Seeking electricians help. Making a extension cord / adapter for welder to dryer.

#1

Hi guys,

I sold my 110v stick welder and decided to move on to MIG.

I recently picked up a dual mig 151 chicago electric complete with 150 tank and regulator.

looking to set it up at my garage with a dryer outlet.

from my search this is what i found.

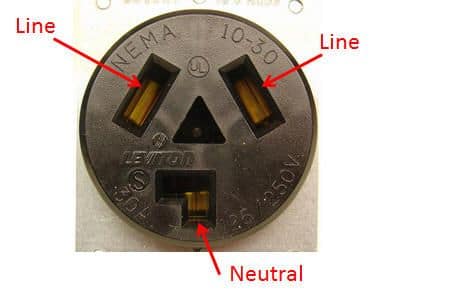

My dryer receptacle is a 10-30

Older style with live/ live / neutral (from what i gather)

The welder plug is

6-50

live / live / ground

In my original search, I would be fine with connecting the neutral from the wall to the welders ground.

Then I found a thread that said this is dangerous and shouldn't do this.

I dont want to mess around with electricity specially a 220 and was wondering what is the truth? can I connect the neutral from the dryer plug to my welder plug?

My focus is not just it working but i want it to work safely.

I also Found some 10/3 wires at homedepot that im thinking should be fine to use as an extension cord. Its wires is green/white/black and it looks heavily insulated(thick rubber). Would this be fine or do i need a special one to use as extension cord?

numbers on it say " (UL) C(UL) SOOW 3/C 10AWG(5.26mm^2) 105*C VW-1 600V E215210 100281-001

seems cheap enough at 1.86 / foot. Im thinking 30' extension should be plenty for my needs.

receptacle box. Looks like the ground on the receptacle is connected to the front plate of it? so basically the ground/nuetral you can touch from the front? is this ok for non wall mounted? Im thinking of using a receptacle box but non mount it since its an extension cord. can I use the metal? or plastic?

Lastly since I would have to use the adapter all the time can I simply bypass the receptacle and just run the wire from the 10-30 plug straight to the welder? basically remove the plug from welder and connect it directly so the welder would have a long 30' plug.

what do you guys think?

safe?

side note I went to turn of the main panel and the breaker for the garage panel. I then opened up the sub panel and tested to make sure everything is indeed off.

I looked (not touch) at the wires thats coming from the dryer receptacle and its looks like 3 wires. 1 red , 1 black and 1 white. (going into a bar with a bunch of white wires. I assume this is neutral?)

the wires thats coming from the main panel has 4 wires. 1 is grounding? the subpanel but has no bar. Just bolted wire to sub pannel. Can this ground be used as a ground for the welder? ^^ if neutral cannot be used.

I sold my 110v stick welder and decided to move on to MIG.

I recently picked up a dual mig 151 chicago electric complete with 150 tank and regulator.

looking to set it up at my garage with a dryer outlet.

from my search this is what i found.

My dryer receptacle is a 10-30

Older style with live/ live / neutral (from what i gather)

The welder plug is

6-50

live / live / ground

In my original search, I would be fine with connecting the neutral from the wall to the welders ground.

Then I found a thread that said this is dangerous and shouldn't do this.

I dont want to mess around with electricity specially a 220 and was wondering what is the truth? can I connect the neutral from the dryer plug to my welder plug?

My focus is not just it working but i want it to work safely.

I also Found some 10/3 wires at homedepot that im thinking should be fine to use as an extension cord. Its wires is green/white/black and it looks heavily insulated(thick rubber). Would this be fine or do i need a special one to use as extension cord?

numbers on it say " (UL) C(UL) SOOW 3/C 10AWG(5.26mm^2) 105*C VW-1 600V E215210 100281-001

seems cheap enough at 1.86 / foot. Im thinking 30' extension should be plenty for my needs.

receptacle box. Looks like the ground on the receptacle is connected to the front plate of it? so basically the ground/nuetral you can touch from the front? is this ok for non wall mounted? Im thinking of using a receptacle box but non mount it since its an extension cord. can I use the metal? or plastic?

Lastly since I would have to use the adapter all the time can I simply bypass the receptacle and just run the wire from the 10-30 plug straight to the welder? basically remove the plug from welder and connect it directly so the welder would have a long 30' plug.

what do you guys think?

safe?

side note I went to turn of the main panel and the breaker for the garage panel. I then opened up the sub panel and tested to make sure everything is indeed off.

I looked (not touch) at the wires thats coming from the dryer receptacle and its looks like 3 wires. 1 red , 1 black and 1 white. (going into a bar with a bunch of white wires. I assume this is neutral?)

the wires thats coming from the main panel has 4 wires. 1 is grounding? the subpanel but has no bar. Just bolted wire to sub pannel. Can this ground be used as a ground for the welder? ^^ if neutral cannot be used.

#2

9 Second Club

iTrader: (13)

Do not sub the ground for the neutral . Those white wires you see in the panel act just like gfci for the circuit/breaker. I would highly recommended to run a new line for the mig. But if thats not an option for you. You can ghetto rig it .From the sub panel you say u have 2 hot 1 groung and 1 neutral. Tap in to the 2 hot and ground by adding the plug you need next to it . by using a junction box and EMT piping and run the wires you need. But like I said before I highly recommend running a new line .

#3

Do not sub the ground for the neutral . Those white wires you see in the panel act just like gfci for the circuit/breaker. I would highly recommended to run a new line for the mig. But if thats not an option for you. You can ghetto rig it .From the sub panel you say u have 2 hot 1 groung and 1 neutral. Tap in to the 2 hot and ground by adding the plug you need next to it . by using a junction box and EMT piping and run the wires you need. But like I said before I highly recommend running a new line .

I dont have a problem running one for my welder in my garage. I own the home and I was thinking of just removing the dryer plug and putting in the 6-50r since i know i wont be using a dryer back there anyways . the inside wall on my garage isnt finished or anything so i have full access, the subpanel to receptacle is only 6 feet away.

My question is then say I remove the dryer receptacle and replace it with a 6-50r. (i would reuse the conduit as it is since it goes to the sub panel.)

I get new wires (i forget what those one strand is called thats meant for permanent mounting)

The Nema 6-50R only has 3 plug still.

2 live and 1 labeled as green vert.

so there is no difference in # of prongs. DO i then not connect the neutral wire on the subpanel and connect it to ground? basically swapping the neutral for ground?

that means i loose the "neutral" and swap for ground?

this is what im working with btw. the dryer plug

converting it to.

#4

9 Second Club

iTrader: (13)

Yeah your on the right track ,if ur removing the dryer completely just re use the same wires that come from the sub panel just swap the neutral for the ground and ull be good to go. Just make sure to label it with green tape or something so if u where ever to leave the house the next ppl or electrician will know that's a ground even tho its a white wire .

#5

Yeah your on the right track ,if ur removing the dryer completely just re use the same wires that come from the sub panel just swap the neutral for the ground and ull be good to go. Just make sure to label it with green tape or something so if u where ever to leave the house the next ppl or electrician will know that's a ground even tho its a white wire .

I have into another issue. looks like the detached garage panel has no grounding rod as i do not see any ground bar on the panel.

do i have to add one on the detached garage?

or can I just tap (using a small ground bar) my ground to the ground on panel. see attached pic.

#6

9 Second Club

iTrader: (13)

oh ok cool. this is what i will go with then.

I have into another issue. looks like the detached garage panel has no grounding rod as i do not see any ground bar on the panel.

do i have to add one on the detached garage?

or can I just tap (using a small ground bar) my ground to the ground on panel. see attached pic.

I have into another issue. looks like the detached garage panel has no grounding rod as i do not see any ground bar on the panel.

do i have to add one on the detached garage?

or can I just tap (using a small ground bar) my ground to the ground on panel. see attached pic.

#7

anyways heres what im thinking.

ground bar with atleast 4 slots. each slot will to connect to

1. ground from main panel

2. ground from rod

3. ground to sub panel(where its grounded now)

4. ground to welder supple(ground prong on 6-50)

what do you think? i have a pic incase i wasnt clear.

edit:

the main panel is bonded together, it was pointed out to me that they are both bolted on the panel.

Last edited by stock400whp; 10-02-2014 at 11:17 PM.