised i am curious as to what TQ to use with the ARPs....use the manual at 74 ft lbs or ARPs recommended the for bolt size at 98 ft lbs

I did chase the threads on the bracket with a balaax tap ( best tap made IMO ) used blue locktite on the threads of the bolt and ARP lube under the bolt head and did use the supplied ARP washer on the bolt and TQd per GM spec

now that the question is raised i am curious as to what TQ to use with the ARPs....use the manual at 74 ft lbs or ARPs recommended the for bolt size at 98 ft lbs

I did chase the threads on the bracket with a balaax tap ( best tap made IMO ) used blue locktite on the threads of the bolt and ARP lube under the bolt head and did use the supplied ARP washer on the bolt and TQd per GM spec

#7

Save the manuals!

iTrader: (5)

Thread locker in this application is redundant and really doesn't do anything. It takes more force to break the torque of a properly fastened bolt, so if a bolt can come loose under the proper torque, the same factors will tear through thread locker. (This is why we don't see GM recommending to use it here.)

He probably shouldn't have suggested anything at all, then. The answer to the problem (either way) requires some design work, which he would not be required to do.

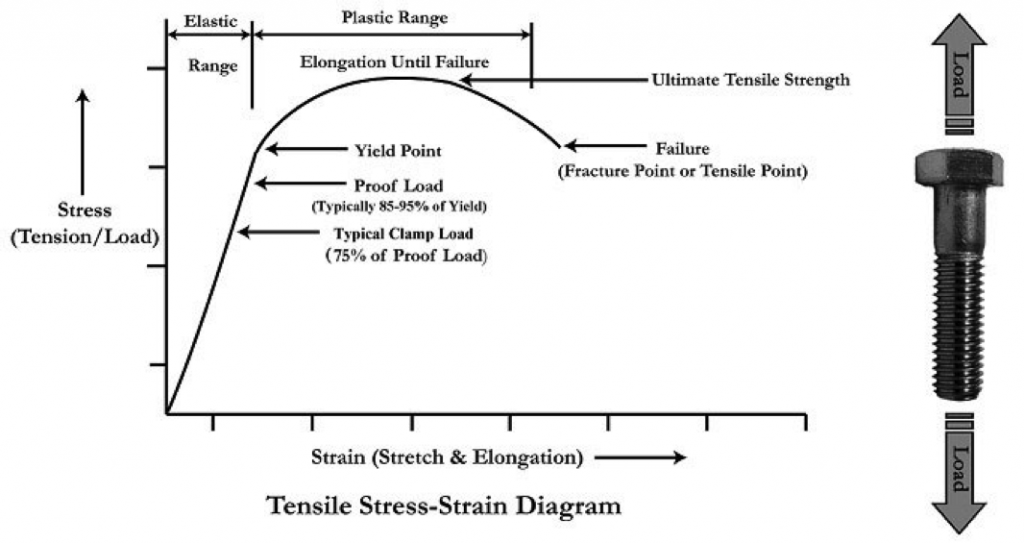

If you want to stay with the ARP bolts, I would calculate a better torque. If the stock GM torque is used, the bolts will not elongate which means: http://www.zerofast.com/proper-bolt-torque

- the parts will not be held together as tightly as GM's engineers originally intended

- the bolts may not develop enough friction to be held in place as tightly as the original bolts

* DISCLAIMER * - The ARP Bolts are stronger. The metal they are going into has not been upgraded. Therefore, if my method below is not correct or if the spindle has any flaws, the threads in the spindle could become stripped.

You could go to this site and reverse calculate the characteristics/type of steel the spindle is made of, using the stock specs: http://www.futek.com/boltcalc.aspx?mode=metric

Bolt Size - 12mm

Bolt Pitch - 1.75

Proof Strength - 830 MPa

Mating Material Length - <This needs to be measured by the Spindle thickness.>

Mating Material - Test the various steel values until the calculator gives back the stock 74 ft. lb torque

Once a similar to stock mating material has been discovered, the new proper torque can be calculated by changing the Bolt Proof Strength to the new value.

If you want to stay with the ARP bolts, I would calculate a better torque. If the stock GM torque is used, the bolts will not elongate which means: http://www.zerofast.com/proper-bolt-torque

- the parts will not be held together as tightly as GM's engineers originally intended

- the bolts may not develop enough friction to be held in place as tightly as the original bolts

* DISCLAIMER * - The ARP Bolts are stronger. The metal they are going into has not been upgraded. Therefore, if my method below is not correct or if the spindle has any flaws, the threads in the spindle could become stripped.

You could go to this site and reverse calculate the characteristics/type of steel the spindle is made of, using the stock specs: http://www.futek.com/boltcalc.aspx?mode=metric

Bolt Size - 12mm

Bolt Pitch - 1.75

Proof Strength - 830 MPa

Mating Material Length - <This needs to be measured by the Spindle thickness.>

Mating Material - Test the various steel values until the calculator gives back the stock 74 ft. lb torque

Once a similar to stock mating material has been discovered, the new proper torque can be calculated by changing the Bolt Proof Strength to the new value.

Trending Topics

#8

Save the manuals!

iTrader: (5)

... and I've been looking for that "Proof Strength" value for the 8740 steel that the ARP bolts are made out of and I can't find it - but with what I have found; it looks like they are far weaker than stock.

I was able to find Yield strength. The stock 10.9 bolts yield at 940 MPa and 8740 steel yields at 550 MPa. So it doesn't look like the ARP bolts are stronger and it also looks like they would yield much sooner.

In terms of torque, the stock torque should be fine since the ARP bolts should stretch more and APR says they can take that force. I would not question if they are really going to be more durable than the stock bolts. ¯\_(ツ)_/¯

I was able to find Yield strength. The stock 10.9 bolts yield at 940 MPa and 8740 steel yields at 550 MPa. So it doesn't look like the ARP bolts are stronger and it also looks like they would yield much sooner.

In terms of torque, the stock torque should be fine since the ARP bolts should stretch more and APR says they can take that force. I would not question if they are really going to be more durable than the stock bolts. ¯\_(ツ)_/¯

#9

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

That 550 MPA value (about 80,000 psi) assumes not heat treating was done. You can heat treat 8740 to pretty high numbers.

Now, that said ... you think you are actually getting 80,000 psi on those bolts with ~50 lbs of torque?

Hint: you are not

TYY is a misnomer. You are torquing to strain, not to yield. If you truly torque to yield, the bolt is permanently longer after torquing it.

A true TTY is typically done with a reduced segment of the bolt to give it a place to stretch.

Now, that said ... you think you are actually getting 80,000 psi on those bolts with ~50 lbs of torque?

Hint: you are not

TYY is a misnomer. You are torquing to strain, not to yield. If you truly torque to yield, the bolt is permanently longer after torquing it.

A true TTY is typically done with a reduced segment of the bolt to give it a place to stretch.

#10

Save the manuals!

iTrader: (5)

Right. I only care so we can find the metallurgical property of these bolts and calculate what their torque should be.

#11

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

Yes tensile = ultimate. In s heat treated scenario, a good number is 80 to 85% of tensile strength for the yield strength. So approx 140-150 ksi (1000psi is 1 ksi) on a tensile of 180 ksi.

How that translates to a proper torque value, idk.

How that translates to a proper torque value, idk.

#14

Save the manuals!

iTrader: (5)

For sure. If you can confirm the Proof Strength of the bolts with ARP, you can take a shot at a new torque. If you want to take the risk of stripping out the knuckle/bracket, you can always use heli-coils as a fall back since they should be stronger than the original threads.

#15

the bracket is 3/4 inch thick so I thought it would easily take 98 ft lbs of TQ.....so I lubed up the bolts with ARP lube ( all their TQ specs on their website is with bolt threads lubed and under the bolt head lubed ) and TQ it to 40...60...80....98 ! since my spindle is loose the hard part was holding that sucker while i TQd it